Superhigh-temperature composting method for livestock and poultry manure

A technology of livestock and poultry manure and composting method is applied in the field of resource utilization of livestock and poultry manure to achieve the effects of convenient transportation, high nitrogen utilization rate and soil organic matter improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The determination of embodiment 1 optimum strain proportioning

[0033] In this example, the 5 species of bacteria are: Bacillus thermourea A, Geobacillus B, Bacillus thermodenitrophilus C, Halothermophilus rubrum D and Thermus thermophilus E, the organic material decomposing agent mentioned above The preparation includes the following steps:

[0034] (1) Bacillus thermourea A, Geobacillus B, Bacillus thermodenitrophilus C, Halothermophilus rubrum D and Thermophilus thermophilus E were respectively inoculated in the fermentation medium and cultured, A, B, C, D, and E strains were cultured at 65°C, 70°C, 60°C, 75°C, and 75°C in sequence, and the culture time was 24 hours;

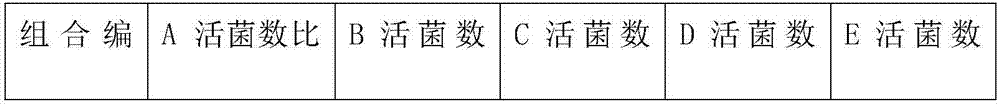

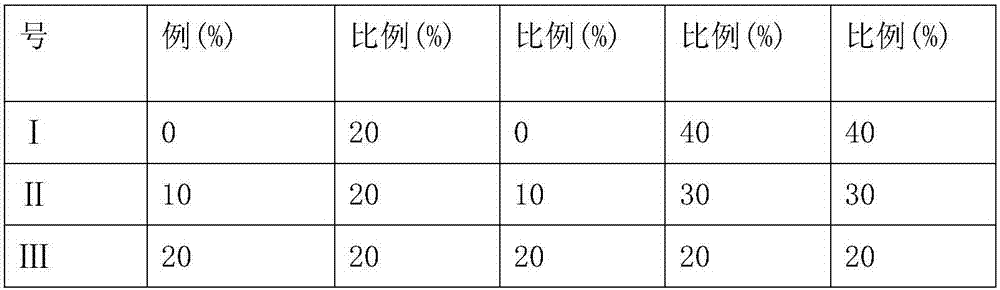

[0035] (2) The 5 bacteria liquids obtained by the above-mentioned steps (1) were cultured, and three combinations were carried out according to the number of live bacteria of each strain (see Table 1), and three groups of mixed fermentation liquids with different ratios were obtained, according to th...

Embodiment 2

[0044] The ultra-high temperature composting of embodiment 2 livestock and poultry manure

[0045] Ultra-high temperature composting method of the experimental group:

[0046] 1) Preparation of organic material decomposing agent: the solid organic material decomposing agent obtained in Example 1 Group III is used in this embodiment;

[0047] 2) Preparation of fermentation raw materials: In terms of mass percentage, mix 85% of fresh chicken manure and 15% of rice straw to obtain the original material, adjust the water content of the original material to 55%, then add an organic material decomposing agent, mix evenly, and obtain Fermented raw material; in this fermented raw material, the mass percentage that the organic material decomposing agent accounts for is 0.1%; 3) the fermented raw material inoculated with the organic material decomposing agent obtained in step 2) is transferred to a composting device (a conventional composting device in the art is can), within 1-2 hours...

Embodiment 3

[0058] Embodiment 3 pot test

[0059] This embodiment is carried out in the pilot base of Jiangsu Provincial Academy of Agricultural Sciences Circular Agriculture Research;

[0060] The test material is Chinese cabbage, and the variety is Shanghai Qing.

[0061] There are 4 treatments in the test:

[0062] Namely T1, no fertilization;

[0063] T2, purified fertilizer (Sateli compound fertilizer N:P2O5:K2O=15:15:15, purchased from Zhongnong New Fertilizer Technology Co., Ltd.);

[0064] T3, Ordinary organic fertilizer (prepared according to the traditional process, the fermentation raw materials are livestock and poultry manure and crop straw, for details, see: Ma Huailiang, Xu Xiuhong. High-temperature composting treatment technology of livestock and poultry manure. Journal of Northeast Agricultural University, 2005, 36(4): 536~540);

[0065] T4 is the ultra-high temperature chicken manure organic fertilizer obtained by the experimental group of Example 3.

[0066] Each t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com