Method for treating fluorine-containing waste electrolyte

A waste electrolyte and content technology, applied in chemical instruments and methods, aluminum fluoride, alkali metal sulfite/sulfite, etc., can solve low raw material utilization rate, unfavorable mass transfer crystallization, and low effective aluminum fluoride content To achieve the effect of improving the purity and fluorine recovery rate, increasing the mass transfer rate, and promoting the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

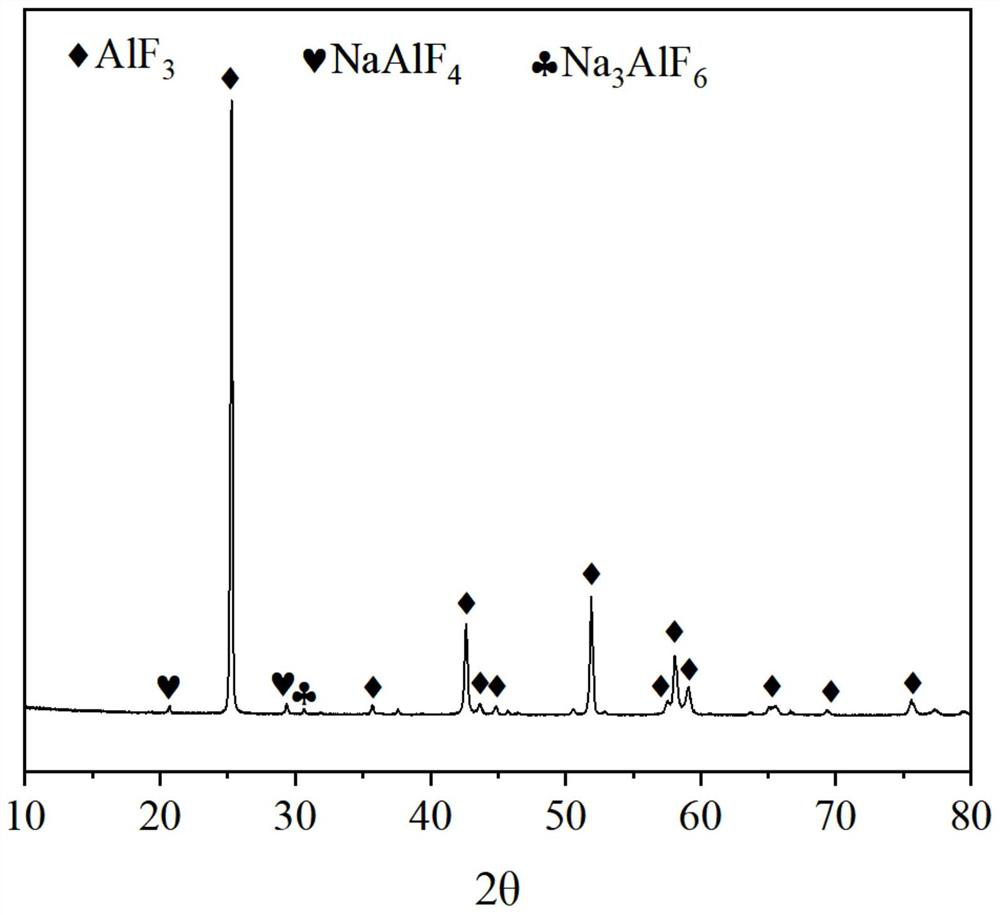

[0038] The steps of the method for treating waste electrolytes containing fluorine in this embodiment are as follows:

[0039] (1) Take 50kg of waste electrolyte from an electrolytic aluminum plant (XRF fluorescence analysis: F 49.68wt.%, Na 21.48wt.%, Al14.48%, Ca 5.46, K 5.13wt.%, O 2.59wt.%, Mg 0.57 wt.%, S 0.18wt.%), crushed to less than 2mm, to obtain waste electrolyte powder, and set aside;

[0040] (2) Take 100kg of aluminum sulfate octadecahydrate and heat it up to 300°C at a rate of 10°C / min, keep it warm for 2 hours, then raise the temperature to 400°C, keep it warm for 2 hours, break it down to less than 2mm after cooling, weigh it, and obtain anhydrous aluminum sulfate powder 51.5 kg for use;

[0041] (3) Take 48kg of spent electrolyte powder, 43kg of anhydrous aluminum sulfate powder and 1.5kg of sodium carbonate and mix evenly, then ball mill until passing through a 100-mesh sieve to obtain mixed powder.

[0042] (4) Put the mixed powder obtained in step (3) in...

Embodiment 2

[0047] Get 50kg of the same waste electrolyte as in Example 1, change the temperature in step (4) to 600°C, and keep other conditions constant, repeat the steps (1)-(6) of Example 1, and finally get 38.6kg of aluminum fluoride product, Obtain by-product potassium sulfate 10.8kg, by-product sodium sulfate 40.5kg. The obtained aluminum fluoride was detected, and the results are shown in Table 1.

Embodiment 3

[0049] Repeat Example 1, the only difference is: the temperature in step (4) is controlled to 580 ° C, and the obtained aluminum fluoride product is tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com