Patents

Literature

58results about How to "Prevent encrustation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

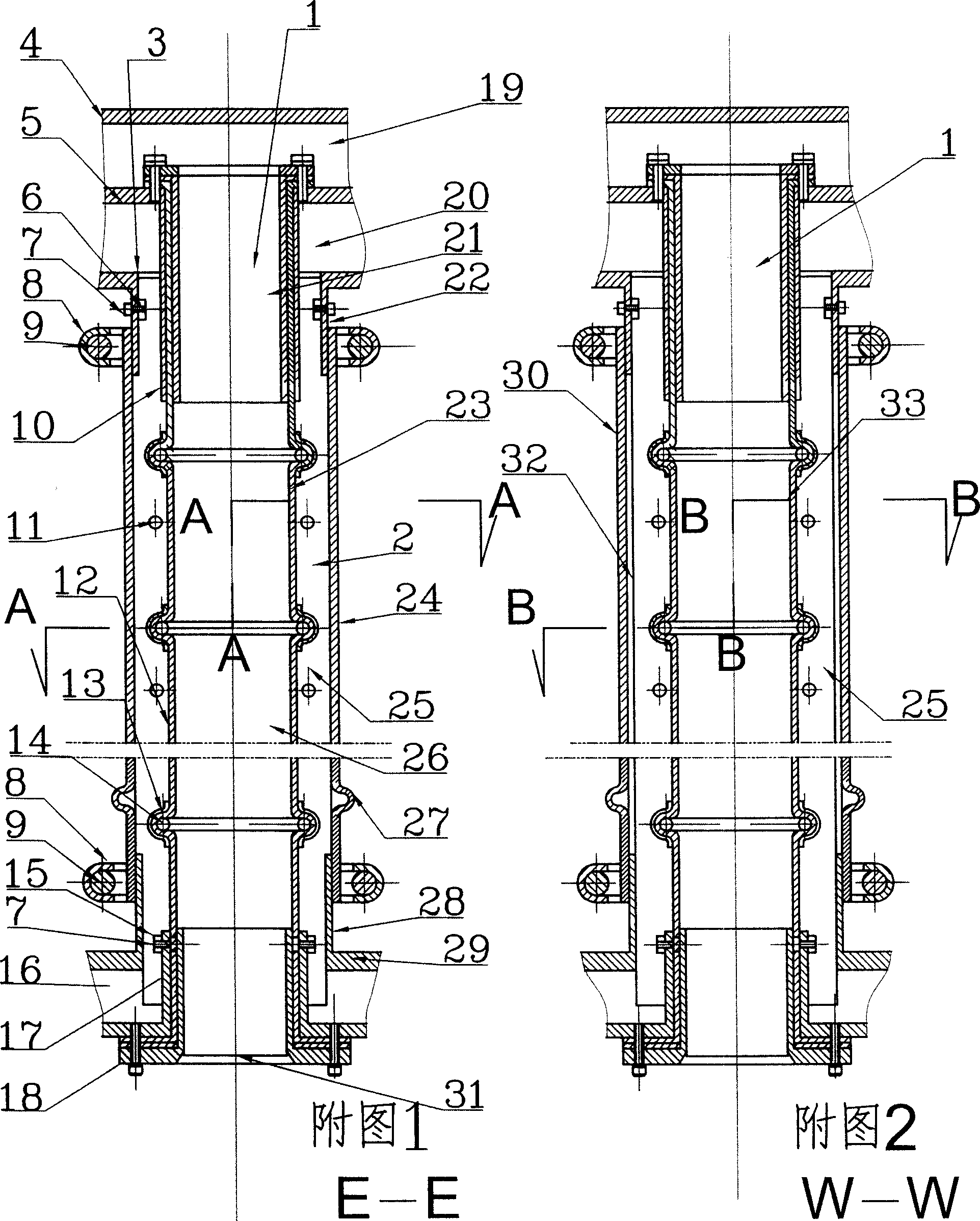

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

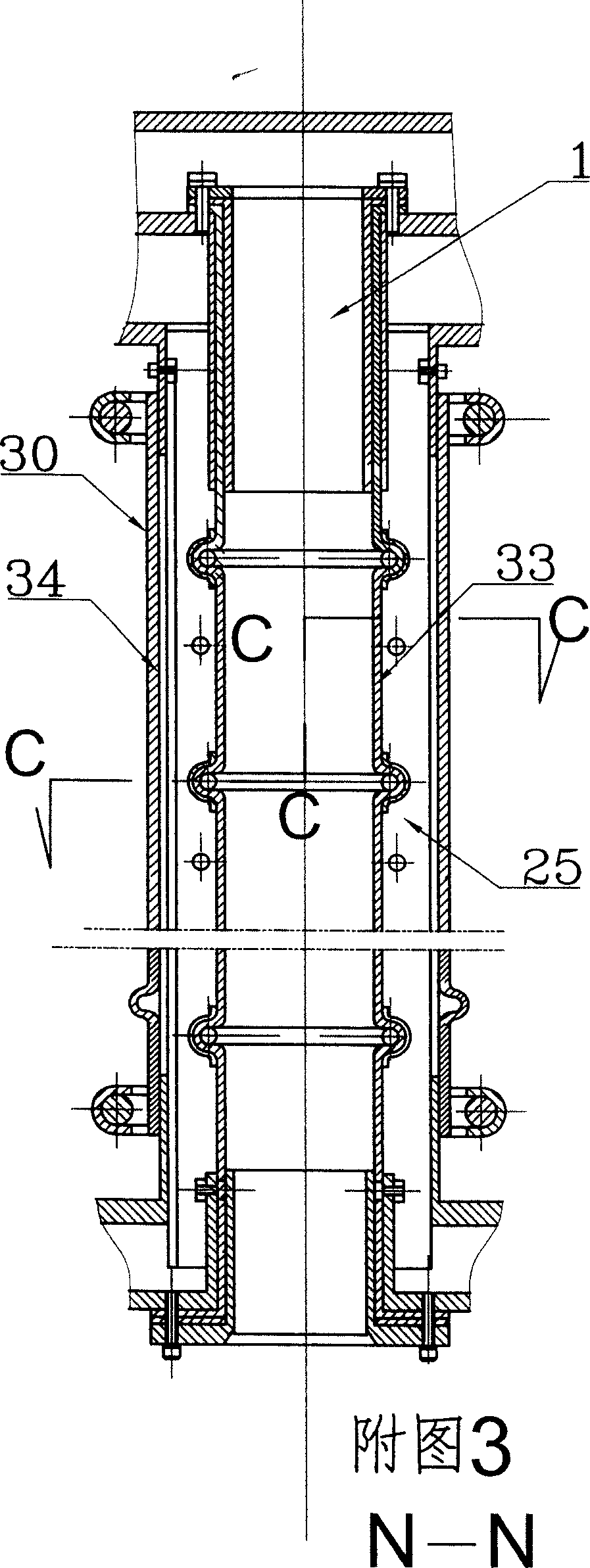

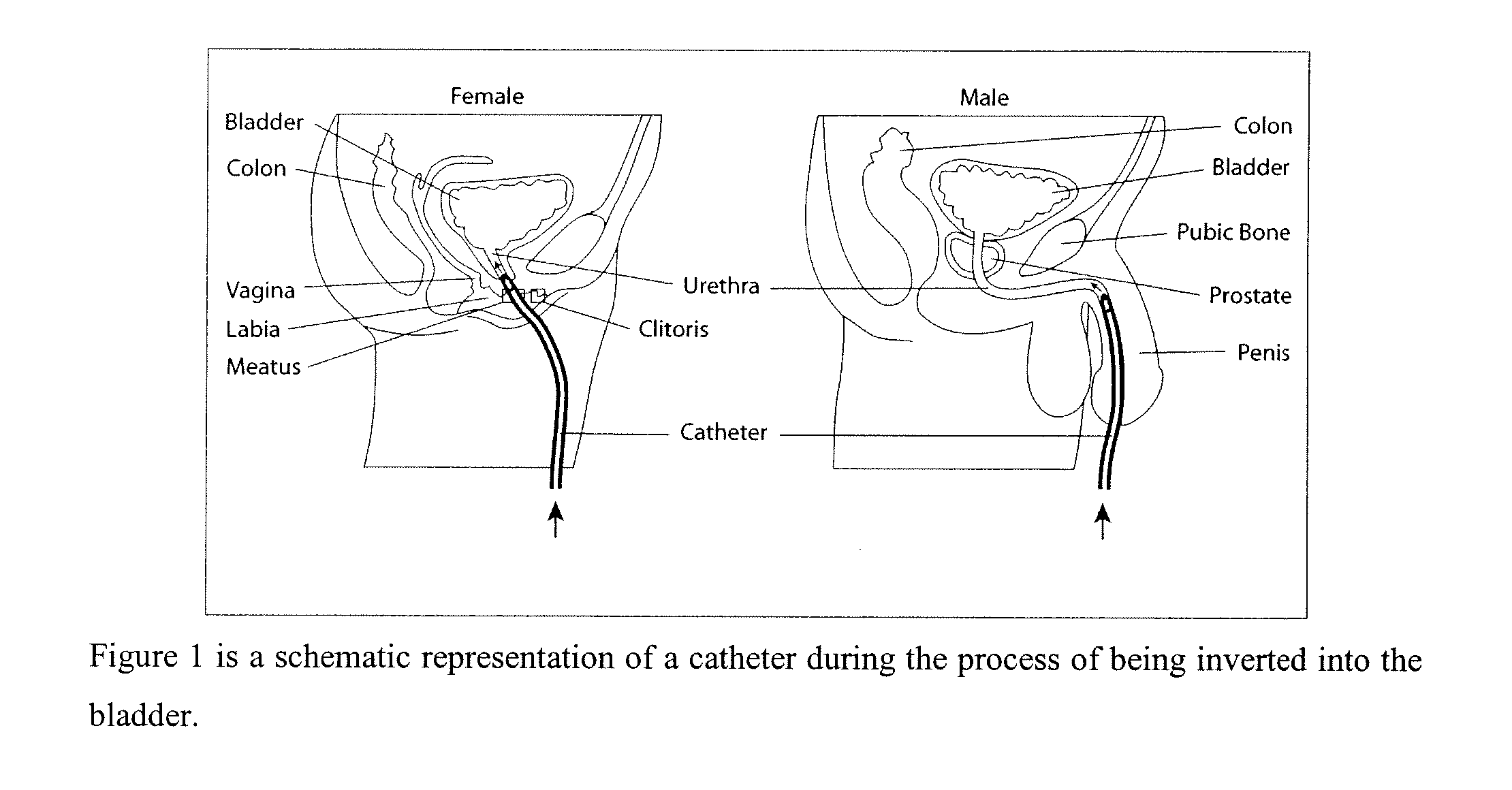

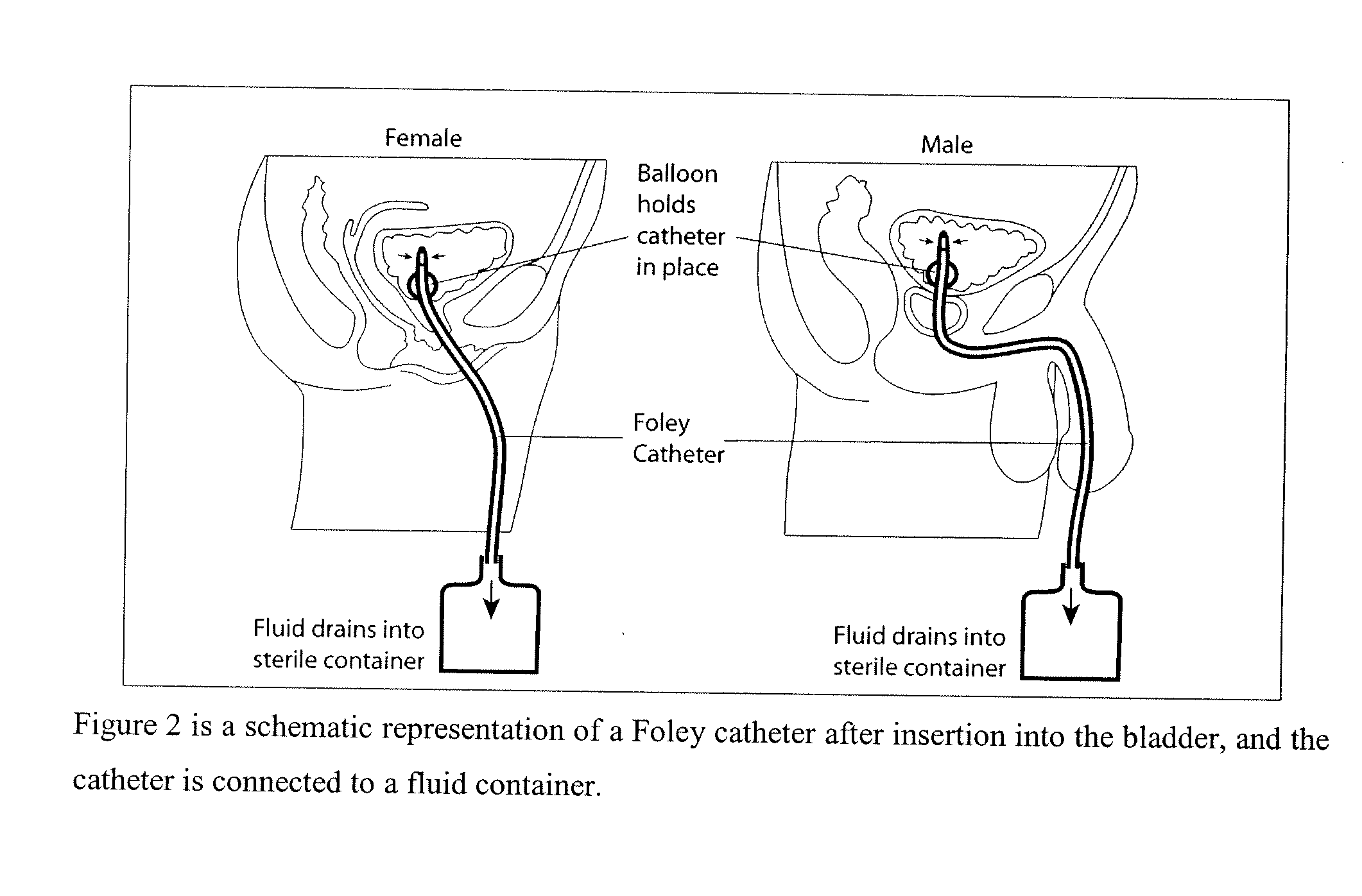

System and method for the prevention of bacterial and fungal infections including Urinary Tract Infections (UTI) using N-halogenated amino acids

InactiveUS20070244449A1Preventing encrustation and blockagePrevent encrustationAntibacterial agentsBiocideCompound (substance)Biofilm

Disclosed is a system that prevents the development of infection and biofilm establishment in medical devices in general, and in particular Urinary Tract Infections (UTI), including Catheter-Associated Urinary Tract Infections (CAUTI). The system comprises a medical device (such as a catheter) and an antimicrobial composition containing an antimicrobial compound. A medical device delivers the composition both to the inside and / or outside portions of the device, as well as to the inside of the bladder itself and to the urethra. Reduction or elimination of the infection may be accomplished by irrigating the medical device, bathing the bladder, or irrigating the bladder with the composition.

