Salt-nitrate continuous separation method

A separation method, a technology of salt nitrate, applied in chemical instruments and methods, alkali metal sulfite/sulfite, alkali metal sulfite/sulfate purification, etc., can solve problems such as high energy consumption and long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

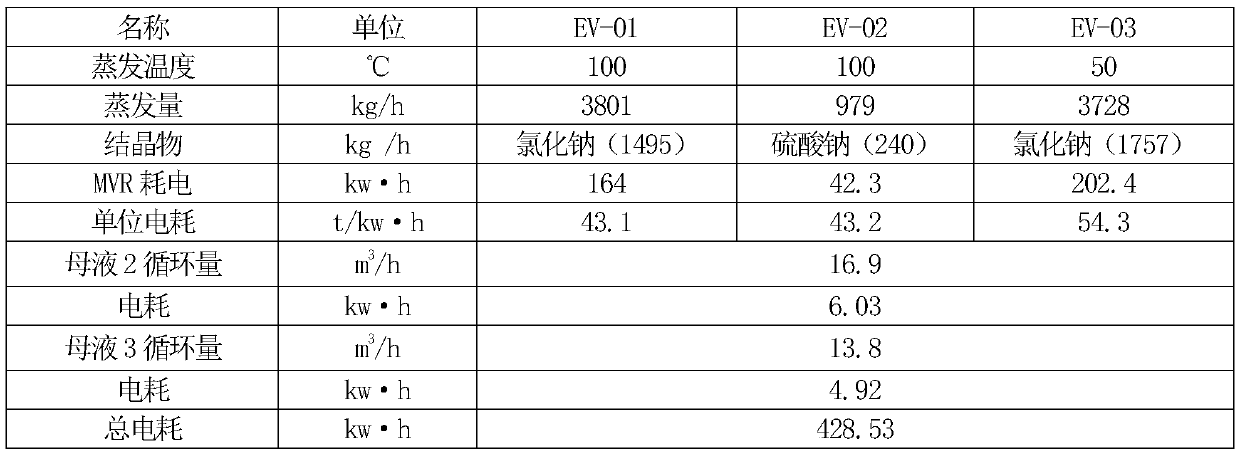

Embodiment 1

[0106] The mass concentrations of sodium chloride and sodium sulfate in the raw brine were detected, which were 27.1% and 2% respectively.

[0107] A1. Introduce 10m3 raw materials into the salt evaporative crystallizer EV-01, evaporate and crystallize sodium chloride at 100°C, and when the mass concentration of sodium sulfate in the solution in the salt evaporative crystallizer EV-01 is 4.25%, mother liquor 1 is formed. Take out the crystallized sodium chloride, centrifuge to obtain sodium chloride, and use GB / T13025.5-2012 method to detect the purity of sodium chloride ≧98.5%.

[0108] A2. Transfer the mother liquor 1 into the nitrate evaporation crystallization tank EV-02, then transfer it to the heat exchanger through the pump A, and transfer it to the salt evaporation crystallization tank EV-03 after heat exchange and cooling; evaporate and crystallize sodium chloride at 50°C, When the mass concentration of sodium sulfate in the salt evaporation crystallization tank EV-03...

