Industrial-grade anhydrous sodium sulfate preparation device and method

A preparation device and technology of sodium sulfate, applied in chemical instruments and methods, preparation forms of alkali metal sulfite/sulfite, alkali metal sulfite/sulfite, etc., can solve the problem of high supersaturation and operating process Problems such as discontinuity and large operating errors, etc., to achieve good economic value, good product quality, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

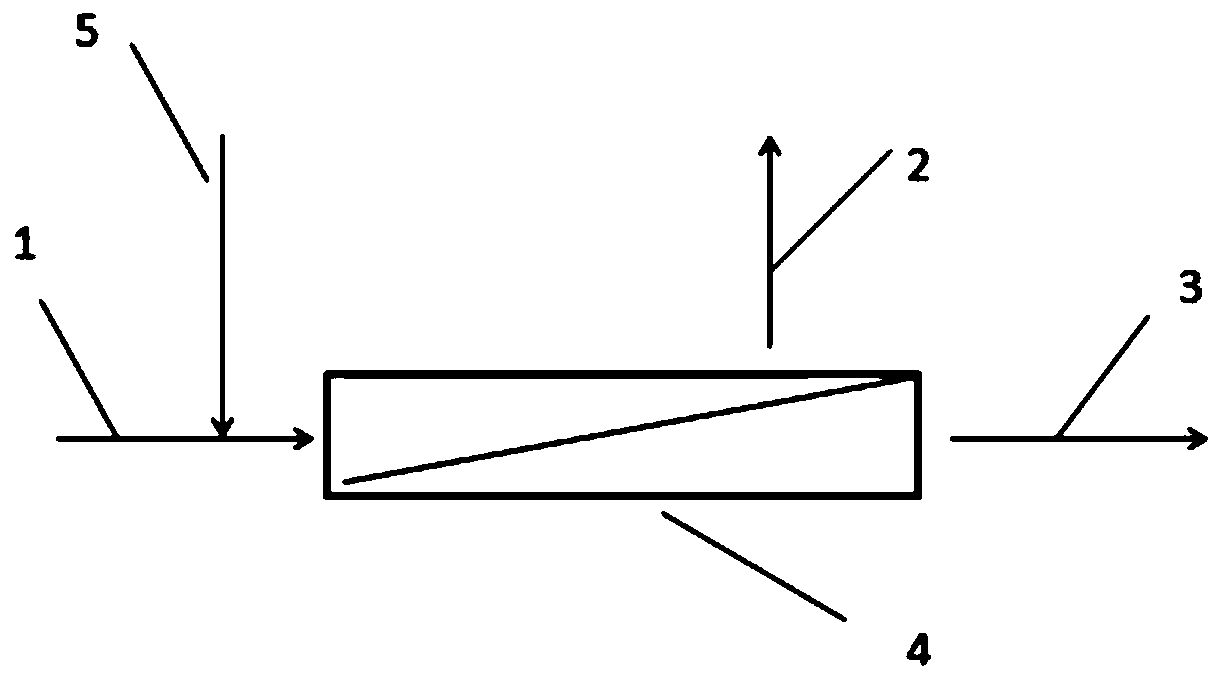

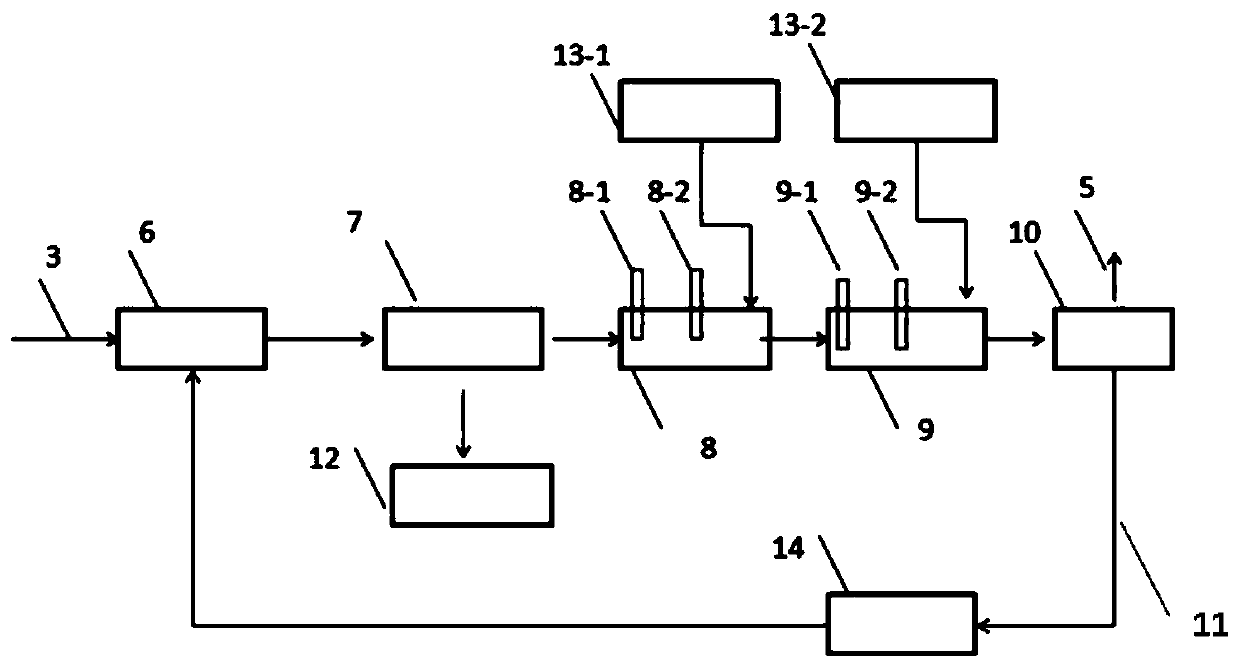

[0029] Such as figure 1 and 2 As shown, the industrial grade sodium sulfate preparation device consists of a membrane concentration system 4, a washing salt mixing tank 1 in a continuous flow salting out crystallization system, a first crystallization settler 7, a first crystallization tank 8, and a second crystallization tank 9 , the second crystallization settler 10, and the reflux circulation pump 14 are connected successively, the first salt adding device 13-1 is connected with the first crystallization tank 8, the second salt adding device 13-2 is connected with the second crystallization tank 9, and the second salt adding device 13-2 is connected with the second crystallization tank 9, A crystal settler 7 is connected to the centrifuge and dryer system 12 . The first crystallization tank 8 includes an online conductivity detection device 8-1 and a stirrer 8-2, and the second crystallization tank 9 includes an online conductance detection device 9-1 and a stirrer 9-2.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com