Owner:NOVABAY PHARM INC

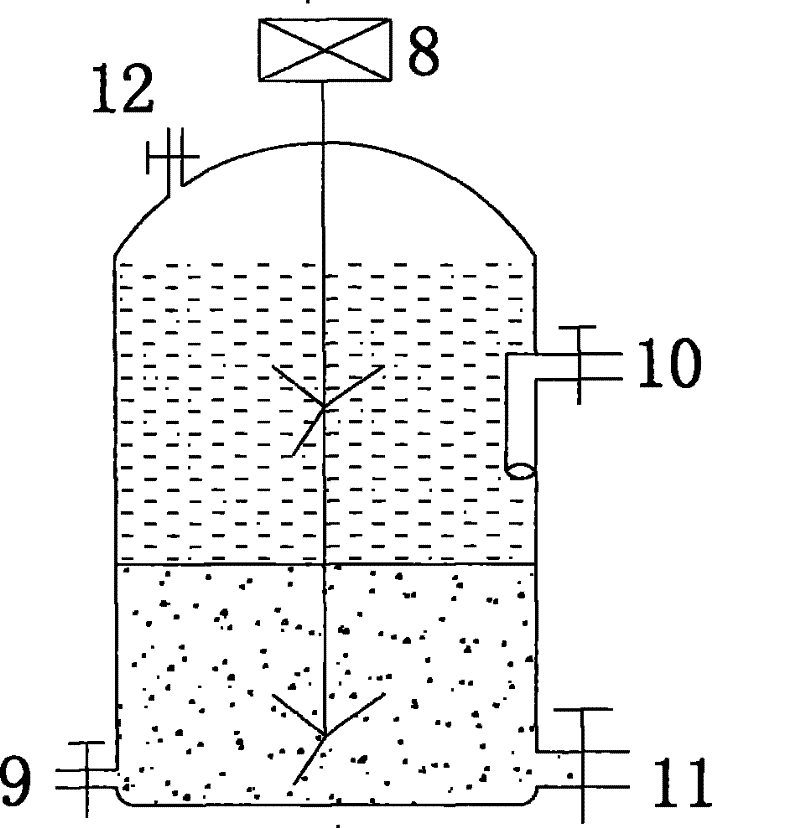

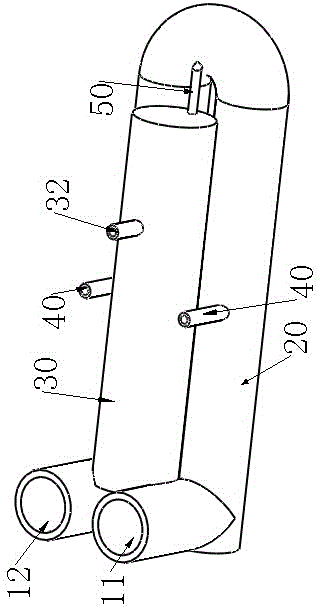

Method for anaerobic fermentation of bloom blue algae

InactiveCN101337758BPrevent encrustationAvoid dischargeWaste based fuelBiological sludge treatmentPhylum CyanobacteriaRetention time

The invention relates to a method for the anaerobic fermentation of bloom-forming cyanobacteria, and belongs to the technical field of the agricultural environmental protection. The method comprises the following steps: pumping the bloom-forming cyanobacteria to a zigzag type acidification pool; and pumping the bloom-forming cyanobacteria after being subjected to acidification treatment to an agitating type anaerobic digestion tank after being improved, so as to generate marsh gas after the anaerobic fermentation. Through combining the promotion or unload or transportation process of the bloom-forming cyanobacteria with deswelling treatment, the investment of a deswelling dedicated device is reduced; the cost is reduced; the effective volume of the subsequent anaerobic digestion tank is improved through the mechanical action of a pump and the extension of the acidification time of the cyanobacteria; and the retention time of the bloom-forming cyanobacteria in the anaerobic digestion tank is shortened; through adding an agitator at the upper part of the digestion tank, the bloom-forming cyanobacteria and sludge at the bottom are fully in contact mixture, thereby increasing the gas production rate of the volume and the organic load, and improving the running efficiency of engineering.

Owner:JIANGSU ACAD OF AGRI SCI

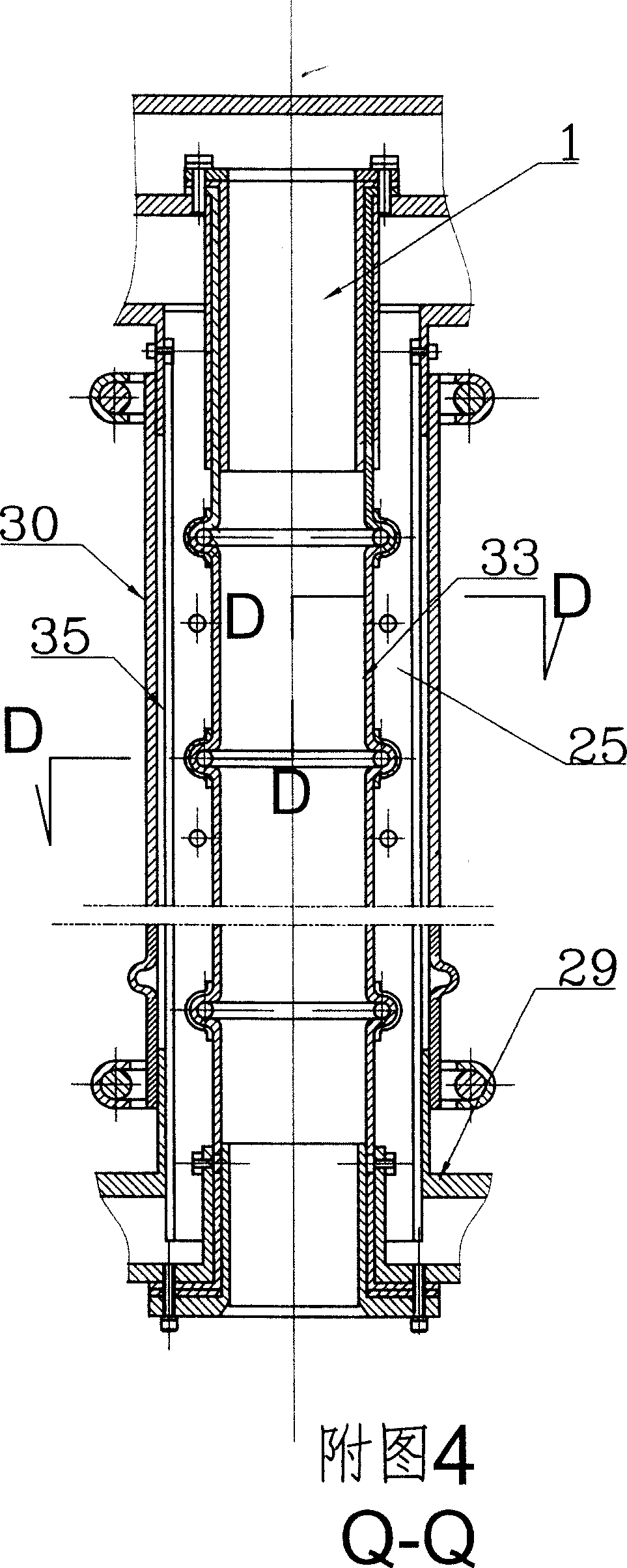

Method for producing biogas by biogas slurry reflux stirring device of auger type biogas generation system

ActiveCN104531513AGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelProcess engineeringSlurry

The invention discloses a method for producing biogas by a biogas slurry reflux stirring device of an auger type biogas generation system. The method comprises the steps of pouring fermentation raw materials from a feeding pipe, fermenting in a fermentation pipeline to produce biogas, respectively gathering the biogas in fermentation areas formed between the feeding pipe / discharging pipe and adjacent gas blocking plates or between the adjacent gas blocking plates, enabling the biogas to occupy the space in the fermentation area, extruding biogas slurry to realize convection, and enabling the biogas slurry to flow to the feeding pipe, the discharging pipe and a bacteria distribution device, wherein the biogas slurry in the fermentation pipe flows into a water pressure room through a drainage hole of the feeding pipe, the drainage hole of the discharging pipe and a drainage pipe of the bacteria distribution device as the liquid level of the biogas slurry in the feeding pipe, the discharging pipe and the bacteria distribution device rises; and using the biogas stored in any one fermentation area, wherein the gas pressure of the biogas stored in the fermentation area is reduced, the biogas slurry in the adjacent fermentation area flows into the fermentation area, and the biogas slurry stored in the water pressure room flows back into the fermentation pipeline through the drainage hole of the feeding pipe, the drainage hole of the discharging pipe and the drainage pipe of the bacteria distribution device to supplement the reduced biogas space, thereby completing the circulating flow of the biogas slurry.

