Lead-free tin-based halide perovskite thin film, preparation method and application thereof

A halide perovskite, lead-free tin-based technology, applied in the field of solar cells, can solve the problems of reducing device efficiency and stability, increasing the complexity and cost of the preparation process, poor stability of tin-based perovskite, etc. Effects of stability, good light absorption properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] x=0.02, FA 0.98 DPPA 0.02 SnI 3 Preparation method of perovskite thin film:

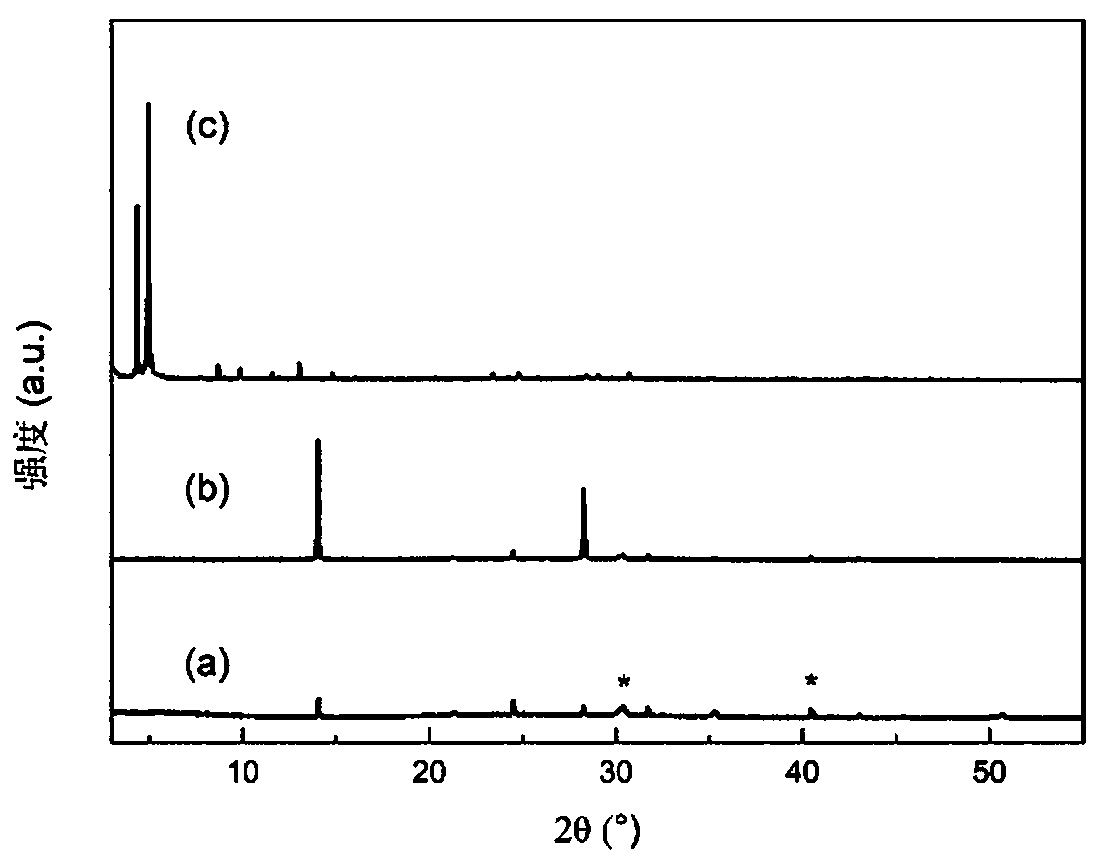

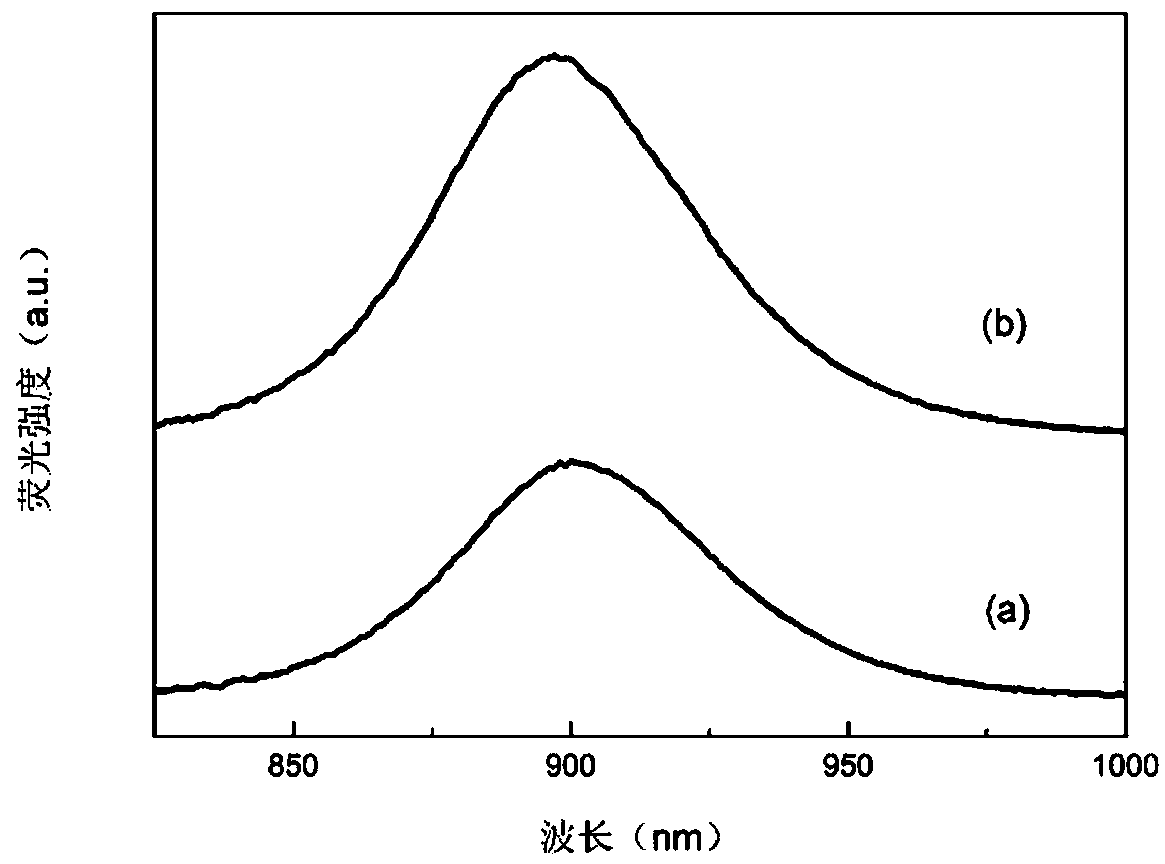

[0039] Weigh out 372mg of stannous iodide, 168mg of formamidine hydroiodide, 6.8mg of 3,3-diphenylpropylamine hydroiodide (DPPAI), and 16mg of stannous fluoride and mixed and dissolved in 800 μL DMF and 200 μL DMSO In the mixed polar solvent, stirring for more than 6h, until the solution is uniform and clear, to obtain FA 0.98 DPPA 0.02 SnI 3Perovskite precursor solution. The resulting solution was filtered through a 0.22 μm pore size polytetrafluoroethylene syringe filter for spin coating. Take 50 μL of the precursor solution and drop it on the PEDOT:PSS substrate, adjust the rotation speed to 4000 rpm and the time for 60 s. In the first 15s of spin coating, use a pipette to pipet 200 μL of chlorobenzene and drop it onto the spinning substrate. After spin coating, annealed at 100 °C for 10 min to obtain dark brown FA 0.98 DPPA 0.02 SnI 3 Perovskite thin films. figure 1 (b), FA 0....

Embodiment 2

[0041] x=1, DPPA 2 SnI 4 Preparation method of film:

[0042] Weigh 372 mg of stannous iodide, 678 mg of 3,3-diphenylpropylamine hydroiodide (DPPAI), and 16 mg of stannous fluoride and mix and dissolve them in a mixed polar solvent of 800 μL DMF and 200 μL DMSO, and stir for more than 6 hours. until the solution is homogeneous and clear to obtain DPPA 2 SnI 4 precursor solution. The resulting solution was filtered through a 0.22 μm pore size polytetrafluoroethylene syringe filter for spin coating. Take 50 μL of the precursor solution and drop it on the PEDOT:PSS substrate, adjust the rotation speed to 4000 rpm and the time for 60 s. In the first 15s of spin coating, use a pipette to pipet 200 μL of chlorobenzene and drop it onto the spinning substrate. After spin coating, annealed at 100 °C for 10 min to obtain yellow DPPA 2 SnI 4 film. figure 1 (c) for DPPA 2 SnI 4 The XRD pattern of the thin film shows that it no longer has the characteristic diffraction peaks of ...

Embodiment 3

[0044] When R=Br, FA 0.98 DPPA 0.02 SnI 2.98 Br 0.02 Preparation method of perovskite thin film:

[0045] Weigh out 372mg of stannous iodide, 168mg of formamidine hydroiodide, 5.8mg of 3,3-diphenylpropylamine hydrobromide (DPPABr), and 16mg of stannous fluoride and mixed and dissolved in 800μL DMF and 200μL DMSO In the mixed polar solvent, stirring for more than 6h, until the solution is uniform and clear, to obtain FA 0.98 DPPA 0.02 SnI 2.98 Br 0.02 Perovskite precursor solution. The resulting solution was filtered through a 0.22 μm pore size polytetrafluoroethylene syringe filter for spin coating. Take 50 μL of the precursor solution and drop it on the PEDOT:PSS substrate, adjust the rotation speed to 4000 rpm and the time for 60 s. In the first 15s of spin coating, use a pipette to pipet 200 μL of chlorobenzene and drop it onto the spinning substrate. After spin coating, annealed at 100 °C for 10 min to obtain dark brown FA 0.98 DPPA 0.02 SnI 2.98 Br 0.02 Pero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com