Method for preparing polymer superhydrophobic surface using controlled etched metal surface as template

A technology of superhydrophobic surface and metal surface, applied in the field of preparing polymer superhydrophobic surface, can solve the problems of insufficient rigidity, easy aging, affecting large-scale application, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Immerse the sheet stainless steel (length and width: 2×2cm, thickness: 2.4mm) into deionized water and ultrasonically (40kHZ, 30min) to clean the surface dirt, then wash with acetone to remove the surface organic impurities, and finally wash with deionized water and let it dry naturally dry, spare;

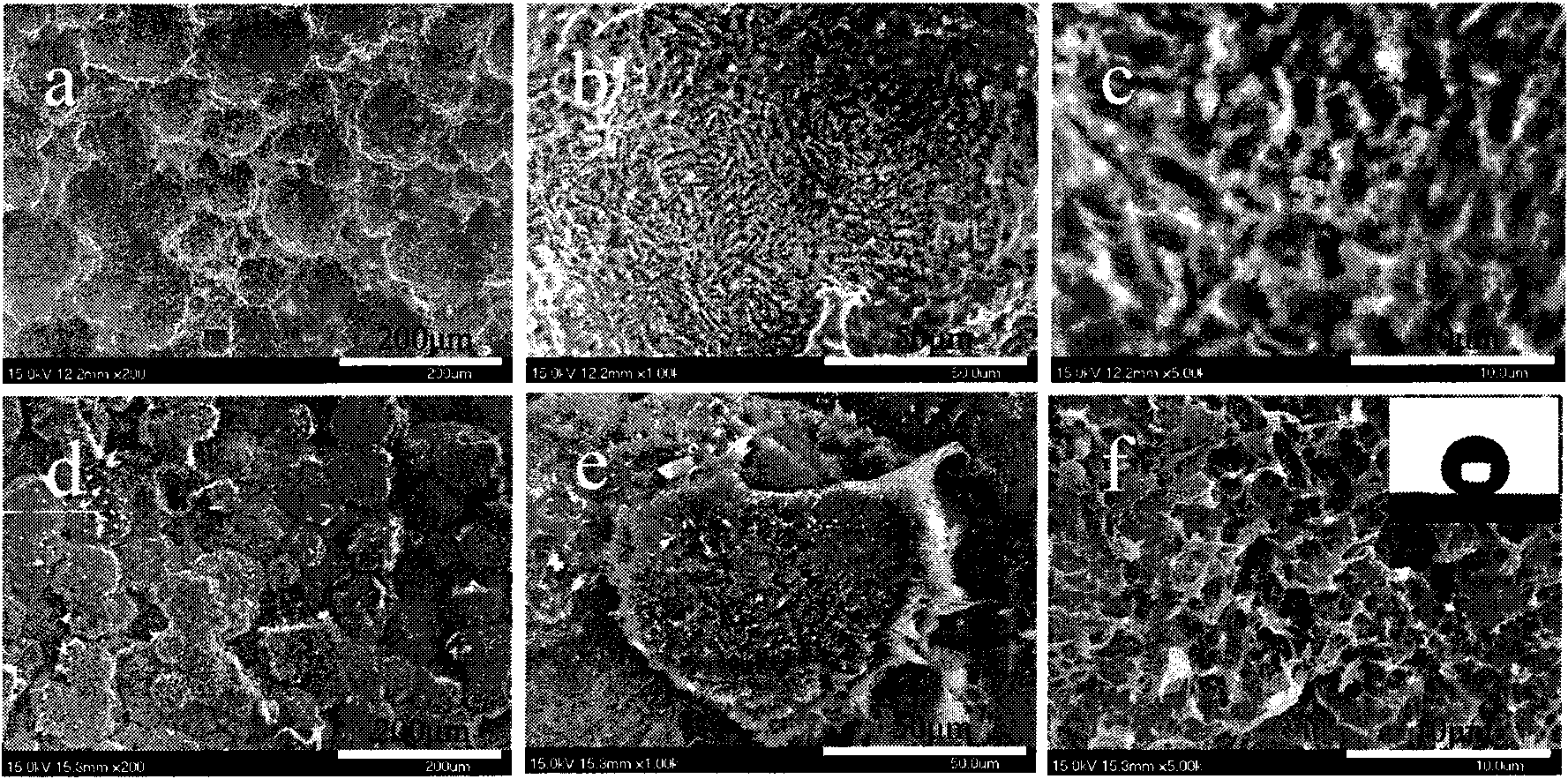

[0042] Put the cleaned stainless steel into FeCl 3 : 600g / L, HCl: 80g / L, H 3 PO 4 : 20g / L, H 2 NCSNH 2 : In 4g / L aqueous solution. At 30°C, 60r / min, agitate for 30min, take it out and wash it with deionized water. The stainless steel surface is distributed with pits of tens to hundreds of microns, and each pit is densely distributed with small pits with a width of about 1 μm and a length of about 3 to 5 μm ( figure 1 a, b, c). At 180°C, 15g / cm 2 Melting and hot pressing LDPE (0.5g) (low density polyethylene, Shanghai Petrochemical, N220) under high pressure for 10 minutes, peeling off after cooling to obtain LDPE film (thickness: 0.6mm), this film well replicates th...