Owner:六安皖智知识产权运营有限公司

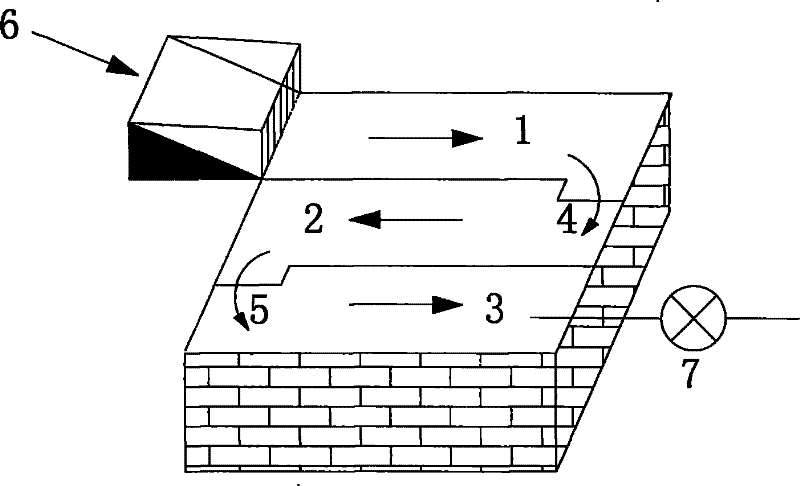

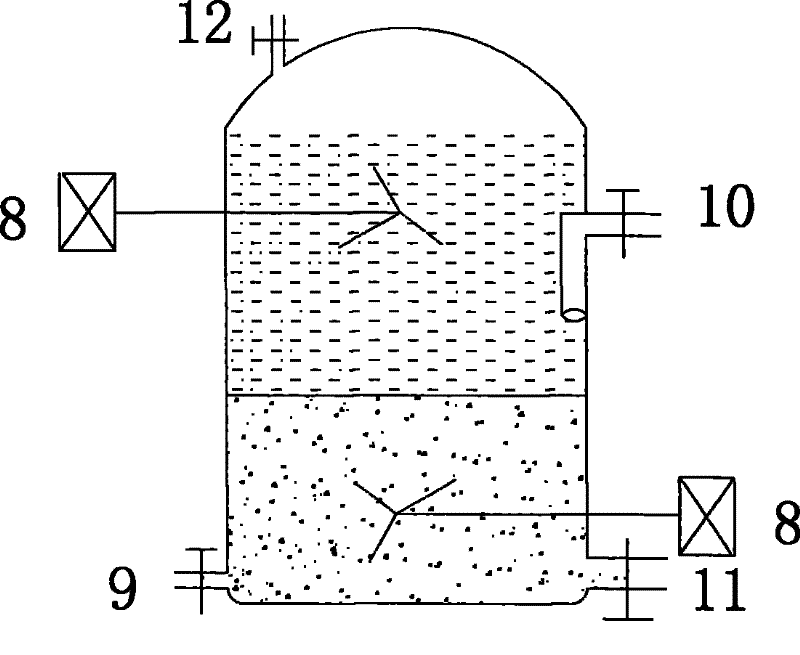

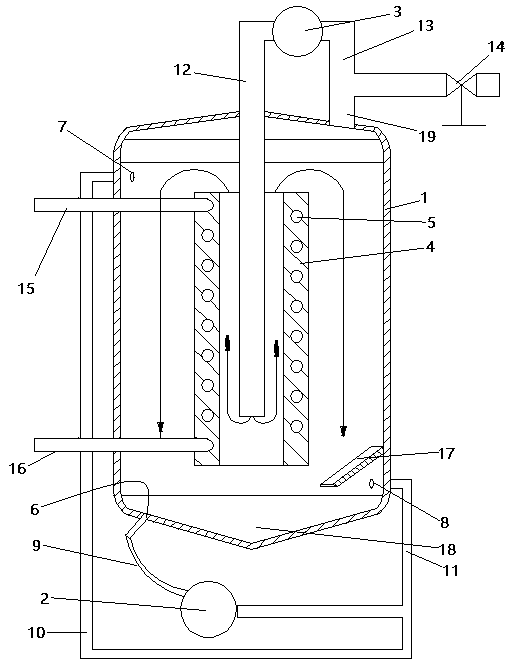

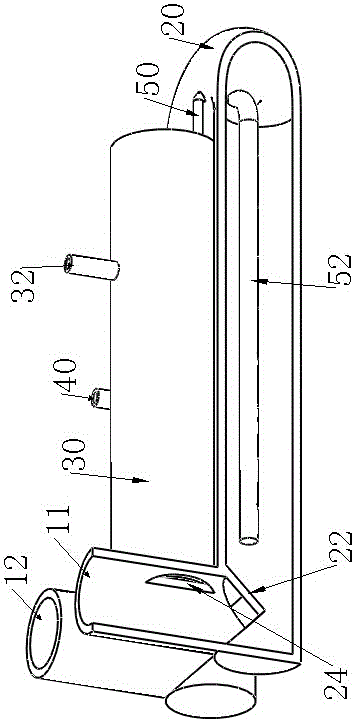

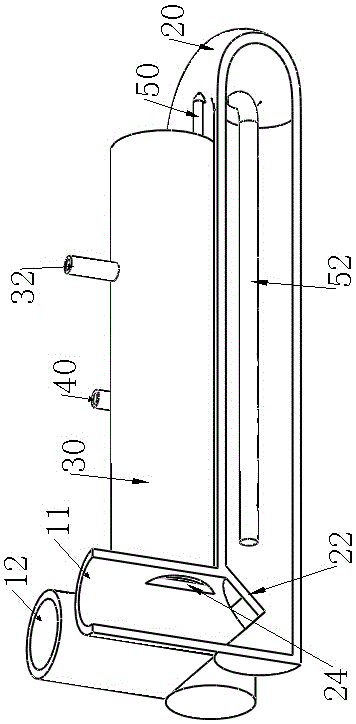

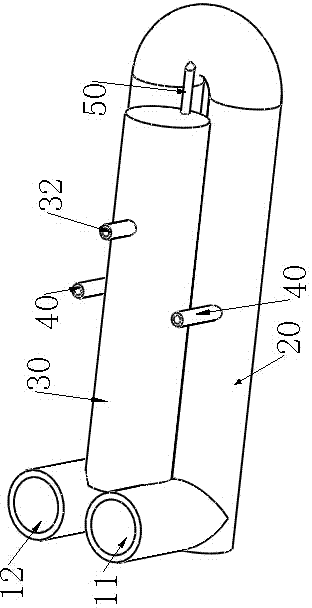

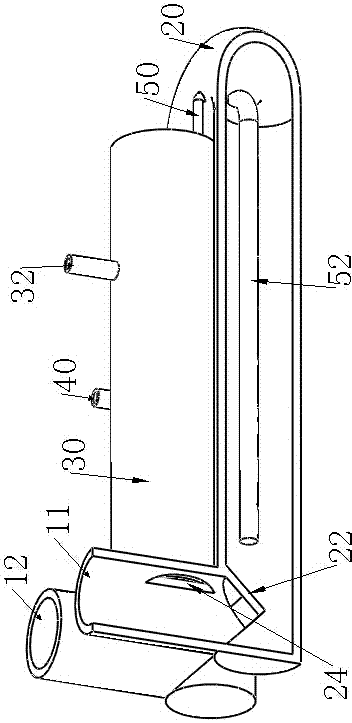

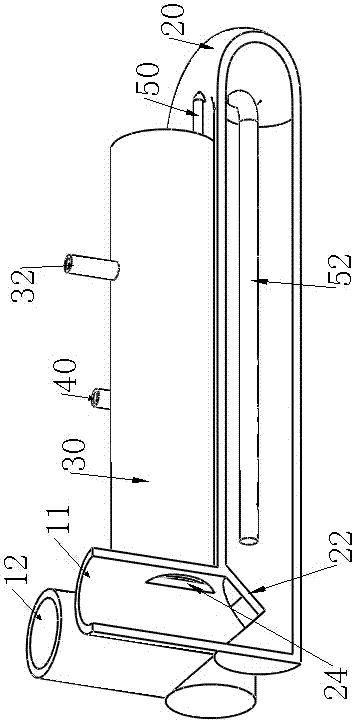

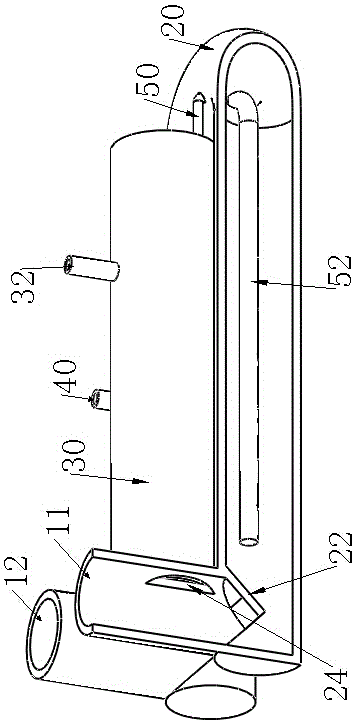

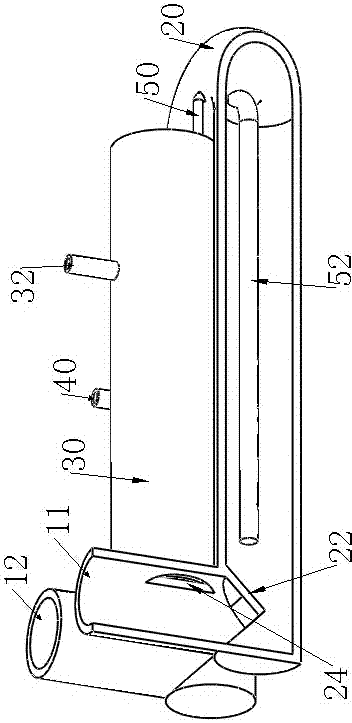

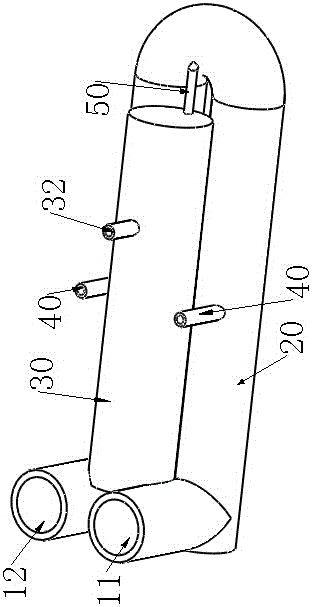

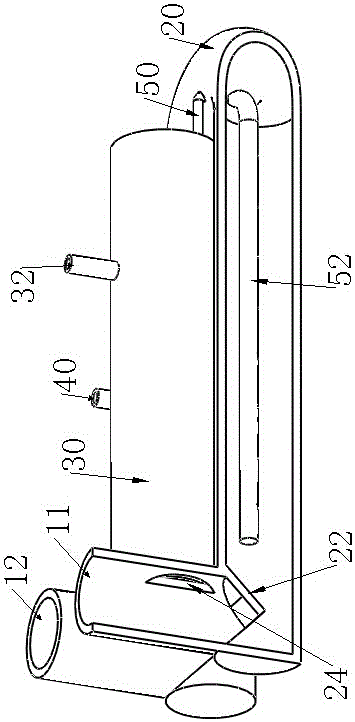

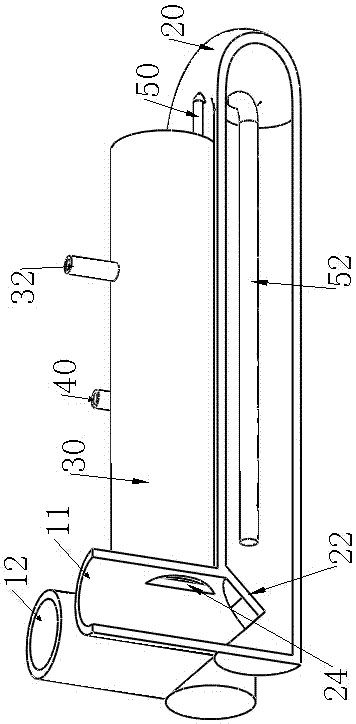

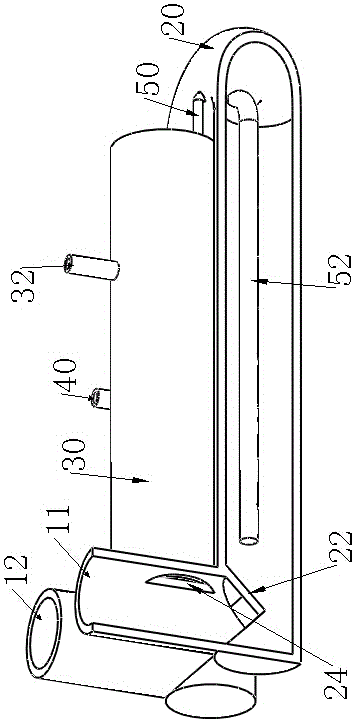

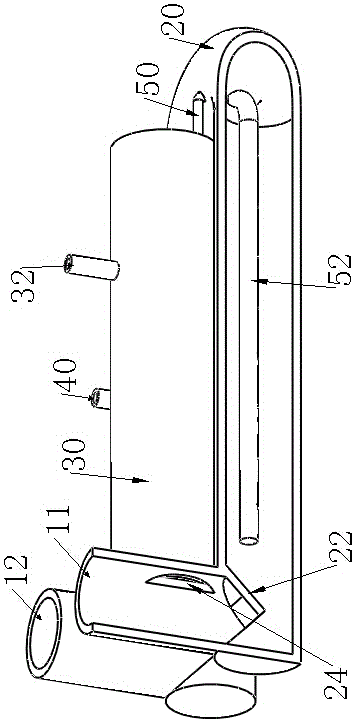

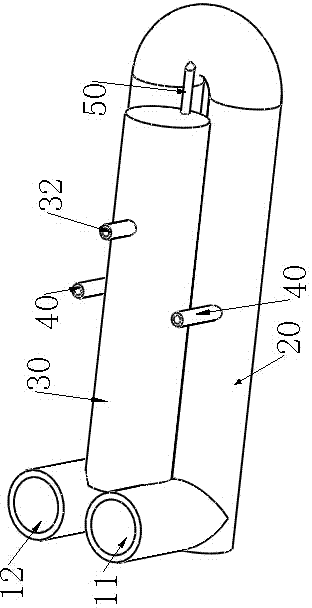

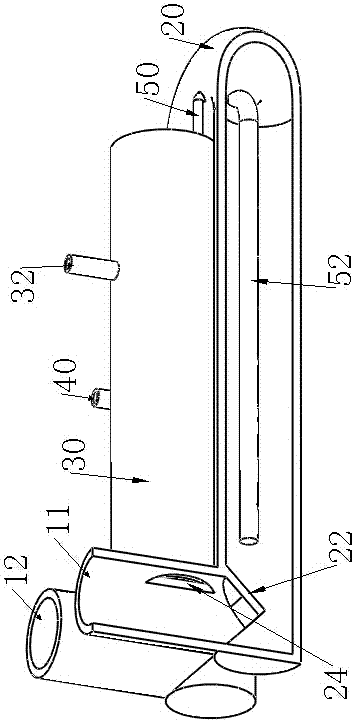

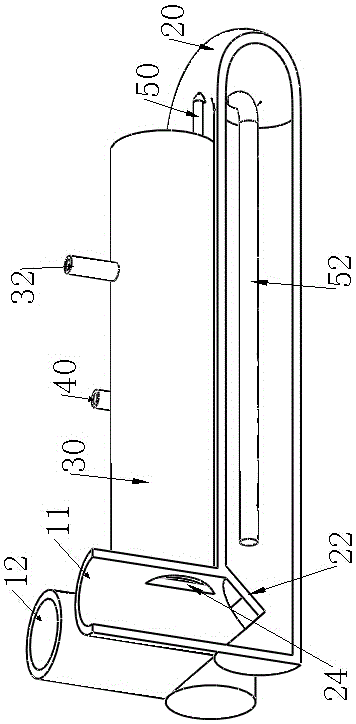

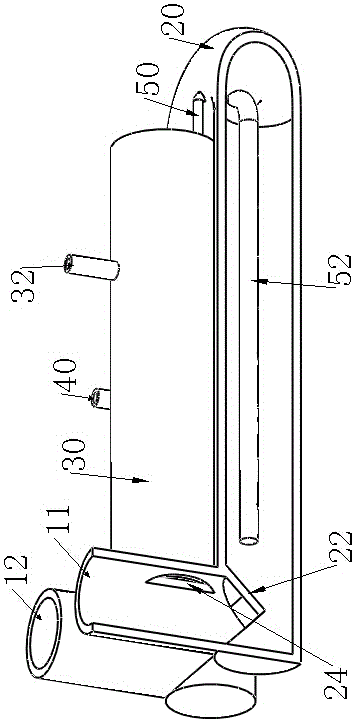

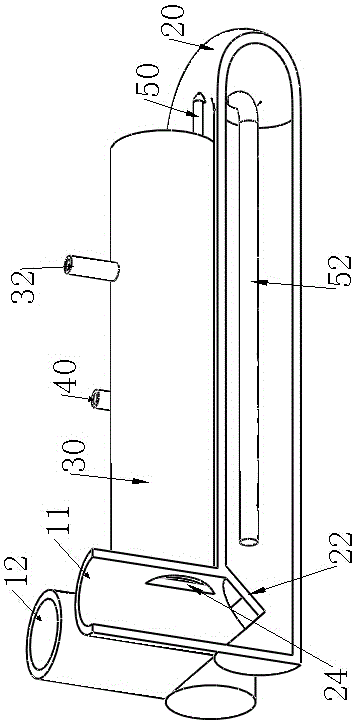

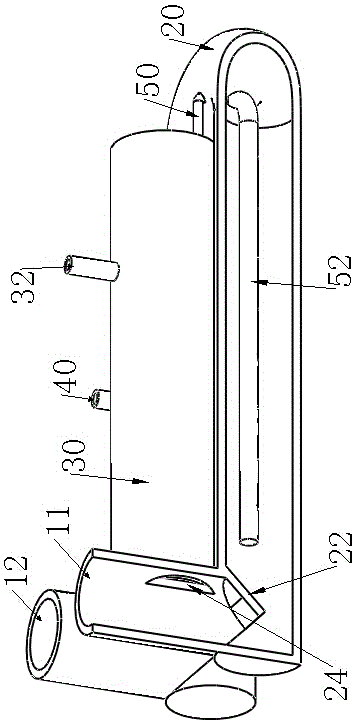

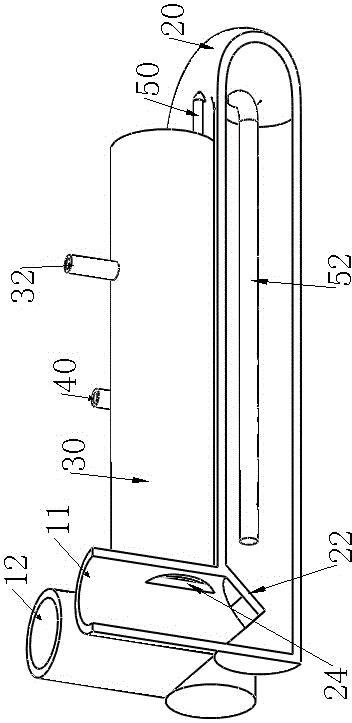

Wet anaerobic fermentation stirring and heat exchange method and wet anaerobic fermentation system

PendingCN110964625ARealize full mixed flowPrevent encrustationBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryEnvironmental engineering

The invention relates to a wet anaerobic fermentation system which comprises an anaerobic fermentation tank, a circulating pump and a booster pump. A vertical sleeve with a flow channel is arranged inthe anaerobic fermentation tank; and the anaerobic fermentation tank is provided with a liquid outlet, a biogas outlet, an upper liquid inlet and a lower liquid inlet. The invention further relates to a wet anaerobic fermentation stirring and heat exchange method. Liquid in the anaerobic fermentation tank flows out through the circulating pump and then flows back into the anaerobic fermentation tank to carry out stirring for the first time; biogas in the anaerobic fermentation tank is pressurized through the booster pump and then the gas is input into the vertical sleeve arranged in the anaerobic fermentation tank, so that the liquid in the vertical sleeve flows upwards, and external liquid flows downwards to be subjected to secondary stirring; and a heat exchange medium flows through theflow channel to exchange heat with the liquid in the anaerobic fermentation tank. The anaerobic fermentation tank has the advantages of being high in degradation efficiency and capable of resisting the distance on the degradation efficiency by the environment temperature; and problems that the anaerobic degradation efficiency is low, and the degradation efficiency is greatly influenced by the environment temperature when the existing anaerobic fermentation tank is used for anaerobic degradation can be solved.

