Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

A processor and function technology, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

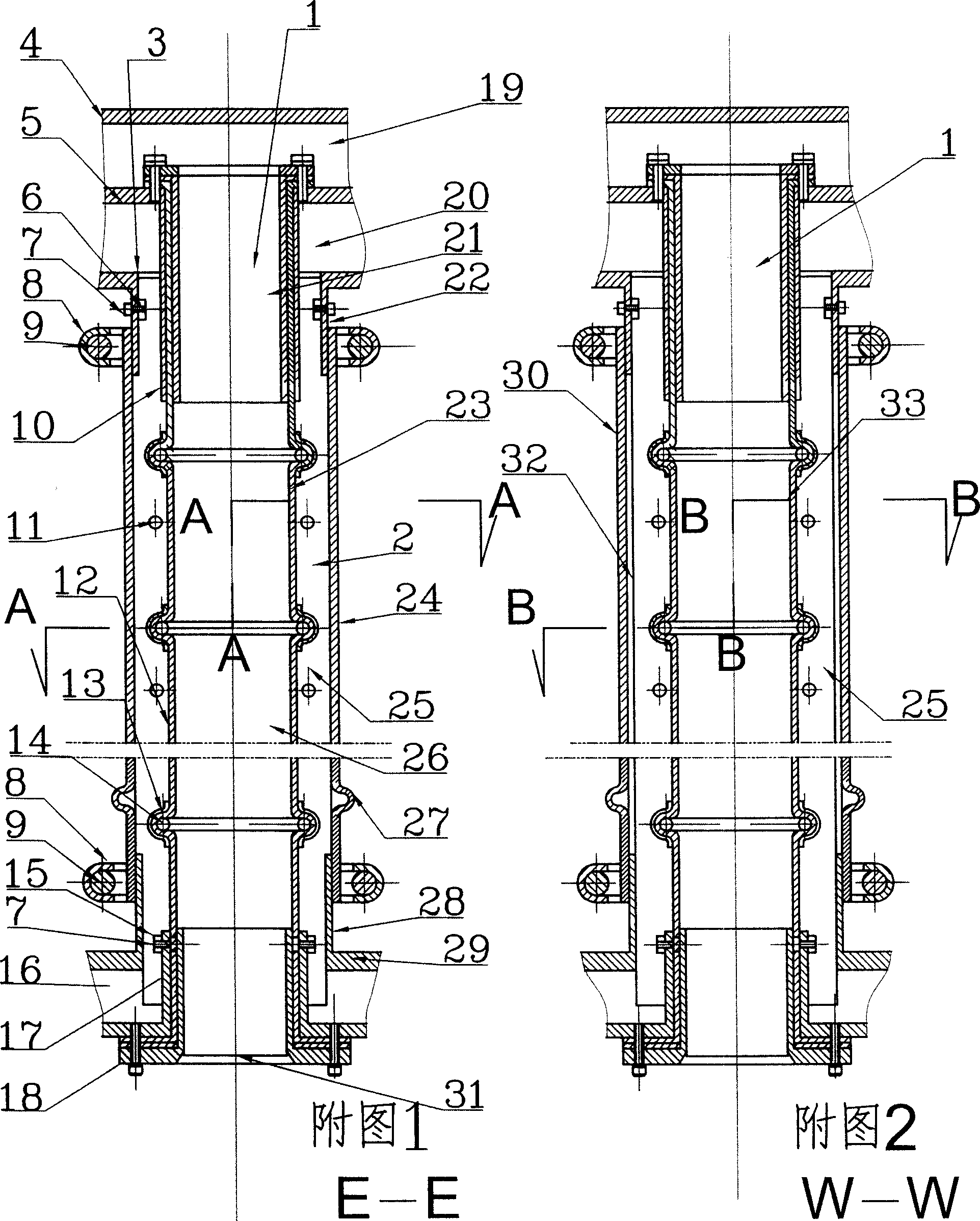

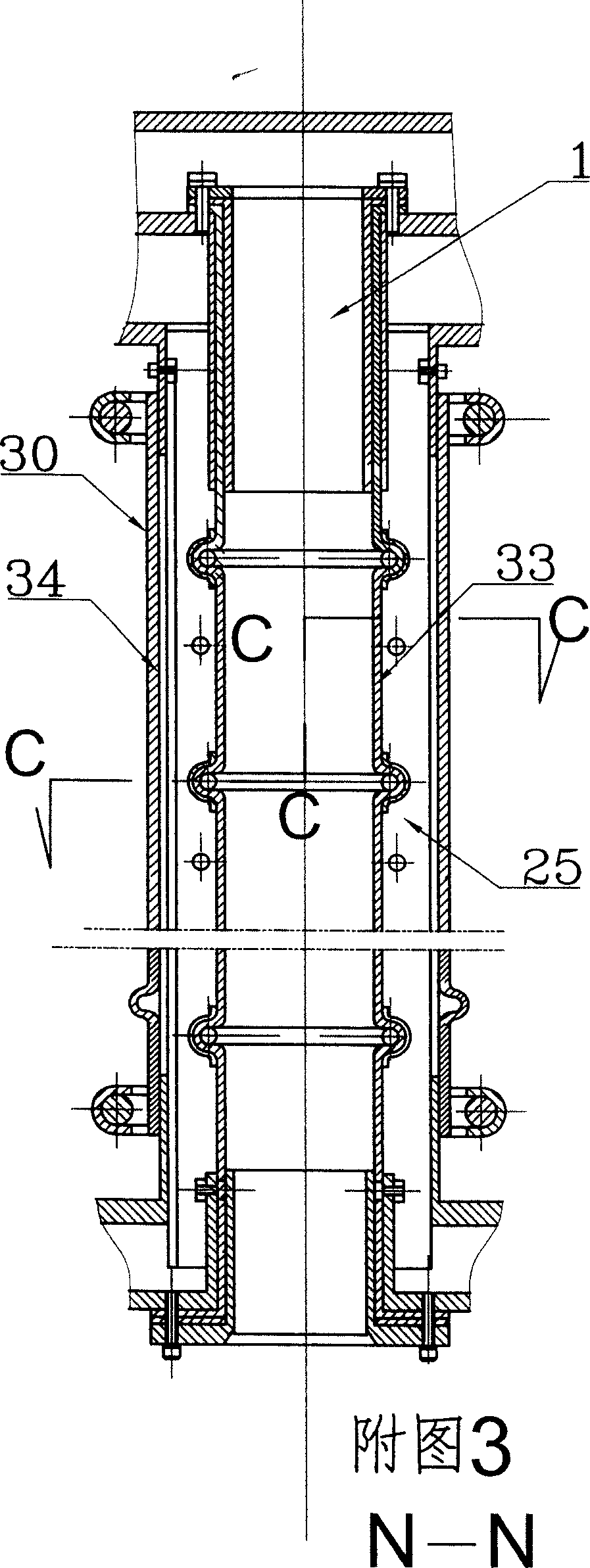

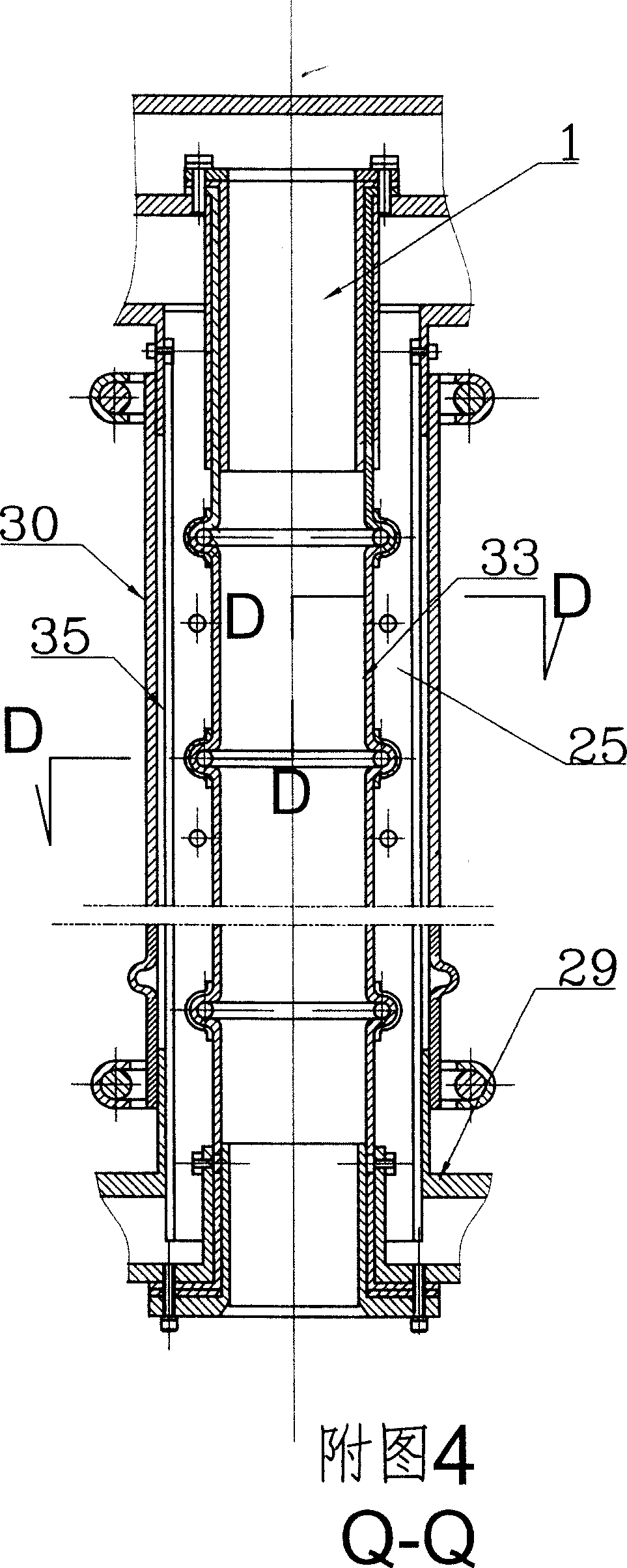

[0085] For easy understanding, the solid-liquid processor of the present invention will be further described below in conjunction with the accompanying drawings.

[0086] The flexible tube type solid-liquid disposer will not repeat the same parts in the embodiments described later and the previous embodiments; if there is no special description, the same reference numerals in the drawings represent the same meaning components, although they are used in different places; When the function of a certain part does not match the name on another occasion, this article will give a special description of the part; when there is no special indication in the process description, the valve is closed.

[0087] As shown in Figures 1 to 9, the filter element 40 includes four membrane units 1, an upper flange chamber 4 and a lower flange chamber 29; the centerlines of the major axes of the four membrane units are parallel to each other and aligned with the upper flange chamber 4 and the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com