Preparation method of large-particle spherical sodium sulfate crystals

A sodium sulfate and large particle technology, applied in the preparation form of alkali metal sulfite/sulfate, chemical instruments and methods, selection of crystallization auxiliary conditions, etc., can solve the problem of difficult to stably control the nucleation and growth of sodium sulfate, increase equipment Cost and production costs, uneven product particle size distribution, etc., to achieve the effect of increasing added value, good filtration performance and anti-caking performance, and improving anti-caking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) At 35°C, add 10.5g of sodium sulfate to 35.0g of water (the volume of the solute sodium sulfate is 3.92cm 3 ), configure sodium sulfate aqueous solution.

[0037] (2) At 35° C., 35.0 g of methanol and 3.92 mL of dichloromethane were mixed to prepare a methanol-dichloromethane mixed solvent.

[0038] (3) Add the sodium sulfate aqueous solution dropwise into the methanol-dichloromethane mixed solvent at a rate of 1% / min, and keep stirring at a stirring rate of 300 rpm; after the dropwise addition, keep stirring for 5 hours.

[0039] (4) Filtrate, wash with ethanol with a mass fraction of 95%, and dry at normal pressure at 40° C. for 12 hours to obtain large spherical sodium sulfate crystals.

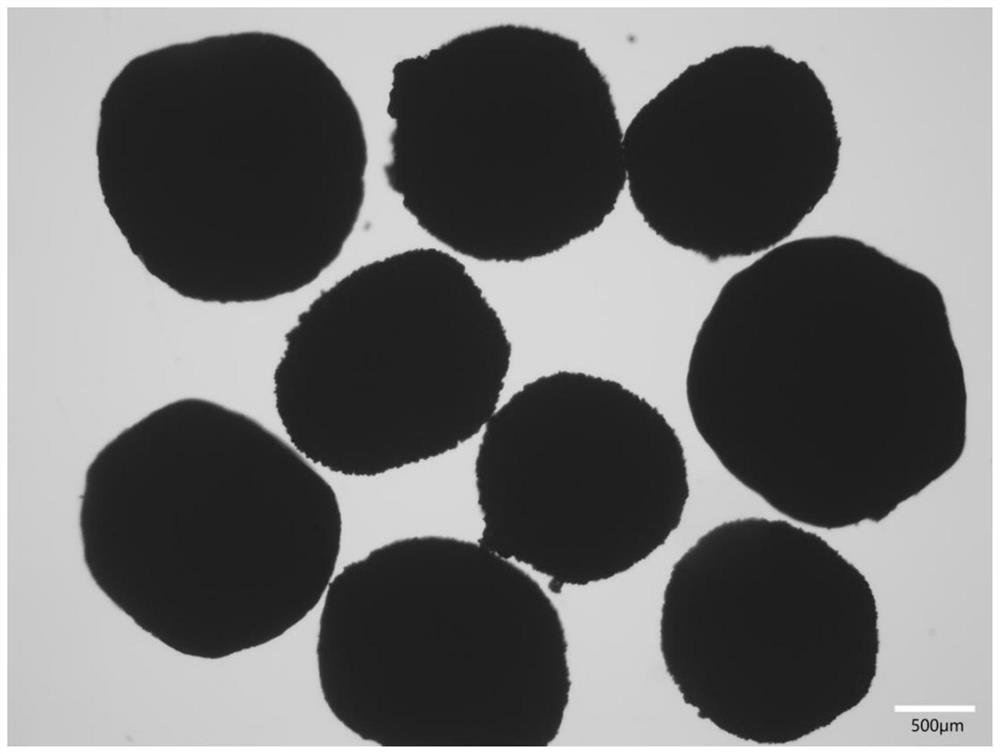

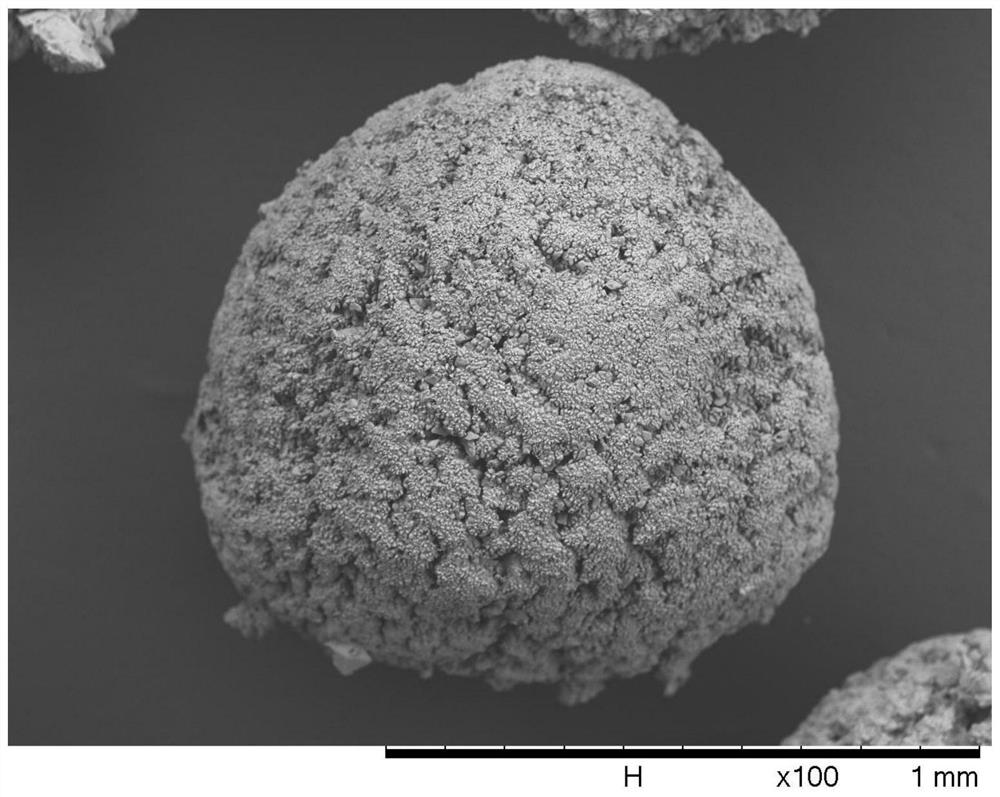

[0040] Photos of large spherical sodium sulfate crystals as figure 1 As shown, the optical microscope photographs are as figure 2 As shown in the scanning electron micrograph image 3 As shown, its average particle size is 850 microns, the angle of repose is 29°, the residual...

Embodiment 2

