Patents

Literature

35results about How to "Improve the efficiency of biogas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

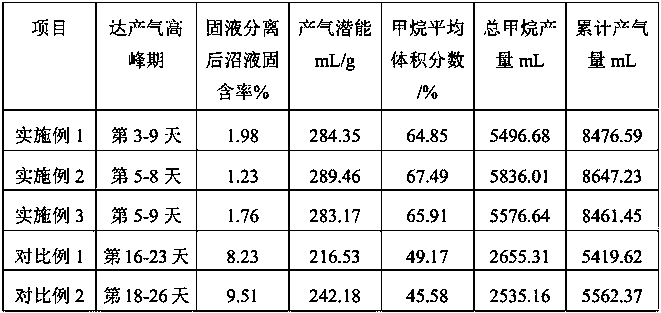

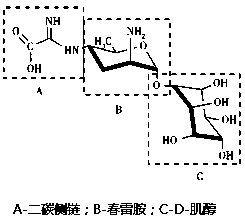

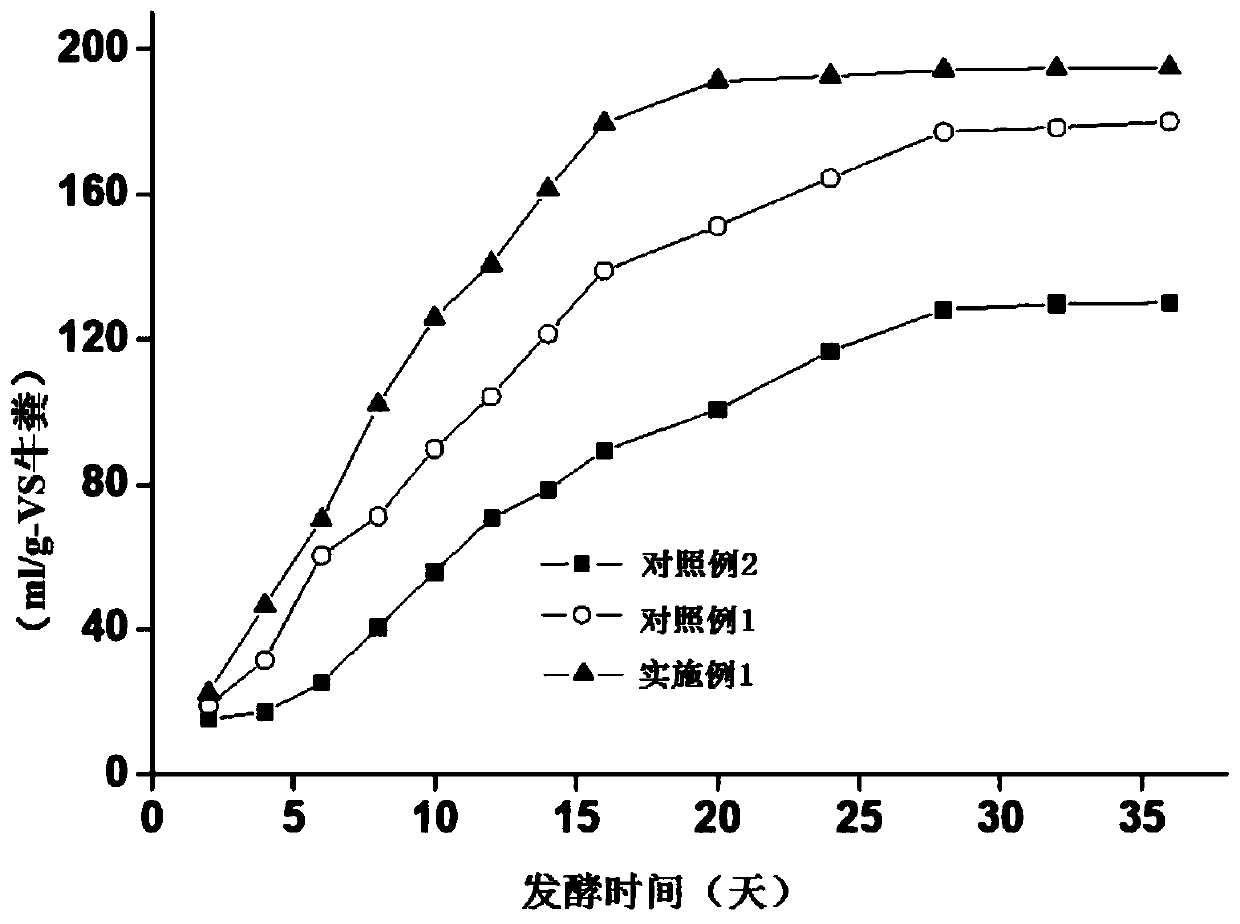

Method for generating biogas by anaerobic fermentation of vegetable straws with high content of lignocellulose

ActiveCN104357489AAchieve reductionRealize harmless useWaste based fuelFermentationCelluloseResource utilization

The invention relates to a method for generating biogas by anaerobic fermentation of vegetable straws with high content of lignocellulose. The method comprises the following steps: after crushing vegetable straws, adding catalysts A and B for pretreatment; mixing the pretreated vegetable straws with fresh cow manure and / or pig manure; adding active sludge as an inoculum; adjusting the pH value to 7.2-8.0; putting into an anaerobic reactor; and carrying out anaerobic fermentation at 30-37 DEG C. Reductive and harmless utilization of vegetable straw wastes can be effectively achieved by resource utilization of the vegetable straws and cow manure, so that the environmental damage is greatly reduced, and meanwhile, the generated biogas, biogas residues and biogas slurry are of relatively high economic values. The method is higher in fermentation starting speed, is hardly acidified in system and is more stable in fermentation process. Compared with single raw material fermentation of cow manure, the gas yielding hold time is lasting, the total gas yield is high, and the comprehensive cost is low.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

