System and method for high-salt wastewater grading crystallization treatment

A technology of crystallization treatment and high salt content, applied in the field of water treatment, can solve the problems of poor quality, unstable operation, high output rate of waste water miscellaneous salt, etc., to reduce pressure, ensure the purity of crystallized salt, and reduce the rate of miscellaneous salt output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

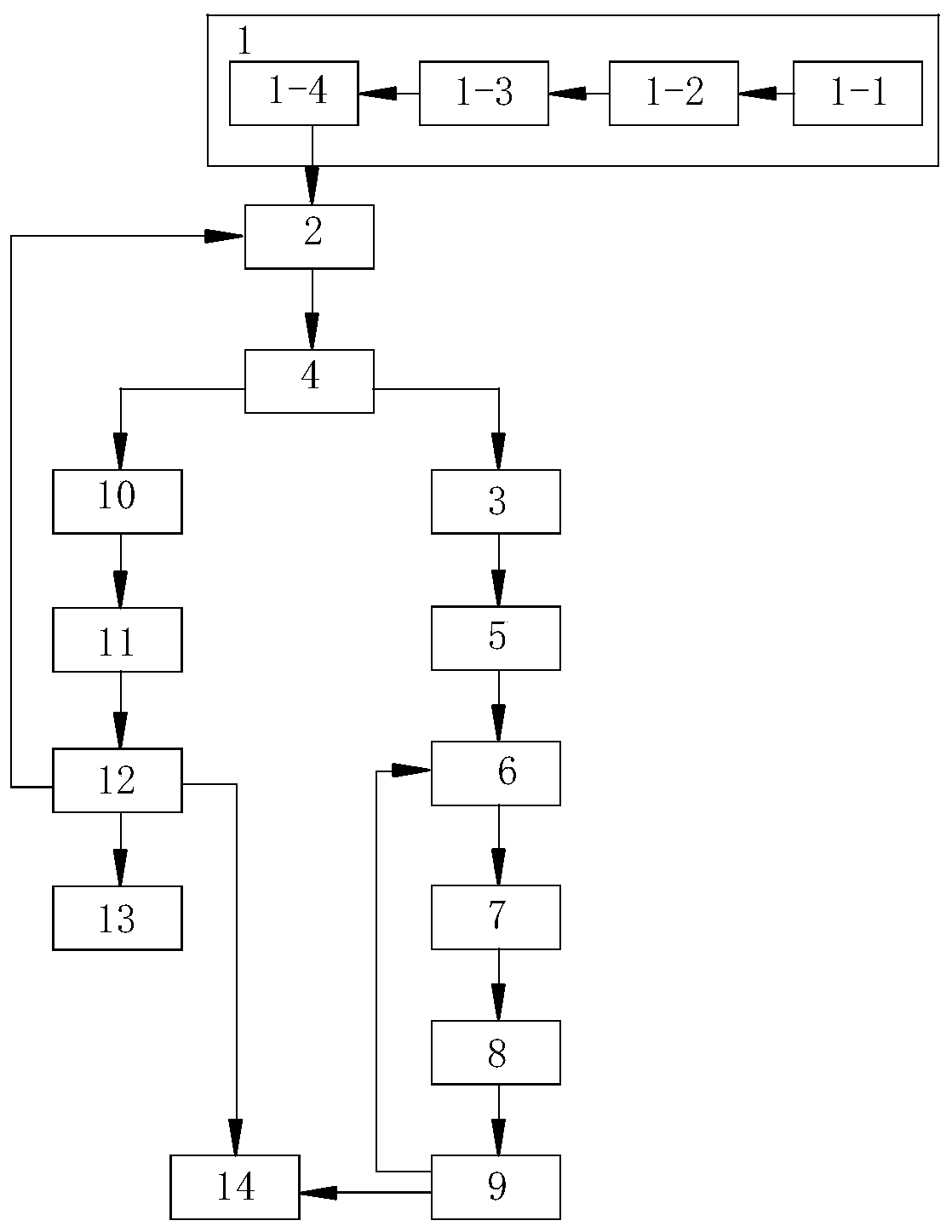

[0053] Embodiment 1: A kind of high saline waste water fractionation crystallization treatment system, it comprises pretreatment device 1, adjustment pool 2, the first waste water concentration device 3, nanofiltration system 4, the first sodium chloride evaporative crystallization device 5, chlorine Sodium chloride mother liquor buffer pool 6, evaporation concentration system 7, potassium nitrate freezing and crystallization system 8, second sodium chloride evaporation and crystallization system 9, advanced oxidation system 10, second wastewater concentration device 11, Glauber's salt freezing and crystallization system 12, Glauber's salt melting or Dissolving crystallization system 13 and miscellaneous salt evaporation crystallization system 14;

