Carbon dioxide resource treatment system and method

A carbon dioxide and disposal system technology, applied in the direction of carbon preparation/purification, electrolysis process, energy input, etc., can solve the problems of poor economy, difficult carbon sequestration technology, difficult to promote and use, etc., to reduce carbon dioxide content and good environmental benefits and economic benefits, to achieve the effect of resource disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

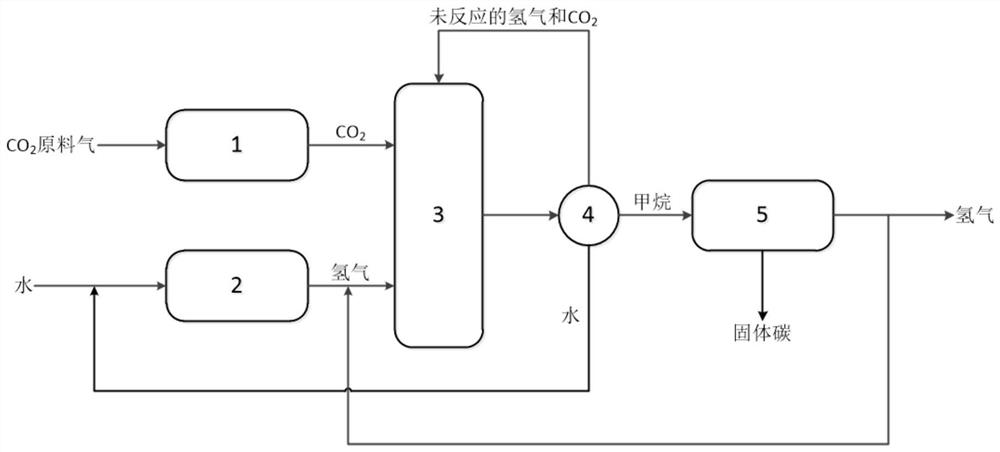

[0048] exist figure 1 The resource disposal of carbon dioxide is carried out in the system shown, and the products are nano-carbon and hydrogen. The specific steps are as follows:

[0049] 1) Convert existing carbon dioxide emission sources (carbon sources), such as cement factory / coal power plant emissions or CO collected in the atmosphere 2 As feed gas, through CO 2 Purification device 1 purifies and removes impurities to obtain high-purity CO2 ;

[0050] 2) Use the water electrolysis hydrogen production device 2 to carry out electrolytic hydrogen production; wherein, the water electrolysis hydrogen production device 2 is specifically an alkaline water electrolyzer, the electrolyte solution is a 30 wt% potassium hydroxide aqueous solution, and the cathode material is Ni or Ni-Mo alloy , the anode material is Ni or Ni-Co alloy, the operating pressure is ≤3MPa, the working temperature is 60-80°C, and the current density is 0.2-0.4mA·cm -2 , the voltage is 1.8~2.4V, the powe...

Embodiment 2

[0057] exist figure 1 The resource disposal of carbon dioxide is carried out in the system shown, and the products are carbon black and hydrogen for tires. The specific steps are as follows:

[0058] 1) Convert existing carbon dioxide emission sources (carbon sources), such as cement factory / coal power plant emissions or CO collected in the atmosphere 2 As feed gas, through CO 2 Purification device 1 purifies and removes impurities to obtain high-purity CO 2 ;

[0059] 2) Use the water electrolysis hydrogen production device 2 to carry out electrolytic hydrogen production; wherein, the water electrolysis hydrogen production device 2 is specifically an alkaline water electrolyzer, the electrolyte solution is a 30 wt% potassium hydroxide aqueous solution, and the cathode material is Ni or Ni-Mo alloy , the anode material is Ni or Ni-Co alloy, the operating pressure is ≤3MPa, the working temperature is 60-80°C, and the current density is 0.2-0.4mA·cm -2 , the voltage is 1.8~2...

Embodiment 3

[0066] exist figure 1 The resource disposal of carbon dioxide is carried out in the system shown, and the products are carbon black and hydrogen for zinc-manganese dry batteries. The specific steps are as follows:

[0067] 1) Convert existing carbon dioxide emission sources (carbon sources), such as cement factory / coal power plant emissions or CO collected in the atmosphere 2 As feed gas, through CO 2 Purification device 1 purifies and removes impurities to obtain high-purity CO 2 ;

[0068] 2) Use the water electrolysis hydrogen production device 2 to carry out electrolytic hydrogen production; wherein, the water electrolysis hydrogen production device 2 is specifically an alkaline water electrolyzer, the electrolyte solution is a 30 wt% potassium hydroxide aqueous solution, and the cathode material is Ni or Ni-Mo alloy , the anode material is Ni or Ni-Co alloy, the operating pressure is ≤3MPa, the working temperature is 60-80°C, and the current density is 0.2-0.4mA·cm -2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com