Method for anaerobic fermentation of bloom blue algae

A cyanobacterial bloom and anaerobic fermentation technology, applied in biological sludge treatment, waste fuel, etc., can solve the problems of gas production failure, affecting the effective volume of anaerobic digester, low gas production efficiency, etc. The effect of prolonging the acidification time of cyanobacteria and increasing the effective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

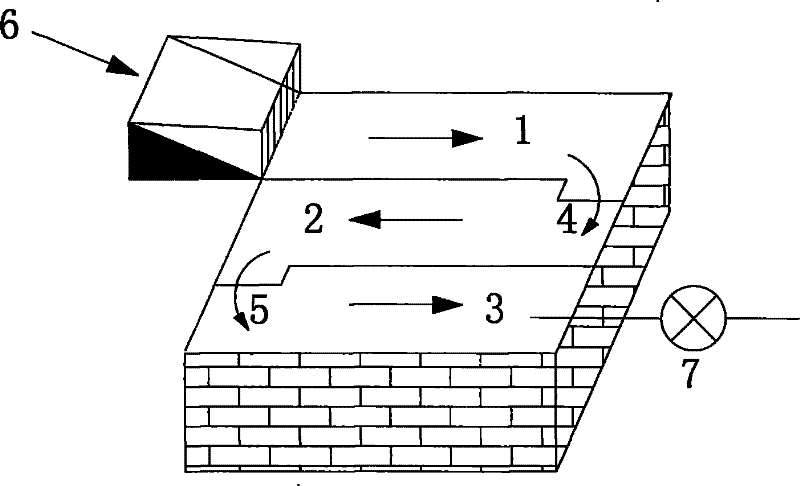

[0021] 1) Design of baffle-type acidification tank: divide the existing one-format acidification tank into 3 grids, leave a flat gap between the grids, and the flat gap 4 between the first grid 1 and the second grid 2 is far away from the feed port 6 At the other end, the flat gap 5 between the second grid 2 and the third grid 3 is located at the same end of the first grid feed 6, so that the bloom cyanobacteria is in the form of deflection when flowing in the acidification pond.

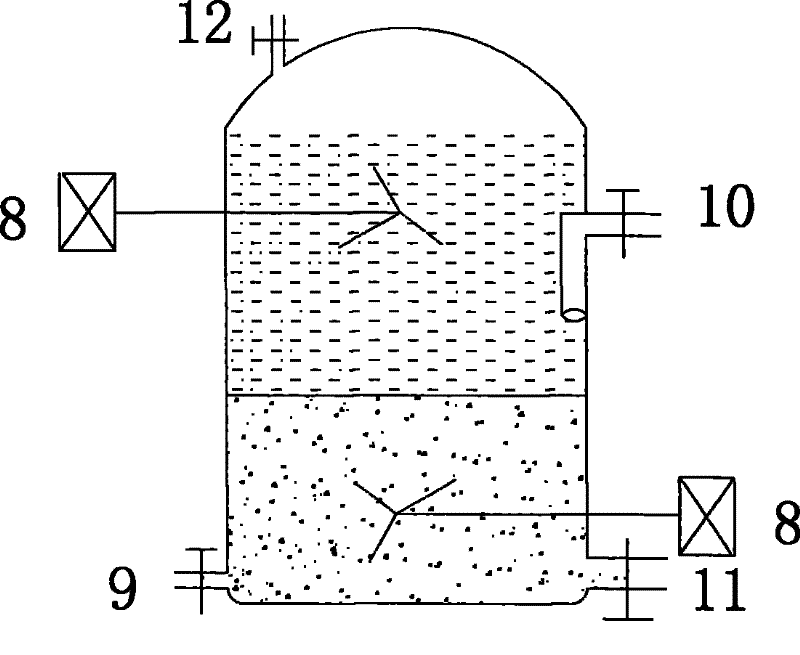

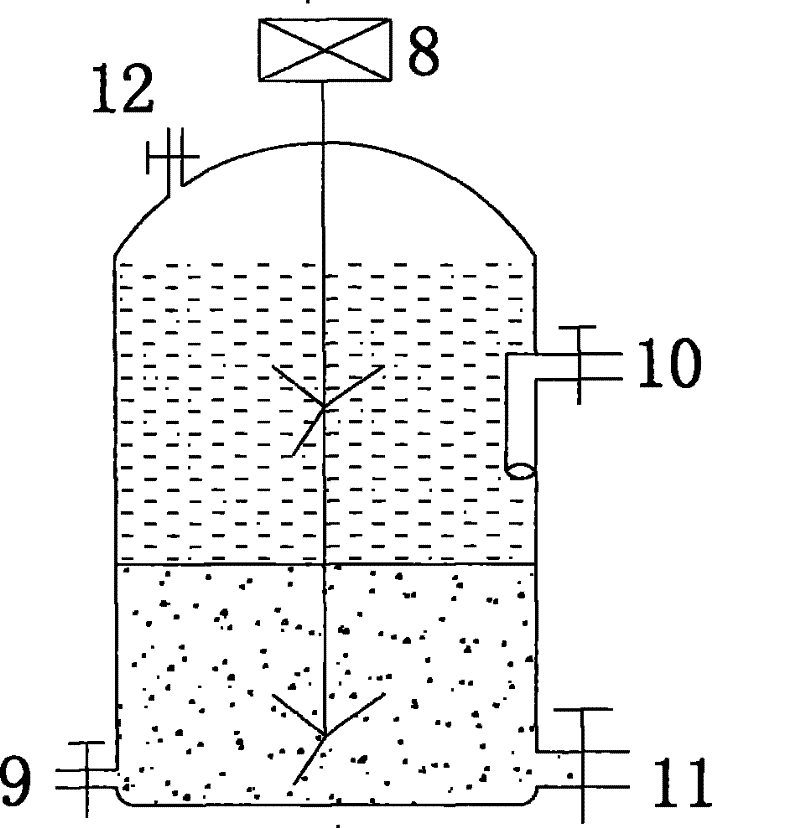

[0022] 2) Improved design of agitated anaerobic digester: add one or several agitators 8 to the upper part of the ordinary agitated anaerobic digester to ensure that the water bloom cyanobacteria floating on the upper part can be fully mixed with the bottom sludge to further The material 9 enters from the bottom of the pond, while the biogas slurry outlet 10 is set in the middle of the digester.

[0023] Example 1

[0024] The volume of the anaerobic digester is 80m 3 , the pool type is an improve...

Embodiment 2

[0026] The volume of the anaerobic digester is 80m 3 , the pool type is an improved stirring digester. Under the condition of 25 ℃, the design residence time is 15 days, and it can handle 5 tons of blooming blue-green algae (about 5m 3 . The acidification pool is designed as a baffle type in 3 formats ( figure 1 ), the effective volume of each grid is 5m 3 . Pump the salvaged bloom cyanobacteria into the transport vehicle, transport it to the cyanobacteria anaerobic fermentation treatment site, put the cyanobacteria into one end of the first compartment of the acidification tank, and transport one vehicle per day, each vehicle is 5 tons, when entering The cyanobacteria bloom in the 1st grid exceeds 5m 3 Finally, the blooming cyanobacteria overflows to the second grid through a flat gap at the other end of the first grid, and when the second grid is full, it overflows to the second grid through the flat gap at the other end opposite to the flat gap between the first and sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com