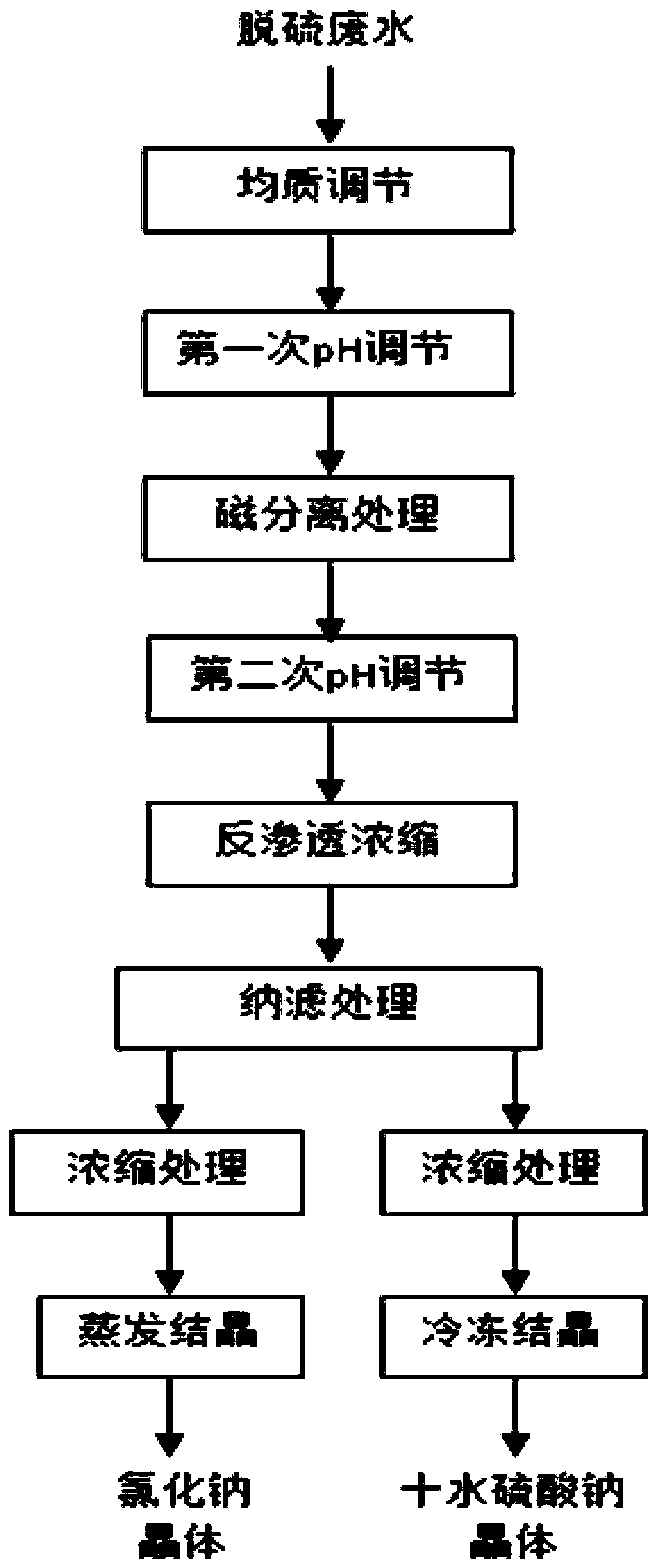

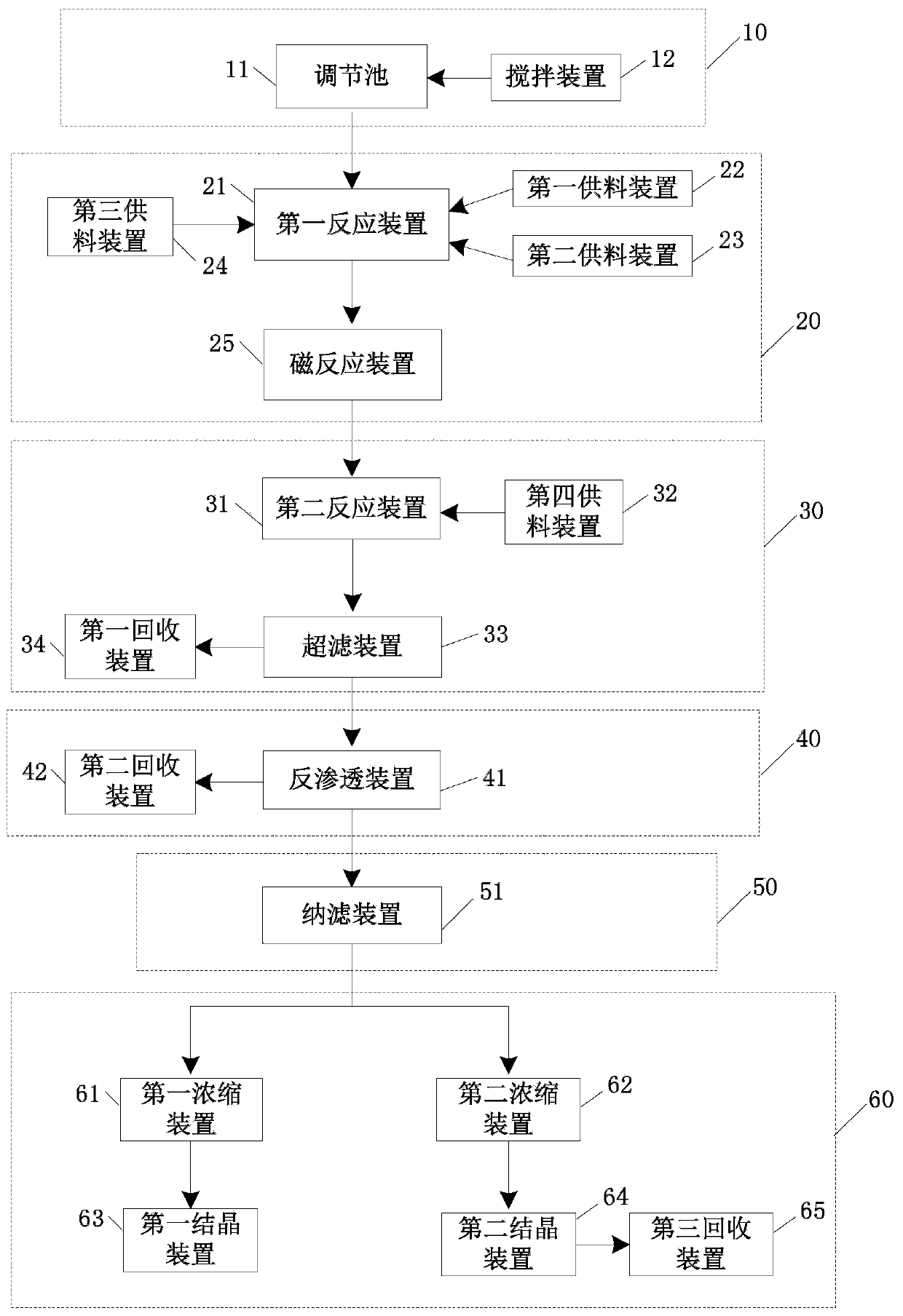

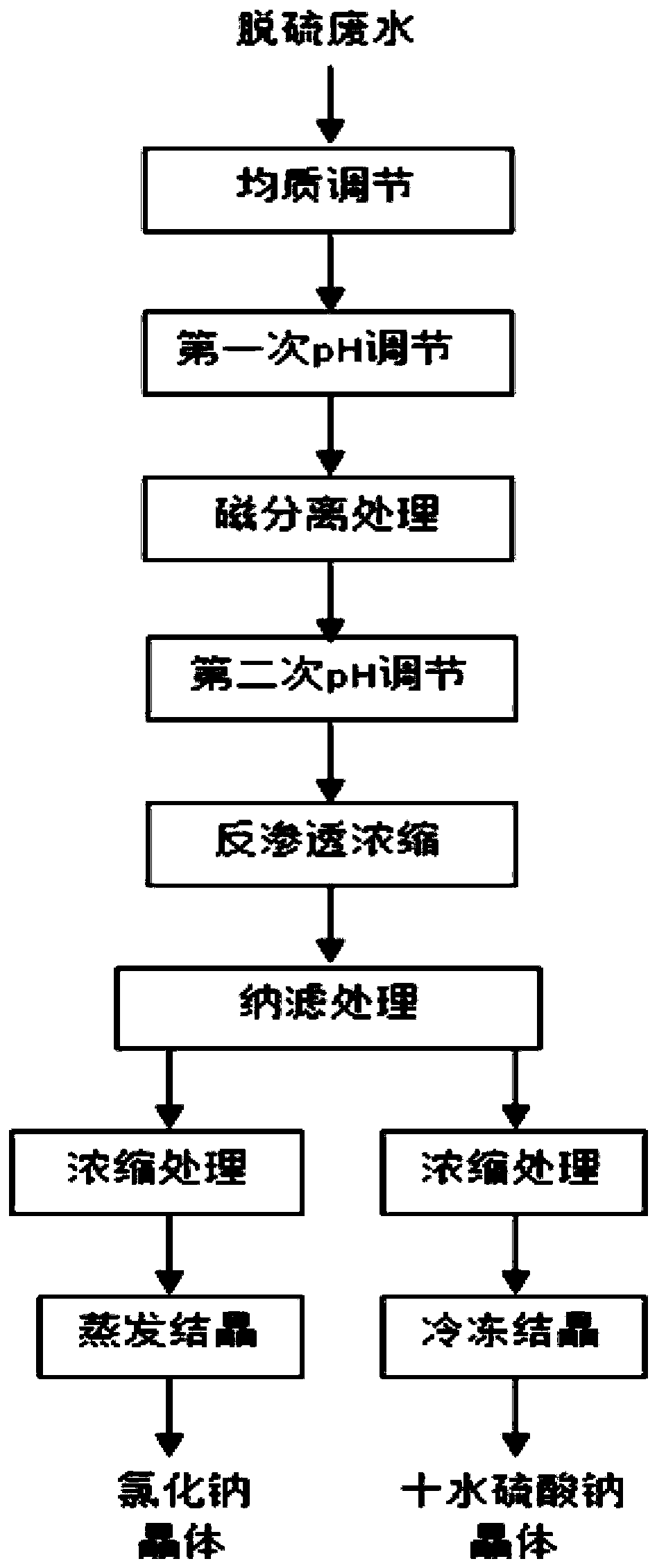

Desulfurization wastewater quality-divided crystallization processing method and processing device

A desulfurization wastewater and treatment method technology, which is applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of large-scale salt crystallization treatment and affect the treatment effect, and reduce the scale , Saving processing costs and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Pass the desulfurization waste water into the regulating tank, carry out homogenization treatment through the agitator, and then pass the desulfurization waste water after homogenization treatment into the reaction tank. Add soda ash and magnesium chloride to the reaction tank to adjust the pH of the desulfurization wastewater to 10, then pass the desulfurization wastewater into the sedimentation tank and add TMT-15 and iron ore particles, turn on the magnetic separation device for 8 minutes, and obtain sediment and supernatant. The sediment is transferred to the sedimentation tank, and the iron ore particles in it are separated by a cyclone for reuse. In