Production system and production process for continuously preparing anhydrous sodium sulfate in acid bath

A technology of production system and production process, applied in the preparation form of alkali metal sulfite/sulfate, purification of alkali metal sulfite/sulfate, dehydration of alkali metal sulfite/sulfate, etc., can solve the problem of small crystal size , Long process flow route, high requirements for plant height, etc., to achieve the effect of uniform and full crystal particles, shorten the process process route, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

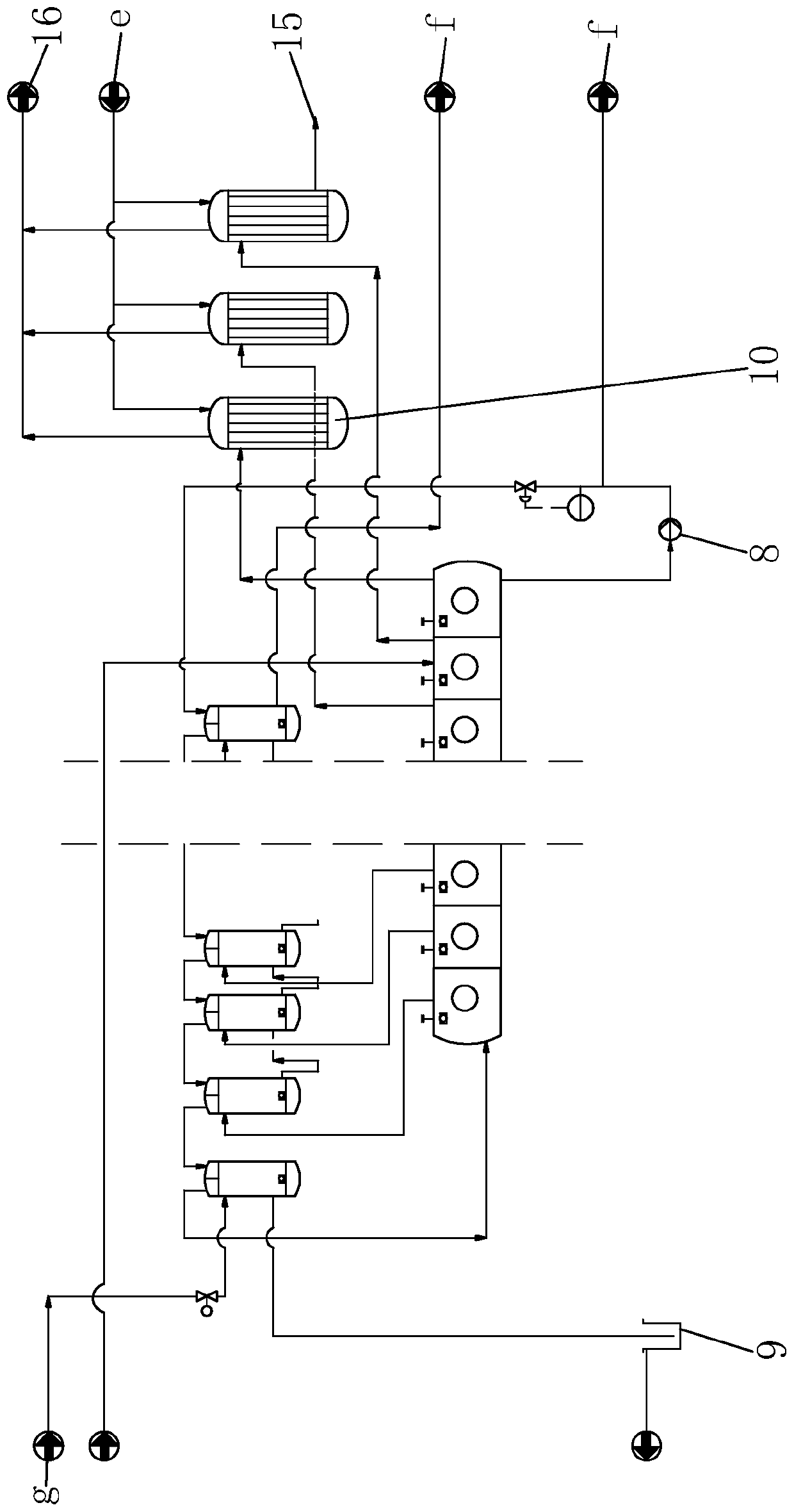

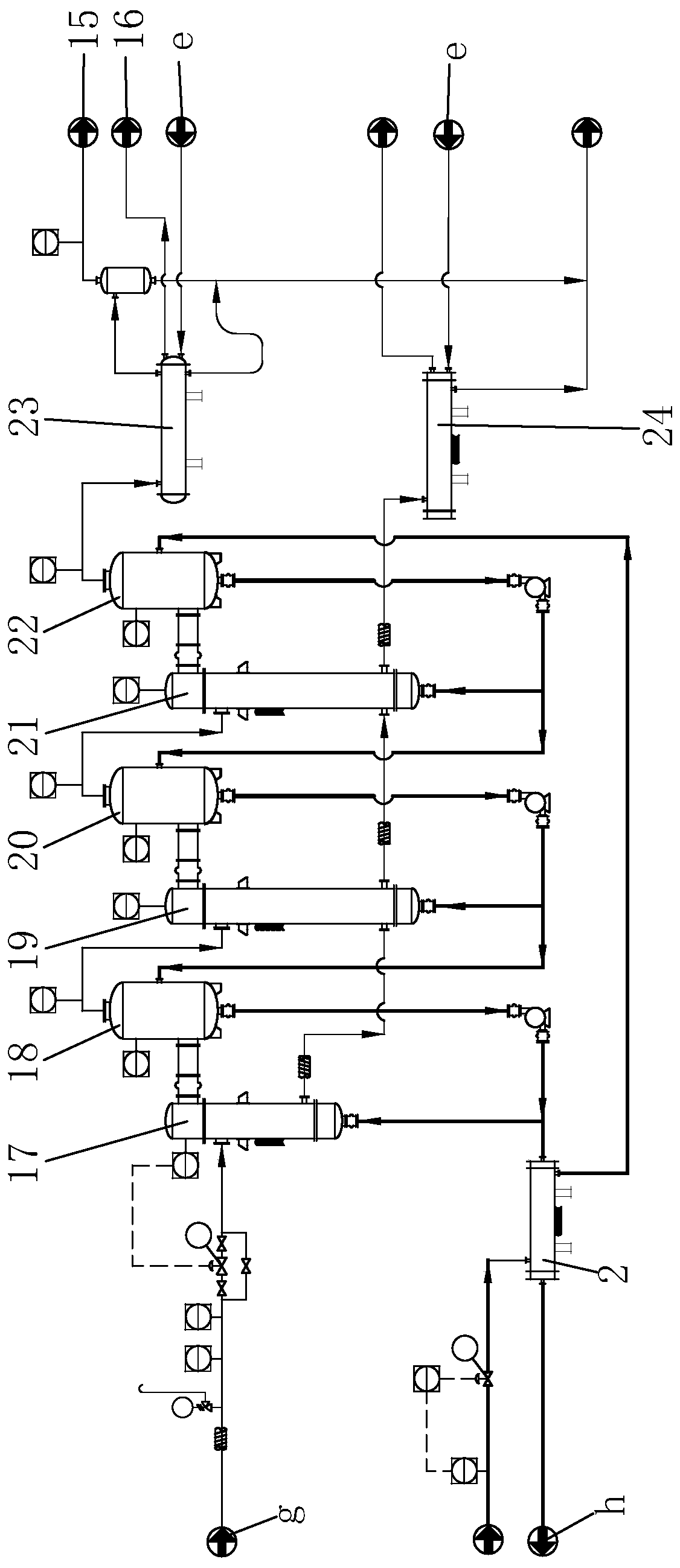

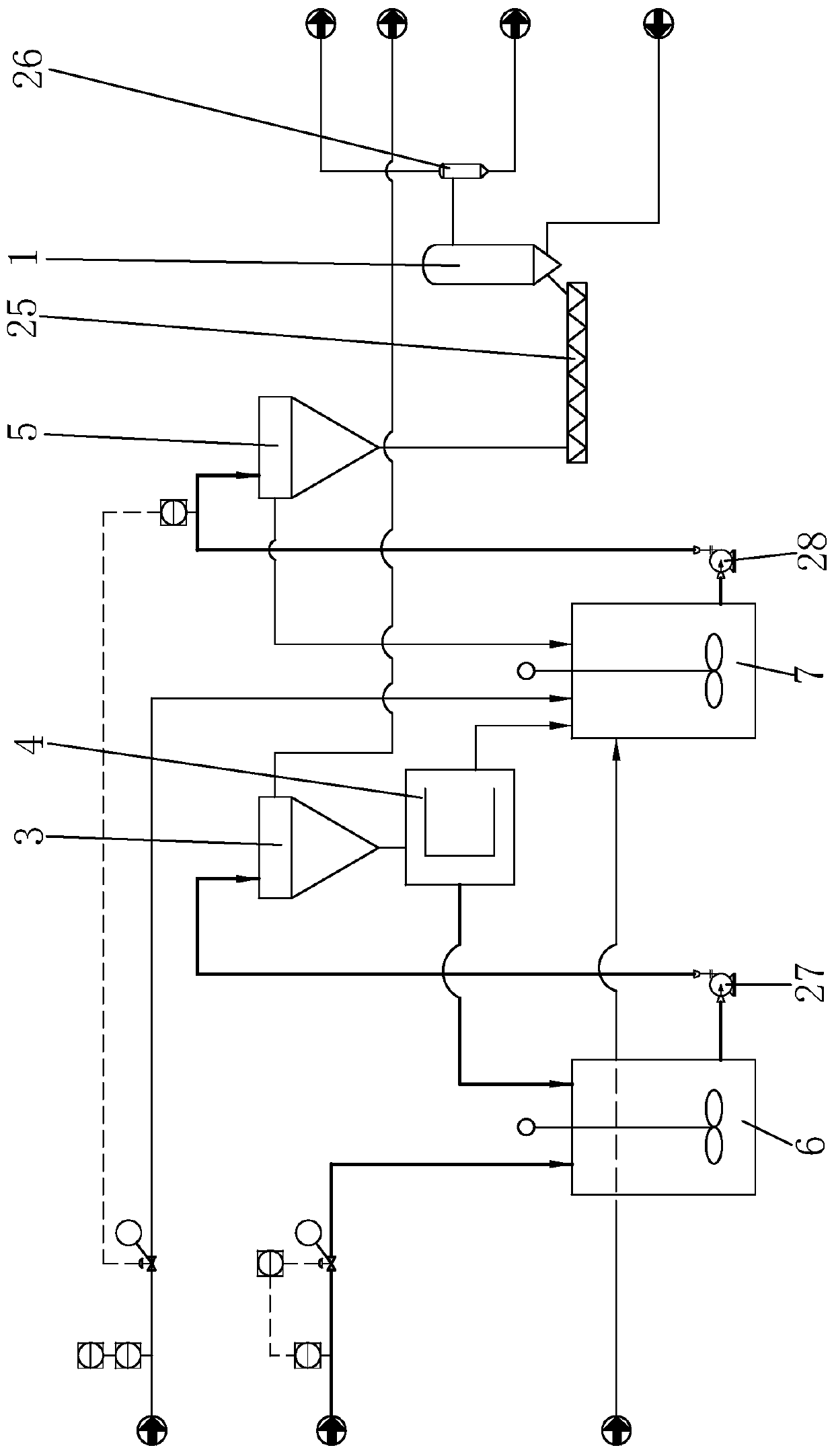

Method used

Image

Examples

Embodiment 1

[0047] The multi-stage flash evaporation device used in the dilute acid bath is 20 stages of 40t / h flash evaporation, the acid bath is heated to 120°C, and the steam-water ratio reaches 0.15:1; the preheater B uses high heat transfer fiber graphite tubes, and the number of tube passes is 6 , the