[0054] The pretreatment device 1 includes a high-density sedimentation tank 1-1, ultrafiltration 1-2, ion exchange resin 1-3 and carbon remover 1-4 connected in sequence; Water inlet connection. The pretreatment device 1 is used t...

Embodiment 2

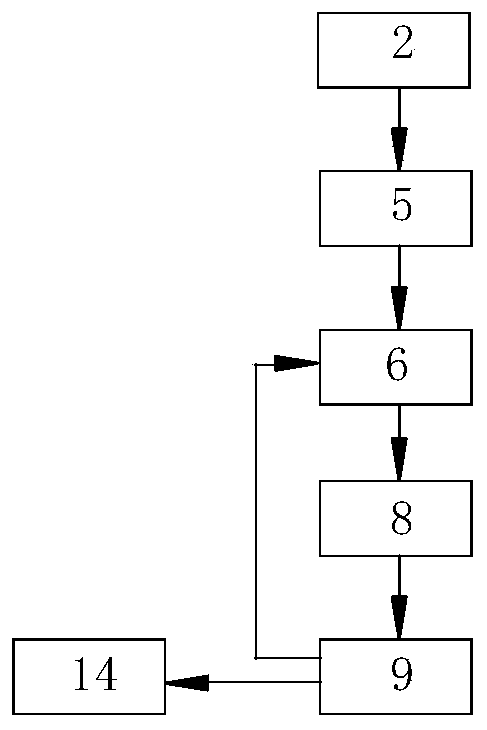

[0059]Embodiment 2: A high-salt wastewater fractionation and crystallization treatment system, which includes a regulating tank 2, a first sodium chloride evaporation crystallization device 5, a sodium chloride mother liquor buffer pool 6, a potassium nitrate freezing crystallization system 8, a second chlorine Sodium chloride evaporative crystallization system 9 and miscellaneous salt evaporative crystallization system 14;

[0060] The water outlet of the regulating tank 2 is connected with the water inlet of the first sodium chloride evaporative crystallization device 5 . The first sodium chloride evaporative crystallization device 5 can be selected from any one of multi-effect evaporative crystallization melting crystallization device, TVR evaporative crystallization melting crystallization device, MVR evaporative crystallization melting crystallization device, falling film+MVR forced circulation evaporation crystallization melting crystallization device or Several, what th...

