Auxiliary frame mounting point structure

A subframe and installation point technology, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve the problems such as difficult subframe detachment, large vibration of the subframe body, and influence of modal stiffness, etc., to achieve Ease of installation and assembly and modular production, improve handling stability and reduce injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

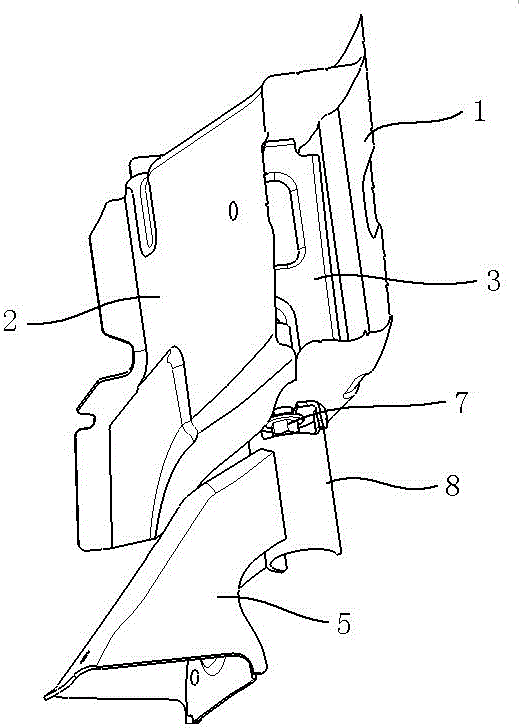

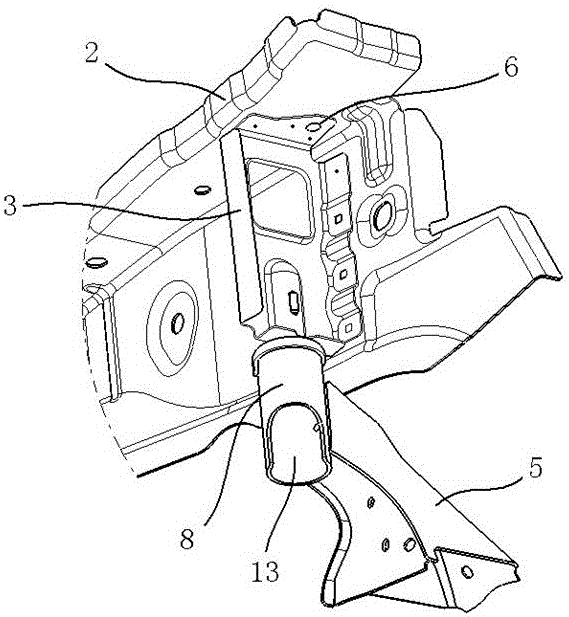

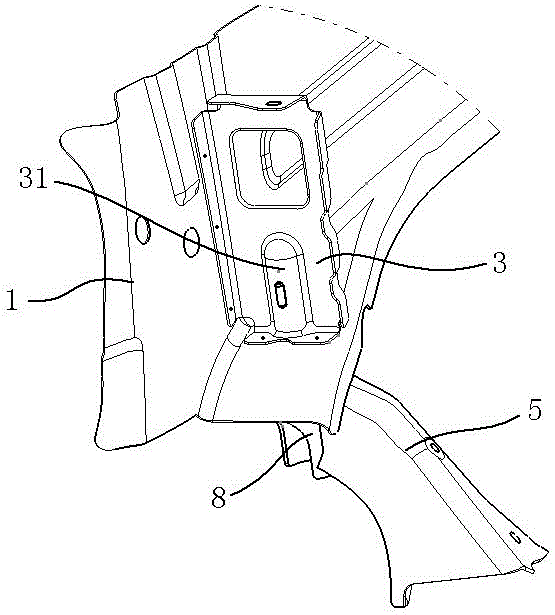

[0023] As shown in the figure, the mounting point structure of the sub-frame in this embodiment includes: a longitudinal beam composed of an outer plate 1, an inner plate 2 and a reinforcing plate 3, an internally threaded sleeve 4, and a sub-frame provided with a mounting support 5, of which:

[0024] The outer plate 1 and the inner plate 2 are welded and connected to form a cavity structure with a frame-shaped closed section. The reinforcement plate 3 is located at the rear end of the longitudinal beam, and there are flanges around the reinforcement plate 3. The reinforcement plate 3 is located in the cavity. The flanges on the left, right and upper and lower sides are overlapped with the inner panel 2 and outer panel 1 of the longitudinal beam, which are used to increase the dynamic stiffness of the installation point of the subframe 5 and ensure the modal stiffness of the subframe 5 when it is installed in the body state ; Specifically, as figure 2 As shown, the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com