Twisted welding wire structure and manufacturing method thereof

A technology of stranded welding wire and manufacturing method, which is applied to the structure of stranded welding wire and its manufacturing field, can solve the problems of insufficient welding wire diameter, uneven welding quality, poor rigidity, etc., and achieves high deposition efficiency, low dilution rate, welding The effect of improving the quality of seam performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

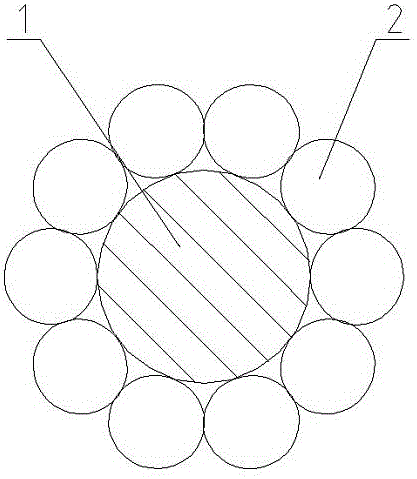

[0062] Example 1: 1+10 unequal diameter monofilament stranded carbon dioxide gas shielded stranded welding wire

[0063] In this embodiment, the central wire 1 adopts a flux-cored wire of φ1.0mm, the peripheral wire 2 adopts a solid cored wire of φ0.4mm, and the diameter of the stranded welding wire is φ1.8mm. Compared with the existing Φ1.2mm and Φ1.8mmΦ2.3mm carbon dioxide gas shielded solid welding wire, the welding deposition speed is faster, and it has the characteristics of high efficiency, high cost and low consumption.

[0064] The winding angle of the peripheral wire 2 is 25°, and the pitch of the helix is 9.43mm;

[0065] This stranded welding wire is a rope-like welding wire with multiple twists around a central wire. Under the protection of carbon dioxide gas, it has better flexibility than a single welding wire of equal diameter, and has a stable, stable, wide range of current, voltage waveform, and stable arc shape to ensure that the weldment has a reasonable ...

Embodiment 2

[0066] Implementation 2: 1+10 unequal diameter monofilament stranded submerged arc welding wire

[0067] In this embodiment, the central wire is φ3.2mm, the peripheral wire is φ1.4mm, and the diameter of the stranded welding wire is φ5.85mm. The diameter of this stranded welding wire is equivalent to φ0.60mm single-wire submerged arc welding wire, but its wire feeding flexibility is excellent. The unique arc characteristics of stranded welding wire reduce the welding current and voltage, and its central wire has a certain impact characteristic, which can ensure the penetration depth and realize the economical performance of high-efficiency and low-consumption welding.

[0068] The winding angle of the peripheral wire 2 is 30°, and the pitch of the helix is 25.0mm.

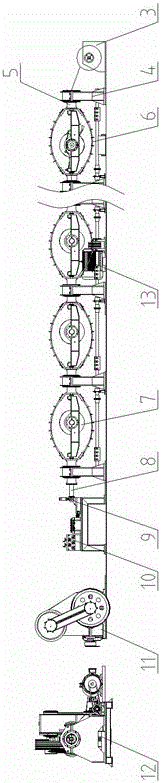

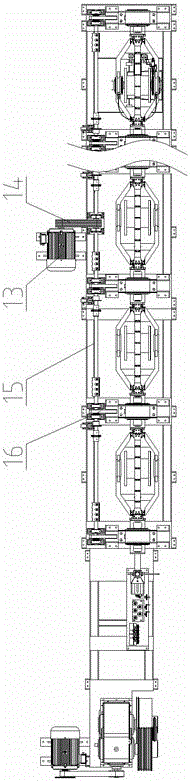

[0069] Its manufacturing method is as follows:

[0070] Step 1. Wind a single welding wire onto the I-shaped wheel assembly;

[0071] Step 2. Install multiple I-shaped wheel assemblies with single welding wires...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com