Owner:浙江卓尚环保能源有限公司

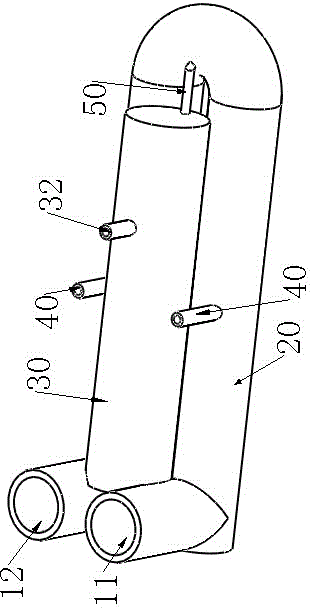

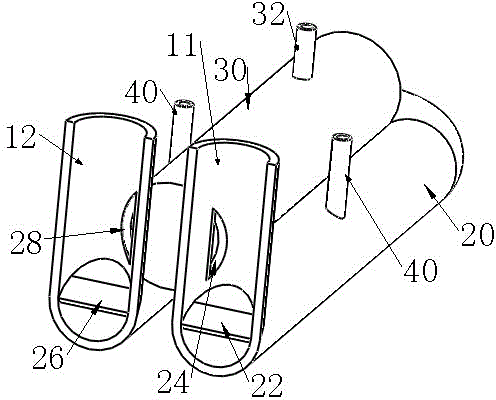

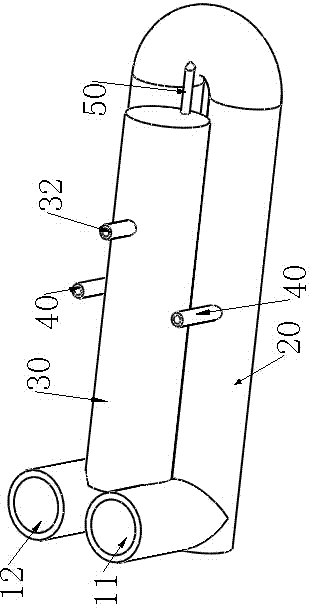

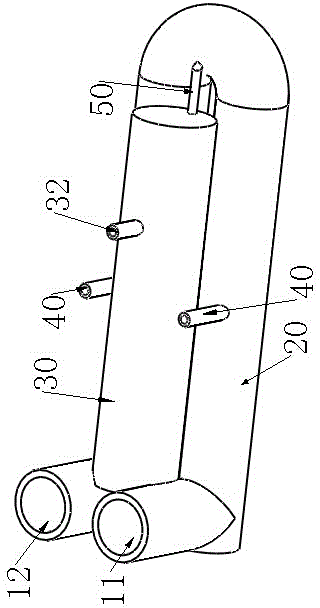

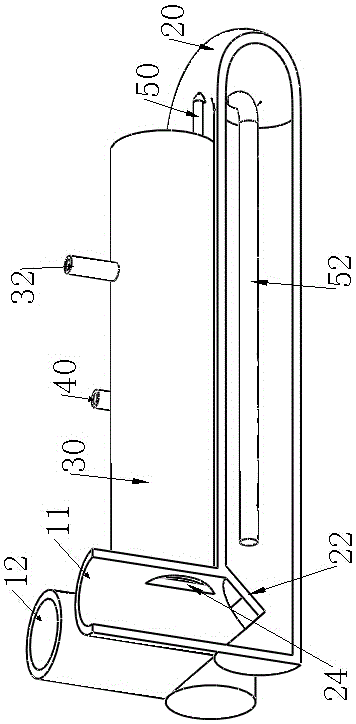

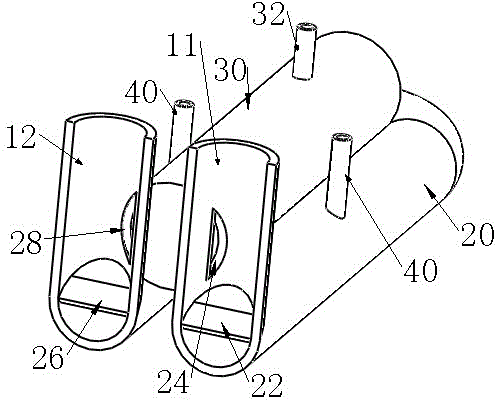

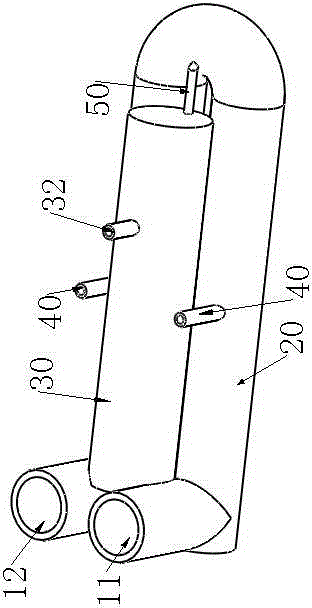

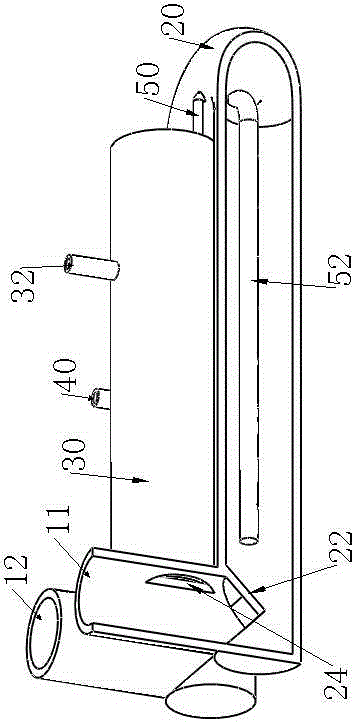

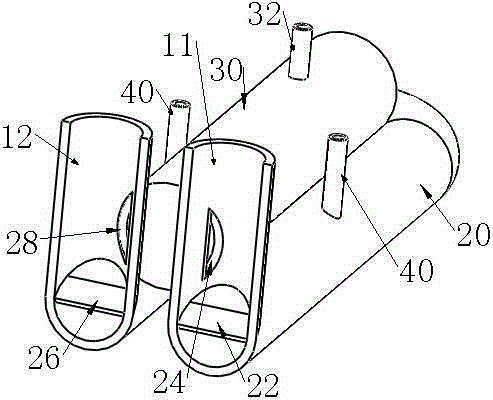

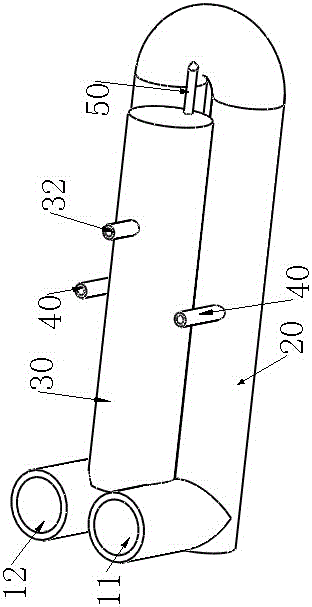

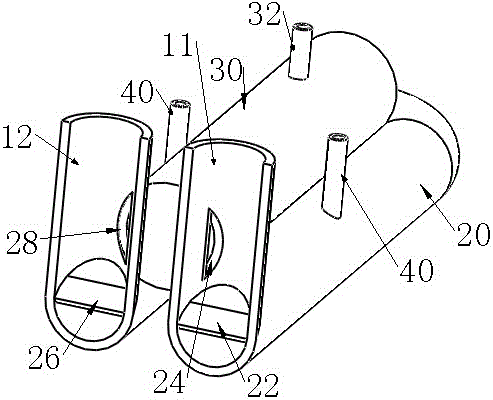

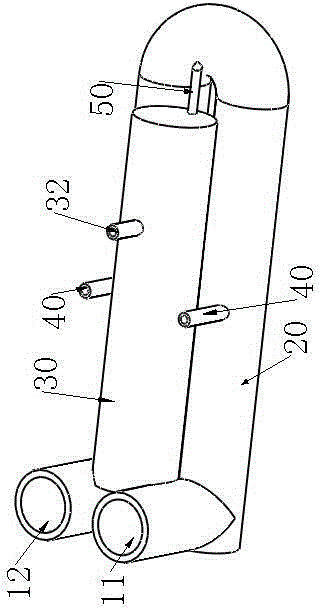

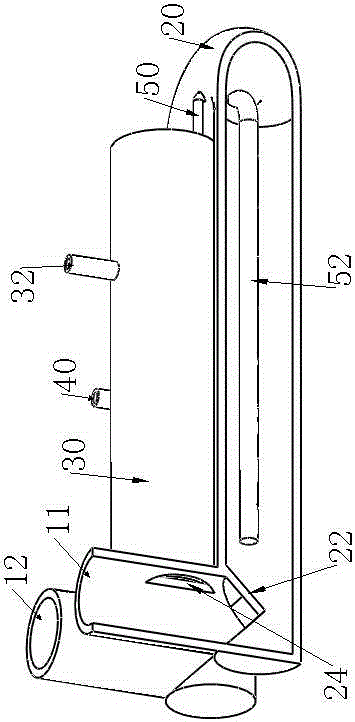

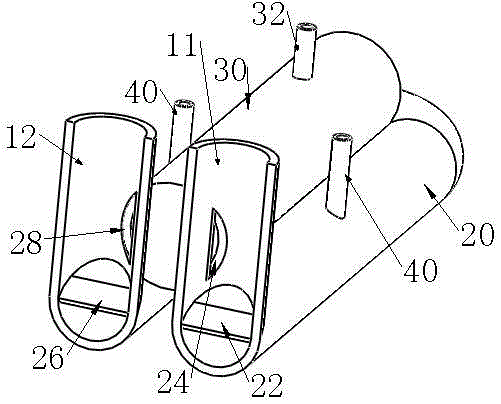

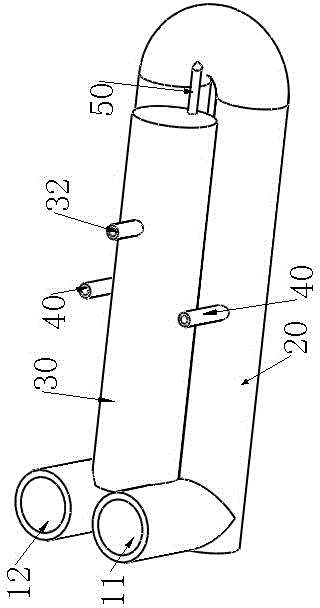

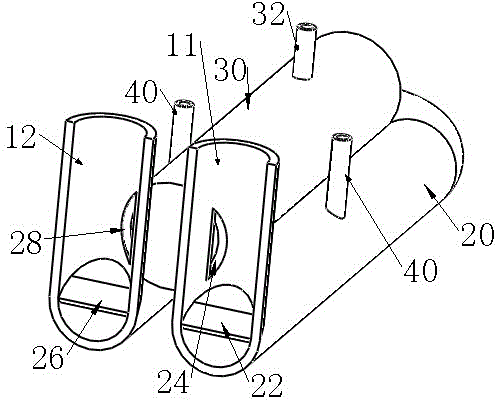

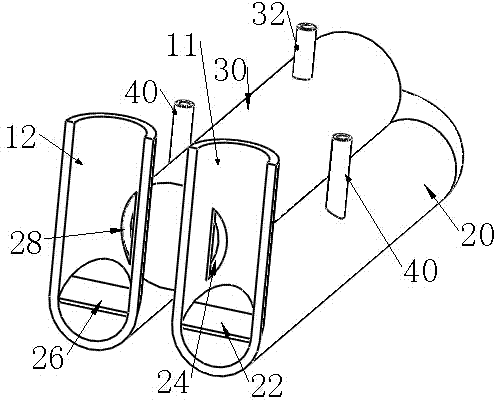

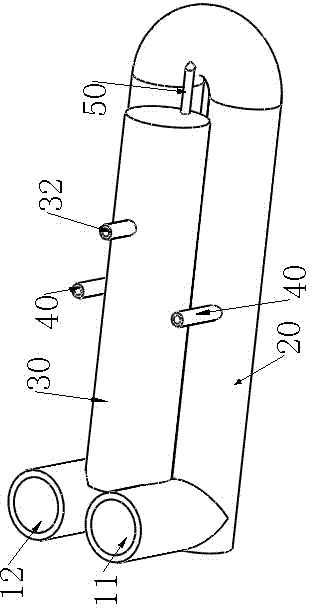

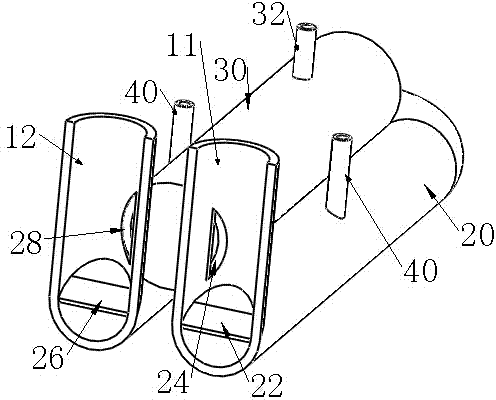

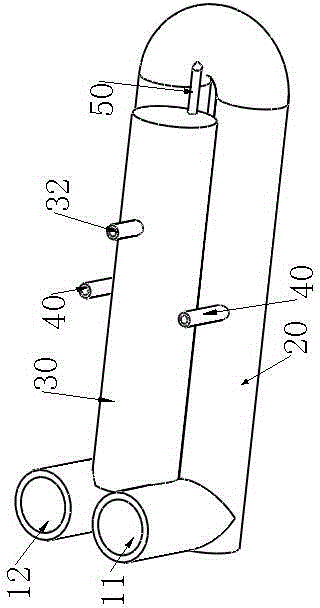

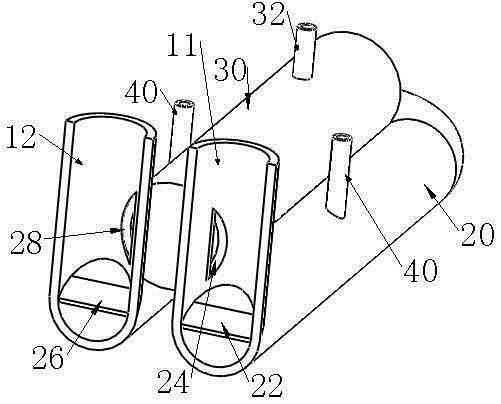

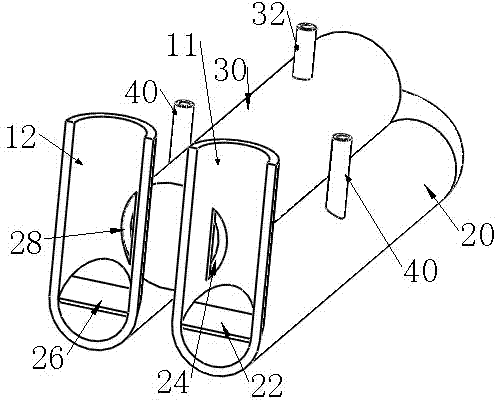

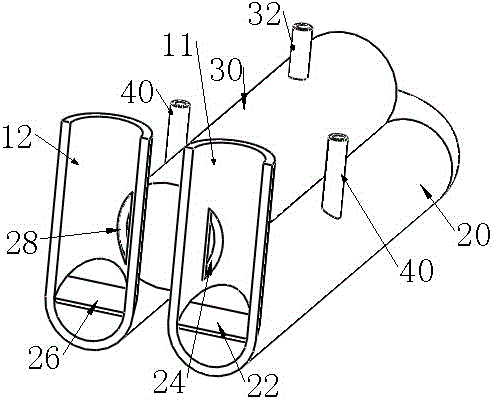

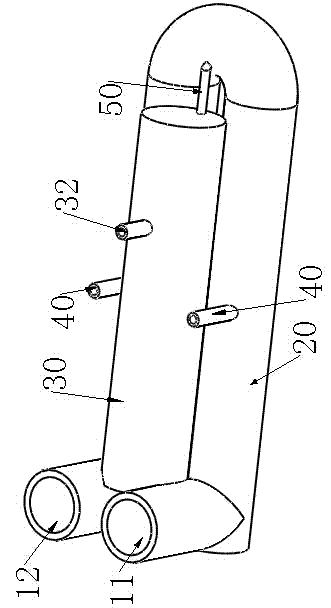

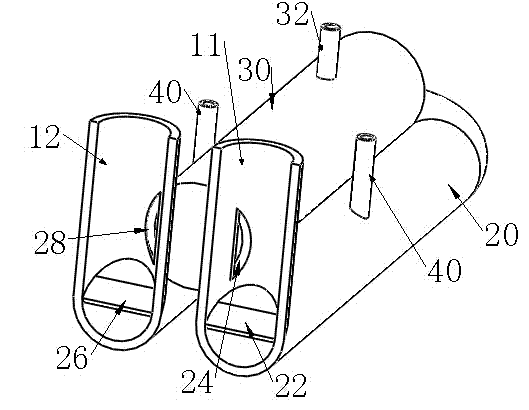

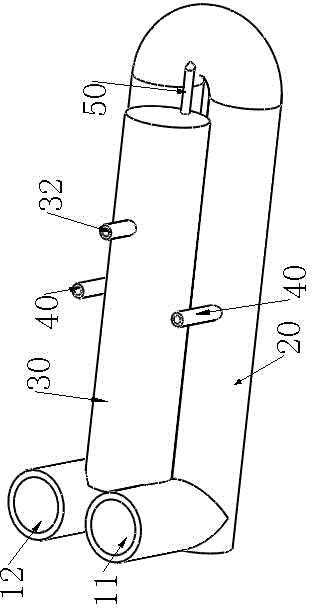

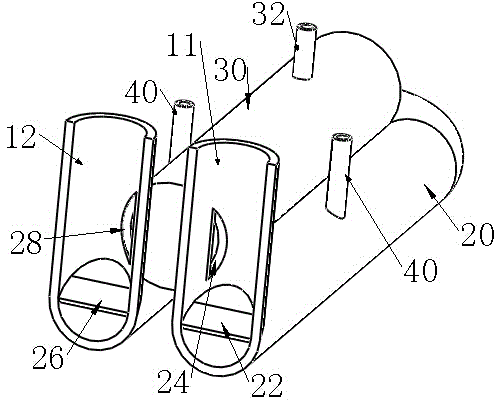

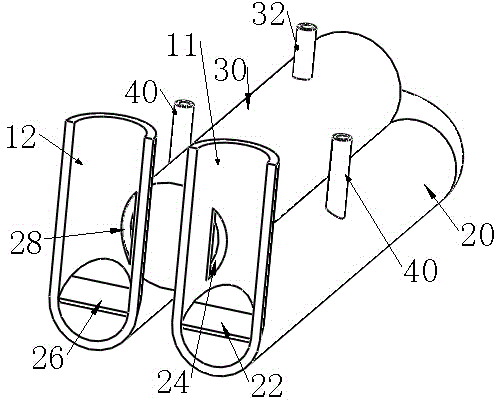

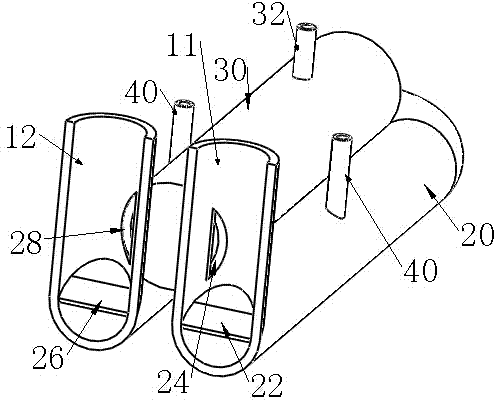

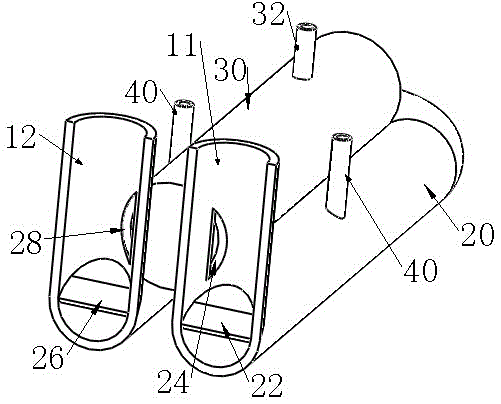

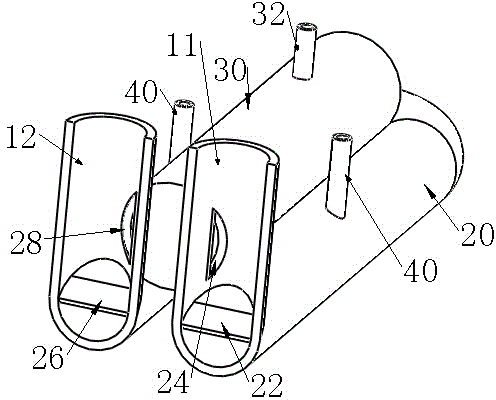

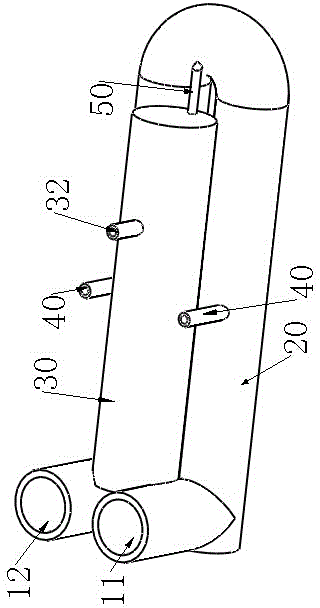

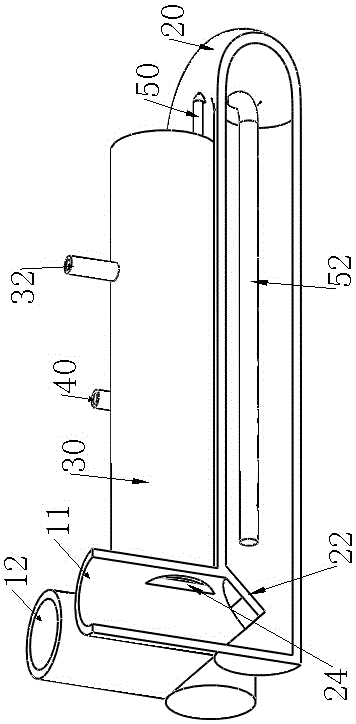

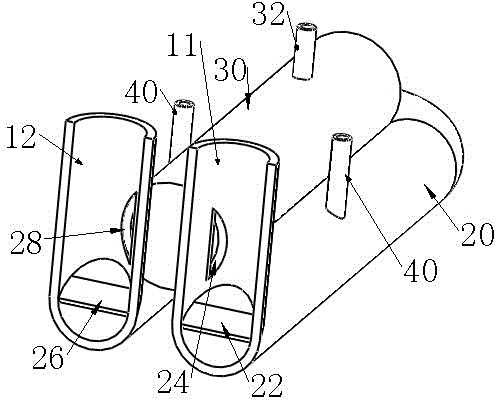

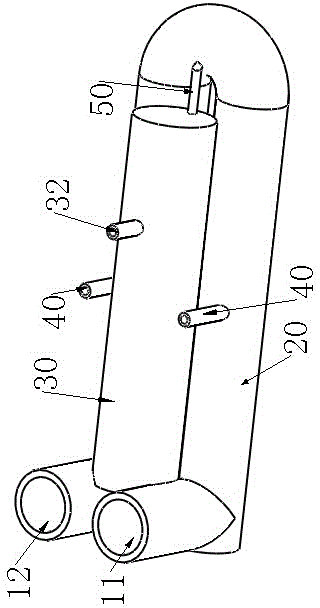

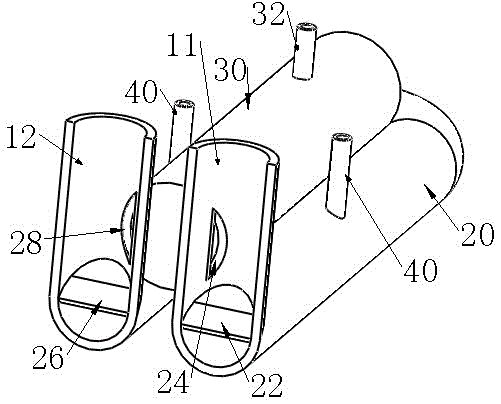

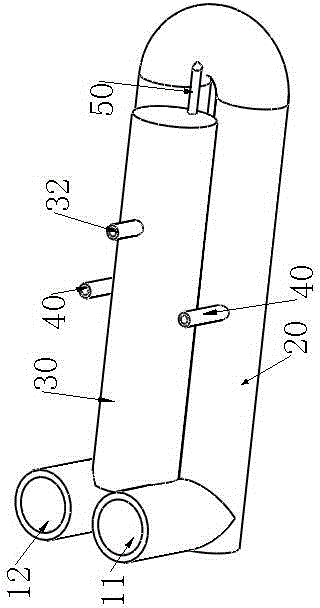

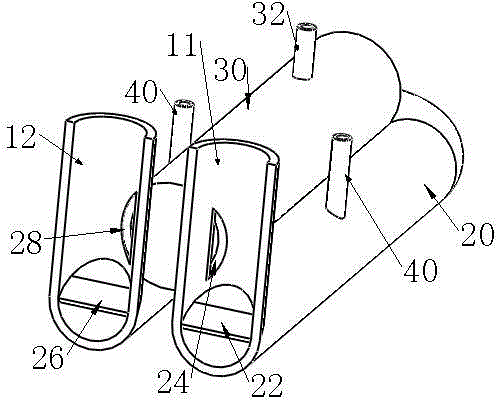

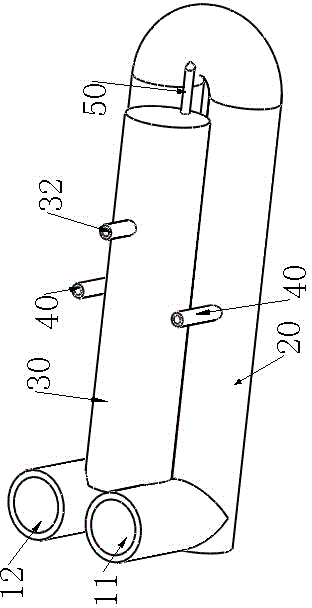

Device for promoting biogas slurry return flow agitation in intertwined biogas generation system

InactiveCN104498340AGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelProcess engineeringSlurry

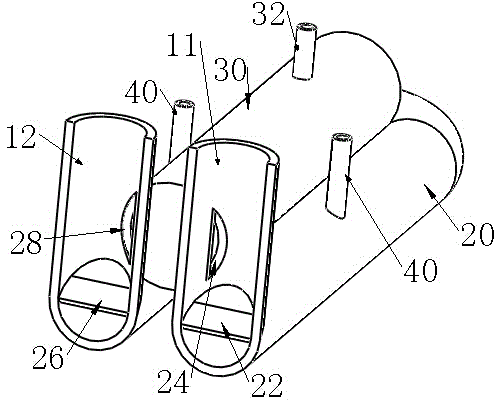

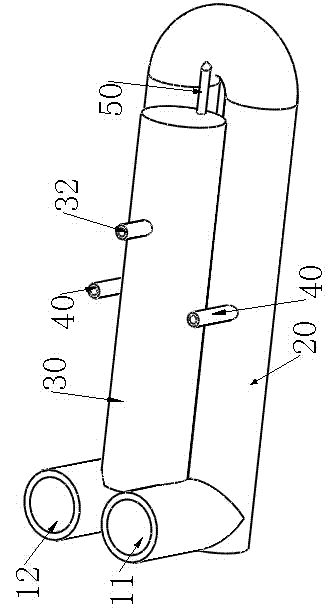

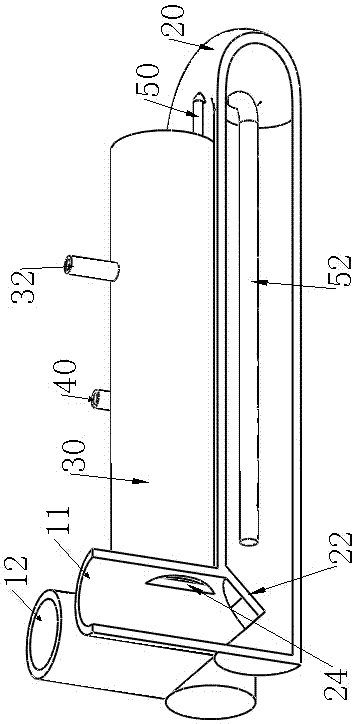

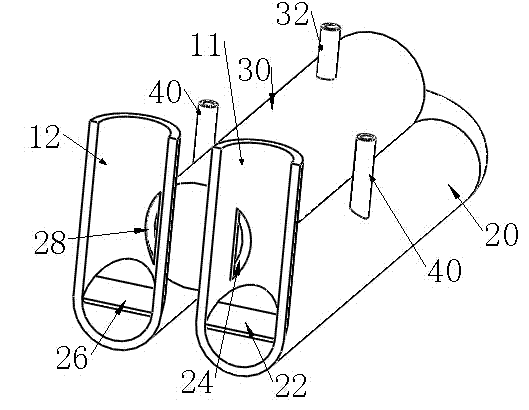

A device for promoting biogas slurry return flow agitation in an intertwined biogas generation system comprises a feeding pipe, a discharging pipe and a U-shaped fermentation pipeline. The U-shaped fermentation pipeline is horizontally placed, the feeding pipe and the discharging pipe are vertically connected with two end sides of the U-shaped fermentation pipeline, a water pressure space is formed on the U-shaped fermentation pipeline, a feeding pipe drain hole is formed in the joint of the water pressure space and the feeding pipe, a discharging pipe drain hole is formed in the joint of the water pressure space and the discharging pipe, a feeding pipe gas baffle plate is arranged at the joint of the U-shaped fermentation pipeline and the