Method and system for separating salt from electrolytic manganese electrolyte salt slag

An electrolytic solution and electrolytic manganese technology, applied in the direction of electrolysis process, electrolysis components, chemical instruments and methods, etc., can solve the problems of high operating cost of manganese electrolyte salt slag, low level of solid waste reduction and high operating cost. The effect of high recovery rate, less waste liquid discharge and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

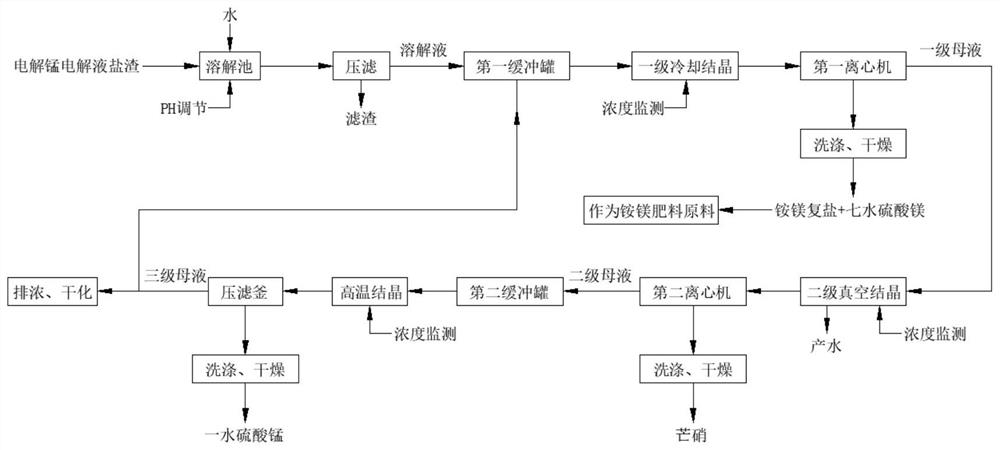

[0031] refer to figure 1 , an electrolytic manganese electrolyte salt slag separation system, including: a dissolution tank, a filter press, a primary buffer tank, a primary cooling crystallization system, a first centrifuge, a secondary vacuum crystallization system, a second centrifuge, and a secondary Buffer tank, three-stage high-temperature crystallization system, filter press kettle, and concentration drainage drying system, the dissolution pool, the filter press, the primary buffer tank, the primary cooling crystallization system, and the first centrifuge , the secondary vacuum crystallization system, the second centrifuge, the secondary buffer tank, the tertiary high-temperature crystallization system, the filter press and the deconcentration drying system are connected in sequence, and the filter press The top of the centrifuge is connected to the dissolution pool, the first centrifuge is connected to the discharge port of the cooling crystallization tank in the prima...

Embodiment 2

[0036] refer to figure 1 , an electrolytic manganese electrolyte salt slag separation system, including: a dissolution tank, a filter press, a primary buffer tank, a primary cooling crystallization system, a first centrifuge, a secondary vacuum crystallization system, a second centrifuge, and a secondary Buffer tank, three-stage high-temperature crystallization system, filter press kettle, and concentration drainage drying system, the dissolution pool, the filter press, the primary buffer tank, the primary cooling crystallization system, and the first centrifuge , the secondary vacuum crystallization system, the second centrifuge, the secondary buffer tank, the tertiary high-temperature crystallization system, the filter press and the deconcentration drying system are connected in sequence, and the filter press The top of the centrifuge is connected to the dissolution pool, the first centrifuge is connected to the discharge port of the cooling crystallization tank in the prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com