Band sawing machine with saw band automation resetting function and control method thereof

An automatic reset and band sawing machine technology, applied in the direction of automatic control devices, sawing machine devices, manufacturing tools, etc., can solve problems such as limiting production efficiency, achieve the effects of reducing production costs, preventing damage to the saw band, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

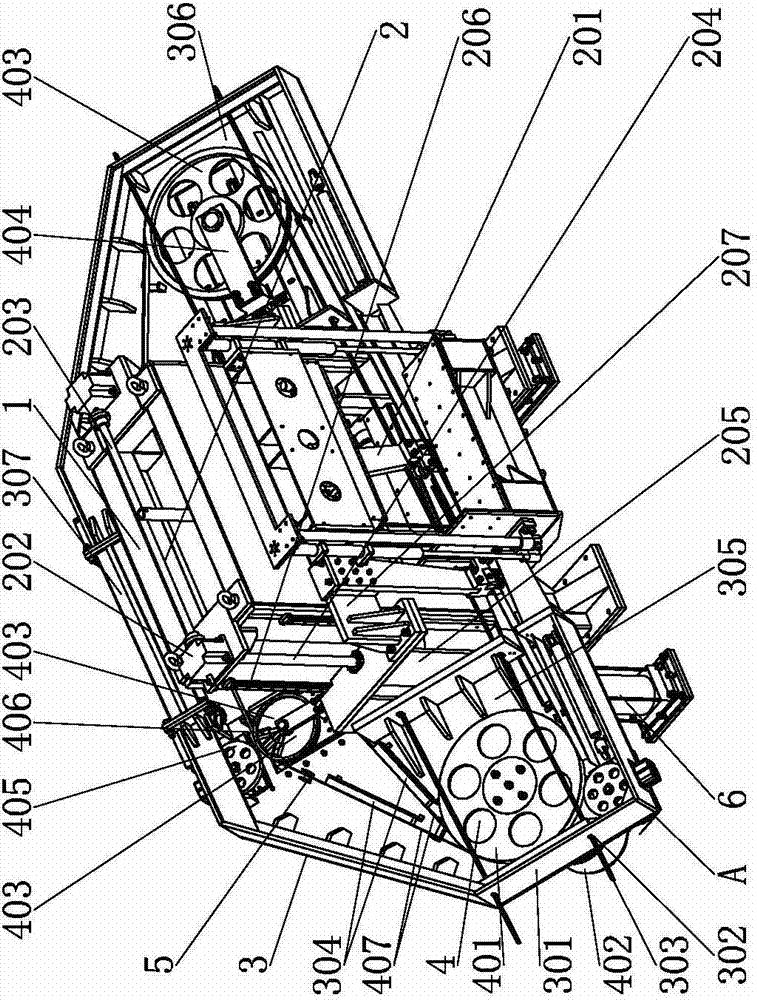

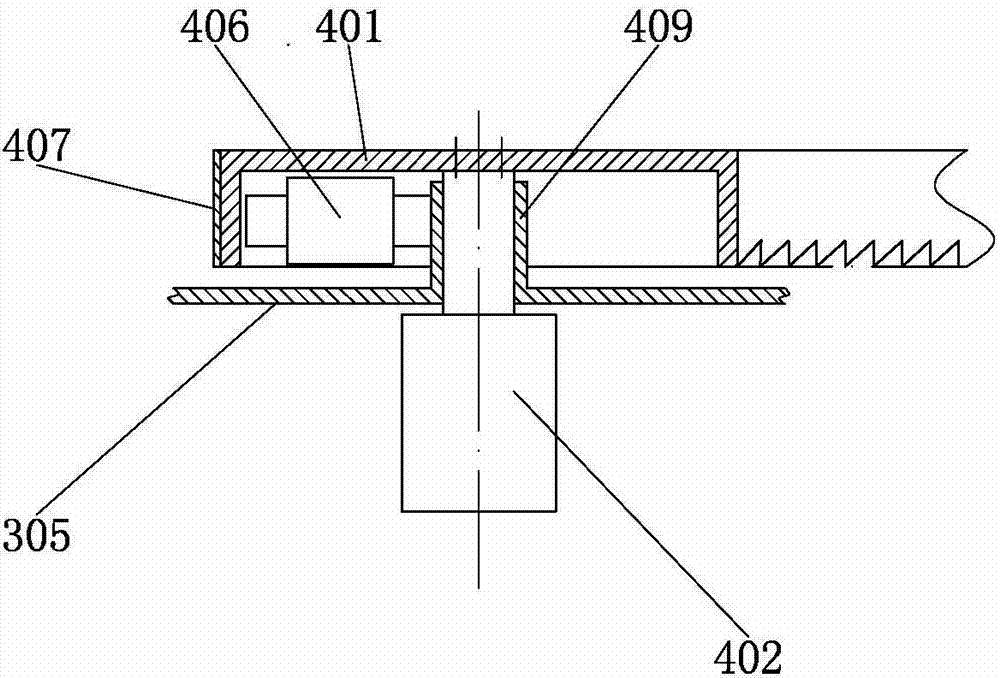

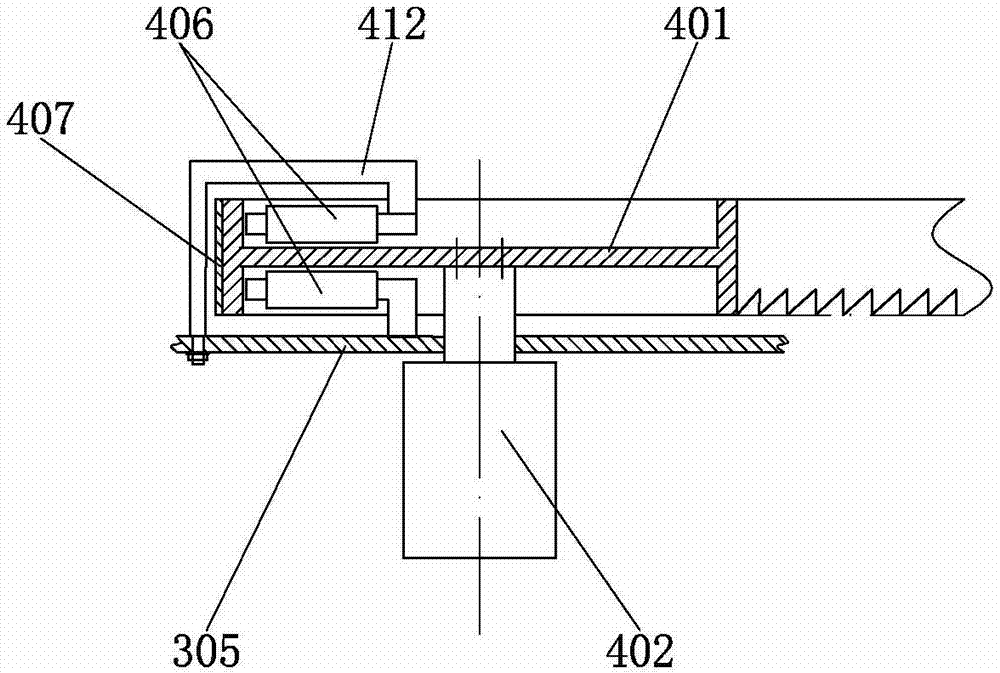

[0043] Such as Figure 1 to Figure 6As shown, this embodiment provides a band sawing machine with automatic reset of the saw band, including a band sawing machine frame assembly 1 composed of profiles and a saw band box lifting device 2, and the saw band box lifting device 2 includes two. The transmission shaft 203 coaxially drives the worm gear and worm mechanism 202. The two worm gear and worm mechanisms 202 are respectively arranged on the left and right sides of the top of the band saw machine frame assembly 1. The two worm gear and worm mechanisms 202 are respectively equipped with rotating threads. Rod 204, the upper end of the rotating threaded rod 204 is connected with the transmission of the worm gear mechanism 202; each of the rotating threaded rods 204 is connected with the box body of the slider box 205 through threads, and the band saw machine frame assembly 1 Two vertical guide rails 206 are respectively arranged on the left and right sides corresponding to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com