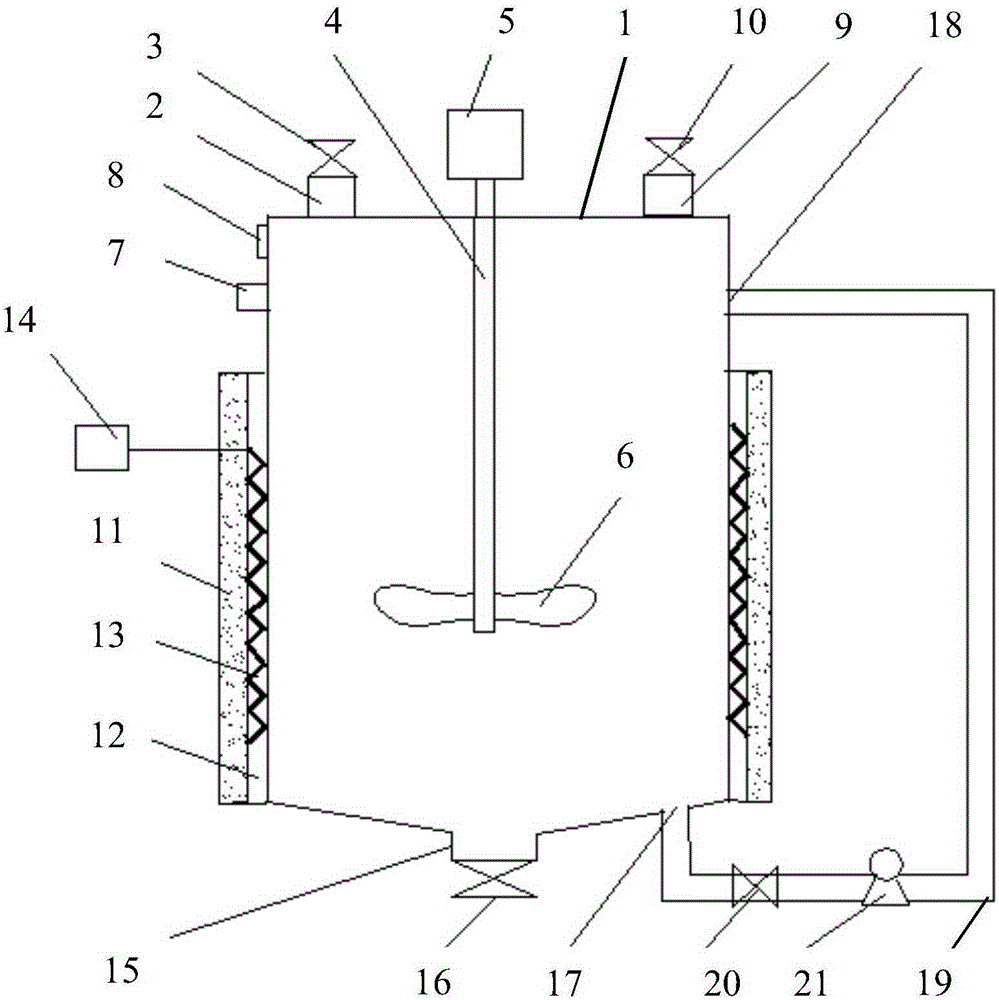

