System and method for preparing byproduct potassium sulfate product through hydrothermal denitration of potassium chloride brine

A technology of potassium sulfate and potassium chloride, used in chemical instruments and methods, calcium/strontium/barium chloride, alkali metal sulfite/sulfite, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Aiming at the following problems in the current potash-alkali plant removal process for sulfate radicals: 1) need to add chemicals, 2) introduce additional impurities, 3) need to discharge solid waste, etc., the present invention proposes a new sulfate radical removal system And method, that is: a sulfate removal process that does not introduce additional impurities and does not generate solid waste, specifically as follows:

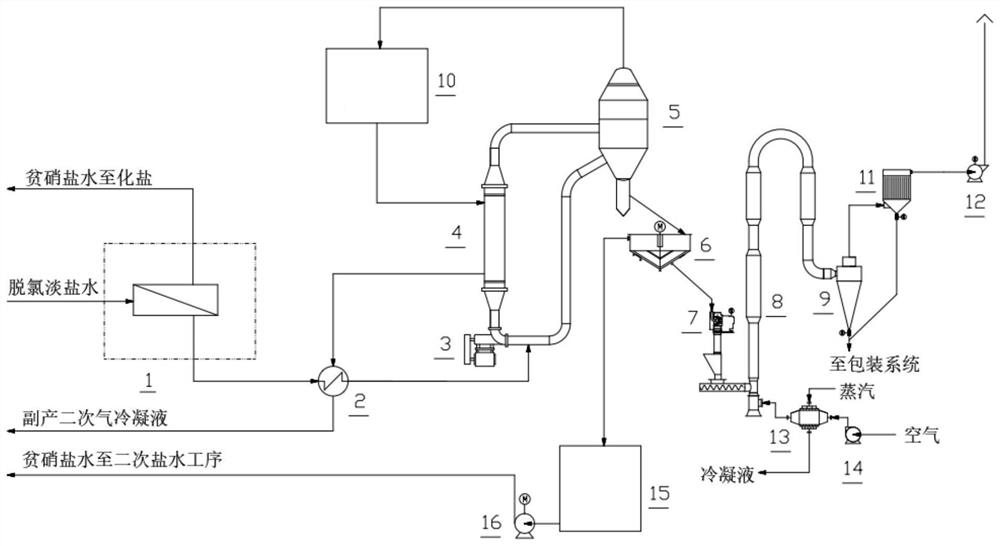

[0044] On the one hand, this embodiment provides a system for potassium chloride brine thermal denitrification by-product potassium sulfate product system, the system includes: nanofiltration membrane concentration unit, heat exchange unit, evaporation crystallization unit, centrifugal separation unit, recovery unit and drying unit, the nanofiltration membrane concentration unit is connected to the evaporation crystallization unit through the heat exchange unit, the evaporation crystallization unit, the centrifugal separation unit and the recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com