[0042] (1) At 40°C, add 14.0g of sodium sulfate to 35.0g of water (the volume of the solute sodium sulfate is 5.22cm 3 ), configure sodium sulfate aqueous solution.

[0043] (2) At 40° C., 70.0 g of ethanol was mixed with 2.61 mL of dichloromethane to prepare a mixed solvent of ethanol-dichloromethane.

[0044] (3) Add the sodium sulfate aqueous solution dropwise into the ethanol-dichloromethane mixed solvent at a rate of 2% / min, and keep stirring at a stirring rate of 500 rpm; after the dropwise addition, keep stirring for 1 h.

[0045] (4) Filtrate, wash with ethanol with a mass fraction of 70%, and dry at normal pressure at 50° C. for 6 hours to obtain large spherical sodium sulfate crystals.

[0046] The average particle size of the spherical particles is 650 microns, the angle of repose is 31°, the residual solvent after filtration is 2.3%, and the caking rate is 3.5%.

Embodiment 3

[0048] (1) At 45°C, add 7.0g of sodium sulfate to 35.0g of water (the volume of the solute sodium sulfate is 2.61cm 3 ), configure sodium sulfate aqueous solution.

[0049] (2) At 45° C., 70.0 g of n-propanol and 2.09 mL of n-hexane were mixed to prepare a n-propanol-n-hexane mixed solvent.

[0050] (3) Add the sodium sulfate aqueous solution dropwise into the n-propanol-n-hexane mixed solvent at a rate of 0.5% / min, and keep stirring at a stirring rate of 400 rpm; after the dropwise addition, keep stirring for 4 hours.

[0051] (4) Filtrate, wash with ethanol with a mass fraction of 95%, and dry at normal pressure at 50° C. for 24 hours to obtain large spherical sodium sulfate crystals.

[0052] The average particle size of the spherical particles is 730 microns, the angle of repose is 30°, the residual solvent after filtration is 1.7%, and the caking rate is 4.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com