Embodiment 2

[0044] Immerse the sheet stainless steel (length and width: 2×2cm, thickness: 2.4mm) into deionized water and ultrasonically (40kHZ, 30min) to clean the surface dirt, then wash with acetone to remove the surface organic impurities, and finally wash with deionized water and let it dry naturally dry, spare;

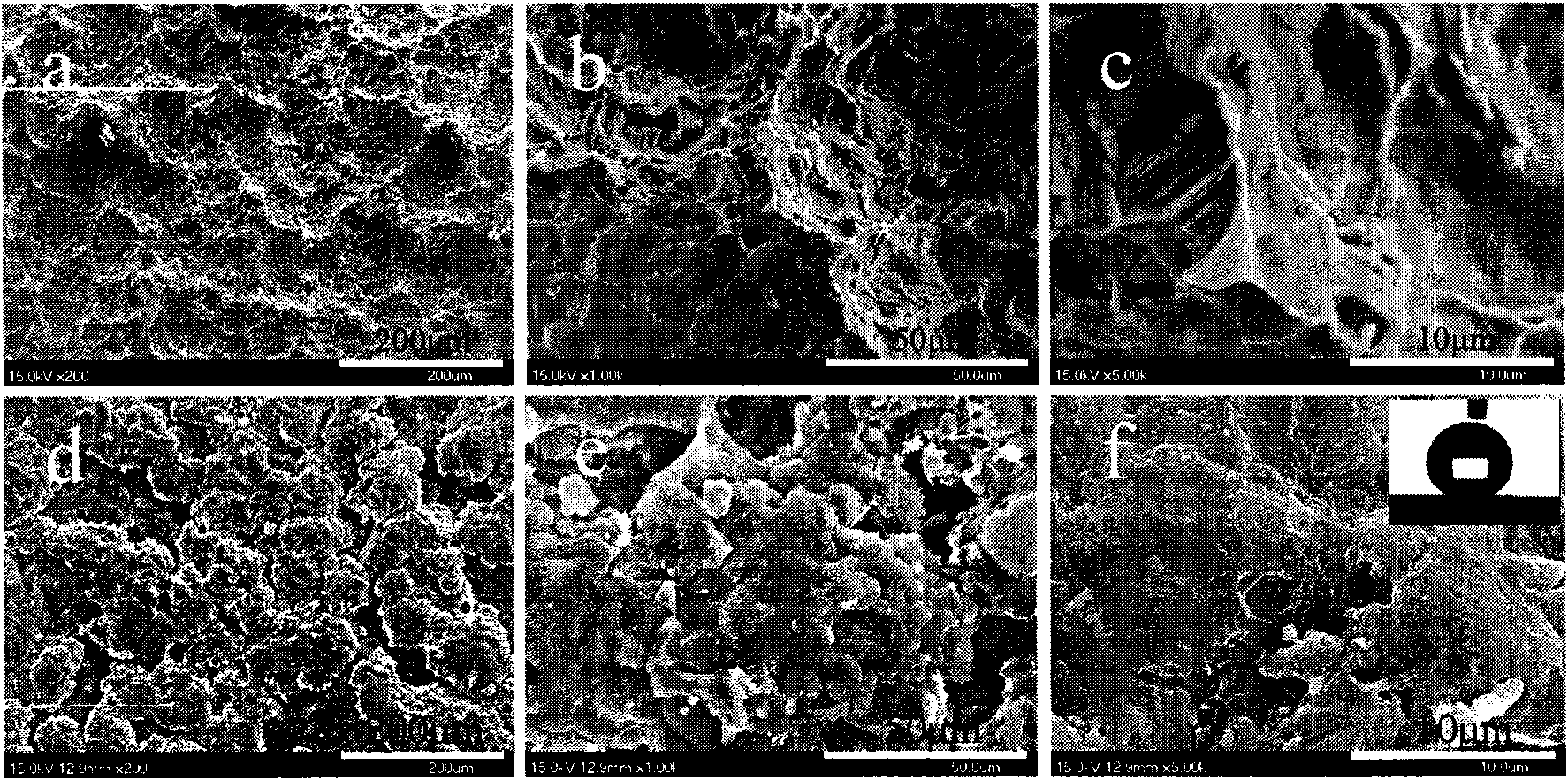

[0045] Put the cleaned stainless steel into FeCl 3 : 600g / L, HCl: 80g / L, H 3 PO 4 : 20g / L, H 2 NCSNH 2 : In 4g / L aqueous solution. At 50°C, 120r / min, etch for 4h, take it out, wash it with deionized water, and dry it. The surface of this stainless steel is etched more seriously, and the surface is uneven ( figure 2 a, b, c). At 180°C, 15g / cm 2 Melting and hot-pressing PP (0.5g) (polypropylene, China Zhenhai Refining & Chemical Co., Ltd., T30S) under high pressure for 10min, peeling off after cooling to obtain PP (thickness: 0.6mm) film ( figure 2 d, e, f). A large number of micron and submicron papillae are distributed on the surface of this PP film. The contac...

