Quality-based and salt-based treatment device and method for high-salinity wastewater in coal chemical industry

A high-salt wastewater and treatment method technology, applied in the field of water treatment, can solve the problems of lack of synergistic and effective technical means for removing fluoride and salt, and achieve the effect of realizing the utilization of water resources and salt resources, simple equipment, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The main water quality characteristics of the coal chemical high-salt wastewater treated in this example are: pH=7.5, the concentration of total dissolved solids (TDS) is 25000 mg / L, and the Cl - The concentration is 3000mg / L, SO 4 2- The concentration is 9000mg / L, Mg 2+ The concentration is 30mg / L, Ca 2+The concentration is 50mg / L, the dissolved silicon concentration is 50mg / L, F - The concentration is 50mg / L, HCO 3 - The concentration of COD is 300mg / L, and the concentration of COD is 80mg / L.

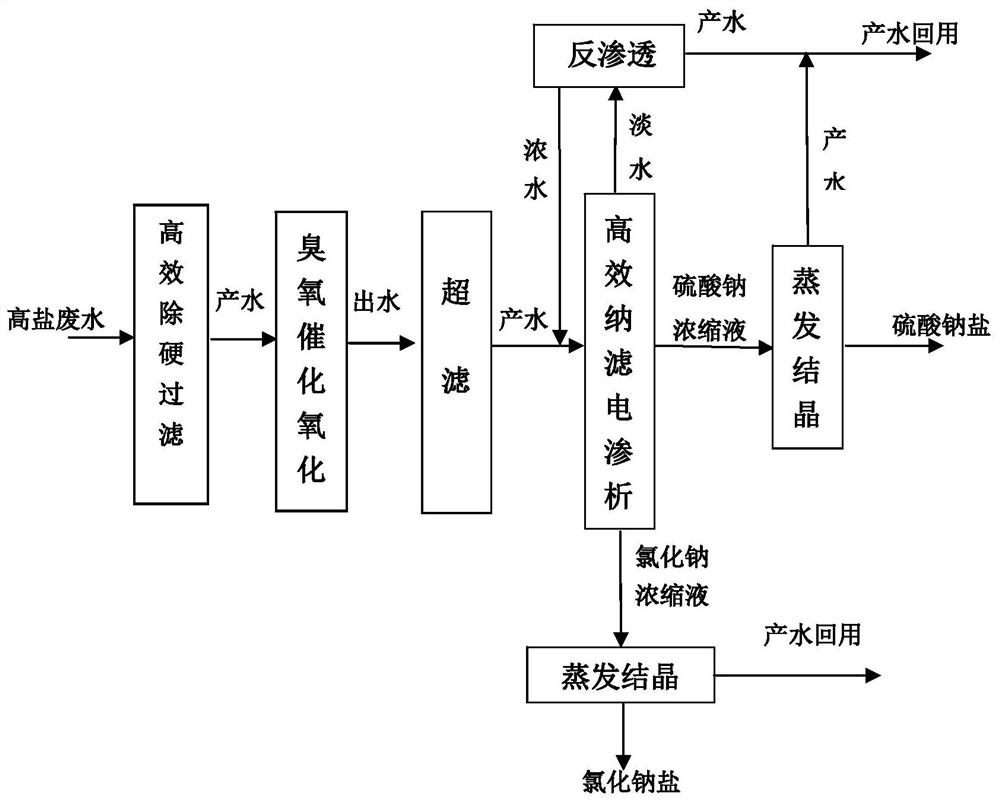

[0083] process such as figure 1 As shown, the specific steps include:

[0084] Step 1, high-salt wastewater from the coal chemical industry enters the high-efficiency hard removal filter unit for treatment. First, add calcium chloride and magnesium chloride to the primary reaction tank, the concentration of which is 0.8g / L, the reaction time is 15min, the effluent overflows into the secondary reaction tank, add sodium carbonate and polyaluminium chloride, and add sodium...

Embodiment 2

[0098] The main water quality characteristics of the coal chemical high-salt wastewater treated in this example are: pH=8, the concentration of total dissolved solids (TDS) is 30000 mg / L, and the Cl - The concentration is 4000mg / L, SO 4 2- The concentration is 10000mg / L, Mg 2+ The concentration is 60mg / L, Ca 2+ The concentration is 100mg / L, the concentration of dissolved silicon is 100mg / L, F - The concentration is 60mg / L, HCO 3 - The concentration of COD is 400mg / L, and the concentration of COD is 100mg / L.

[0099] process such as figure 1 As shown, the specific steps include:

[0100] Step 1, high-salt wastewater from the coal chemical industry enters the high-efficiency hard removal filter unit for treatment. First, add calcium chloride and magnesium chloride to the first-level dosing reaction tank, the concentration of which is 1.1g / L and 1.5g / L respectively, and the reaction time is 20min. The effluent overflows into the second-level dosing reaction tank, and sodi...

Embodiment 3

[0114] The main water quality characteristics of the coal chemical high-salt wastewater treated in this example are: pH=8.5, the concentration of total dissolved solids (TDS) is 35000 mg / L, and the Cl - The concentration is 5000mg / L, SO 4 2- The concentration is 12000mg / L, Mg 2+ The concentration is 90mg / L, Ca 2+ Concentration of 150mg / L, dissolved silicon concentration of 150mg / L, F - The concentration is 80mg / L, HCO 3 - The concentration of COD is 500mg / L, and the concentration of COD is 120mg / L.

[0115] process such as figure 1 As shown, the specific steps include:

[0116]Step 1, high-salt wastewater from the coal chemical industry enters the high-efficiency hard removal filter unit for treatment. First, calcium hydroxide and magnesium oxide are added to the primary reaction tank at concentrations of 1.5g / L and 2.0g / L respectively, and the reaction time is 30 minutes. The effluent overflows into the secondary reaction tank, and sodium carbonate and polymerized chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com