Degradable plastic composition as well as preparation method and application thereof

A technology for degrading plastics and compositions, applied in the field of polymer materials, can solve the problems of poor comprehensive mechanical properties, poor mold release, and long molding cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

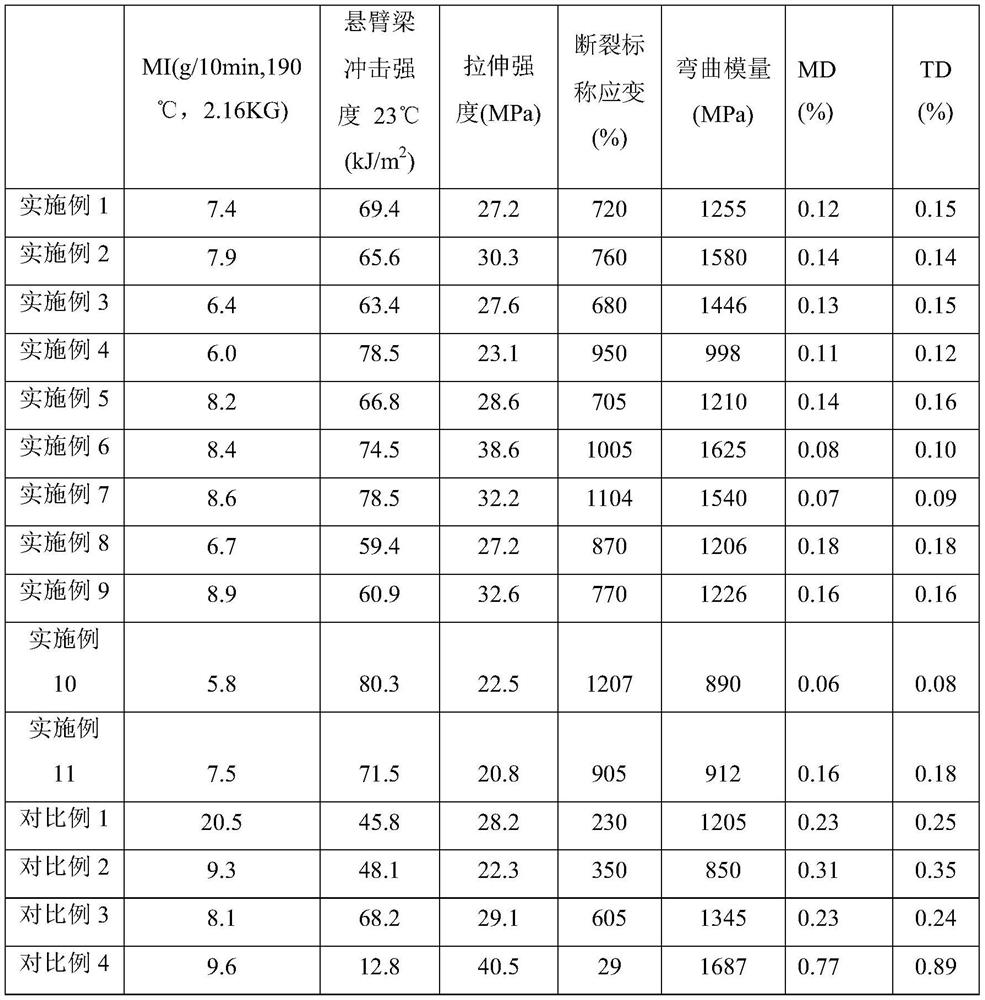

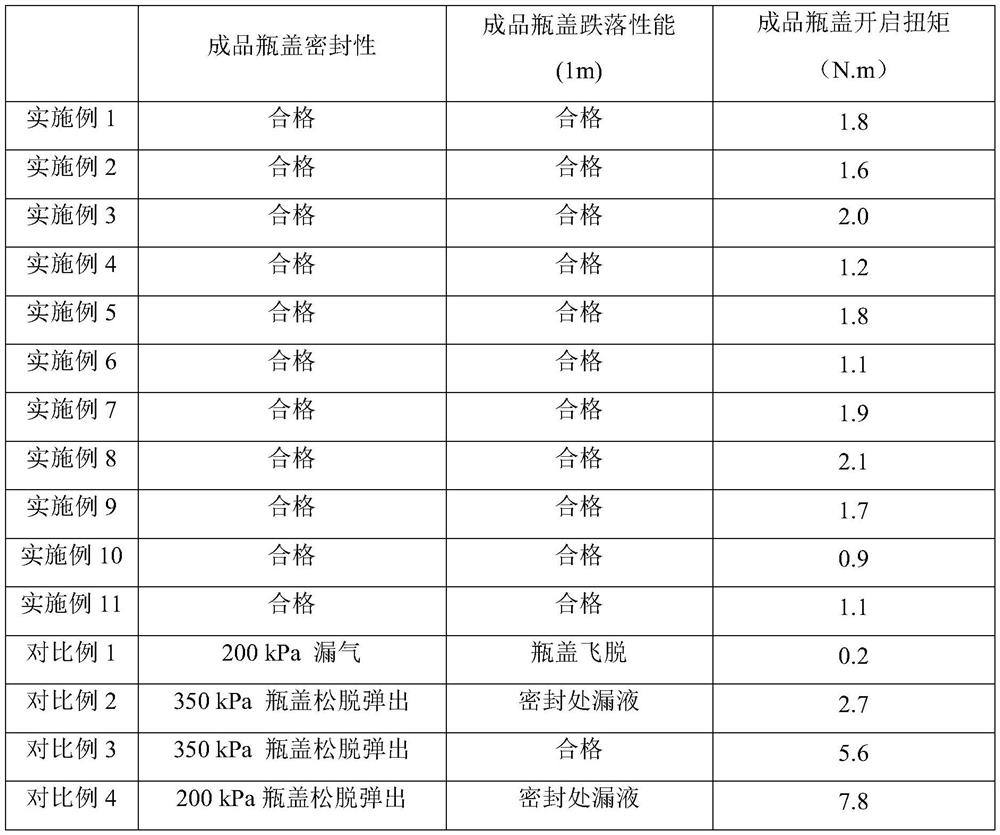

Examples

preparation example Construction

[0059] Preparation method of degradable plastic:

[0060] Bake the degradable resin shown in Examples and Comparative Examples in a vacuum oven at 85°C for 6 hours, then fully mix the degradable resin, toughening agent, and compatibilizer in a high-speed mixer, and add a nucleating agent during the stirring process , anti-hydrolysis agent and chain extender, finally add smooth agent, and optionally add oxidant, mix well and then transfer it to the extruder with twin-screw and 11-section barrel with length-to-diameter ratio of 40-60 for melt extrusion The temperature of the barrel is 135-200° C. during melt extrusion, and the rotational speed of the extruder is 200-350 rpm during melt extrusion to obtain degradable plastics.

[0061]The barrel temperature of each section is: the temperature of the second section barrel is 125°C, the third section barrel temperature is 200°C, the fourth section barrel temperature is 190°C, the fifth section barrel temperature is 190°C, the sixth...

Embodiment 1

[0065] The raw materials of degradable plastics include the following components in parts by weight:

[0066] PLA: (from Total Corbien, model: L130, MI=10g / 10min 190°C, 2.16kg) 60 parts

[0067] PBS: (from Tunhe, Lanshan, model: TH803S, MI=18g / 10min 190°C, 2.16kg) 35.3 parts