Embodiment 3

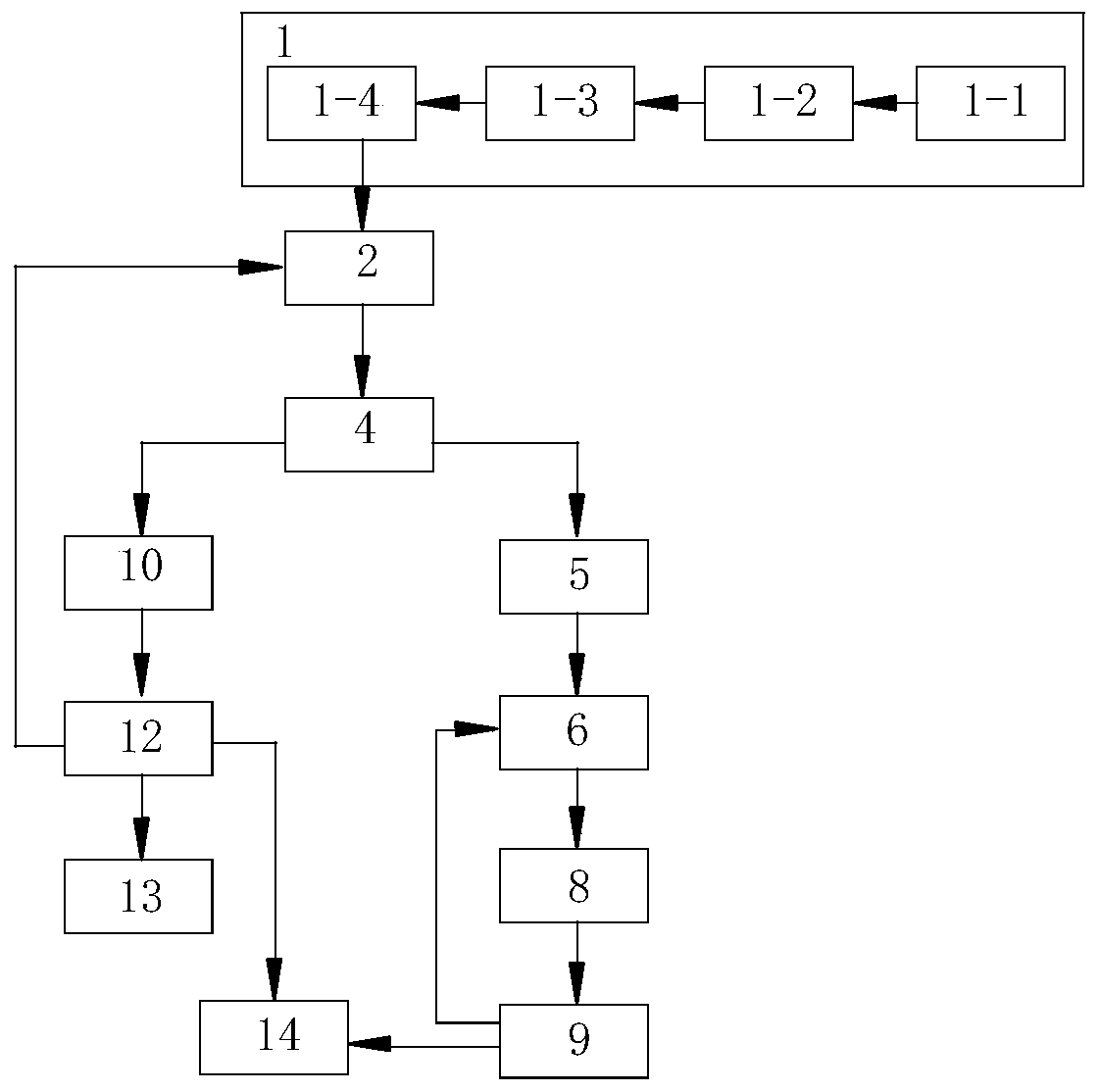

[0062] Embodiment 3: a kind of highly saline waste water fractionation crystallization treatment system, it comprises pretreatment device 1, adjustment tank 2, nanofiltration system 4, first sodium chloride evaporative crystallization device 5, sodium chloride mother liquor buffer pool 6, Potassium nitrate freeze crystallization system 8, second sodium chloride evaporative crystallization system 9, advanced oxidation system 10, Glauber's salt freeze crystallization system 12, Glauber's salt melting or dissolving crystallization system 13 and miscellaneous salt evaporative crystallization system 14;

[0063] The pretreatment device 1 includes a high-density sedimentation tank 1-1, ultrafiltration 1-2, ion exchange resin 1-3 and carbon remover 1-4 connected in sequence; Water inlet connection. The pretreatment device 1 is used to remove calcium and magnesium ions, particles, microorganisms, silicon dioxide, and alkalinity in wastewater.

[0064] The water outlet of the regulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com