Finishing coat of waterborne coiled steel coating and preparation method of finishing coat

A coil and coating technology, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve problems such as restricting the development of water-based coil coatings, difficult to achieve weather resistance, etc., and achieve good performance, fullness, and adhesion of cured products. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

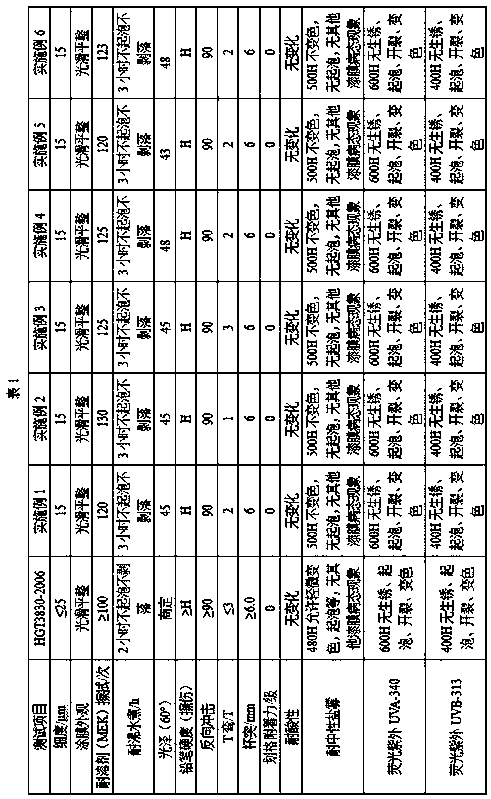

Examples

Embodiment 1

[0050] A water-based coil coating finish paint, the mass ratio of each component is: 20 parts of water-based polyester resin, 50 parts of anti-rust slurry, 7 parts of amino resin, 0.1 part of acid catalyst, 0.25 parts of wetting agent, leveling 0.2 parts of antifoaming agent, 0.15 parts of antifoaming agent, 2 parts of adhesion promoter, 0.3 parts of wetting and dispersing agent, 3 parts of ethylene glycol monobutyl ether, 2.2 parts of n-butanol, 5 parts of ethanol, 2 parts of anti-settling agent, matting Powder 1.5 parts, deionized water 6 parts, pH regulator 0.3 parts.

[0051]Among them, the weight ratio of each component of the antirust slurry is: 22 parts of water-based polyester resin, 2 parts of zinc phosphate, 5 parts of aluminum tripolyphosphate, 3 parts of talcum powder, 34.7 parts of titanium dioxide and 5 parts Titanium iron powder, 15 parts of deionized water, 5 parts of ethylene glycol monobutyl ether, 3 parts of n-butanol, 5 parts of wetting and dispersing agent...

Embodiment 2

[0074] A water-based coil coating finish paint, the mass ratio of each component is: 25 parts of water-based polyester resin, 45 parts of antirust slurry, 7 parts of amino resin, 0.1 part of acid catalyst, 0.25 parts of wetting agent, leveling 0.2 parts of antifoaming agent, 0.15 parts of antifoaming agent, 2 parts of adhesion promoter, 0.3 parts of wetting and dispersing agent, 3 parts of ethylene glycol monobutyl ether, 2.2 parts of n-butanol, 2 parts of ethanol, 2 parts of anti-settling agent, matting Powder 1.5 parts, deionized water 9 parts, pH regulator 0.3 parts.

[0075] Among them, the weight ratio of each component of the antirust slurry is: 22 parts of water-based polyester resin, 2 parts of zinc phosphate, 5 parts of aluminum tripolyphosphate, 3 parts of talcum powder, 34.7 parts of titanium dioxide and 5 parts Titanium iron powder, 15 parts of deionized water, 5 parts of ethylene glycol monobutyl ether, 3 parts of n-butanol, 5 parts of wetting and dispersing agent...

Embodiment 3

[0090] A water-based coil coating finish paint, the mass ratio of each component is: 20 parts of water-based polyester resin, 50 parts of antirust slurry, 10 parts of amino resin, 0.1 part of acid catalyst, 0.25 parts of wetting agent, leveling 0.2 parts of antifoaming agent, 0.15 parts of antifoaming agent, 2 parts of adhesion promoter, 0.3 parts of wetting and dispersing agent, 3 parts of ethylene glycol monobutyl ether, 2.2 parts of n-butanol, 2 parts of ethanol, 2 parts of anti-settling agent, matting Powder 1.5 parts, deionized water 6 parts, pH regulator 0.3 parts.

[0091] Among them, the weight ratio of each component of the antirust slurry is: 22 parts of water-based polyester resin, 2 parts of zinc phosphate, 5 parts of aluminum tripolyphosphate, 3 parts of talcum powder, 34.7 parts of titanium dioxide and 5 parts Titanium iron powder, 15 parts of deionized water, 5 parts of ethylene glycol monobutyl ether, 3 parts of n-butanol, 5 parts of wetting and dispersing agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com