[0068] Toughener: 2 parts of ethylene-methyl acrylate-glycidyl methacrylate (from Arkema AX8900, France)

[0069] Compatibilizer: PLA-g-MAH (maleic anhydride graft rate 0.85%, MI=16g / 10min 190°C, 2.16kg) 1 part

[0070] Chain extender: (derived from BASF ADR 4370F, France, with 9 epoxy functional groups) 0.1 parts

[0071] Anti-hydrolysis agent: (from Rheinland, Germany, BioAdimide100, monomeric carbodiimide, molecular weight 362g / mol) 0.1 part

[0072] Nucleating agent: amide nucleating agent (from Shanxi Institute of Chemical Industry TMC-306) 0.1 parts

[0073] Talc powder (10000 mesh particle size) 1 part

[0074] Slippery agent: erucamide 0.1 parts

[0075] Antioxidant 168 0.1 parts

[0076] ...

Embodiment 2

[0078] The raw materials of degradable plastics include the following components in parts by weight:

[0079] PLA: (from Total Corbien, model: L130, MI=10g / 10min 190°C, 2.16kg) 70 parts

[0080] PBS: (from Tunhe, Lanshan, model: TH803S, MI=18g / 10min 190°C, 2.16kg) 26.1 parts

[0081] Toughener: (from Arkema AX8900, France) 1 part

[0082] Compatibilizer: PLA-g-MAH (maleic anhydride graft rate 1.05%, MI=9g / 10min 190°C, 2.16kg) 1 part

[0083] Chain extender: (derived from BASF ADR 4370F, France, with 9 epoxy functional groups) 0.1 parts

[0084] Anti-hydrolysis agent: (from Rheinland, Germany, BioAdimide100, monomeric carbodiimide, molecular weight 362g / mol) 0.1 part

[0085] Nucleating agent: 0.2 parts of sorbitol nucleating agent (derived from Milliken 8000K)

[0086] Talc powder (10000 mesh particle size) 1 part

[0087] Slippery agent: erucamide 0.2 parts

[0088] Antioxidant 168 0.1 parts

[0089] Antioxidant 1010 0.2 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| izod impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com