A method for preparing funnel-shaped sodium sulfate from high-salt wastewater

A high-salt wastewater, anhydrous sodium sulfate technology, applied in the preparation form of alkali metal sulfite/sulfate, chemical instruments and methods, alkali metal sulfite/sulfite, etc., to achieve uniform crystal particle size distribution, extended Residence time, the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

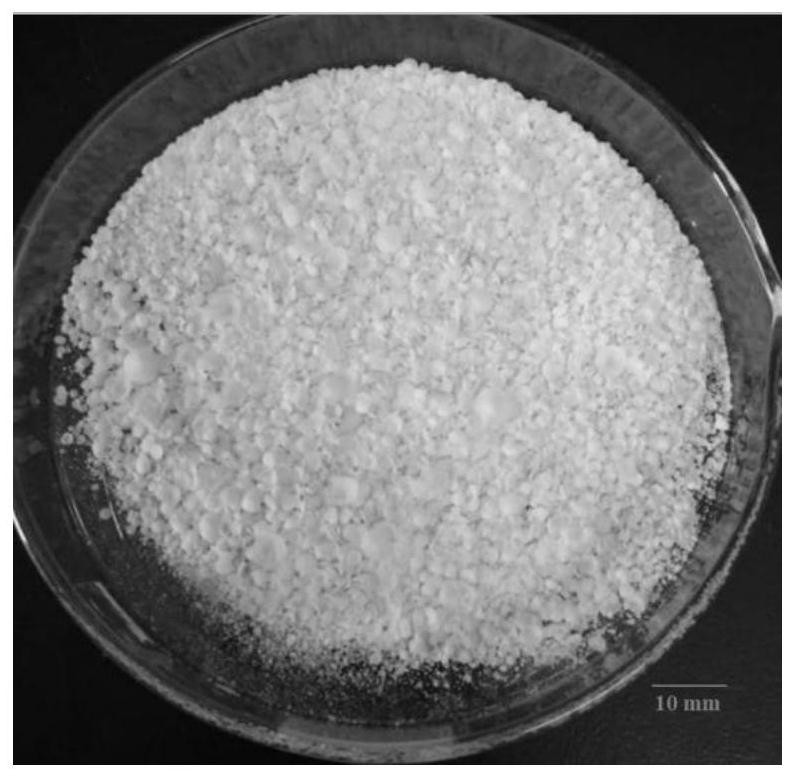

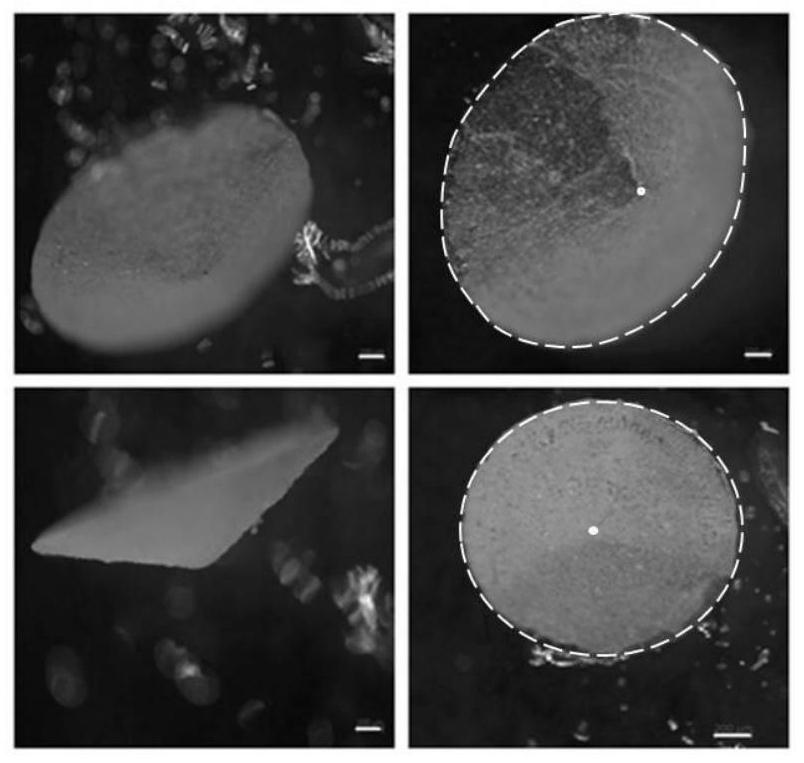

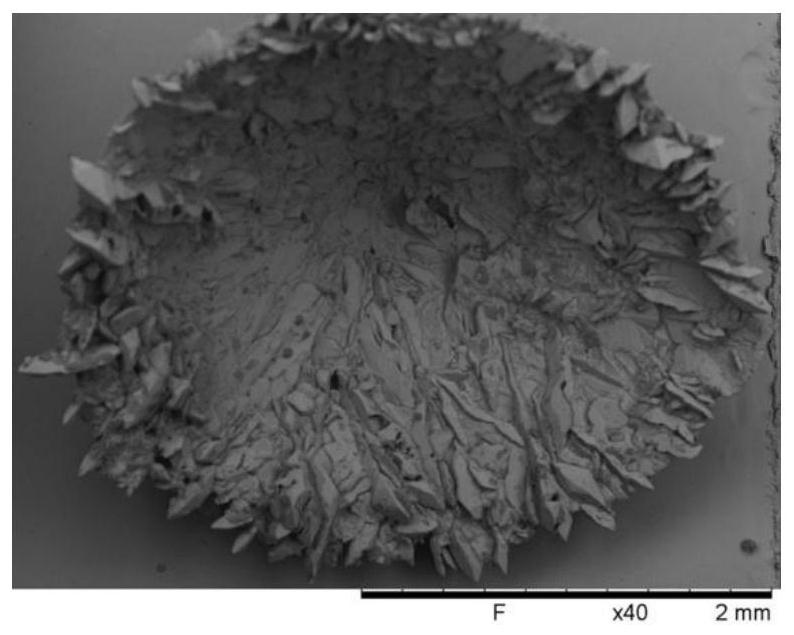

Embodiment 1

[0033] Add 120mL of waste water (density 1.2g / mL) containing 28% (mass percent) sodium sulfate to a 150mL crystallizer, control the stirring rate to 200rpm, add sodium hydroxide to adjust the pH to 11, and heat to 80°C after constant temperature, Start to use negative pressure evaporation, the vacuum degree is controlled to 0.04MPa, and the evaporated water volume is 30mL. Then filter, place the wet solid phase at 105°C, and dry under normal pressure for 8 hours to constant weight to obtain a funnel-shaped sodium sulfate product. The moisture content of the product is 4.63%, and the purity is 98.45%. The photos of the product as a whole and the micrographs and electron micrographs of individual particles are as follows: figure 1 and figure 2 (The short line in the lower right corner of the figure indicates that the length is 200 μm, and the edge and endpoint of the funnel-shaped crystal are marked with a white dotted line and a white dot, respectively.) As shown, the product...

Embodiment 2

