High-salinity wastewater evaporative crystallization system and method thereof

A technology for evaporative crystallization and high-salt wastewater, which is applied in the directions of evaporative separation and crystallization, crystallization separation, and solution crystallization, which can solve the problem of low comprehensive income of crystalline salt, inability to guarantee the purity of crystalline salt, and inability to accurately control the transfer point of mother liquor and crystalline salt material Level and other issues, to reduce investment and treatment costs, to ensure the rate of crystallization of salt resources, saving the effect of melting crystallization system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

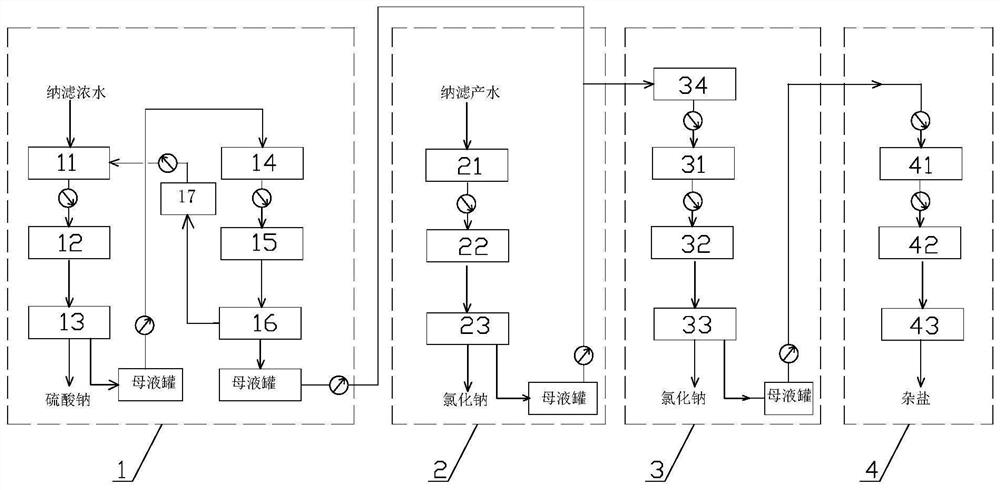

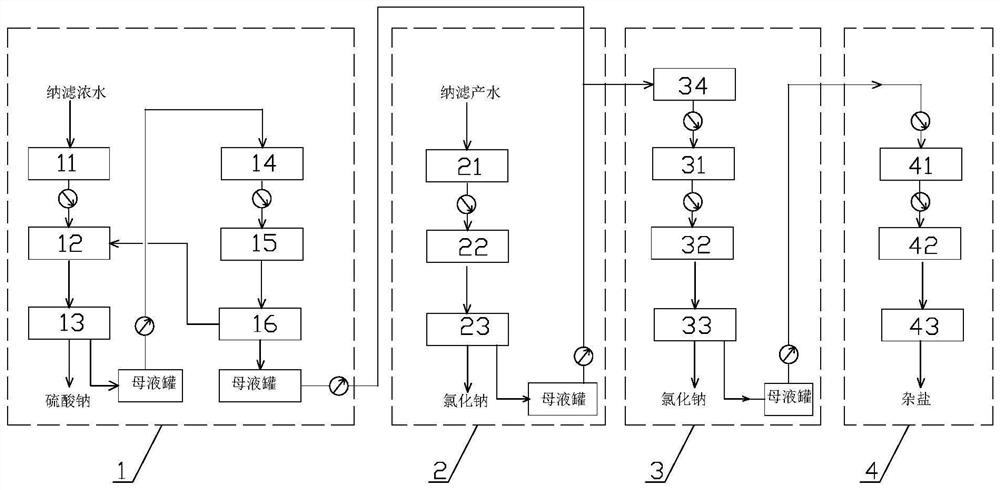

[0039] Embodiment 1: as figure 1 As shown, a high-salt wastewater evaporation crystallization system includes a sodium sulfate crystallization unit 1, a first sodium chloride crystallization unit 2, a second sodium chloride crystallization unit 3 and a miscellaneous salt crystallization unit 4,

[0040] Sodium sulfate crystallization unit 1 comprises sodium sulfate evaporative crystallizer 11, the first thickener 12, the first centrifuge 13, freezing crystallizer 14, the second thickener 15 and the second centrifuge 16, nanofiltration concentrated water is sent into Sodium sulfate evaporation crystallizer 11, the discharge port of sodium sulfate evaporation crystallizer 11 is communicated with the inlet pipeline of the first thickener 12, and the outlet of the first thickener 12 is communicated with the inlet pipeline of the first centrifuge 13, The outlet of the first centrifuge 13 is the first sodium sulfate outlet, and the liquid outlet of the first centrifuge 13 is communi...