feeding pipe, a discharging pipe gas baffle plate is arranged at the joint of the U-shaped fermentation pipeline and the discharging pipe, at least one gas baffle plate is arranged between the discharging pipe gas baffle plate and the feeding pipe gas baffle plate, a fermentation area is formed among the feeding / discharging pipe and the adjacent gas baffle plates or between the adjacent gas baffle plates, an independent gas collecting pipe is arranged at the top of each fermentation area, the top of each fermentation area is connected with the independent gas collecting pipe, and a valve is arranged on each gas collecting pipe. A U-shaped channel-type fermentation device is used, a fermentation path is long, biogas slurry sufficiently flows in the system by control of water pressure difference and one-way valves, bacteria are driven to be uniformly distributed, crusting is effectively prevented, and gas generating rate is high.

Owner:程阳 +6

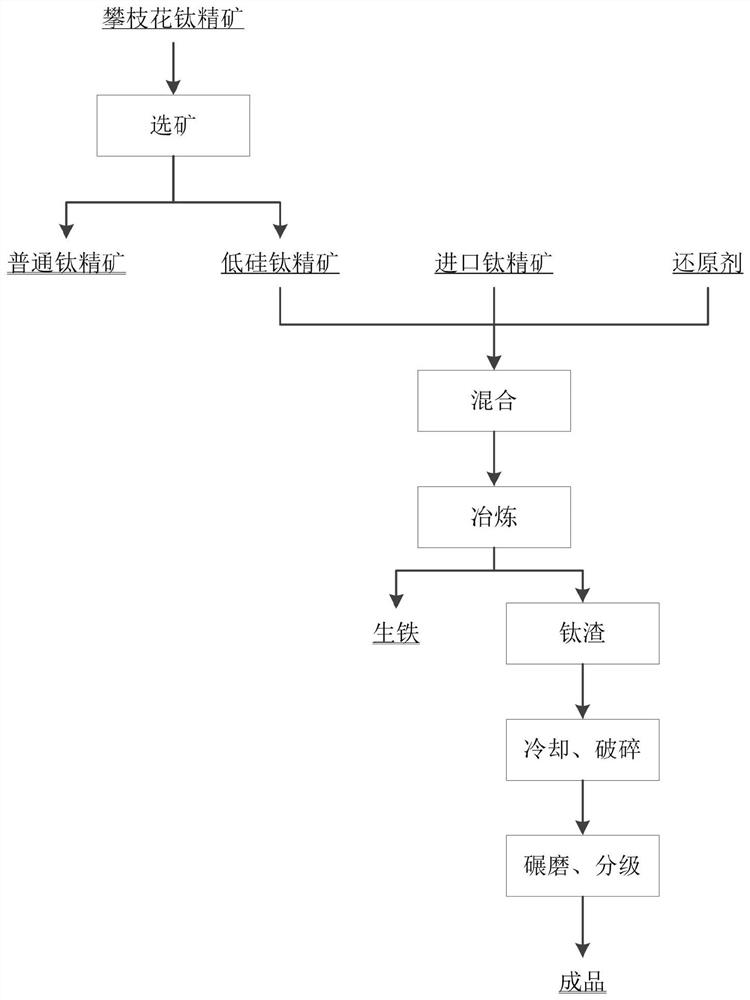

Flotation reagent for high-calcium-magnesium vanadium titano-magnetite and method for preparing chlorinated titanium-rich material from high-calcium-magnesium vanadium titano-magnetite

ActiveCN113318865ALow impurity contentSolve the problem that it is difficult to be used in the production of titanium-rich chloride materialsFlotationProcess efficiency improvementSmelting processTitanomagnetite

The invention discloses a high-calcium-magnesium vanadium titano-magnetite flotation reagent which comprises a composite reagent, a collecting agent, a regulating agent and an inhibitor, and the composite reagent is composed of synthetic dodecylamine, tall acid and mixed amine. The invention further discloses a method for preparing the chlorinated titanium-rich material from the high-calcium-magnesium vanadium titano-magnetite. The method comprises the step of carrying out flotation by using the flotation reagent for the high-calcium-magnesium vanadium titano-magnetite. The flotation reagent for the high-calcium-magnesium vanadium titano-magnetite has the advantages that the content of impurities in Panxi titanium concentrate can be greatly reduced, and a foundation is laid for post-smelting of high titanium slag meeting the chlorination index requirement; (2) outsourcing titanium concentrate with the particle size of 200-500 meshes is blended with the titanium concentrate, so that the crusting phenomenon in the smelting process can be prevented, the slag overturning risk is reduced, and meanwhile, the comprehensive yield of the titanium element is increased; and 3) the problem that Panxi titanium concentrate is difficult to produce the chlorinated titanium-rich material is solved, and the method has the advantages of short process, low cost and the like.

