Organic waste fermentatively-processing device

A technology for organic waste and disposal equipment, applied in the field of organic waste fermentation disposal equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, the first preferred embodiment of the organic waste fermentation disposal device of the present invention will be described in detail with reference to the accompanying drawings.

[0029] Example.

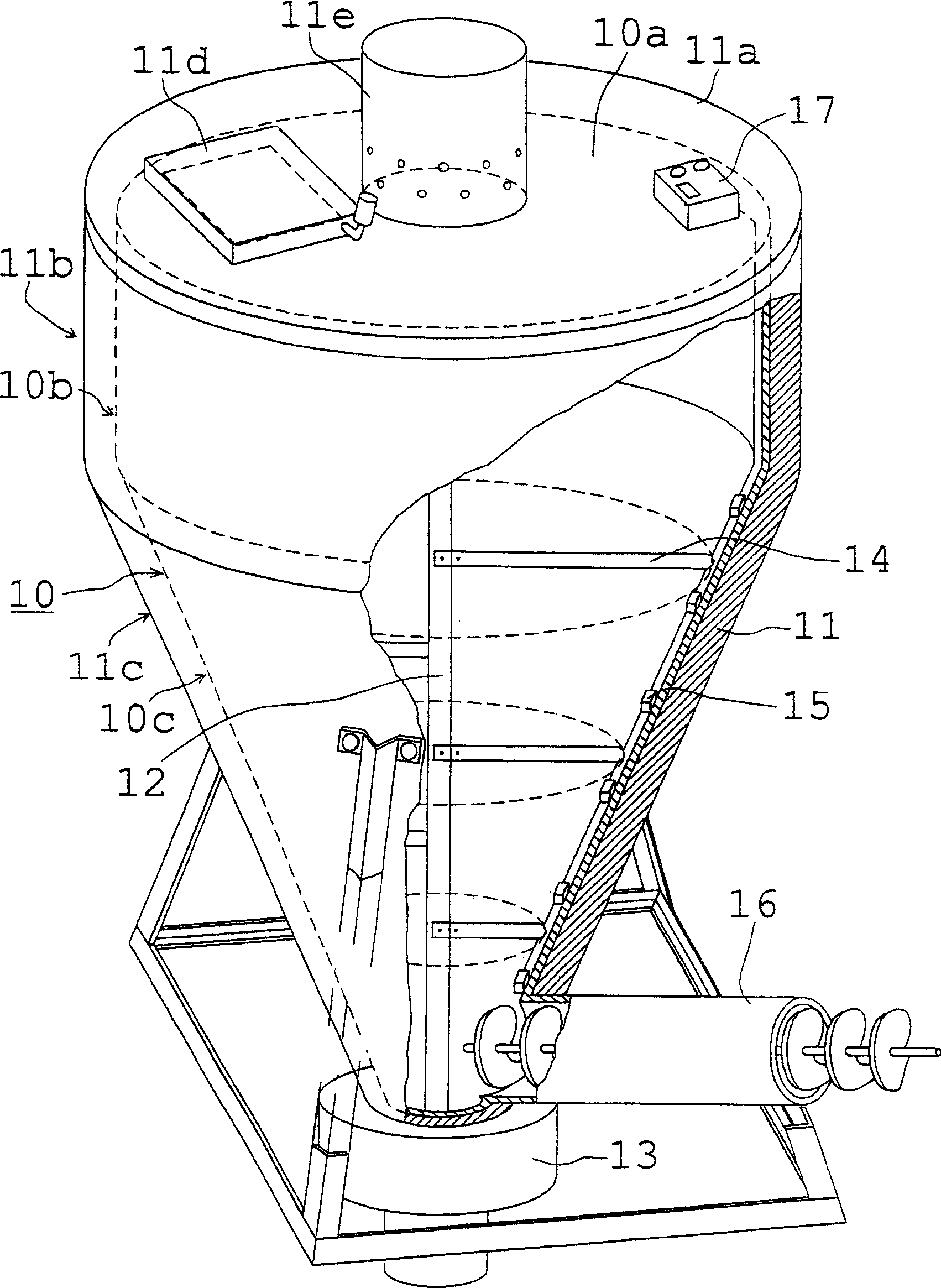

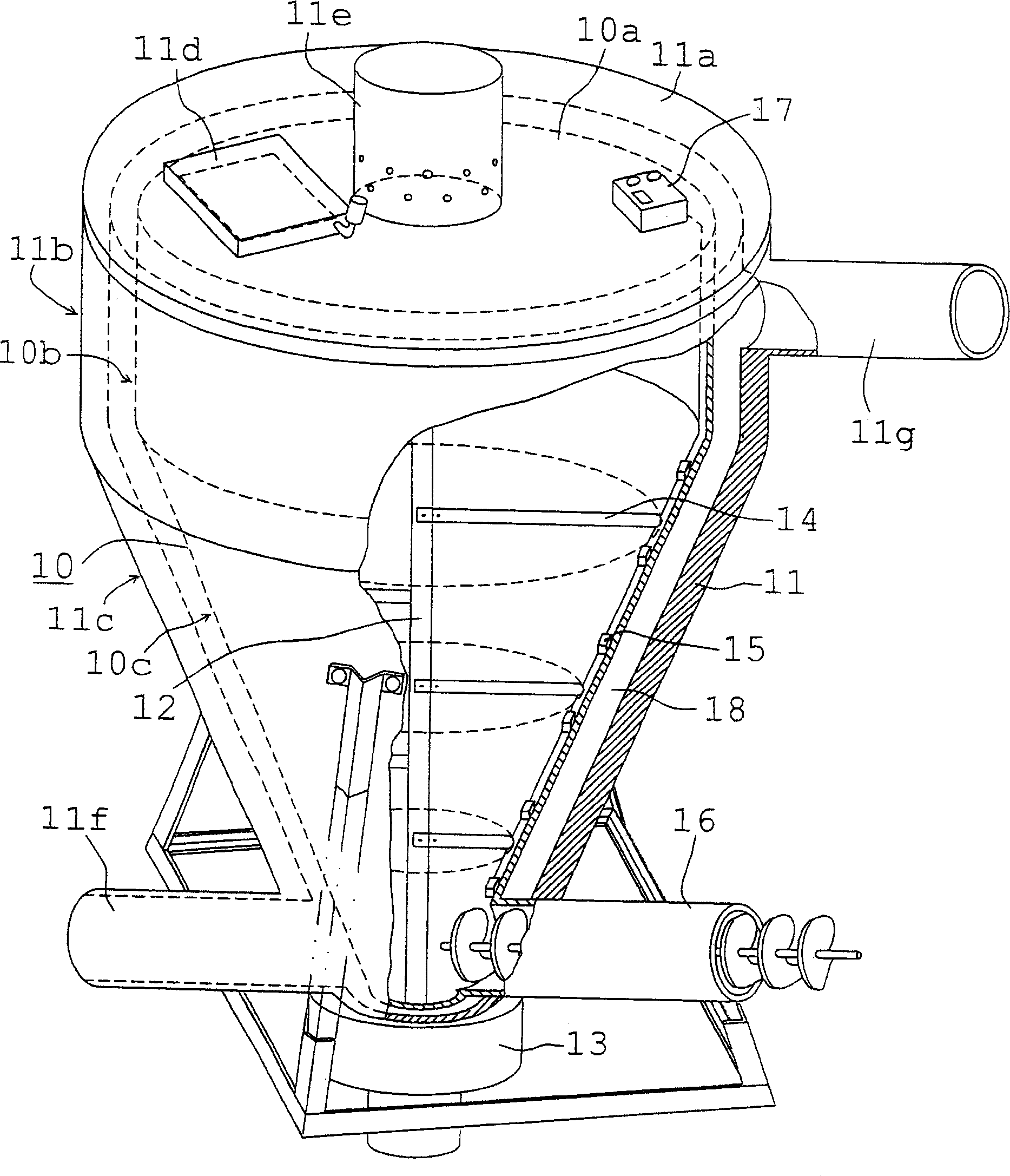

[0030] figure 1 It is the overall perspective view of the organic waste fermentation disposal device of the present preferred embodiment.

[0031] The organic waste fermentation disposal device in the present invention is schematically constituted as follows: a substantially inverted conical disposal pool 10, an insulating material 11 covering the disposal pool 10, a rotating shaft 12 penetrating through the disposal pool 10 and supported by the disposal pool 10, connecting to the rotating shaft 12 a motor 13 at the bottom, a plurality of blades 14 vertically fixed to the rotating shaft 12 at regular intervals, a plurality of thermal sensors 15 for measuring the temperature of different areas inside the disposal pool 10, and a screw conveyor 16 for sending the treate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com