High-strength durable wooden I-shaped beam

An I-beam, durable technology, applied in the direction of joists, girders, trusses, etc., can solve the problems of environmental pollution, destruction, consumption of natural resources and energy, etc., and achieve the effect of convenient support and disassembly, easy cutting, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

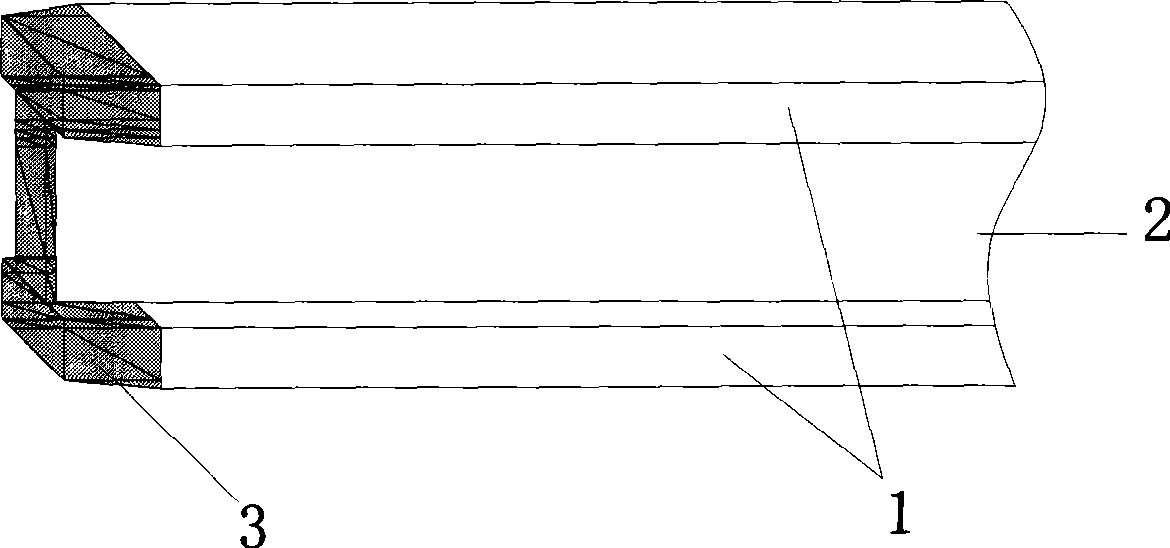

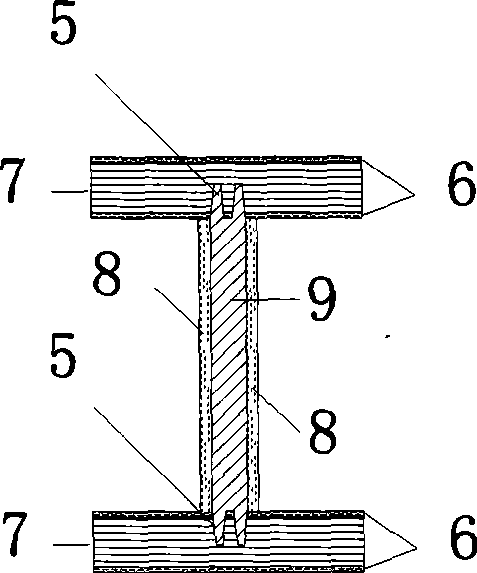

[0026] Such as figure 1 and figure 2 As shown, a high-strength and durable wooden I-beam includes upper and lower flanges 1 , a middle web 2 and end protective sleeves 3 . The flange 1 and the web 2 are all provided with a flange modified veneer 6 and a web modified veneer 8 on the surface, using low molecular weight water-soluble phenolic resin (PF) or melamine-formaldehyde resin (MF) ) etc. to dip the veneer to achieve waterproof, anti-corrosion, anti-deformation and flame-retardant effects.

[0027] The flange substrate 7 is a fast-growing material LVL such as poplar, and a layer of flange modified veneer 6 in the same direction is arranged every 1 to 3 layers of fast-growing materials LVL such as poplar. The material used for the edge modification treatment veneer 6 is a fast-growing veneer such as poplar (its direction along the grain is consistent with the length direction of the I-beam), and the plate used for the flange 1 can be formed at one time by LVL processing ...

Embodiment 2

[0029] Such as figure 1 and figure 2 As shown, a high-strength and durable wooden I-beam includes upper and lower flanges 1 , a middle web 2 and end protective sleeves 3 . The flange 1 and the web 2 are all provided with a flange modified veneer 6 and a web modified veneer 8 on the surface, using low molecular weight water-soluble phenolic resin (PF) or melamine-formaldehyde resin (MF) ) etc. to dip the veneer to achieve waterproof, anti-corrosion, anti-deformation and flame-retardant effects.

[0030] The flange substrate 7 is a fast-growing material LVL such as poplar, and a layer of flange modified veneer 6 in the same direction is arranged every 1 to 3 layers of fast-growing materials LVL such as poplar. The material used for the edge modification treatment veneer 6 is a fast-growing veneer such as poplar (its direction along the grain is consistent with the length direction of the I-beam), and the plate used for the flange 1 can be formed at one time by LVL processing ...

Embodiment 3

[0032] Such as figure 1 and figure 2 As shown, a high-strength and durable wooden I-beam includes upper and lower flanges 1 , a middle web 2 and end protective sleeves 3 . The flange 1 is provided with a flange modified veneer 6 on the surface; the web 2 is composed of three layers of glulam, the middle web substrate 9 is masson pine glulam, and the web on the surface is modified. The permanent treatment veneer 8 is a masson pine laminated board, using low molecular weight water-soluble phenolic resin (PF) or melamine-formaldehyde resin (MF) to impregnate the veneer, so as to achieve waterproof, anti-corrosion, anti-deformation and Flame retardant and other effects.

[0033]The flange substrate 7 is a fast-growing material LVL such as poplar, and a layer of flange modified veneer 6 in the same direction is arranged every 1 to 3 layers of fast-growing materials LVL such as poplar. The material used for the edge modification treatment veneer 6 is a fast-growing veneer such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com