Owner:宜宾天原海丰和泰有限公司 +1

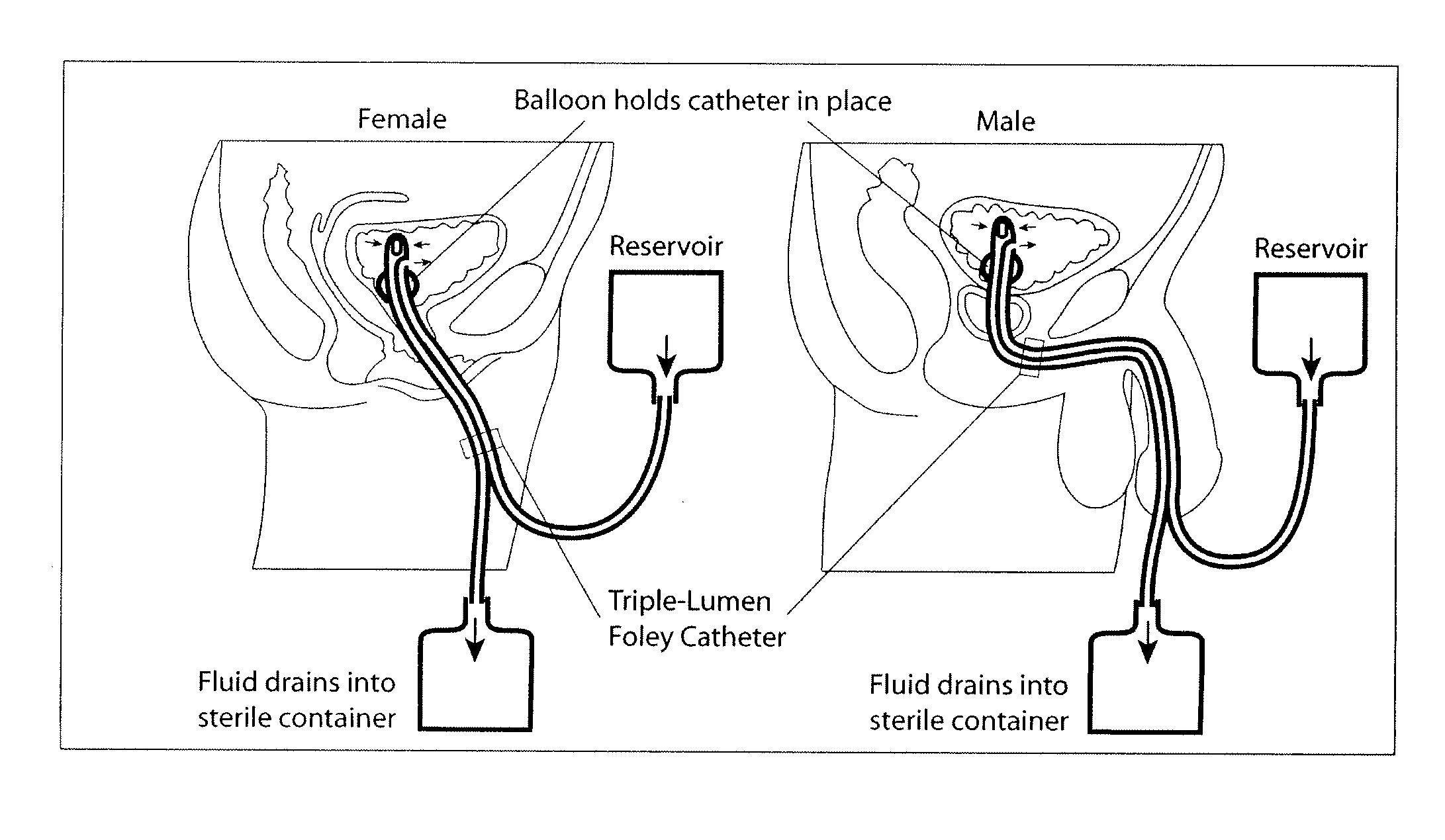

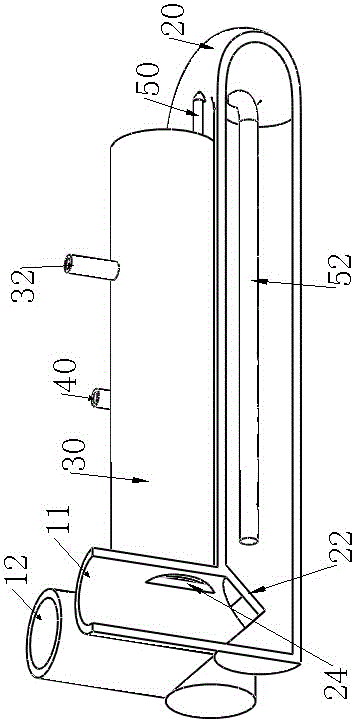

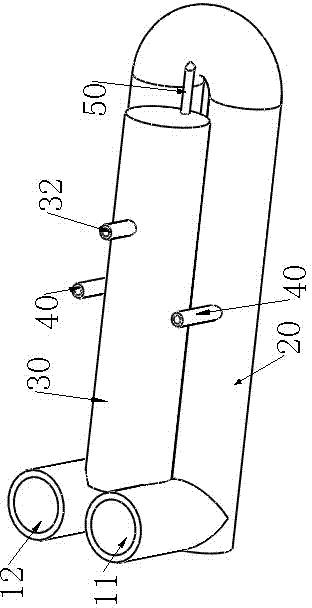

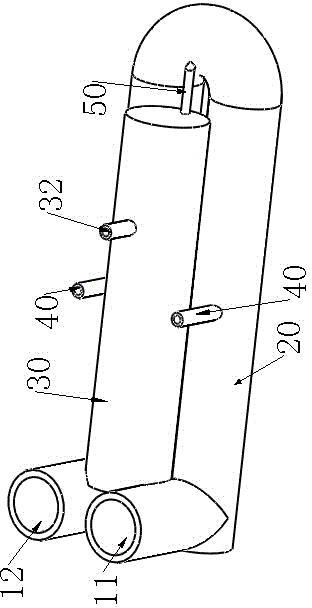

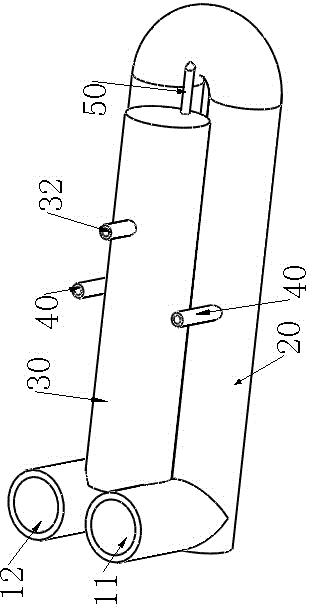

Ultra-efficient methane generation system with curved pneumatic extrusion biogas slurry flow and agitation

ActiveCN104498343BGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelSlurryProcess engineering

The invention discloses a bend type pneumatic extrusion biogas fluid stirred flow super efficient methane generation system. The bend type pneumatic extrusion biogas fluid stirred flow super efficient methane generation system comprises a feed pipe, a discharge pipe and a U-shaped fermentation pipeline, the U-shaped fermentation pipeline is horizontally placed, the feed pipe and the discharge pipe are vertically connected with two end sides of the U-shaped fermentation pipeline, a hydraulic pressure room is located at the upper part of the U-shaped fermentation pipeline, the connection part between the hydraulic pressure room and the feed pipe is the feed pipe drain hole, the connection part between the hydraulic pressure room and the discharge pipe is the discharge pipe drain hole, the connection part between the U-shaped fermentation pipeline and the feed pipe is provided with a feed pipe gas baffle plate, the connection part between the U-shaped fermentation pipeline and the discharge pipe is provided with a discharge pipe gas baffle plate, at least one gas baffle plate is formed between the discharge pipe gas baffle plate and the feed pipe gas baffle plate, a fermentation region is formed between the feed pipe / discharge pipe and the adjacent gas baffle plate or between the adjacent gas baffle plates, an independent gas collecting pipe is arranged at the top of each fermentation region; the top of each fermentation region is connected with the independent gas collecting pipe and the independent gas collecting pipe is provided with a valve body; the fermentation line is long by adopting the U-shaped channel-type fermentation device, the biogas fluid can flow in the system for driving the bacteria to be evenly distributed through the control of the water pressure difference and the one-way valve, the crusting phenomenon can be effectively prevented and the gas yield is high.

Owner:六安皖智知识产权运营有限公司

A device for improving the turbulence effect of biogas slurry in the curved methane generation system

InactiveCN104498338BImprove flowGood convection stirring effectGas production bioreactorsWaste based fuelProcess engineeringSlurry

A device for improving the turbulence effect of biogas slurry in a curved methane generation system, which includes: feed pipe, discharge pipe, U-shaped fermentation pipe, the U-shaped fermentation pipe is placed horizontally, and the feed pipe and discharge pipe are vertically connected to the U-shaped fermentation pipe. On both ends of the pipeline, a water pressure room is placed on the upper part of the U-shaped fermentation pipeline. A feed pipe air baffle is set at the connection position between the pipeline and the feed pipe, a discharge pipe air baffle is set at the connection position between the U-shaped fermentation pipeline and the discharge pipe, the discharge pipe air baffle and the feed pipe air baffle There is also at least one air baffle between them, and a fermentation area is formed between the inlet / outlet pipe and the adjacent air baffle or between the adjacent air baffles, and the top of each fermentation area is provided with an independent collector Trachea; the top of each fermentation area is connected to an independent gas collection pipe, and the gas collection pipe is equipped with a valve body; the U-shaped channel fermentation device is adopted, the fermentation route is long, and the biogas slurry is realized by using the control of water pressure difference and one-way valve It flows fully in the system and drives the uniform distribution of bacteria, effectively preventing crusting and high gas production rate.

Owner:佛山市高科气体有限公司

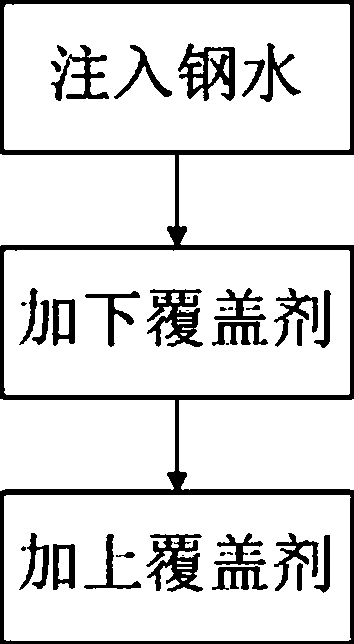

Method for lowering consumption of tundish covering agent

The invention relates to a method for lowering the consumption of a tundish covering agent and belongs to the technical field of metallurgy. The method comprises the steps that 1), molten steel is injected into tundish; 2), a lower covering agent is added to the tundish to keep the temperature of the molten steel so as to prevent secondary oxidation of the molten steel; and 3), an upper covering agent is added to the tundish to keep the temperature of the lower covering agent so as to prevent the surface of the lower covering agent from crusting. In the low-carbon low-silicon steel productionprocess, the upper covering agent such as low-cost carbonized rice hulls covers the high-cost lower cover agent, the surface of the lower covering agent can be prevented from generating crusting phenomenon, the casting blank slag inclusion problem caused by crusting of the lower covering agent is avoided, the consumption of the high-cost lower covering agent is lowered, and the manufacturing costis lowered.

Owner:HEBEI IRON AND STEEL

Biogas Fermentation System of Panlong-style Cloth Bacteria in Several Partitions

ActiveCN104513789BGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelEnvironmental engineeringMechanical engineering

Owner:河北德瑞环保设备有限公司

Ultra-efficient biogas generation device that promotes the circulation of biogas slurry by air pressure

ActiveCN104496142BFull flowEvenly distributedWaste based fuelBiological sludge treatmentProcess engineeringEnvironmental engineering

The invention discloses an ultra-high-efficiency biogas generating device that air pressure promotes biogas slurry circulation, which includes a feed pipe, a discharge pipe, and a U-shaped fermentation pipe. The U-shaped fermentation pipe is placed horizontally, and the feed pipe and the discharge pipe are connected vertically. At both ends of the U-shaped fermentation pipeline, a water pressure room is placed on the upper part of the U-shaped fermentation pipeline. The connection between the water pressure room and the feed pipe is the drain hole of the feed pipe, and the connection between the water pressure room and the discharge pipe is the discharge hole of the discharge pipe. A feed pipe air baffle is set at the connection position between the U-shaped fermentation pipeline and the feed pipe, and a discharge pipe air baffle is set at the connection position between the U-shaped fermentation pipeline and the discharge pipe; the U-shaped fermentation pipeline is provided with a gas collecting pipe. The drain hole of the feed pipe is provided with a one-way valve to control the one-way flow of the biogas slurry in the water pressure chamber into the feed pipe. The fermentation route is long, using the control of water pressure difference and one-way valve to realize the full flow of biogas slurry in the system, and to drive the uniform distribution of bacteria, effectively prevent crusting, high gas production rate, suitable for large-scale production.

Owner:广东新科迪环保科技有限公司

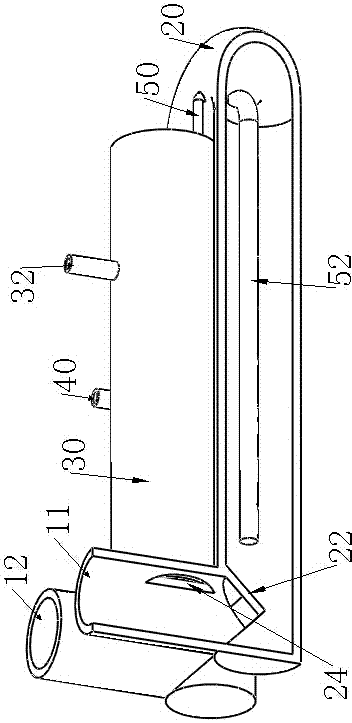

Method for Promoting Biogas Generation System with Evenly Distributed Bacterial Species by Bacteria Spreading Device

InactiveCN104529118BAchieve circular flowImprove filtration efficiencyWaste based fuelBiological sludge treatmentDraining tubeEngineering

The invention discloses a method for producing biogas by use of a biogas generation system with a bacterium distributor for promoting even distribution of bacteria. The method comprises the following steps that: fermentation raw materials are poured into a U-shaped fermentation pipeline via a feed pipe and fermented to produce biogas, the biogas is gathered in the space between a feed pipe gas baffle plate and a discharge pipe gas baffle plate in the U-shaped fermentation pipeline so as to occupy the space in the fermentation pipeline and push the biogas slurry in the fermentation pipeline to flow into the feed pipe, the discharge pipe and the bacterium distributor and further flow into a water pressure chamber unidirectionally via a discharge pipe drain hole and flow into the water pressure chamber via the drain pipe of the bacterium distributor; and when the biogas stored in the fermentation pipeline is output to the outside via a gas collecting pipe, the pressure of the biogas in the fermentation pipeline drops and the biogas stored in the water pressure chamber unidirectionally flows into the fermentation pipeline via the feed pipe drain hole and returns to the fermentation pipeline via the drain pipe of the bacterium distributor, and therefore, circular flow of the biogas slurry is completed.

Owner:康洪祥

Super-efficient biogas generation system with function of promoting biogas liquid flowing and bacterial distribution under gas pressure

ActiveCN104512992AAchieve circular flowImprove filtration efficiencyWaste based fuelBiological sludge treatmentProcess engineeringEnvironmental engineering

The invention discloses a super-efficient biogas generation system with a function of promoting biogas liquid flowing and bacterial distribution under the gas pressure. The biogas generation system is characterized in that a feeding pipe and a discharging pipe are vertically connected to the two sides of a U-shaped fermentation pipeline; a water pressure chamber is formed in the upper part of the U-shaped fermentation pipeline; a feeding pipe water outlet is formed in the joint of the water pressure chamber and the feeding pipe; a discharging pipe water outlet is formed in the joint of the water pressure chamber and the discharging pipe; a feeding pipe gas baffle is arranged at the joint of the U-shaped fermentation pipeline and the feeding pipe; a discharging pipe gas baffle is arranged at the joint of the U-shaped fermentation pipeline and the discharging pipe; a gas collecting pipe is arranged on the U-shaped fermentation pipeline; the water pressure chamber is connected with a bacterial distribution device; a water discharge pipe of the bacterial distribution device is connected to one side, deviating from the feeding pipe and the discharging pipe, of the water pressure chamber; the other side of the water discharge pipe is connected and fixed to a U-shaped bacterial distribution pipe in the fermentation pipeline; the U-shaped bacterial distribution pipe is matched with the fermentation pipeline in shape and extends into the fermentation pipeline; a plurality of bacterial distribution holes are vertically formed in the U-shaped bacterial distribution pipe.

Owner:六安皖智知识产权运营有限公司

Method for generating biogas in intertwined partitioned super-efficient bacteria distribution biogas fermentation system

InactiveCN104498344AGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelProcess engineeringSlurry

The invention discloses a method for generating biogas in an intertwined partitioned super-efficient bacteria distribution biogas fermentation system. The method includes the steps: pouring fermentation raw materials from a feeding pipe and fermenting the raw materials in a fermentation pipeline to generate the biogas; using the biogas stored in an optional fermentation area. The biogas is respectively gathered in fermentation areas formed among the feeding / discharging pipe and adjacent gas baffle plates or between the adjacent gas baffle plates, occupies space in the fermentation areas, squeezes biogas slurry in convection and flows towards the feeding pipe and the discharging pipe, and the biogas slurry in the fermentation pipeline flows into a water pressure space through a drain hole of the discharging pipe along with rise of the liquid level of the biogas slurry in the feeding pipe and the discharging pipe. The pressure of the biogas stored in the optional fermentation area is reduced, the biogas slurry in an adjacent fermentation area flows towards the optional fermentation area, and the biogas slurry stored in the water pressure space unidirectionally flows into the fermentation pipeline through a drain hole of the feeding pipe and flows back into the fermentation pipeline through the drain hole of the discharging pipe to supplement reduced biogas space, so that circulating flow of the biogas slurry is finished.

Owner:陆永柱

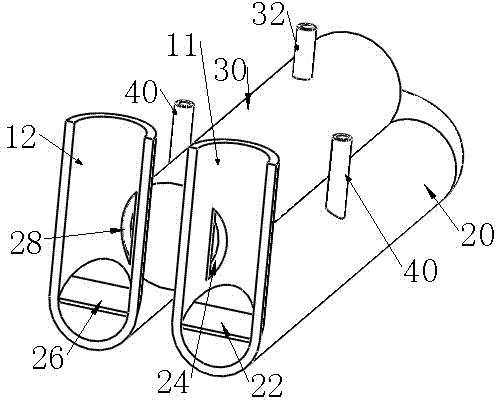

Hydraulic double-pipe channel type biogas generator

InactiveCN104496144BAchieve circular flowImprove filtration efficiencyWaste based fuelBiological sludge treatmentTube drainageProcess engineering

The invention discloses a hydraulic double-pipe channel type biogas generating device, which includes a feed pipe, a discharge pipe, and a U-shaped fermentation pipe. The U-shaped fermentation pipe is placed horizontally, and the feed pipe and the discharge pipe are vertically connected to the U-shaped fermentation pipe. At both ends of the pipeline, a water pressure room is placed on the upper part of the U-shaped fermentation pipeline. A feed pipe air baffle is set at the connection position between the pipeline and the feed pipe, and a discharge pipe air baffle is set at the connection position between the U-shaped fermentation pipeline and the discharge pipe; The position of the drainage hole is provided with a one-way valve to control the one-way flow of the biogas slurry in the fermentation pipeline into the water pressure room, and the one-way valve is set on the drain hole of the feed pipe to control the one-way flow of the biogas slurry in the water pressure room into the feed pipe; The channel-type fermentation device has a long fermentation route, and uses the control of water pressure difference and one-way valve to realize the full flow of biogas slurry in the system, and to drive the uniform distribution of bacteria, effectively preventing crusting, high gas production rate, suitable for Large-scale production.