[0035] Add 120mL of waste water containing 28% (mass percent) sodium sulfate to a 150mL crystallizer, control the stirring rate to 100rpm, add sodium hydroxide to adjust the pH value to 14, heat to 50°C after constant temperature, start to use negative pressure evaporation, vacuum The degree of control is 0.07MPa, and the amount of distilled water is 35mL. After 50 seconds of filtration, the wet solid phase was completely placed at 105°C, and dried under normal pressure for 8 hours to constant weight to obtain a funnel-shaped sodium sulfate product. The moisture content of the product is 5.56%, the purity is 96.63%, the distribution range of the cone angle of the funnel is 120-150°, and the mass percentage of the product with a particle size ≥ 300 μm is 90.22%.

Embodiment 3

[0037] Add 120mL of waste water containing 30% (mass percent) sodium sulfate to a 150mL crystallizer, control the stirring rate to 400rpm, add sodium hydroxide to adjust the pH value to 12, heat to 60°C after constant temperature, start to use negative pressure evaporation, vacuum The degree of control is 0.05MPa, and the amount of distilled water is 30mL. Then filter, place the wet solid phase at 105°C, and dry under normal pressure for 10 hours to constant weight to obtain a funnel-shaped sodium sulfate product. The moisture content of the product is 7.03%, the purity is 95.88%, the distribution range of the cone angle of the funnel is 120-150°, and the mass percentage of the product with a particle size ≥ 300 μm is 91.35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com