Quick-replacing-type hob main shaft of numerically-controlled gear hobbing machine

A gear hobbing machine and hob technology, which is applied to metal processing mechanical parts, driving devices, metal processing equipment, etc., can solve the problems of high cost and complicated equipment, and achieve the effects of convenient processing, simple structure and small torsional deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

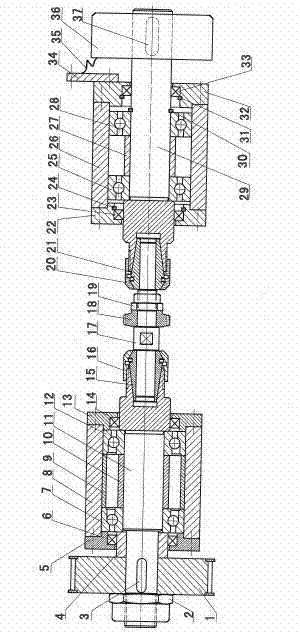

[0021] like figure 1 As mentioned above, the hob spindle of the CNC gear hobbing machine in this embodiment includes: a torque input part, a hob installation part, and an auxiliary support part, wherein the torque input shaft is located on the left and the auxiliary support part is located on the right.

[0022] The torque input components include timing pulley 1, first lock nut 2, torque input shaft key 3, spacer 4, torque input shaft 11, first angular contact ball bearing 7, second angular contact ball bearing 12, input shaft Bearing seat 8, first sealing ring 6, second sealing ring 14, first bearing end cover 5, second bearing end cover 13, large bearing adjustment sleeve 9, small bearing adjustment sleeve 10, torque input shaft elastic chuck 15 and The first pressure cap 16 used in conjunction with the elastic collet, wherein the torque input shaft elastic collet 15 is installed on one end of the torque input shaft 11, and the first locking nut 2, the synchronous pulley...

Embodiment 2

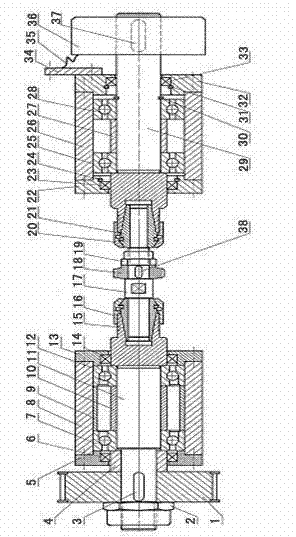

[0049] like figure 2 As shown, the torque input part and the auxiliary support part in this embodiment are the same as those of the first embodiment, the hob installation shaft key 38 is set on the hob installation shaft 17, the keyway is milled out on the hob installation shaft 17, and the hob installation shaft The key 38 is placed in the keyway, and the hob mounting shaft 17 transmits torque to the hob 18 through the hob mounting shaft key 38, which is more convenient for mounting and dismounting, and has good centering.

Embodiment 3

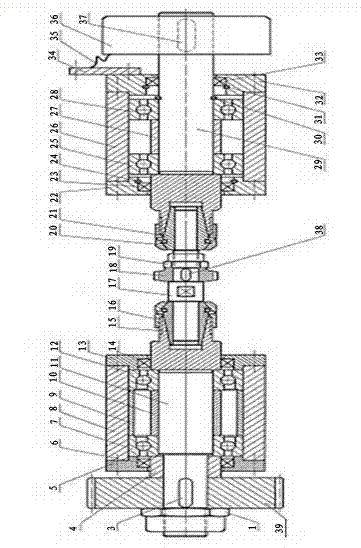

[0051] like image 3 As shown, the hob mounting member and the auxiliary supporting member in this embodiment are the same as those in Embodiment 1, and the synchronous pulley 1 in the torque input member is replaced by a gear 39 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com