Method for deeply refining saline water by resource utilization of waste salt

A deep refining and resource-based technology, applied in chemical instruments and methods, preparation forms of alkali metal sulfite/sulfate, oxidized water/sewage treatment, etc., can solve problems such as waste salt recovery methods that need to be improved, and achieve environmental relief Effect of pressure, good economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

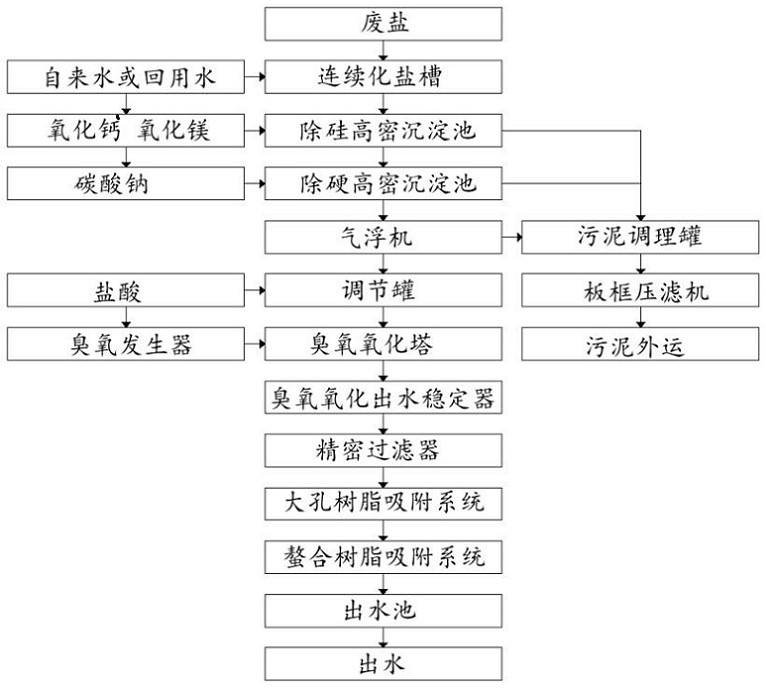

[0026] refer to figure 1 , a method for resource utilization of waste salt and deep refining of brine, comprising the following steps:

[0027] The first step: transport the waste salt to the salt tank, add water to stir and dissolve to obtain crude brine; transport the waste salt to the salt tank through a belt conveyor, and add water to add tap water or add recycled water;

[0028] Step 2: Put the coarse brine in the first step into the silicon and hardness removal system, add chemical agents, and the effluent of the silicon removal and hardness removal system contains some ash, calcium salt and magnesium salt particles that have not completely settled; the brine passes through The lift pump enters the silicon and hard removal system; the chemical agents added to the silicon and hard removal system are calcium oxide, magnesium oxide and sodium carbonate; the main chemical reactions involved include the following: ; ; ;

[0029] The third step: the effluent from the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com