Detachable type mechanical arm cable-bunching device adopting peripheral slide spherical hinge connection

A technology of circumferential sliding and sliding connectors, which is applied in the field of robots, can solve problems such as the inability to adjust the diameter of the cable clamp, damage to the cloth belt and cable, and affect the appearance of the mechanical arm, so as to facilitate maintenance and replacement, reduce stress and deformation , Simple and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The wire harness device provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

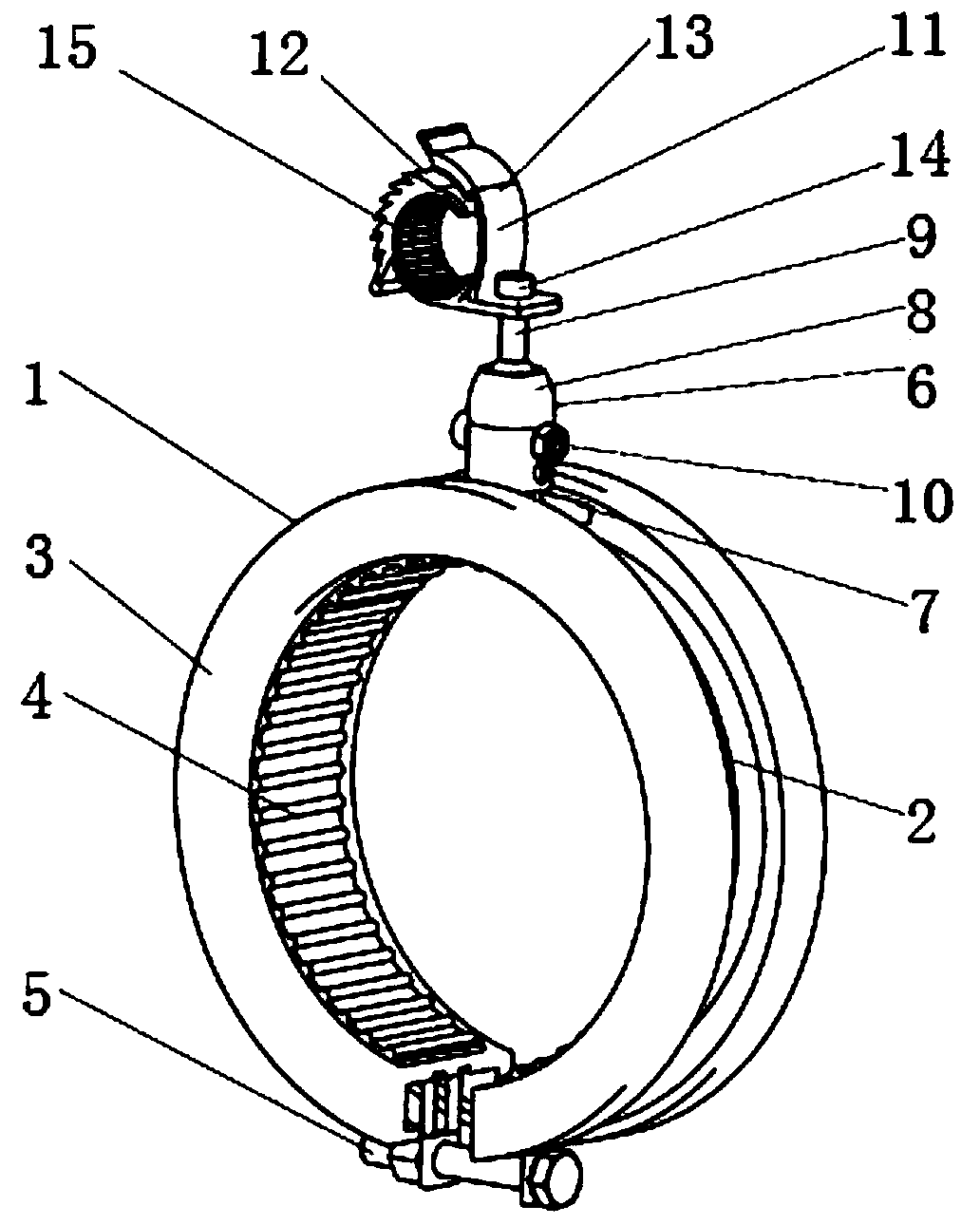

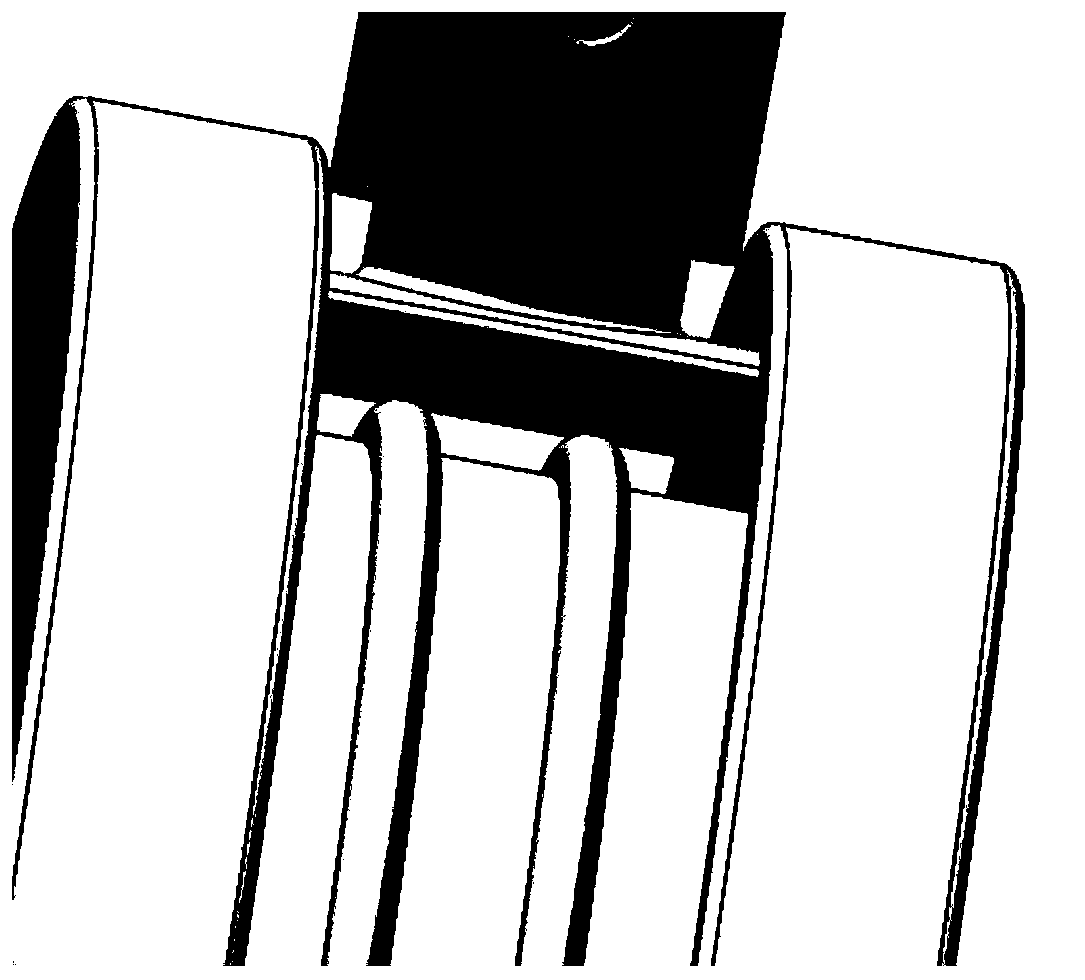

