Polyethylene resin and preparation method thereof

A technology of polyethylene resin and polyethylene, which is applied in the field of polyethylene resin and its preparation, can solve the problems of poor uniformity of mixed resin, and achieve the effect of high transparency and strong rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

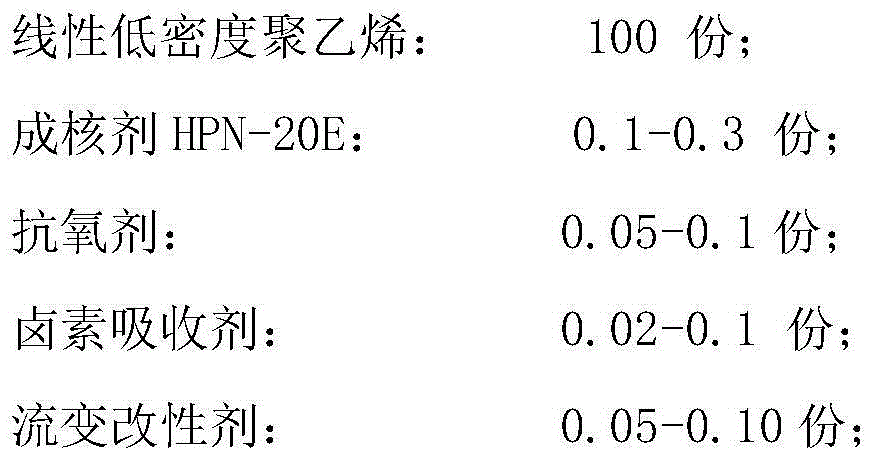

[0024] A kind of polyethylene resin, is prepared by weight parts by following material:

[0025]

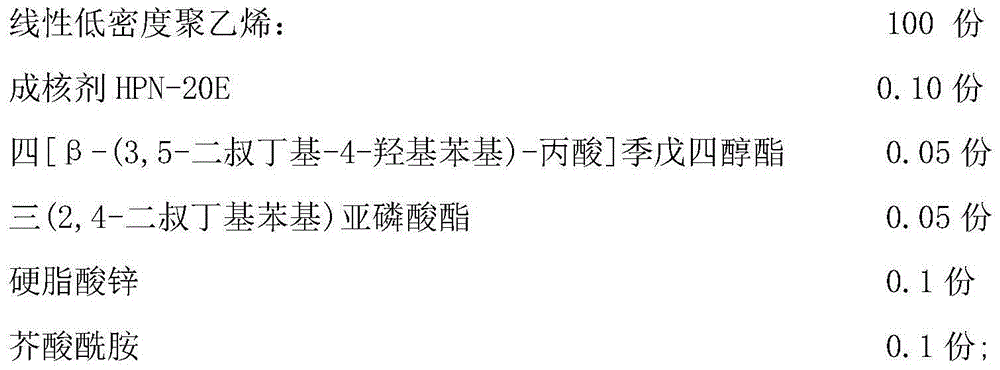

[0026] The preparation method of the polyethylene resin is: adding nucleating agent HPN-20E, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) -Propionic acid] pentaerythritol ester, tris(2,4-di-tert-butylphenyl) phosphite, ZnSt and erucamide are uniformly mixed mechanically, melted and granulated by a twin-screw extruder, and obtained after packaging.

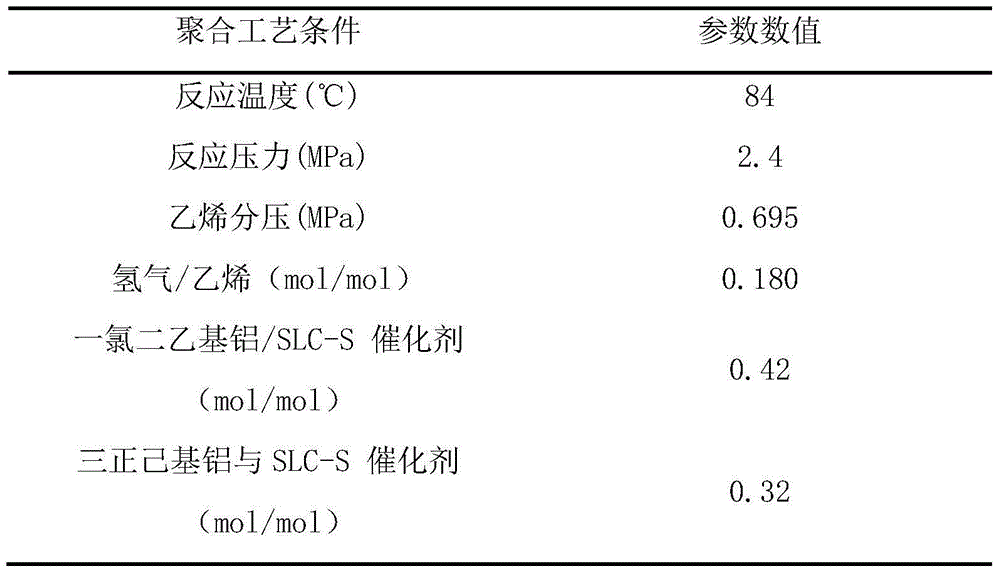

[0027] The linear low density polyethylene mentioned above is prepared by the following method: on the Unipol gas phase process polyethylene device, ethylene gas with a volume fraction of 99.9% is used as a raw material, 1-butene is used as a comonomer, and hydrogen is used as a chain Transfer agent, adopts catalyzer SLC-S, carries out gas-phase polymerization gained, and each technological parameter in the polymerization process is shown in Table 1: and tri-n-hexyl aluminum

[0028] Table 1

[0029]

Embodiment 2

[0031] A kind of polyethylene resin, is prepared by weight parts by following material:

[0032]

[0033] The preparation method of the polyethylene resin is: adding nucleating agent HPN-20E, 1,3,5, tri(3,5-di-tert-butyl, 4-hydroxyl benzyl)-s-2,4,6-(1H,3H,5H)trione, bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite, hydrotalcite and stearic acid amide for mechanical After being uniformly mixed, it is melted and granulated by a twin-screw extruder, and obtained after packaging.

[0034] The linear low-density polyethylene is prepared by the following method: on the Unipol gas-phase process polyethylene device, ethylene gas with a volume fraction of 99.9% is used as a raw material, 1-butene is used as a comonomer, and hydrogen is used as a chain transfer Agent, adopts catalyzer SLC-S, carries out gas-phase polymerization gained, and each technological parameter in the polymerization process is shown in Table 2:

[0035] Table 2

[0036]

[0037] The preparation me...

Embodiment 3

[0039] A kind of polyethylene resin, is prepared by weight parts by following material:

[0040]

[0041] The preparation method of the polyethylene resin is: adding nucleating agent HPN-20E, β-(3,5-di-tert-butyl-4-hydroxyphenyl)-propane to linear low-density polyethylene according to the above weight ratio Octadecyl alcohol ester, tris(2,4-di-tert-butylphenyl) phosphite, calcium stearate and ethylene distearyl diamine were mixed mechanically, and melted by twin-screw extruder tablets, obtained after packaging.

[0042] The linear low-density polyethylene is prepared by the following method: on the Unipol gas-phase process polyethylene device, ethylene gas with a volume fraction of 99.9% is used as a raw material, 1-butene is used as a comonomer, and hydrogen is used as a chain transfer Agent, adopts catalyzer SLC-S, carries out gas-phase polymerization gained, and each technological parameter in the polymerization process is shown in table 3:

[0043] table 3

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com