Comprehensive utilization device and method for sludge

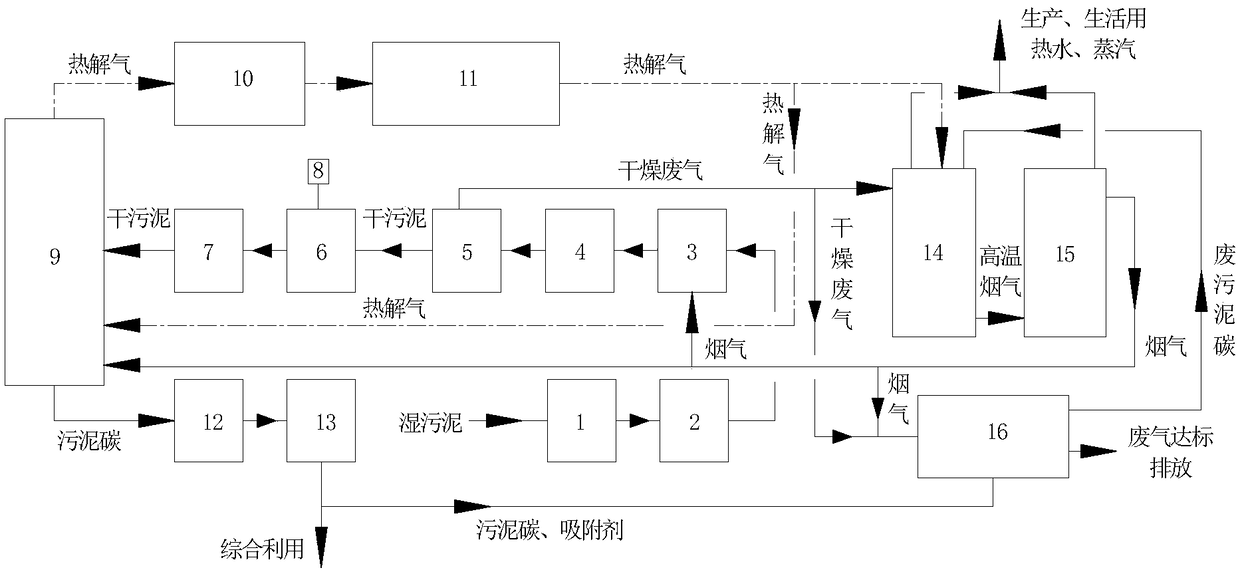

A technology for sludge and dry sludge, which is used in pyrolysis sludge treatment, dehydration/drying/concentrated sludge treatment, special forms of dry distillation, etc. It can avoid the problems of secondary pollution, realize sludge safety and reduce resource consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The dewatered sludge from the municipal sewage treatment plant is transported to the wet sludge storage tank through the belt conveying system, and then the wet sludge is transported to the dryer through the wet sludge belt conveying system. In the horizontal drum dryer, the wet sludge and The dry flue gas at 300°C is directly contacted, and the wet sludge is dried into dry sludge with a moisture content of 5%, and then the dry sludge and part of the dry sludge collected by the cyclone dust collector and bag filter pass through the dry sludge conveying system It is transported to the dry sludge storage tank for storage, and finally the dry sludge is transported to the sludge pyrolysis gasifier through the belt conveying system, where it is pyrolyzed and gasified at 600°C. Among them, the sludge pyrolysis gasifier is firstly powered by natural gas Start the furnace as a fuel, raise the temperature of the furnace to 600°C, and when the sludge pyrolysis gas produced by slud...

Embodiment 2

[0053] The dewatered sludge from the municipal sewage treatment plant is conveyed to the wet sludge storage tank through the belt conveying system, and then the wet sludge is conveyed to the dryer through the wet sludge belt conveying system. In the horizontal drum dryer, the wet sludge is mixed with 250 The dry flue gas at ℃ is directly contacted, and the wet sludge is dried into dry sludge with a moisture content of 20%, and then the dry sludge and part of the dry sludge collected by the cyclone dust collector and bag filter pass through the dry sludge belt conveying system It is transported to the dry sludge storage tank for storage, and finally the dry sludge is transported to the sludge pyrolysis gasifier through the belt conveying system, where it is pyrolyzed and gasified at 450°C. Among them, the sludge pyrolysis gasifier is firstly powered by natural gas Start the furnace as fuel, raise the temperature of the furnace to 450°C, and when the sludge pyrolysis gas produced...

Embodiment 3

[0057] The dewatered sludge from the municipal sewage treatment plant is transported to the wet sludge storage tank through the belt conveying system, and then the wet sludge is transported to the dryer through the wet sludge belt conveying system. In the horizontal drum dryer, the wet sludge is mixed with 200 The dry flue gas at ℃ is directly contacted, and the wet sludge is dried into dry sludge with a moisture content of 35%, and then the dry sludge and part of the dry sludge collected by the cyclone dust collector and bag filter pass through the dry sludge belt conveying system It is transported to the dry sludge storage tank for storage, and finally the dry sludge is transported to the sludge pyrolysis gasifier through the belt conveying system, and the pyrolysis gasification is carried out at 350°C. Among them, the sludge pyrolysis gasifier is firstly powered by natural gas Start the furnace as fuel, raise the temperature of the furnace to 350°C, and when the sludge pyrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com