Owner:徐幸利 +2

Methane generation system hydraulically and pneumatically promoting uniform bacteria distribution

ActiveCN104498339AGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelSlurryMechanical engineering

A methane generation system hydraulically and pneumatically promoting uniform bacteria distribution comprises a feeding pipe, a discharging pipe and a U-shaped fermentation pipeline. The U-shaped fermentation pipeline is horizontally placed, the feeding pipe and the discharging pipe are vertically connected with two end sides of the U-shaped fermentation pipeline, a water pressure space is formed on the U-shaped fermentation pipeline, a feeding pipe drain hole is formed in the joint of the water pressure space and the feeding pipe, a discharging pipe drain hole is formed in the joint of the water pressure space and the discharging pipe, a feeding pipe gas baffle plate is arranged at the joint of the U-shaped fermentation pipeline and the feeding pipe, a discharging pipe gas baffle plate is arranged at the joint of the U-shaped fermentation pipeline and the discharging pipe, at least one gas baffle plate is arranged between the discharging pipe gas baffle plate and the feeding pipe gas baffle plate, a fermentation area is formed among the feeding / discharging pipe and the adjacent gas baffle plates or between the adjacent gas baffle plates, an independent gas collecting pipe is arranged at the top of each fermentation area, the top of each fermentation area is connected with the independent gas collecting pipe, and a valve is arranged on each gas collecting pipe. A U-shaped channel-type fermentation device is used, a fermentation path is long, biogas slurry sufficiently flows in the system by control of water pressure difference and one-way valves, bacteria are driven to be uniformly distributed, crusting is effectively prevented, and gas generating rate is high.

Owner:海门名驰工业设计有限公司

Method for generating methane with a methane generating device with a curved ultra-long fermentation path

ActiveCN104498335BFull flowEvenly distributedGas production bioreactorsWaste based fuelMethane fermentationSlurry

The invention discloses a method for generating methane in a methane generation device with a bent super-long fermentation path. The method includes the steps: pouring fermentation raw materials from a feeding pipe and fermenting the raw materials in a fermentation pipeline to generate the methane; using the methane stored in an optional fermentation area. The methane is respectively gathered in fermentation areas formed among the feeding / discharging pipe and adjacent gas baffle plates or between the adjacent gas baffle plates, occupies space in the fermentation areas, squeezes biogas slurry in convection and flows towards the feeding pipe, the discharging pipe and a bacteria distribution device, and the biogas slurry in the fermentation pipeline unidirectionally flows into a water pressure space through a drain hole of the discharging pipe and flows into the water pressure space through a drain pipe of the bacteria distribution device along with rise of the liquid level of the biogas slurry in the feeding pipe, the discharging pipe and the bacteria distribution device. The pressure of the methane stored in the optional fermentation area is reduced, the biogas slurry in an adjacent fermentation area flows towards the optional fermentation area, and the biogas slurry stored in the water pressure space unidirectionally flows back into the feeding pipe through a drain hole of the feeding pipe and flows back into the fermentation pipeline through the drain pipe of the bacteria distribution device to supplement reduced methane space, so that circulating flow of the biogas slurry is finished.

Owner:六安皖智知识产权运营有限公司

U-shaped biogas fermentation system

ActiveCN104496143AReduce air pressureFull flowWaste based fuelBiological sludge treatmentProcess engineeringEnvironmental engineering

The invention discloses a U-shaped biogas fermentation system. The U-shaped biogas fermentation system comprises a feed pipe, a discharge pipe, a U-shaped fermentation pipeline, wherein the U-shaped fermentation pipeline is arranged horizontally; the feed pipe and the discharge pipe are vertically connected to the two end sides of the U-shaped fermentation pipeline; a water pressure chamber is arranged on the upper part of the U-shaped fermentation pipeline; a feed pipe drain hole is formed in the connection position of the water pressure chamber and the feed pipe, while a discharge pipe drain hole is formed in the connection position of the water pressure chamber and the discharge pipe; a feed pipe gas stop plate is arranged at the connection position of the U-shaped fermentation pipeline and the feed pipe, while a discharge pipe gas stop plate is arranged at the connection position of the U-shaped fermentation pipeline and the discharge pipe; a gas collecting pipe is arranged on the U-shaped fermentation pipeline; a one-way valve for controlling the biogas slurry in the U-shaped fermentation pipeline to flow into the water pressure chamber in one direction is arranged at the position of the discharge pipe drain hole; a U-shaped channel-type fermentation device is adopted and the fermentation path is long; sufficient flowing of the biogas slurry in the system is realized by virtue of the water pressure difference and the control of the one-way valve; besides, bacteria are distributed evenly to effectively prevent crusting; the U-shaped biogas fermentation system is high in gas generation rate and suitable for large-scale production.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

Efficient biogas generation system capable of improving turbulence effect of biogas slurry by virtue of biogas pressure

ActiveCN104529117AFull flowEvenly distributedWaste based fuelBiological sludge treatmentProcess engineeringSlurry

The invention discloses an efficient biogas generation system capable of improving the turbulence effect of biogas slurry by virtue of biogas pressure. A U-shaped fermentation pipeline is horizontally arranged, a material inlet pipe and a material outlet pipe are vertically connected with both end sides of the U-shaped fermentation pipeline, a hydraulic pressure room is arranged at the upper part of the U-shaped fermentation pipeline, the connection position of the hydraulic pressure room and the material inlet pipe is a material inlet pipe drainage hole, the connection position of the hydraulic pressure room and the material outlet pipe is a material outlet pipe drainage hole, a material inlet pipe baffle plate is arranged at the connection position of the U-shaped fermentation pipeline and the material inlet pipe, a material outlet pipe baffle plate is arranged at the connection position of the U-shaped fermentation pipeline and the material outlet pipe and a biogas collection pipe is arranged on the U-shaped fermentation pipeline; the hydraulic pressure room is also connected with a bacteria-distribution device, one end side, departing from the material inlet pipe and the material outlet pipe, of the hydraulic pressure room is connected with a drainage pipe of the bacteria-distribution device, the other end of the drainage pipe is connected with a U-shaped bacteria-distribution pipe which is fixed inside the fermentation pipeline, the U-shaped bacteria-distribution pipe corresponds to the fermentation pipeline in shape and extends into the fermentation pipeline and a plurality of vertically upwards bacteria-distribution holes are formed in the U-shaped bacteria-distribution pipe.

Owner:六安皖智知识产权运营有限公司

Biogas generation method of biogas generation system with strain distribution achieved under driving of biogas slurry flowing promoted by air pressure

InactiveCN104478188AAchieve circular flowImprove filtration efficiencySpecific water treatment objectivesWaste based fuelProcess engineeringFermentation

The invention discloses a biogas generation method of a biogas generation system with strain distribution achieved under driving of biogas slurry flowing promoted by air pressure. The biogas generation method comprises the following steps that fermentation raw materials are poured into a U-shaped fermentation pipeline through a feeding pipe for fermentation, so that biogas is generated, the biogas is gathered in a space between a feeding pipe gas blocking plate and a discharging pipe gas blocking plate in the U-shaped fermentation pipe, and the biogas occupies the space in the fermentation pipe and squeezes biogas slurry in the fermentation pipe to flow into a drainage pipe for the feeding pipe, a discharging pipe and a strain distribution device and then flow into a water pressure chamber through a drainage hole of the discharging pipe, a drainage hole of the feeding pipe and a drainage pipe of the strain distribution device; when the biogas stored in the fermentation pipe is delivered to the outside through a gas collection pipe, the pressure of the biogas in the fermentation pipe is lowered, the biogas slurry stored in the water pressure chamber flows back into the fermentation pipe through the drainage hole of the discharging pipe, the drainage hole of the feeding pipe and the drainage pipe of the strain distribution device, and then circulating flowing of the biogas slurry is achieved.

Owner:潘磊

Super-efficient biogas generation device pneumatically promoting circulating flow of biogas slurry

ActiveCN104496142AFull flowEvenly distributedWaste based fuelBiological sludge treatmentProcess engineeringSlurry

The invention discloses a super-efficient biogas generation device pneumatically promoting circulating flow of biogas slurry. The super-efficient biogas generation device comprises a feeding pipe, a discharging pipe and a U-shaped fermentation pipeline, the U-shaped fermentation pipeline is horizontally placed, the feeding pipe and the discharging pipe are vertically connected with two end sides of the U-shaped fermentation pipeline, a water pressure space is formed in the upper portion of the U-shaped fermentation pipeline, a feeding pipe drain hole is formed in the joint of the water pressure space and the feeding pipe, a discharging pipe drain hole is formed in the joint of the water pressure space and the discharging pipe, a feeding pipe gas baffle plate is arranged at the joint of the U-shaped fermentation pipeline and the feeding pipe, a discharging pipe gas baffle plate is arranged at the joint of the U-shaped fermentation pipeline and the discharging pipe, a gas collecting pipe is arranged on the U-shaped fermentation pipeline, a one-way valve is arranged at the feeding pipe drain hole and controls the biogas slurry in the water pressure space to unidirectionally flow into the feeding pipe, and the position of the feeding pipe drain hole is lower than that of the discharging pipe drain hole. A U-shaped channel-type fermentation device is used, a fermentation path is long, the biogas slurry sufficiently flows in a system by control of water pressure difference and the one-way valve, bacteria are driven to be uniformly distributed, crusting is effectively prevented, gas generating rate is high, and the super-efficient biogas generation device is suitable for large-scale production.