flow velocity in the tube reaches 1.8m / s, the heat transfer coefficient of the preheater is significantly increased, and the heat exchange area is correspondingly significantly reduced. The diameter of the preheater B is 1600mm.

Embodiment 2

[0049] The dilute acid bath is turned into a concentrated acid bath after being flashed by a multi-stage flash evaporation device. The evaporator used in the concentrated acid bath is a three-effect 3.5t / h evaporator with an evaporation capacity of 10t / h and a unit energy consumption of 1.25:1, that is, the unit Weight Yuan Mingfen consumes 1.25 units of weight steam, which is significantly lower than the current industry average of 1.8-1.9:1. The acid bath flows through the heater A through the forced circulation pump, and the flow rate reaches 2-2.5m / s. The crystals pass through the heating tube quickly without scaling on the surface of the heating tube. The solid-liquid mixture is finally discharged from the first-effect evaporation crystallizer, and the solid content reaches 40-45%.

Embodiment 3

[0051] The concentrated material (solid-liquid mixture) discharged from the secondary thickener is fed from the bottom of the rotary airflow dryer, and an agitator is provided in the dryer cylinder 13 to promote the fluidization of the wet material. The preheated fresh air (150°C) enters the dryer cylinder 13 through the gas distributor, and the hot air flows upward in a spiral shape. Under the joint action of the agitator, the wet material is dispersed into small particles and presents a fluidized state. Determine the particle size of sodium sulfate as required to be 150 μm. At this time, the residence time is controlled at 200-300 s. A classification ring 12 is provided in the dryer cylinder 13. After classification, materials with suitable particles and qualified moisture are discharged from the discharge port 14. The gas is carried to the cyclone separator 26 for gas-solid separation, and unqualified materials fall into the lower part of the dryer and continue to participat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com