Acidic wastewater treatment system and technological method

A technology of acid wastewater and treatment system, applied in metallurgical wastewater treatment, water/sewage treatment, degassed water/sewage treatment, etc., can solve the problem of increasing investment cost and treatment cost, high wastewater treatment cost, unbearable for enterprises, etc. problems, to achieve the effect of saving civil construction and equipment investment costs, realizing resource disposal, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

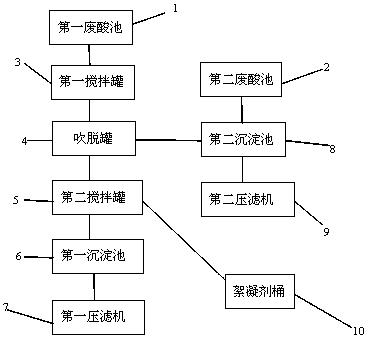

[0041] Such as figure 1 , an acidic wastewater treatment system, comprising a first waste acid pool 1, a second waste acid pool 2, an ore barrel, an alkali barrel, a flocculant barrel 10, a first stirring tank 3, a stripping tank 4, and a second stirring tank 5. The first sedimentation tank 6, the first filter press 7, the second sedimentation tank 8, and the second filter press 9, the first waste acid tank 1 stores a mixed acid composed of hydrochloric acid and nitric acid, and the second Sulfuric acid or phosphoric acid is stored in the waste acid pool 2, and the mineral material barrel is equipped with natural mineral materials. The first waste acid pool 1 is connected to the water inlet of the first stirring tank 3 through the first pump body, and the first stirring tank 3 is provided with a feed port for adding the natural mineral material in the mineral material barrel, the first stirring tank 3 is provided with an agitator, and the water outlet of the first stirring tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com