Mixing process and filling unit for vacuum stone

A unitary, vacuum stone technology, which is applied in the field of mixing technology, can solve the problems of reducing the strength of synthetic stone and difficult to increase the strength of synthetic stone, and achieves the effects of small usage, convenient stirring and processing, and convenient molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

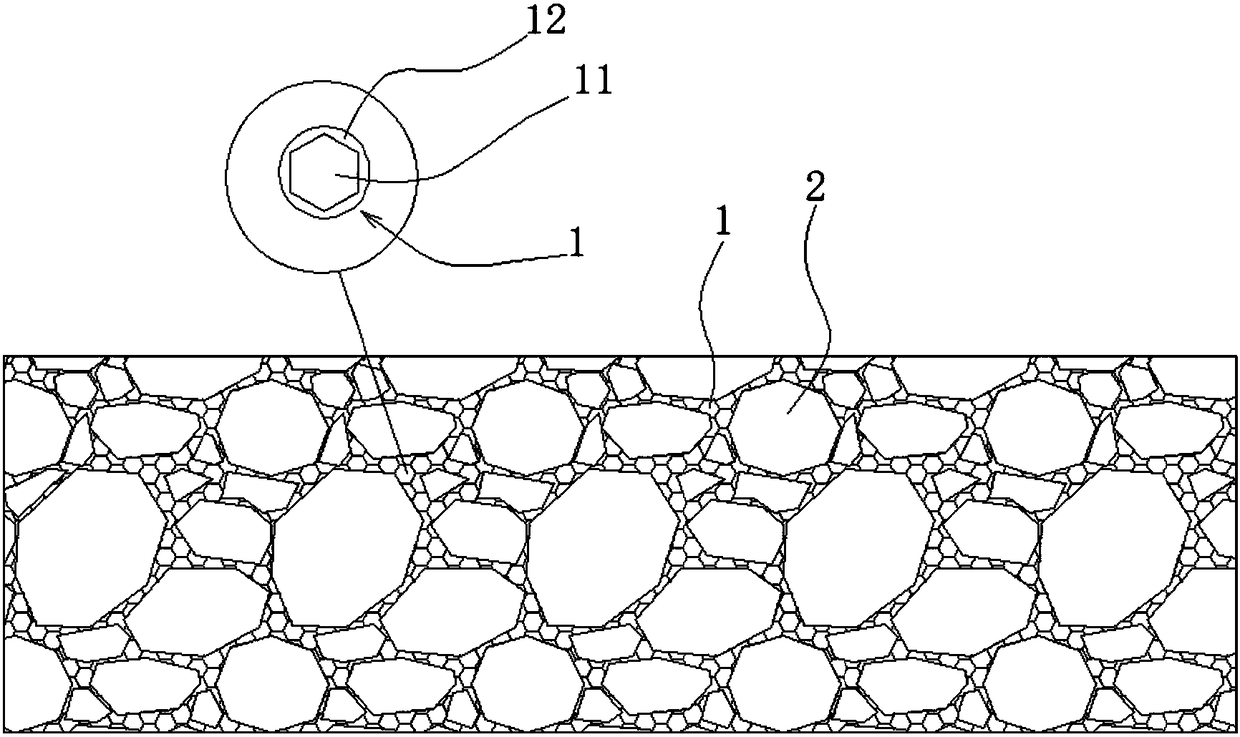

[0033] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings. The following description is merely exemplary in nature and is not intended to limit the application or uses of the present disclosure. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

[0034] see figure 1 , a kind of mixing process used in vacuum stone provided by the present invention comprises the following steps,

[0035] Prepare the filling unit body 1, mix the fine-grained solid particle filler 11 with the liquid filler, so that the surface of the solid particle filler 11 forms a flexible liquid-filled film 12; the fine-grained solid particle filler 11 in the present invention As the smallest particle size filling unit, the flexible liquid-filled membrane 12 has a plastic shape, and ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com