Municipal sludge treatment method and heat pump and solar energy coupling system for implementing method

A technology of municipal sludge and treatment method, applied in the field of heat pump-solar coupling system, can solve the problems of increased transportation cost, extrusion, large stacking area, etc., and achieve the effect of significant economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

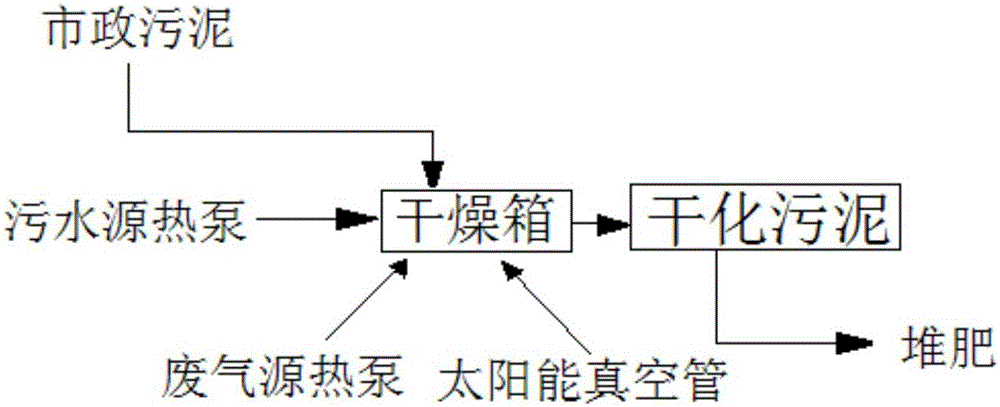

[0059] A municipal sludge treatment method, comprising the following steps:

[0060] Take the municipal sludge and put it in the drying box;

[0061] The heat collected by the sewage source heat pump and the waste gas generated during the sewage treatment process are heated by the heat collected by the sun through the Fresnel lens, and then the heat collected by the air source heat pump and the heat collected by the solar vacuum tube are introduced into the drying box for sludge Dehydration and drying;

[0062] The sludge is dried to a water content of 68%, and fermented at room temperature in a closed environment for 35 days to obtain fertilizer.

Embodiment 2

[0064] A municipal sludge treatment method, comprising the following steps:

[0065] Take the municipal sludge and put it in the drying box;

[0066] After the sewage is treated by the centrifugal sewage heat exchanger, the sewage source heat pump is used to collect heat, and the collected heat is passed into the drying box through the heat pipe;

[0067] The Fresnel lens gathers the heat collected by sunlight to heat the exhaust gas collected by the gas collection device, and the heated exhaust gas is collected by the air source heat pump and passed into the drying box through the heat pipe;

[0068] The heat collected by the solar vacuum tube is introduced into the drying oven through the heat conduction tube;

[0069] The drying box is used to dehydrate and dry the sludge in it by controlling the heat from different sources;

[0070] The sludge was dried to a water content of 70%, and the fertilizer obtained in Example 1 was added in an amount of 1% of the weight of the s...

Embodiment 3

[0072] A municipal sludge treatment method, comprising the following steps:

[0073] Take the municipal sludge and put it in the drying box;

[0074] After the sewage is treated by the centrifugal sewage heat exchanger, the sewage source heat pump is used to collect heat, and the collected heat is passed into the drying box;

[0075] The Fresnel lens gathers the heat collected by sunlight to heat the exhaust gas collected by the gas collection device, and the heated exhaust gas is collected by the air source heat pump and passed into the drying box;

[0076] The heat collected by the solar vacuum tube is introduced into the drying oven;

[0077] Control heat from different sources for sludge dehydration and drying;

[0078] The sludge is dried to a water content of 72%, and the fertilizer obtained in Example 1 is added in an amount of 1% of the sludge weight. After mixing, put it into the first fermentation bin and ferment at room temperature for 15 days, and then the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com