Embodiment 3

[0047] Immerse flake brass (length and width: 2×2cm, thickness: 3.1mm) into deionized water and ultrasonically (40kHZ, 30min) to clean the surface dirt, then clean with acetone to remove surface organic impurities, and finally clean with deionized water, nitrogen blow dry, spare;

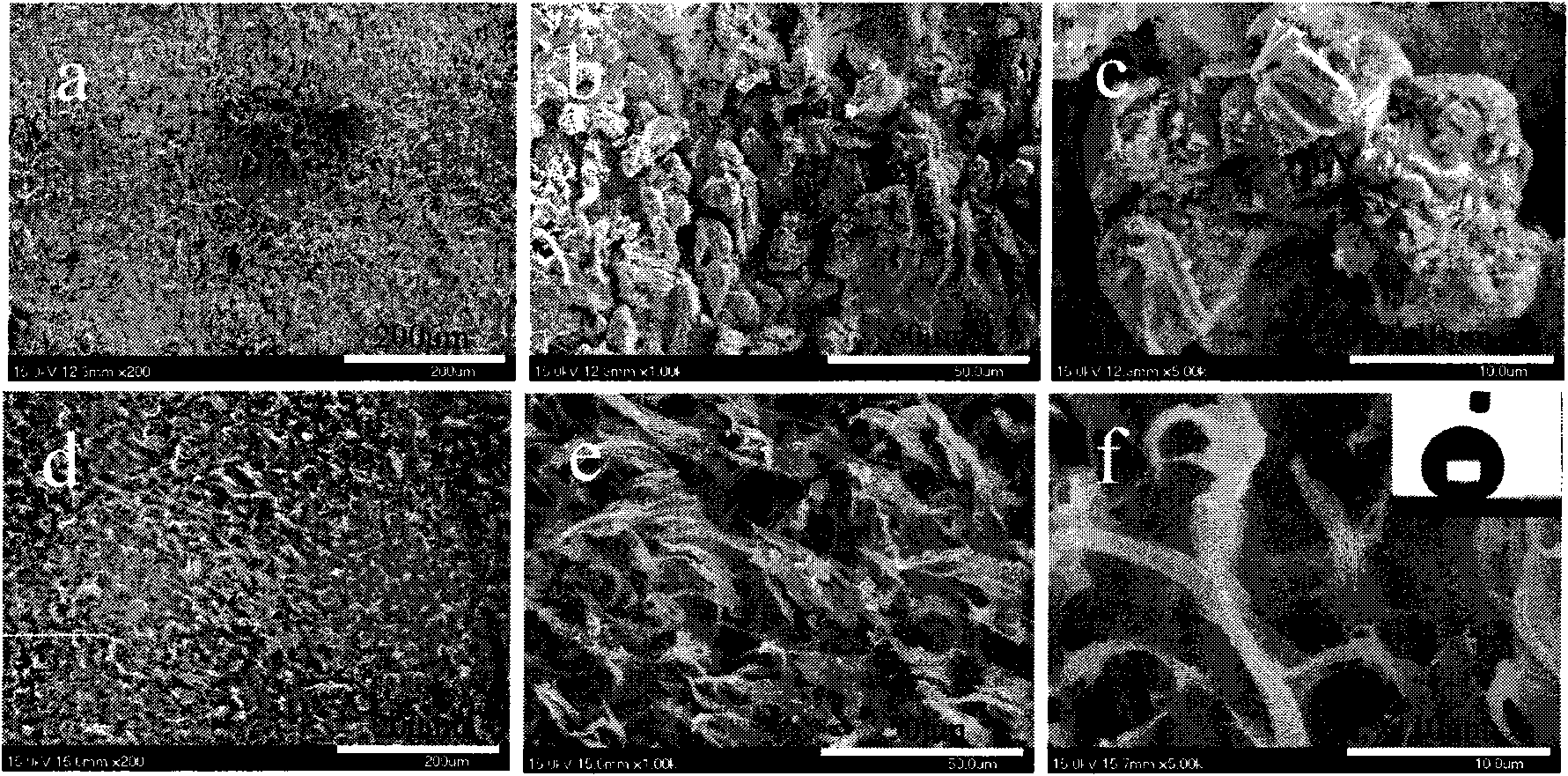

[0048] Put the cleaned brass into FeCl 3 : 400g / L, HCl: 80g / L aqueous solution, etched for 1.5h, taken out, washed with deionized water, and dried. After the brass sheet was etched, a large number of "rock"-like protrusions of tens of microns were evenly distributed on the surface ( image 3 a, b, c). At 180°C, 15g / cm 2 Melt and heat press LDPE (0.5g) under pressure for 10min, peel off after cooling to obtain LDPE (thickness: 0.6mm) film. A large number of elongated papillae ( image 3 d, e, f), the contact angle with water is 152±2.1°, and the rolling angle is ~5°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com