High frequency vibrating screen

A technology of high-frequency vibrating screen and sieve plate, applied in the direction of filter screen, solid separation, grille, etc. The reliability of the machine structure is poor, so as to improve the dehydration effect, prevent the phenomenon of stockpiling and water running, and reduce the torsional deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

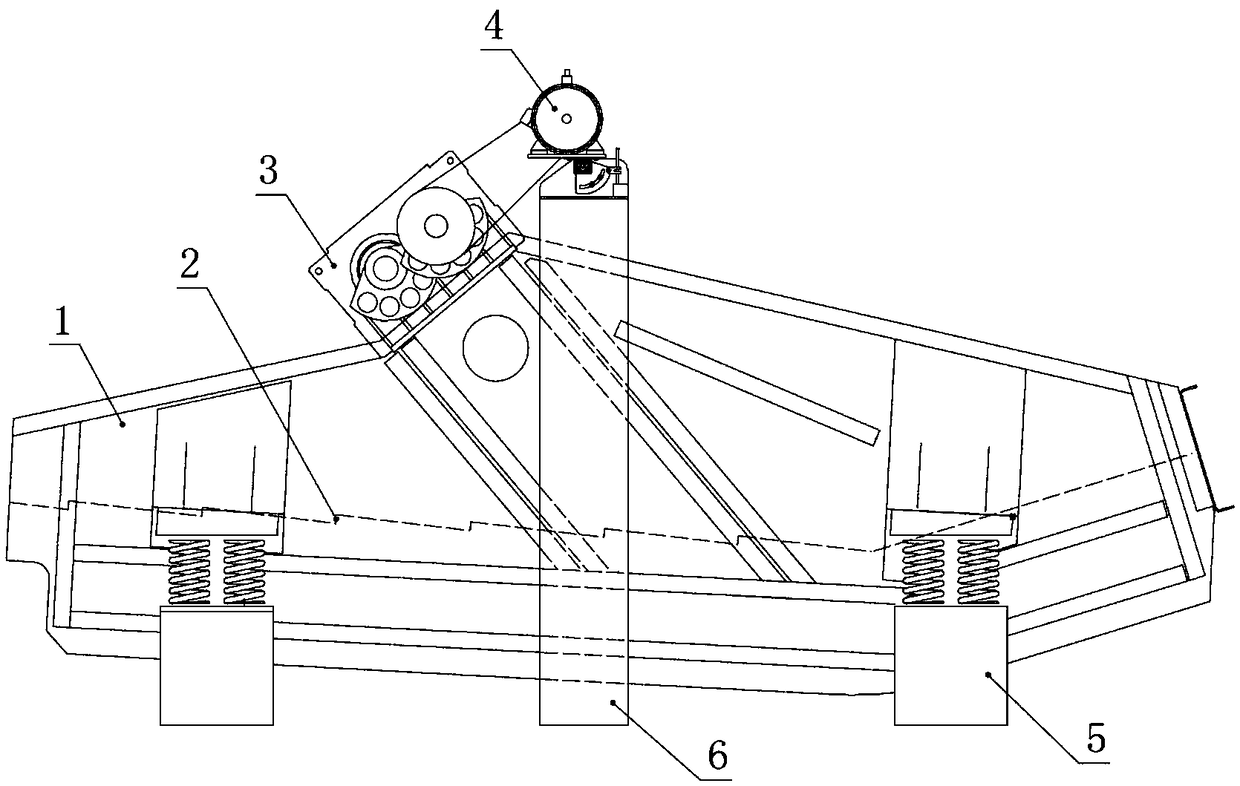

[0036] see figure 1 , The present invention includes a screen box 1, a screen plate 2, a forced synchronous box-type vibrator 3, a drive system 4, a support 5 and a transmission seat 6. The forced synchronous vibrator 3 is installed on the screen box 1, the screen box 1 is installed on the support 5, the traditional system 4 is installed on the transmission seat 6, and the screen box 1 is driven by the vibration generated by the forced synchronous box vibrator 3. Do reciprocating linear motion under the action of vibration force.

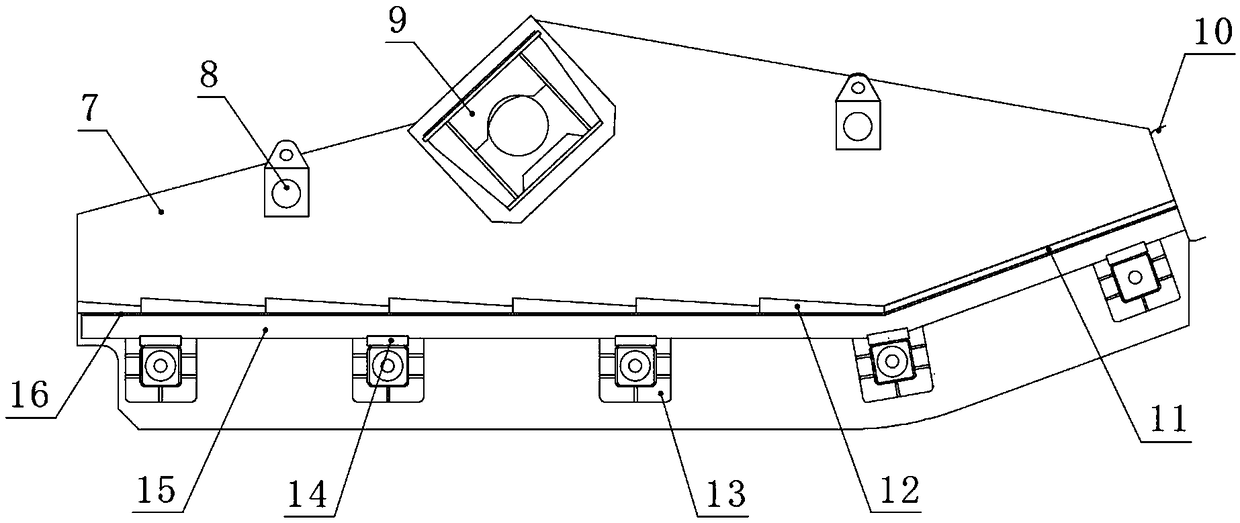

[0037] see image 3 , the screen box 2 is composed of side plates 7, reinforcing beams 8, driving beams 9, feeding baffles 10, crossbeams 13, longitudinal beam support plates 14, longitudinal beams 15, etc.; reinforcing beams 8, driving beams 9, feeding baffles 10. The flanges at both ends of the beam 13 and the side plate 7 are connected by bolts; the longitudinal beam support plate 14 with a “∟” cross-section structure is symmetrically fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com