Embodiment 2

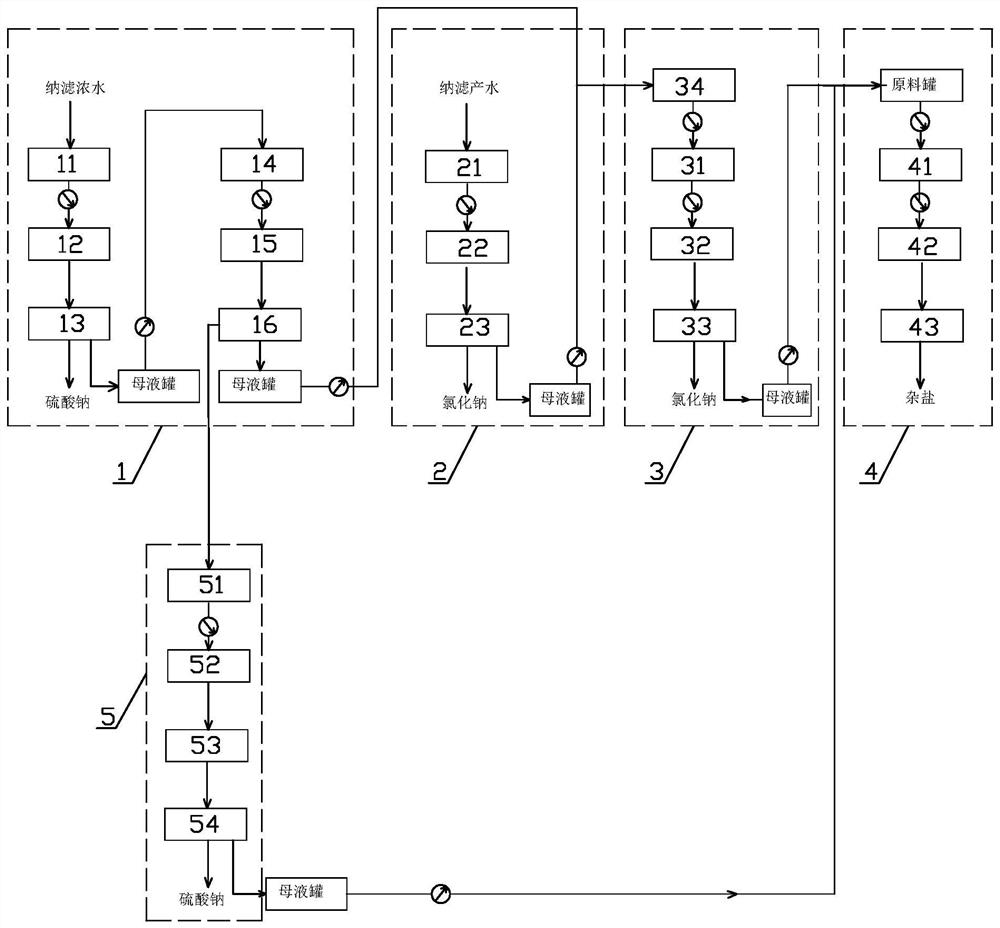

[0065] Embodiment 2: its overall structure is identical with embodiment 1, and difference is, as image 3 As shown, it also includes a melting crystallization unit 5, and the melting crystallization unit 5 includes a second dissolution tank 51, a melting crystallizer 52, the sixth thickener 53 and the sixth centrifuge 54, and the outlet of the second centrifuge 16 is connected to The inlet pipeline of the second dissolving tank 51 is communicated, and the outlet of the second dissolving tank 51 is communicated with the inlet pipeline of melting crystallizer 52, and the outlet of melting crystallizer 52 is communicated with the inlet pipeline of the sixth thickener 53, and the sixth The outlet of the thickener 53 is communicated with the inlet pipeline of the sixth centrifuge 54, and the discharge port of the sixth centrifuge 54 is the second sodium sulfate outlet, and the liquid outlet of the sixth centrifuge 54 is connected with the miscellaneous salt evaporation crystallizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com