addition, the hardness of the supernatant was measured to be 3ml / L, and hydrochloric acid was added to the supernatant to adjust the pH to 7, and then ultrafiltration was performed through an ultrafilter to filter out suspended solids and colloidal impurities therein to obtain a turbidity of 0.15NTU concentrated water...

Embodiment 2

[0074] Pass the desulfurization waste water into the regulating tank, carry out homogenization treatment through the agitator, and then pass the desulfurization waste water after homogenization treatment into the reaction tank. Add liquid caustic soda and lime to the reaction tank to adjust the pH of the desulfurization wastewater to 12, then pass the desulfurization wastewater into the sedimentation tank and add TMT-15 and iron ore particles, turn on the magnetic separation device for 8 minutes, and obtain precipitates and supernatant. The sediment is transferred to the sedimentation tank, and the iron ore particles in it are separated by a cyclone for reuse. In addition, the hardness of the supernatant was measured to be 4ml / L, and hydrochloric acid was added to the supernatant to adjust the pH to 6.5, and then ultrafiltration was performed through an ultrafilter to filter out suspended solids and colloidal impurities therein to obtain a turbidity of 0.15NTU concentrated wa...

Embodiment 3

[0076] Pass the desulfurization waste water into the regulating tank, carry out homogenization treatment through the agitator, and then pass the desulfurization waste water after homogenization treatment into the reaction tank. Add liquid caustic soda and lime to the reaction tank to adjust the pH of the desulfurization wastewater to 9, then pass the desulfurization wastewater into the sedimentation tank and add PAC, TMT-15 and iron ore particles, and turn on the magnetic separation device for 8 minutes to obtain Precipitate and supernatant. The sediment is transferred to the sedimentation tank, and the iron ore particles in it are separated by a cyclone for reuse. In addition, the hardness of the supernatant was measured to be 3.5ml / L, and hydrochloric acid was added to the supernatant to adjust the pH to 7.5, and then ultrafiltration was performed through an ultrafilter to filter out suspended solids and colloidal impurities therein to obtain a turbidity of 0.15 Concentrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com