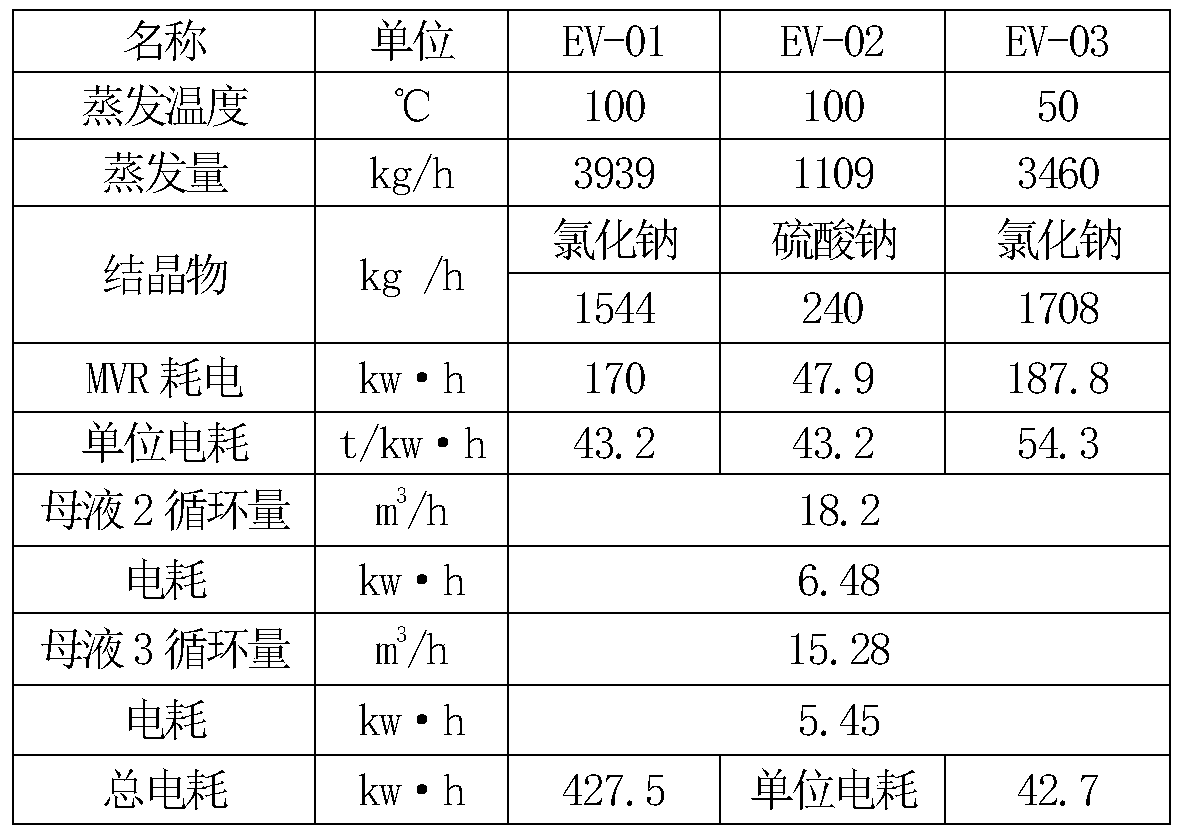

Embodiment 2

[0116] 1) Detect the mass concentrations of sodium chloride and sodium sulfate in the raw brine, which are 27.1% and 2% respectively.

[0117] A1, the 10m 3 The raw material is introduced into the salt evaporative crystallizer EV-01, and sodium sulfate is evaporated and crystallized at 100°C. When the mass concentration of sodium sulfate in the solution in the salt evaporative crystallizer EV-01 is 4.4%, mother liquor 1 is formed. The crystallized sodium chloride was taken out and centrifuged to obtain sodium chloride. The purity of sodium chloride is detected by GB / T13025.5-2012 method ≧98.5%.

[0118] A2. Transfer the mother liquor 1 into the nitrate evaporation crystallization tank EV-02, then transfer it to the heat exchanger through the pump A, and transfer it to the salt evaporation crystallization tank EV-03 after heat exchange and cooling; evaporate and crystallize sodium chloride at 50°C, When the mass concentration of sodium sulfate in the salt evaporation crystall...

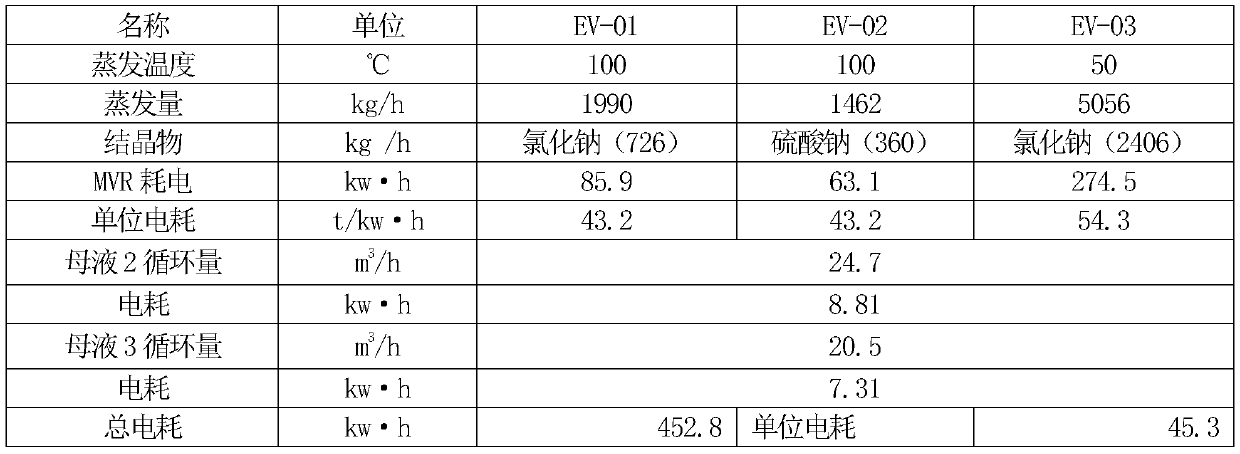

Embodiment 3

[0126] 1) Detect the mass concentrations of sodium chloride and sodium sulfate in the raw brine, which are 26.1% and 3% respectively.

[0127] A1, the 10m 3 The raw material is introduced into the salt evaporative crystallizer EV-01, and sodium sulfate is evaporated and crystallized at 100°C. When the mass concentration of sodium sulfate in the solution in the salt evaporative crystallizer EV-01 is 4.1%, mother liquor 1 is formed. The crystallized sodium chloride was taken out and centrifuged to obtain sodium chloride. The purity of sodium chloride is detected by GB / T13025.5-2012 method ≧98.5%.

[0128] A2. Transfer the mother liquor 1 into the nitrate evaporation crystallization tank EV-02, then transfer it to the heat exchanger through the pump A, and transfer it to the salt evaporation crystallization tank EV-03 after heat exchange and cooling; evaporate and crystallize sodium chloride at 50°C, When the mass concentration of sodium sulfate in the salt evaporation crystall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com