[0026] The invention provides a detachable mechanical arm harness device connected by a circumferential sliding ball hinge, such as figure 1 , Figure 2A , Figure 2B , image 3 , Figure 4 and Figure 5 As shown, the wire harness device specifically includes a double wire hoop mechanism 1 , a ball hinge connection mechanism 6 and a wire harness clamp mechanism 11 , and the double wire hoop mechanism 1 is connected to the wire harness clamp mechanism 11 through the ball hinge connection mechanism 6 .

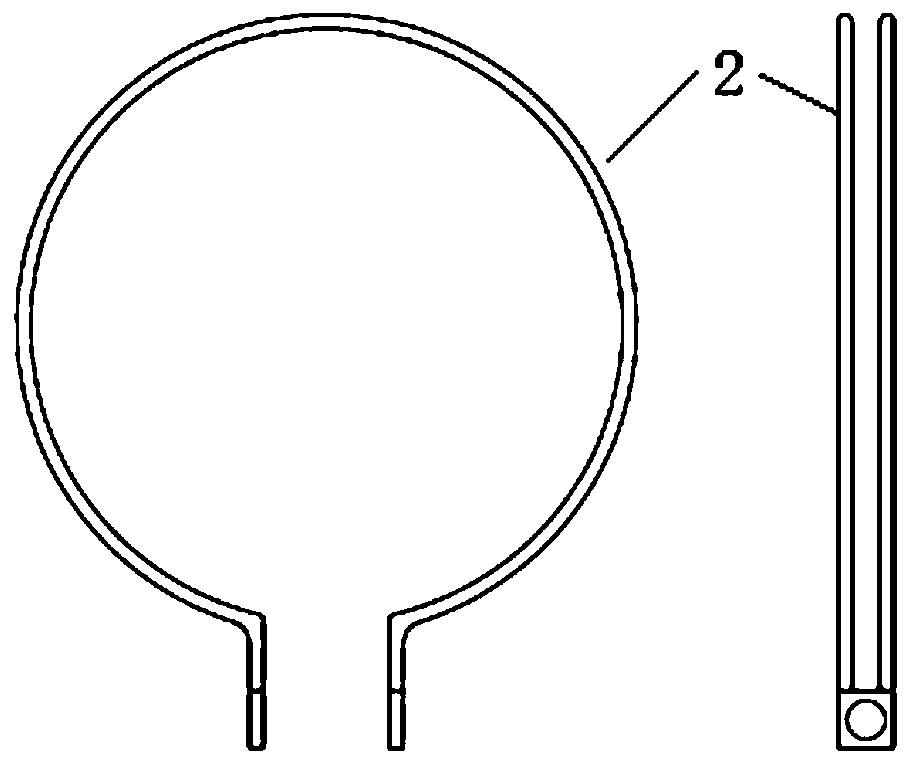

[0027] The double-wire hoop mechanism 1 includes metal double wires 2, metal hoops 3 and hoop connecting bolts 5; the metal hoop 3 is ring-shaped, such as image 3 As shown, it can be hugged on the robotic arm. As shown in Figure 2, the metal double wire 2 is in the shape of a double ring wire, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com