Composting method capable of carrying out damp and hot preprocessing to accelerate composting of livestock excrement

A technology of livestock and poultry manure and composting method, which is applied in the direction of biological organic part treatment, fertilizer made from biological waste, and chemical fertilizer treatment heating/cooling, etc. It can solve the problems of slow temperature rise, insufficient total amount of compost, and low degradation rate, etc., to achieve Reduce the volatilization of ammonia, improve composting efficiency, and promote the effect of heating up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 organic material decomposing agent

[0033] The 5 strains were all from compost environment. Inoculate the strain into 100ml of improved beef extract peptone liquid medium for shaking flask culture, the culture temperature is 60-70°C, the shaking table speed is 180 rpm, and the cultures obtained after 12 hours of cultivation are respectively inoculated into 1L of improved beef extract peptone liquid In the culture medium, ferment for 12 hours according to the above-mentioned conditions, and use it as the seed liquid fermented in the fermenter.

[0034] Five strains (Bacillus thermourea, Geobacillus, Bacillus thermodenitrophilus, Halothermophilus rubrum and Thermus thermophilus) were respectively inoculated on solid medium, cultured at 60°C for 24 hours, and single The colony is connected to the slant medium (the formula is the same as the solid medium), and then cultivated at 60°C for 24 hours, and the bacteria on the surface of the medi...

Embodiment 2

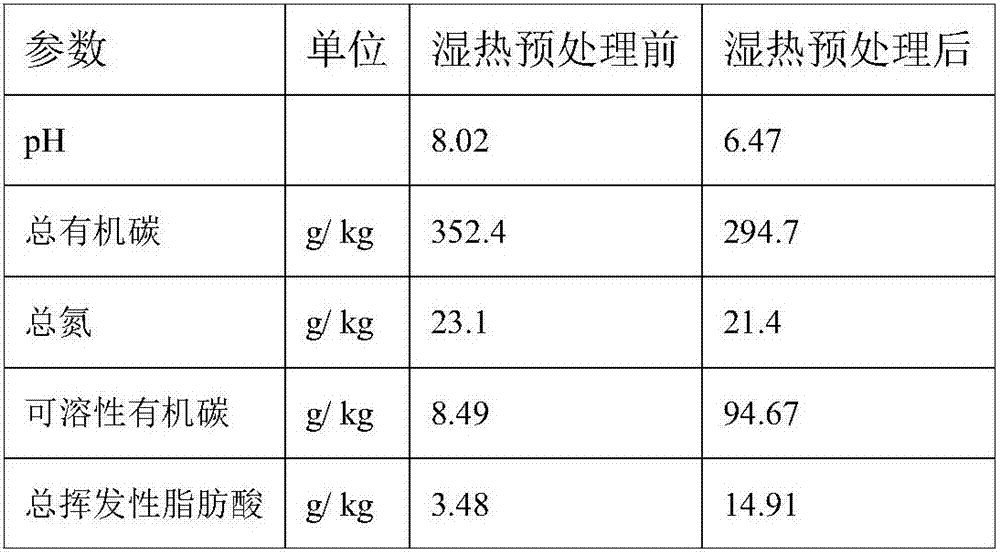

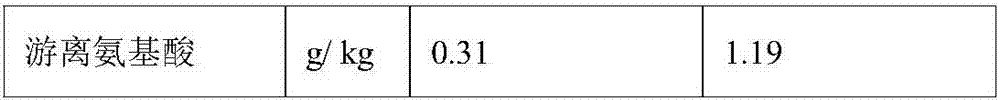

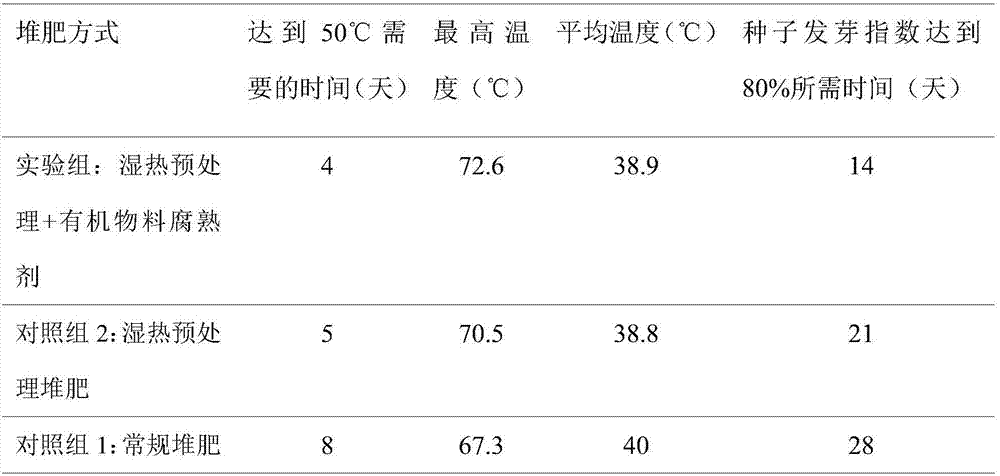

[0038] The compost raw material used in the present embodiment gets the chicken manure of certain large-scale chicken farm, and moisture content is 85%, and composting method is divided into traditional composting (control group 1), only wet heat pretreatment composting (control group 2), and the present invention's Three kinds of composting (experimental group) were provided with moist heat pretreatment and inoculation of organic material decomposing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com