Novel extraction crystallization method for preparing potassium sulfate crystals, fluidization device and application of fluidization device

A technology of extraction crystallization and fluidization device, applied in the field of fluidization device, new extraction crystallization method, and preparation of potassium sulfate crystals, can solve the problems of small particle size of potassium sulfate crystals, dust pollution in processing places, irregular crystal morphology, etc. Simple production process, reduce secondary nucleation, improve the effect of phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

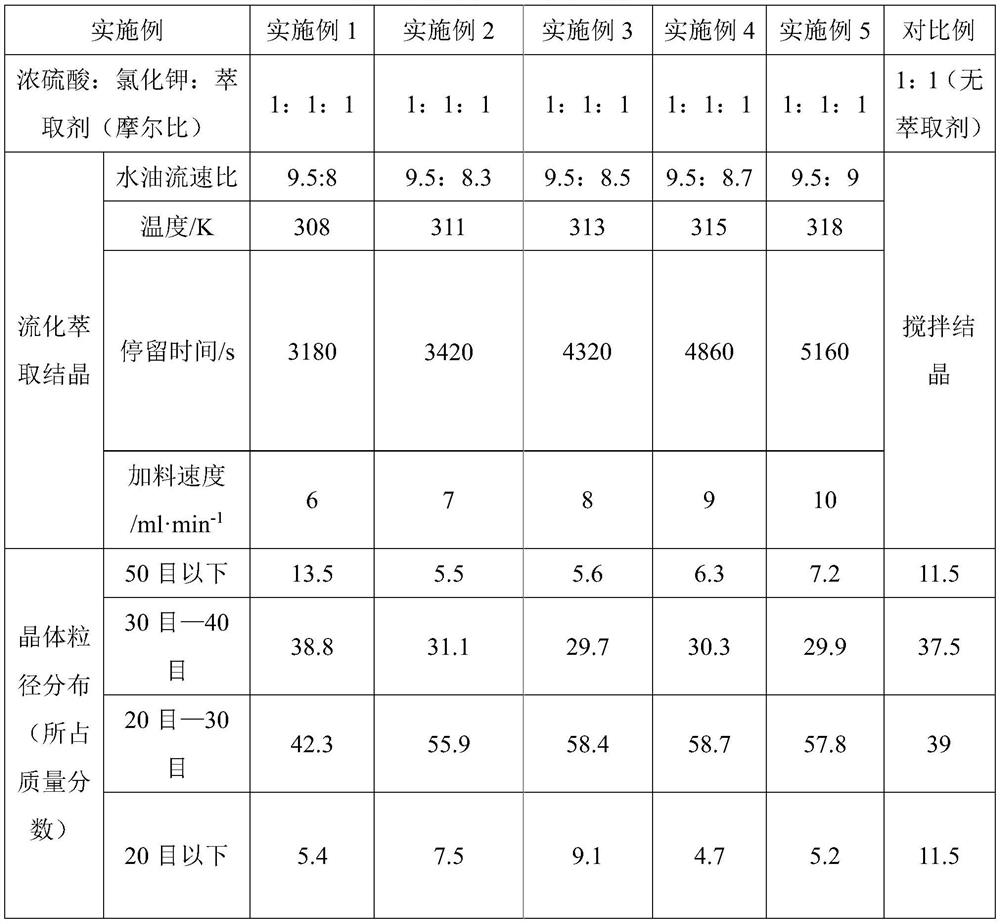

Examples

Embodiment Construction

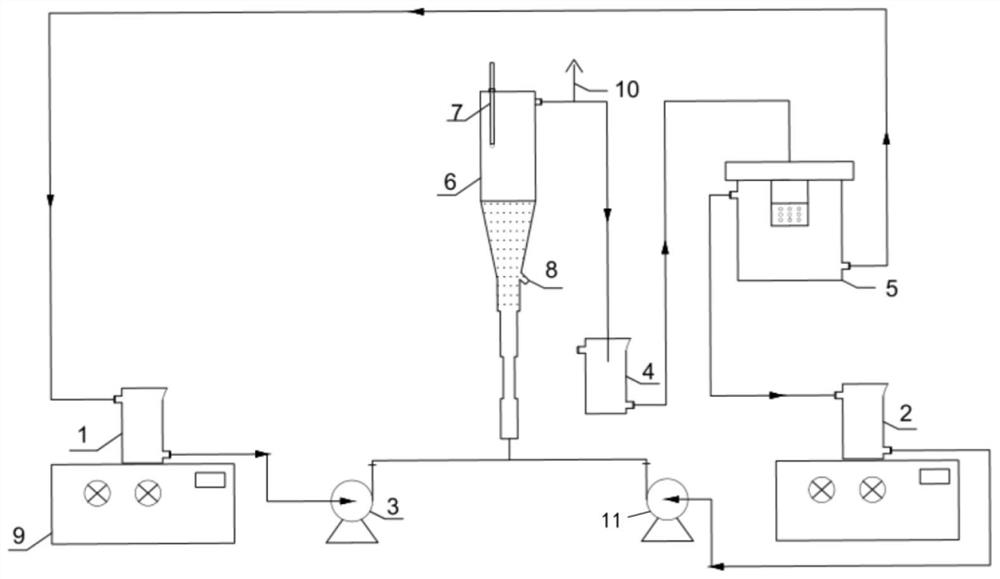

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

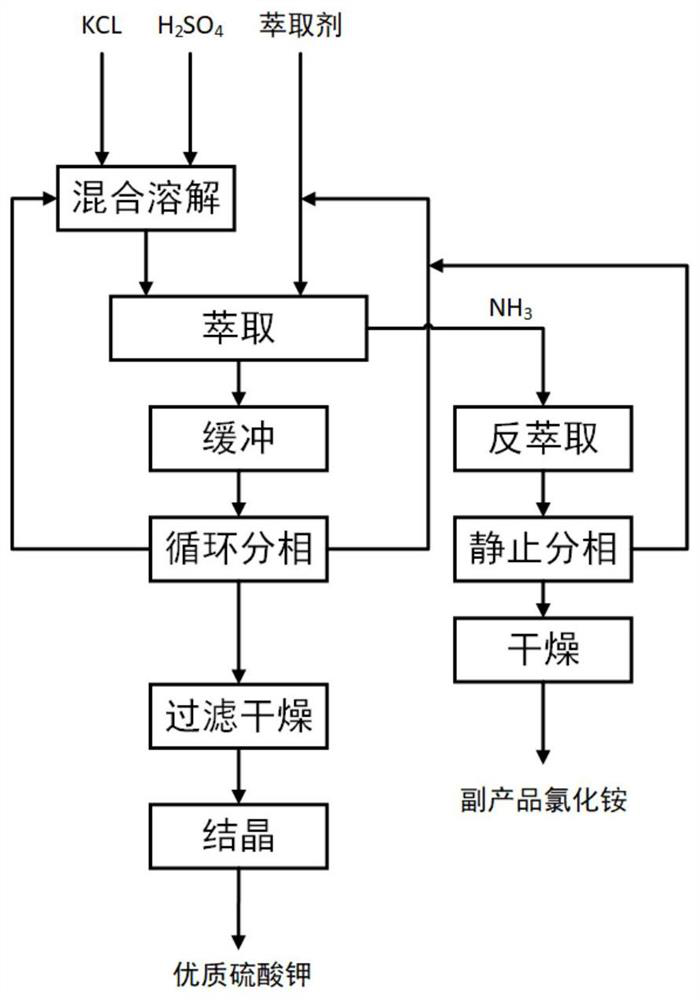

[0038] One, a kind of novel extraction crystallization method of preparing potassium sulfate crystal, comprises the steps:

[0039] Mixing and dissolving: Mix concentrated sulfuric acid and potassium oxide in proportion to mix and dissolve to obtain a mixed solution.

[0040] Extraction: use the extractant to extract the mixed solution, and use the extractant to extract the hydrogen chloride in the solution at normal temperature.

[0041] Circulation and phase separation: the mixed solution and the extractant are circulated separately, and the mixed solution is subjected to crystallization circulation, so that potassium sulfate crystals are continuously crystallized and precipitated during the circulation process. The extractant is subjected to extraction and stripping cycles, the extractant after extraction of the mixed solution is stripped, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com