Stirring machine for sweet potato powder processing

The technology of sweet potato flour and mixer is applied in the directions of mixer accessories, mixers with rotary stirring devices, mixers, etc., and can solve the problems of inability to increase the water absorption effect of sweet potato flour, stirring for a long time, and easy to produce dough, etc. Achieve the effect of increasing the stability of connection and installation, improving stirring efficiency and ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are listed below, and detailed descriptions are as follows in conjunction with the accompanying drawings.

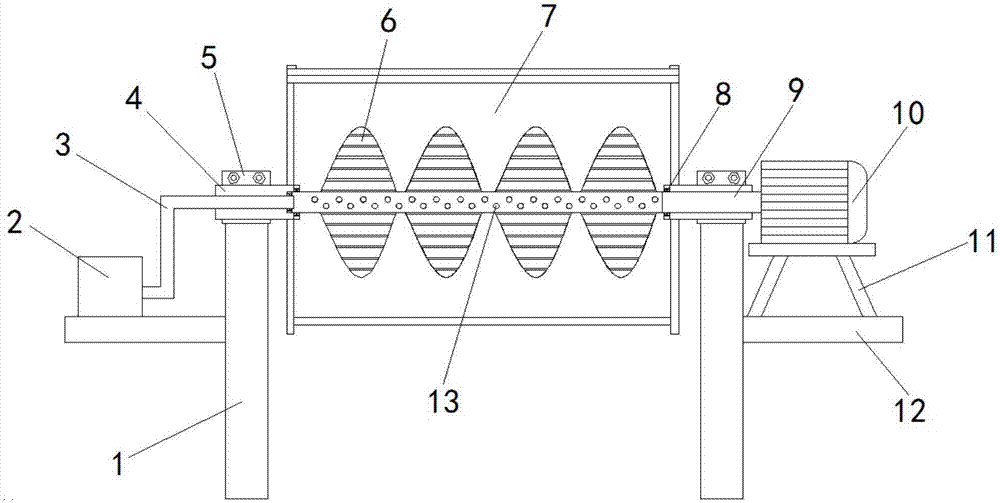

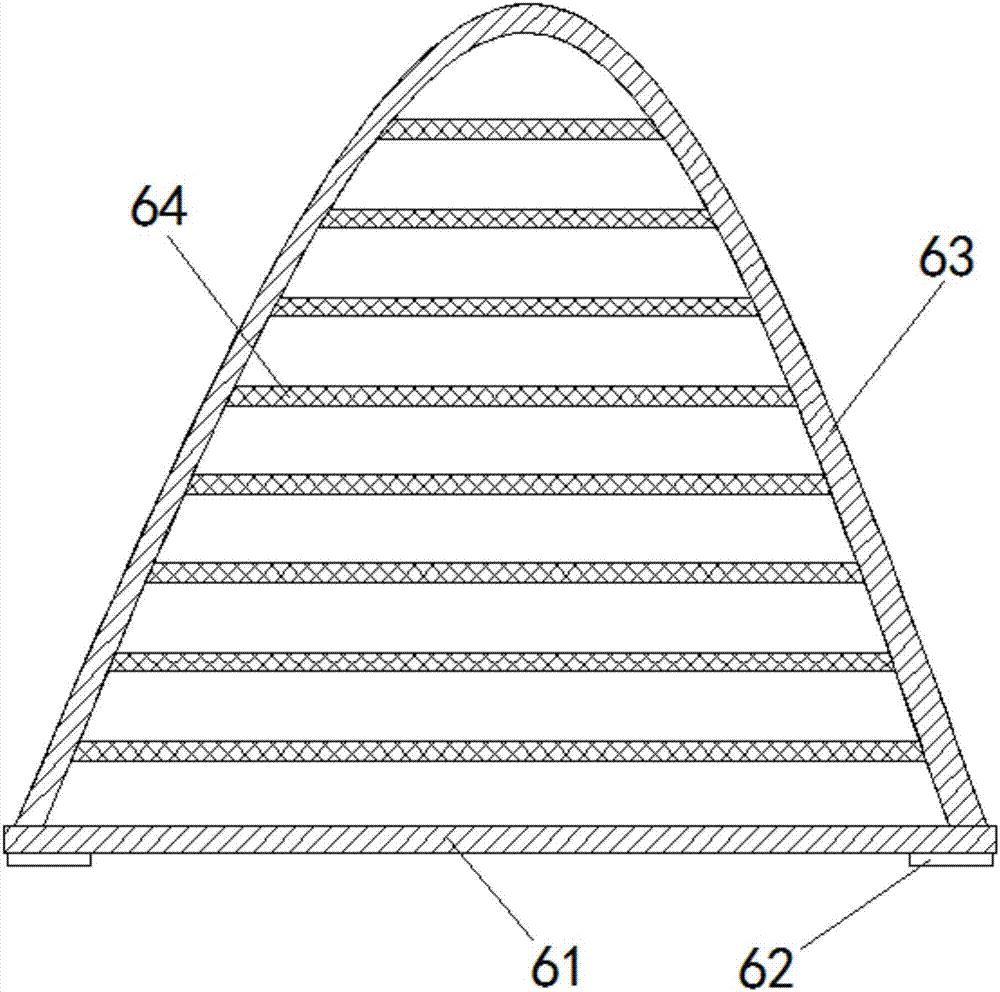

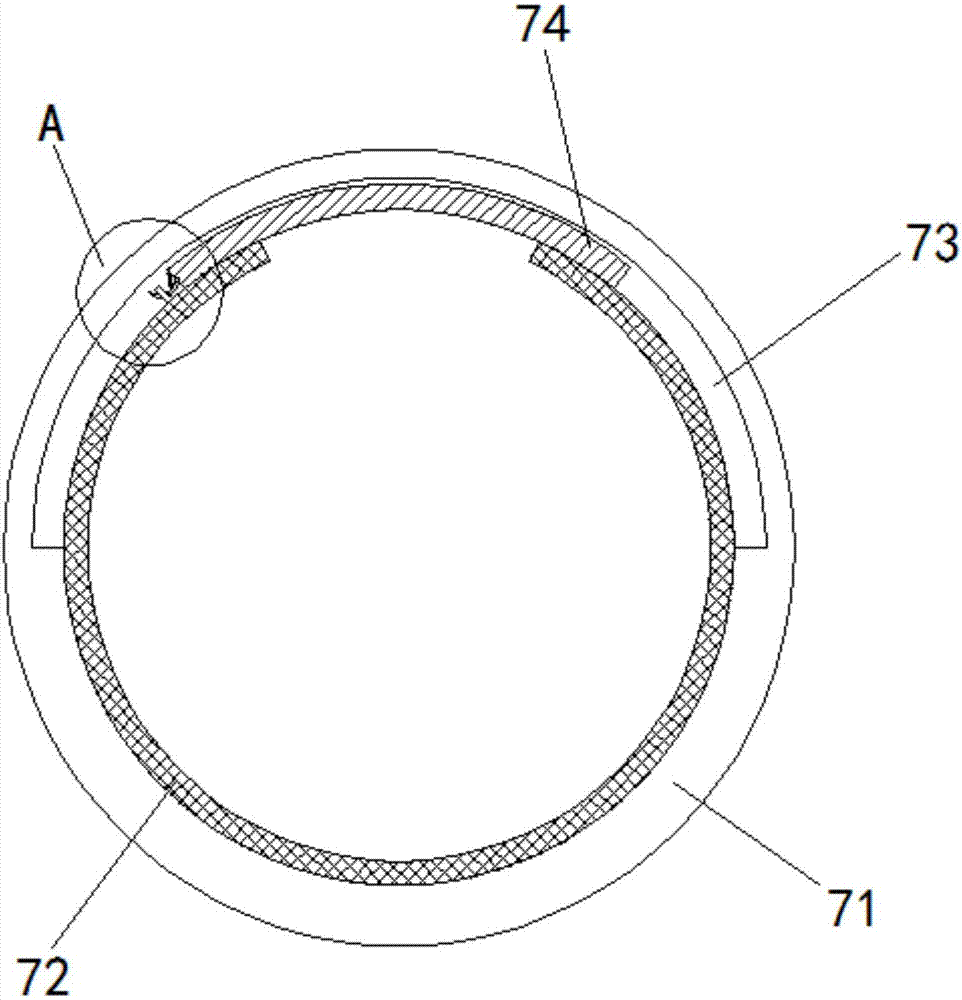

[0022] Combine below Figure 1-4 The mixer for processing sweet potato powder of the present invention is described in detail: a mixer for processing sweet potato flour, comprising a support 1, a water pump 2, a water delivery pipe 3, a stirring blade 6, a mixing box 7, a rotating shaft 9 and a motor 10, the support 1 The upper end of the upper end is provided with a fixing hoop 5, and the inside of the fixing hoop 5 is connected with a supporting short pipe 4, and a stirring box 7 is connected between the supporting short pipes 4, and the stirring box 7 is composed of a lower arc plate 72, an upper arc plate 74 It is composed of two end sealing plates 71, the end sealing plate 71 is a circular panel, the two ends of the lower arc p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com