Railway vehicle bogie

A technology for railway vehicles and bogies, applied in the field of bogies, can solve the problems of being unfavorable to reduce self-weight and unsprung mass, difficult to improve operation speed, and high operation and maintenance costs, so as to improve curve passing performance, improve vertical and lateral The performance and structure are compact and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

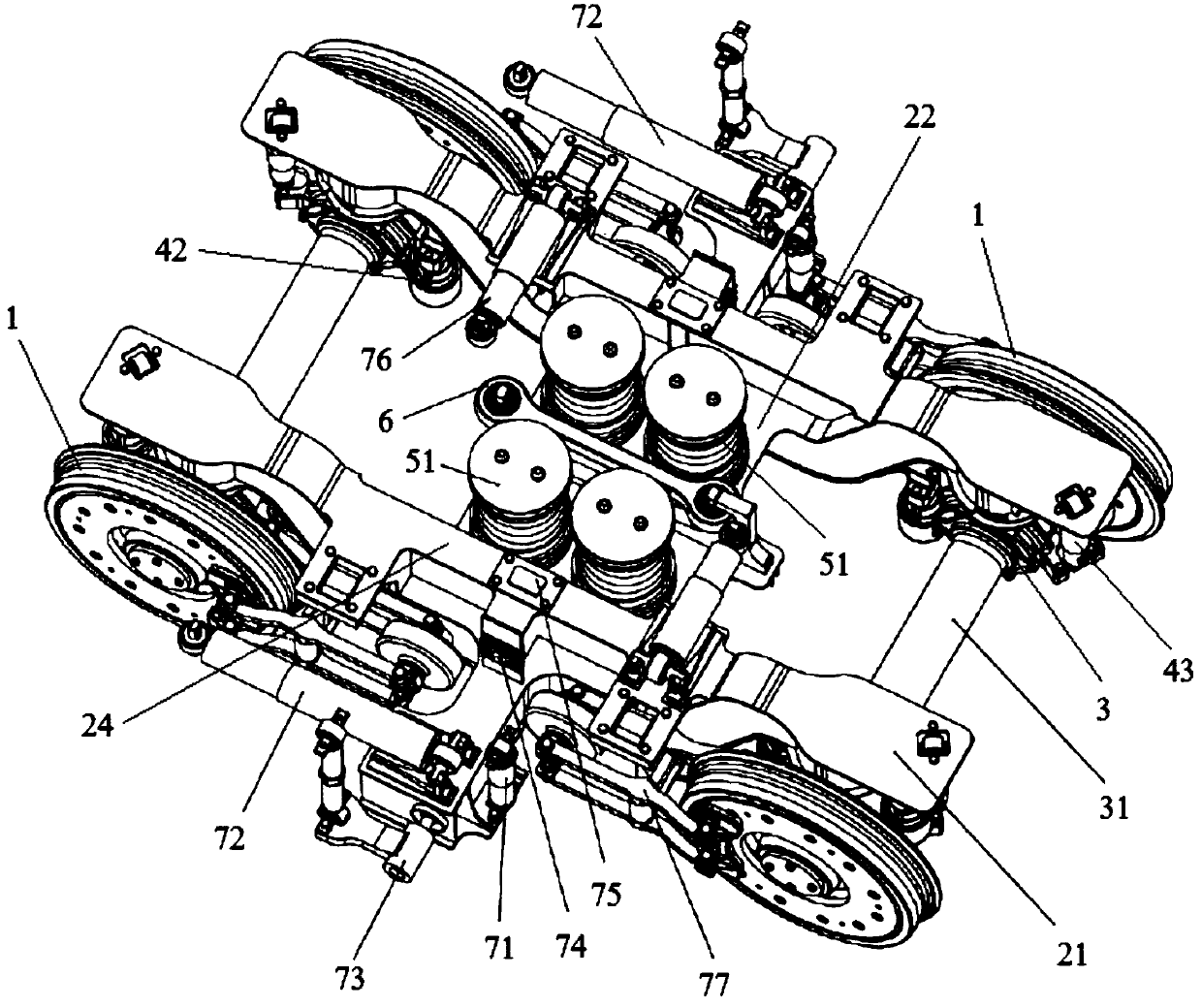

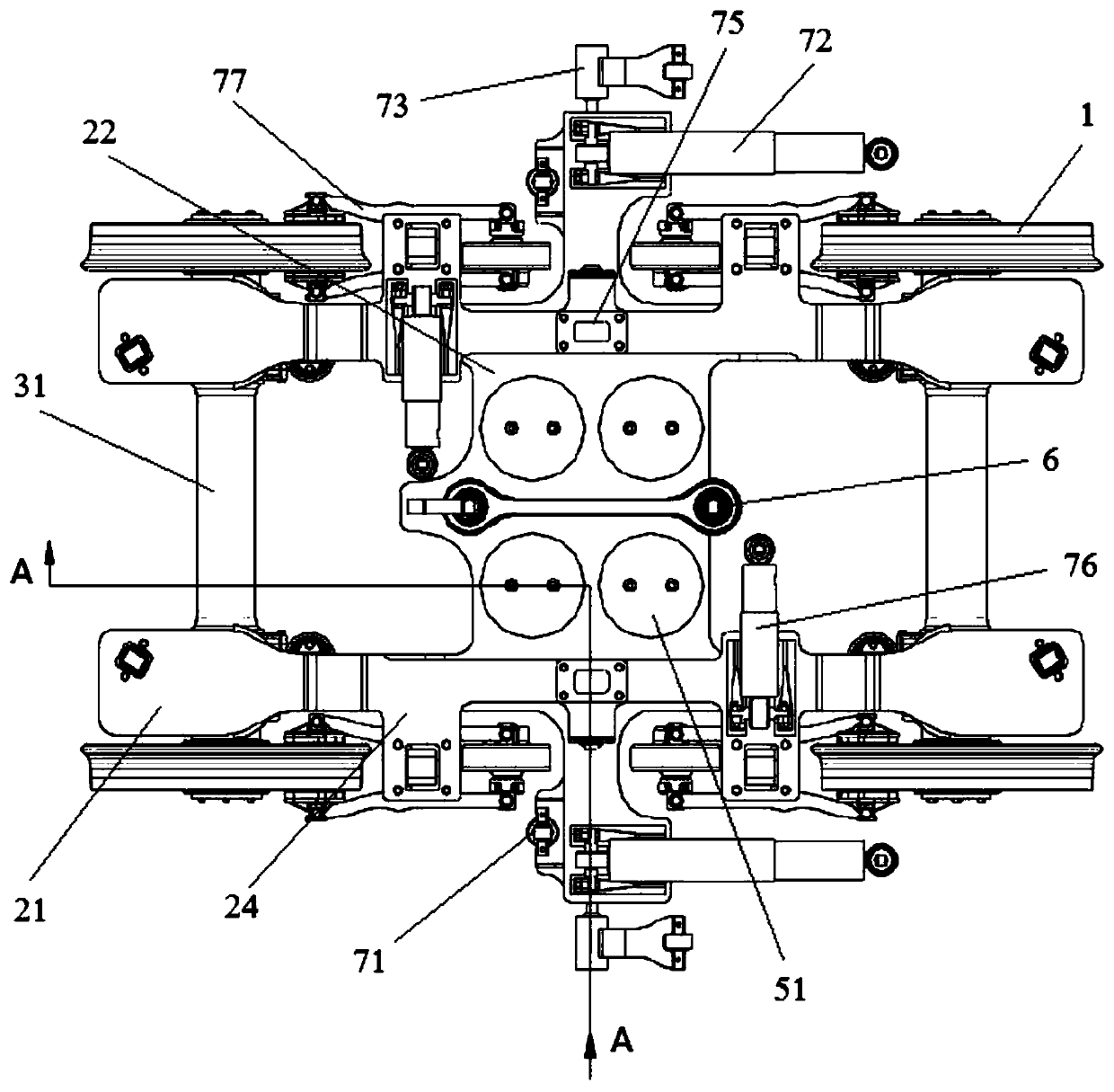

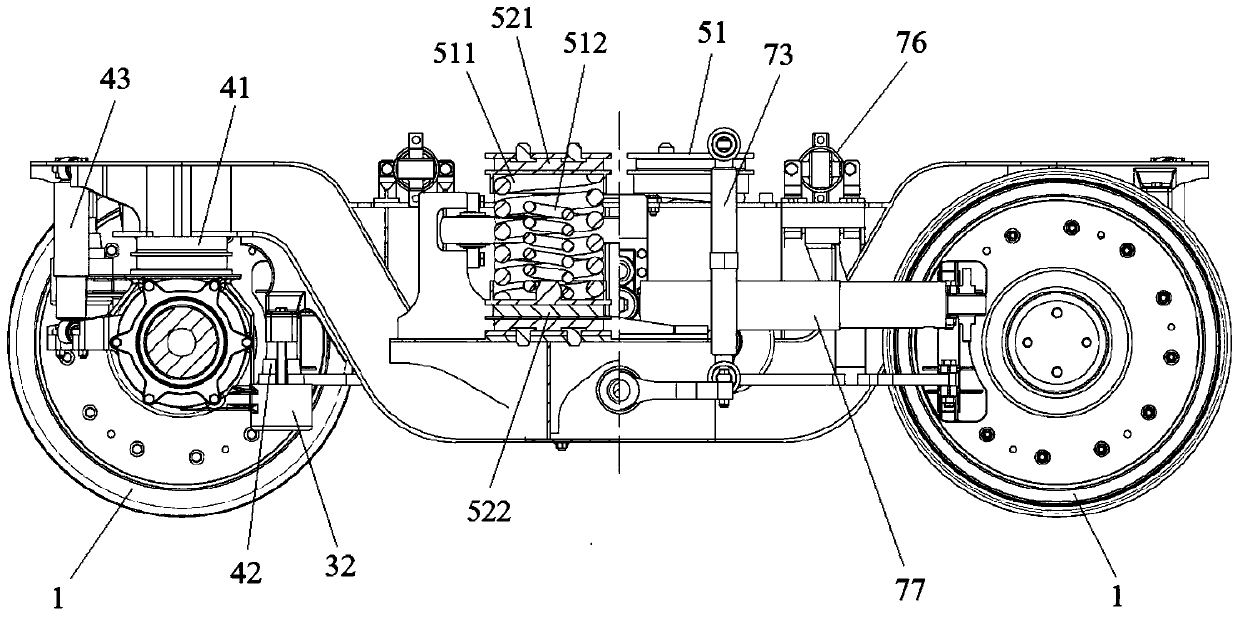

[0040] Such as Figure 1-8 As shown, a railway vehicle bogie according to the present invention comprises:

[0041] Wheel set, including wheel 1;

[0042] The frame is arranged on the inner side of the wheel set and includes two side beams 21 and a cross beam 22. The middle part of the side beam 21 has a concave section, and the cross beam 22 is connected between the two concave sections. The top surface of the concave section is connected with a web 23 and a cover 24;

[0043] The axle box 3 is arranged on the inner side of the wheel set and is used to connect the axle 31;

[0044] A series of suspension devices, including a series of spring parts 41 and a series of positioning parts 42, the series of spring parts 41 are connected to the top of the axle box 3, and the series of positioning parts 42 are connected to both sides of the axle box 3 The two primary positioning parts 42 are arranged symmetrically with respect to the axis of the axle box 3, and the primary spring pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com