Owner:广东新科迪环保科技有限公司

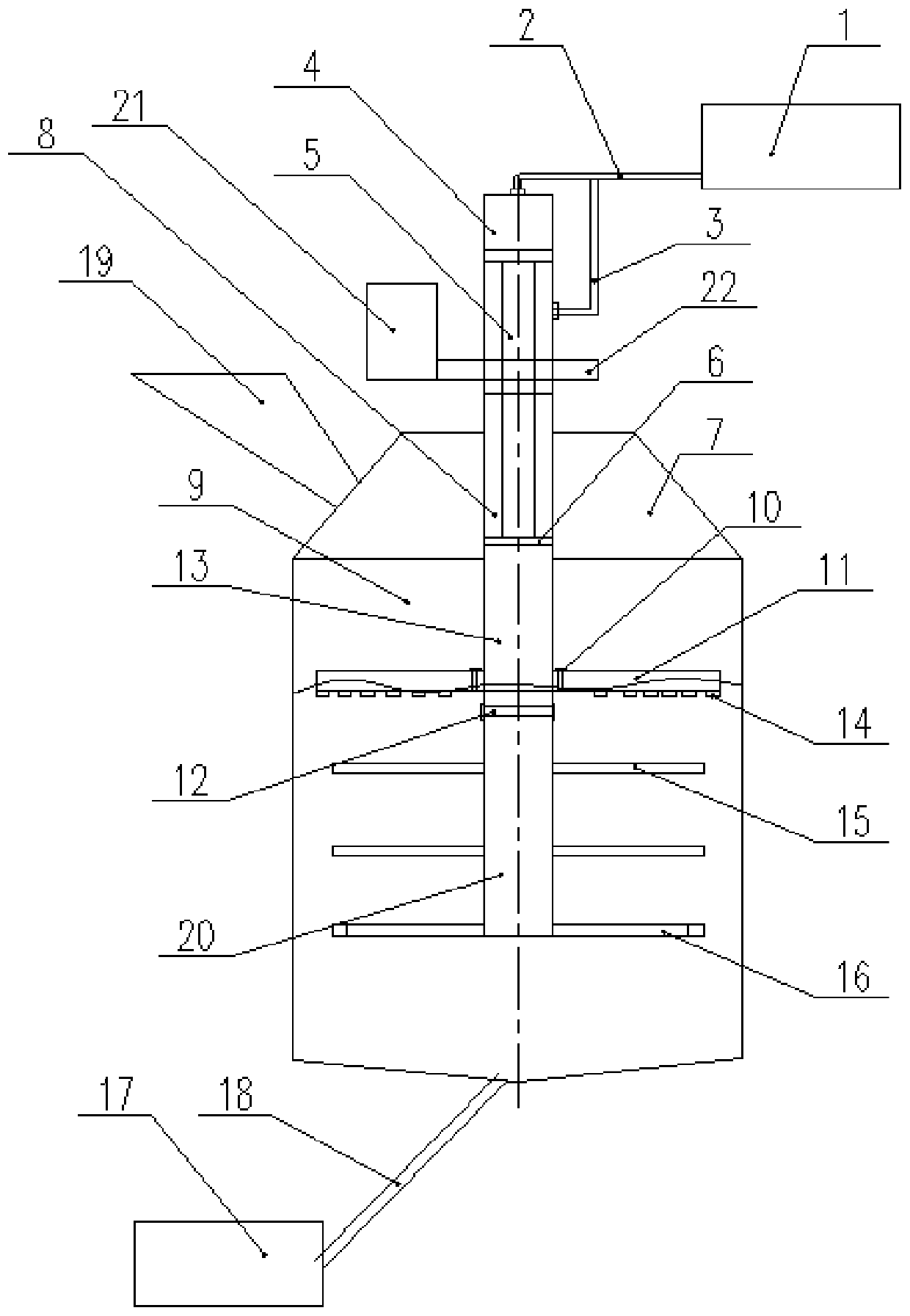

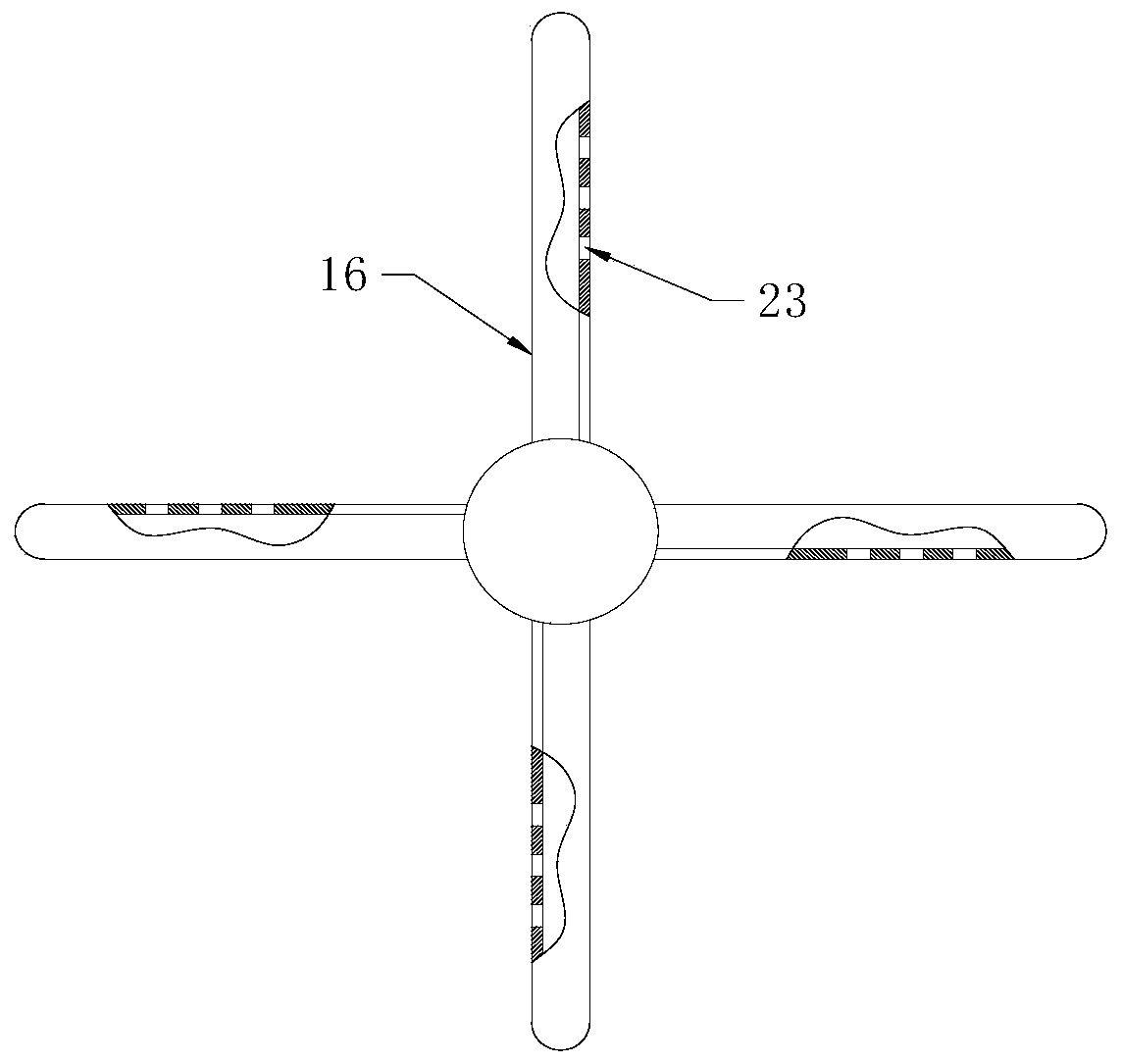

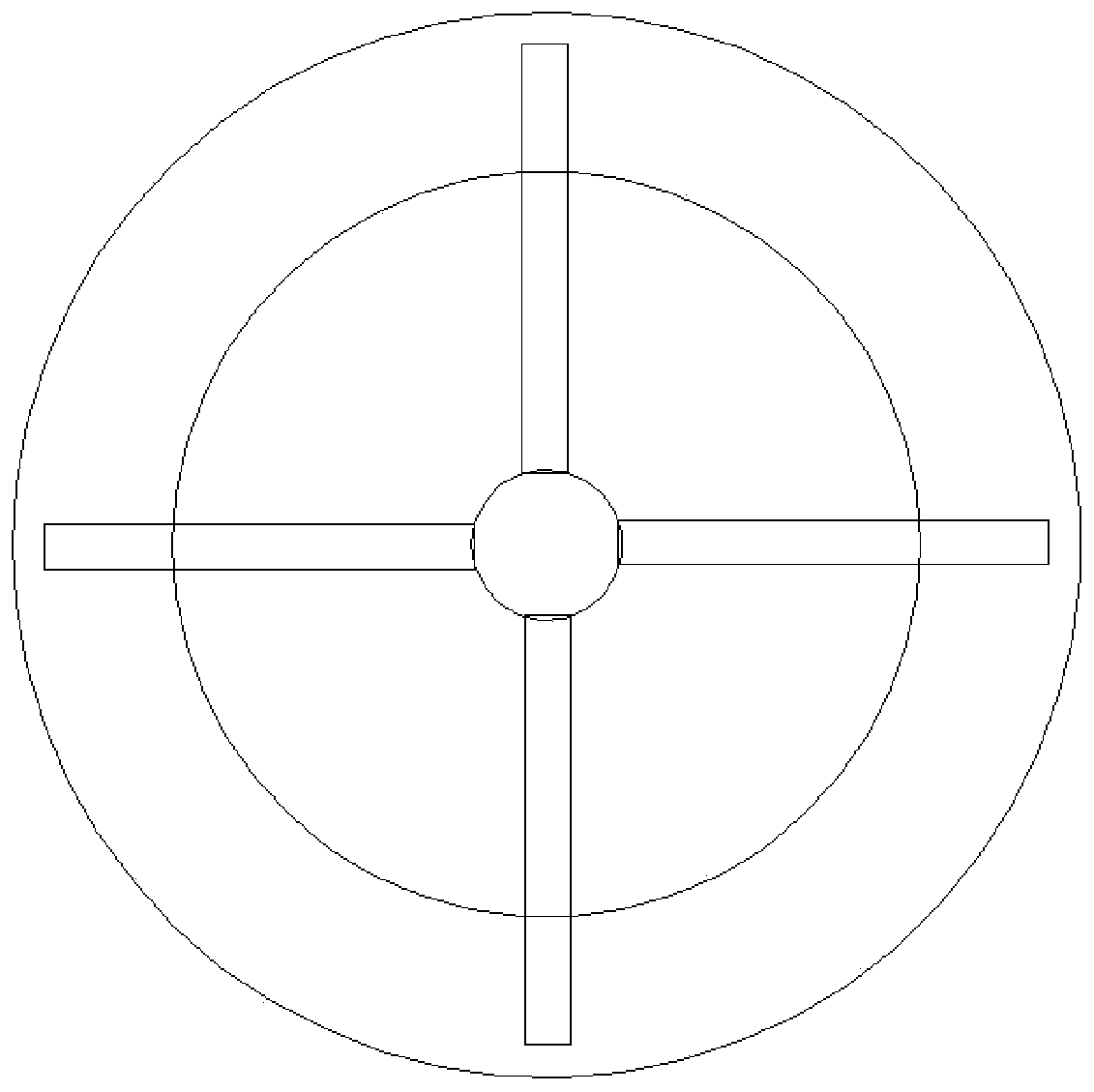

Novel rod liquid stirring type feces anaerobic fermentation device

PendingCN110295103AGood suspensionImprove uniformityBioreactor/fermenter combinationsBiological substance pretreatmentsHydraulic cylinderAnimal feces

The invention discloses a novel rod liquid stirring type feces anaerobic fermentation device. The device comprises a fermentation tank, a dirt inlet and a dirt suction structure, a hollow stand columnis driven by a driving structure to rotate is arranged in the center of the fermentation tank, a hydraulic cylinder is arranged on the top of the hollow stand column, and the hollow stand column is divided into a suction cavity and a liquid discharge cavity; a piston rod of the hydraulic cylinder penetrates into the suction cavity and provided with a suction head dividing the suction cavity intoa vacuum cavity and a liquid suction cavity, a hollow liquid suction arm with a liquid suction opening is arranged on the outer wall of the liquid absorption cavity, and a liquid inlet check valve isarranged at the communication portion of the hollow liquid suction arm and the liquid suction cavity; multiple hollow liquid discharge arms provided with liquid discharge openings formed in the side walls are uniformly arranged on the outer wall of the liquid discharge cavity in the circumferential direction. According to the feces anaerobic fermentation device, the uniformly of fermentation solution mixing is greatly improved, the feces suspension effect is improved, and meanwhile the crusting phenomenon is avoided.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Method for producing biogas by Panlong ultra-high-efficiency biogas fermentation system

ActiveCN104498341BFull flowEvenly distributedGas production bioreactorsWaste based fuelBiogas productionAtmospheric pressure

The invention discloses a biogas production method for a dragon type super-effective biogas fermentation system. The biogas production method for the dragon type super-effective biogas fermentation system includes steps that fermentation raw material is poured into a fermentation pipeline from a feed pipe, the fermentation raw material ferments in the fermentation pipeline to generate biogas, biogas is accumulated in fermentation zones formed between the feed / discharge pipe and adjacent gas baffle plate or between adjacent gas baffle plates, the biogas takes up the space in the fermentation zones and extrudes biogas slurry to generate convection and flow to the feed pipe and discharge pipe, and the biogas slurry in the fermentation pipeline inflows to a water pressure room in one direction through a water drain hole of the discharge pipe along with the rising of the biogas slurry surfaces in the feeding pipe and discharge pipe; the biogas in any one of the fermentation zones is used to reduce the biogas pressure in the fermentation zone, the biogas slurry in the adjacent fermentation zones flows to the fermentation zone, and the biogas slurry stored in the water pressure room returns to the fermentation pipeline in one direction through a water drain hole of the feed pipe to complement the reduced biogas space so as to finish circular biogas slurry flow.

Owner:启东市和洪农副产品专业合作社

Method for producing methane by using methane fermentation generator based on one-way flowing of biomass fluid to promote uniform distribution of strains

ActiveCN104556614AReduce air pressureFull flowWaste based fuelBiological sludge treatmentMethane fermentationProcess engineering

The invention discloses a method for producing methane by using a methane fermentation generator based on one-way flowing of biomass fluid to promote uniform distribution of strains. According to the method, fermentation materials are poured into a U-shaped fermentation pipeline through a feeding pipe and fermented to produce methane which gathers in a space between a gas baffle of the feeding pipe and a gas baffle of a discharge pipe in the U-shaped fermentation pipeline, occupies the space in the fermentation pipeline and squeezes the biomass fluid in the fermentation pipeline to move to the feeding pipe, the discharge pipe and a strain distributor, and the biomass fluid firstly unidirectionally flows into a hydraulic chamber through a drain hole of the discharge pipe and then unidirectionally flows to the hydraulic chamber through a drainage pipe of the strain distributor when the level of the biomass fluid in the hydraulic chamber reaches the lowest position of the drainage pipe of the strain distributor; and when the methane stored in the fermentation pipeline is output to the outside through a gas collection pipe, the pressure of the methane in the fermentation is reduced, and the biomass fluid stored in the hydraulic chamber unidirectionally returns to the fermentation pipeline through the drain hole of the feeding pipe to finish the circulation flowing of the biomass fluid.

Owner:海门市初享工业设计有限公司

Methane generation system in several U-shaped fermentation zones

InactiveCN104498342BFull flowEvenly distributedGas production bioreactorsWaste based fuelGeneration rateMethane fermentation

The invention provides a U-shaped methane generation system with multiple fermentation regions. The U-shaped methane generation system comprises a feed pipe, a discharge pipe and a U-shaped fermentation pipeline, wherein the U-shaped fermentation pipeline is arranged horizontally; the feed pipe and the discharge pipe are vertically connected to the two end sides of the U-shaped fermentation pipeline; a water pressure chamber is arranged on the upper part of the U-shaped fermentation pipeline; a feed pipe drain hole is formed in the connection position of the water pressure chamber and the feed pipe, while a discharge pipe drain hole is formed in the connection position of the water pressure chamber and the discharge pipe; a feed pipe gas stop plate is arranged at the connection position of the U-shaped fermentation pipeline and the feed pipe, while a discharge pipe gas stop plate is arranged at the connection position of the U-shaped fermentation pipeline and the discharge pipe; at least one gas stop plate is further arranged between the feed pipe gas stop plate and the discharge pipe gas stop plate; a fermentation region is formed between the feed / discharge pipe and the adjacent gas stop plate or the adjacent gas stop plate; an independent gas collecting pipe is arranged at the top of each fermentation region; the top of each fermentation region is connected with the independent gas collecting pipe and a valve is arranged on the gas collecting pipe; a U-shaped channel-type fermentation device is adopted and the fermentation path is long; sufficient flowing of the biogas slurry in the system is realized by virtue of the water pressure difference and the control of a one-way valve; besides, bacteria are distributed evenly to effectively prevent crusting; the U-shaped methane generation system with multiple fermentation regions is high in gas generation rate and suitable for large-scale production.

Owner:刘国东 +2

Biogas fermentation device with one-way flow of biogas slurry to promote uniform distribution of bacteria

ActiveCN104609690BFull flowEvenly distributedSpecific water treatment objectivesWaste based fuelDraining tubeMethane fermentation

The invention discloses a biogas fermentation device for promoting uniform distribution of strains through unidirectional biogas slurry flow. The biogas fermentation device comprises a feed pipe, a discharge pipe and a U-shaped fermentation pipeline, wherein a water pressure room is placed at the upper part of the U-shaped fermentation pipeline; the water pressure room is connected to a bacteria distribution device; the bacteria distribution device consists of a drain pipe, a U-shaped bacteria distribution pipe and bacteria distribution holes; the side, deviating from the feed pipe and the discharge pipe, of the water pressure room is connected to the drain pipe of the bacteria distribution device, and the other side of the drain pipe is connected to the U-shaped bacteria distribution pipe fixed in the fermentation pipeline; a one-way valve for controlling biogas slurry in the water pressure room to unidirectionally flow in the feed pipe is arranged on a feed pipe drainage hole, a one-way valve for controlling biogas slurry in the discharge pipe to unidirectionally flow in the water pressure room is arranged on a discharge pipe drain hole, and a one-way valve for controlling biogas slurry in the fermentation pipeline to unidirectionally flow in the water pressure room is arranged on the drain pipe of the bacteria distribution device; the horizontal plane where the lowest point of the drain hole of the discharge pipe is positioned, is lower than the horizontal plane where the lowest point of the drain pipe of the bacteria distribution device is positioned.

Owner:六安皖智知识产权运营有限公司

Method for generating biogas by hydraulic double-pipe channel type biogas generating device

InactiveCN104529119BAchieve circular flowImprove filtration efficiencyGas production bioreactorsWaste based fuelProcess engineeringSlurry

The invention discloses a method for generating biogas by a hydraulic double-pipe channel type biogas generating device. The steps include: pouring fermentation materials into a U-shaped fermentation pipeline through a feed pipe and fermenting to generate biogas, and the biogas is accumulated in the U-shaped fermentation pipeline. In the space between the feed pipe air baffle and the discharge pipe air baffle, biogas occupies the space in the fermentation pipe and squeezes the biogas slurry in the fermentation pipe to flow into the feed pipe and discharge pipe, and drain through the discharge pipe The hole flows into the water pressure room in one direction; when the biogas stored in the fermentation pipeline is output to the outside through the gas collecting pipe, the pressure of the biogas in the fermentation pipeline drops, and the biogas slurry stored in the water pressure room flows back into the fermentation pipeline through the drainage hole of the feed pipe , to complete the circulation of biogas slurry.

Owner:尹铁力 +6

Method for producing methane by virtue of bent-type multi-zone fermentation super-efficient methane generation system

InactiveCN104531512AGood convection stirring effectImprove distributionGas production bioreactorsWaste based fuelWater dischargeSlurry

The invention discloses a method for producing methane by virtue of a bent-type multi-zone fermentation super-efficient methane generation system. The method comprises the following steps: pouring a fermenting raw material from a feeding pipe and fermenting in fermenting pipelines to produce methane, respectively gathering methane inside fermentation zones formed between a material inlet / outlet pipe and adjacent air baffle plates or between adjacent air baffle plates so that methane occupies spaces inside the fermentation zones and squeezes biogas slurry to form convection; when the air pressure of methane stored inside the fermentation zone is reduced, enabling the biogas slurry inside the adjacent fermentation zones to flow towards the fermentation zones, wherein biogas slurry stored inside a hydraulic pressure room returns to the fermenting pipelines in a one-way manner through a water discharge hole of the feeding pipe and a water discharge pipe of a strain-distribution device and a water discharge pipe of the discharge pipe; and when the level of the biogas slurry stored inside the hydraulic pressure room is reduced below the lowest point of the water discharge hole in the discharge pipe, enabling biogas slurry stored inside the hydraulic pressure room to flow into the fermenting pipelines in a one-way manner through the water discharge hole of the feeding pipe and the water discharge pipe of the bacteria-distribution device.

Owner:陆永柱

Dragon type super-effective biogas fermentation system

ActiveCN104498337AFull flowEvenly distributedGas production bioreactorsWaste based fuelProcess engineeringSlurry

The invention discloses a dragon type super-effective biogas fermentation system. The dragon type super-effective biogas fermentation system comprises a feeding pipe, a discharge pipe and a U-shaped fermentation pipeline, the U-shaped fermentation pipeline is arranged horizontally, the feeding pipe and discharge pipe are vertically connected with two ends of the U-shaped fermentation pipeline, the upper part of the U-shaped fermentation pipeline is provided with a water pressure room, a water drain hole of the feeding pipe is formed in the joint between the water pressure room and the feeding pipe, a water drain hole of the discharge pipe is formed in the joint between the water pressure room and the discharge pipe, a feeding pipe gas baffle plate is arranged at the joint between the U-shaped fermentation pipeline and the feeding pipe, a discharge pipe gas baffle plate is arranged at the joint between the U-shaped fermentation pipeline and the discharge pipe, at least one gas baffle plate is arranged between the discharge pipe gas baffle plate and the feeding pipe gas baffle plate, a fermentation zone is formed between the feeding / discharge pipe and the adjacent gas baffle plate or between the adjacent gas baffle plates, and an independent gas gathering pipe is arranged at the top of each fermentation zone; the top of each fermentation zone is connected with the independent gas gathering pipe, and the gas gathering pipe is provided with a valve. By means of the U-shaped passage type fermentation device, the fermentation route is long, biogas slurry completely flows in the system under the control of water pressure difference and a check valve, the strain is driven to distribute uniformly, the crusting phenomenon is effectively avoided, and the gas productivity is high; the dragon type super-effective biogas fermentation system is suitable for scale production.

Owner:六安皖智知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com