Sodium sulfate TVR single-effect evaporation and crystallization system

A single-effect evaporation and crystallization system technology, which can be used in the preparation of alkali metal sulfite/sulfite, alkali metal sulfite/sulfate, alkali metal compounds, etc. The mother liquor does not take recycling measures to achieve the effect of improving the utilization rate, preventing the erosion of raw materials, and having a large practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

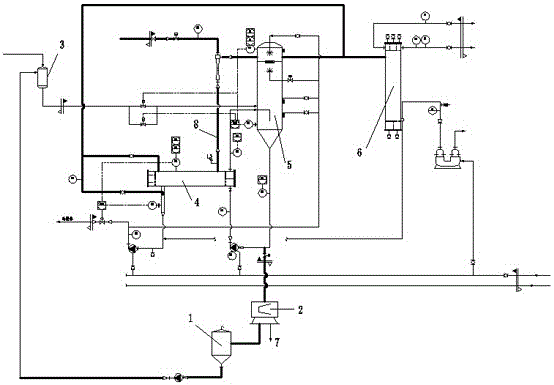

[0011] A sodium sulfate TVR single-effect evaporation crystallization system, comprising a mother liquor tank 1, a centrifuge 2, a preheater 3, a TVR compressor 4, a cooling crystallizer 5 and a condenser 6, the mother liquor outlet of the mother liquor tank 1 and the preheater 3 inlets are connected, the preheater 3 outlets are connected to the cooling crystallizer 5 mother liquor inlet, the TVR compressor 4 steam inlet is connected to the raw steam pipeline 8, the TVR compressor 4 steam outlet is connected to the cooling crystallizer 5 steam inlet, and the cooling crystallizer The material outlet of the device 5 is connected to the centrifuge 2, the cooling water outlet of the cooling crystallizer 5 is connected to the condenser 6, and the centrifuge 2 is connected to the mother liquor tank 1; the centrifuge 2 is a filter type centrifuge; the bottom of the centrifuge 2 A filter cake 7 is provided; the inside of the mother liquor tank 1 is coated with an anti-corrosion coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com