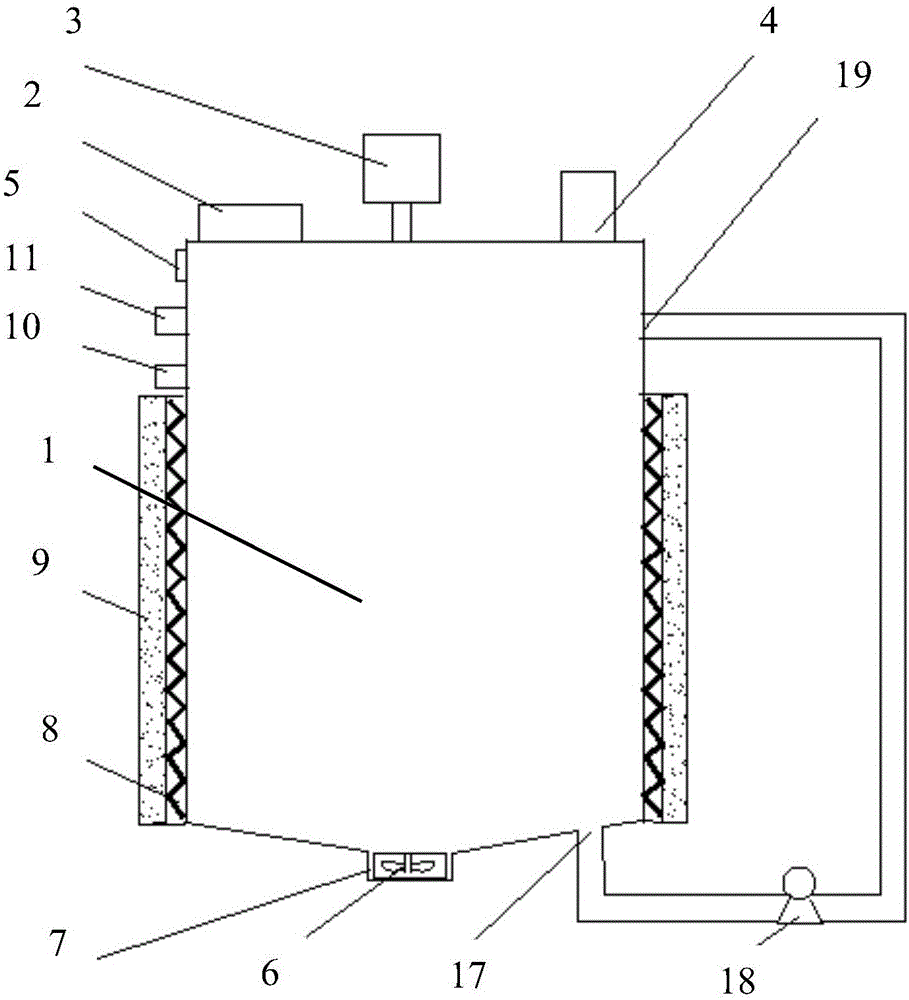

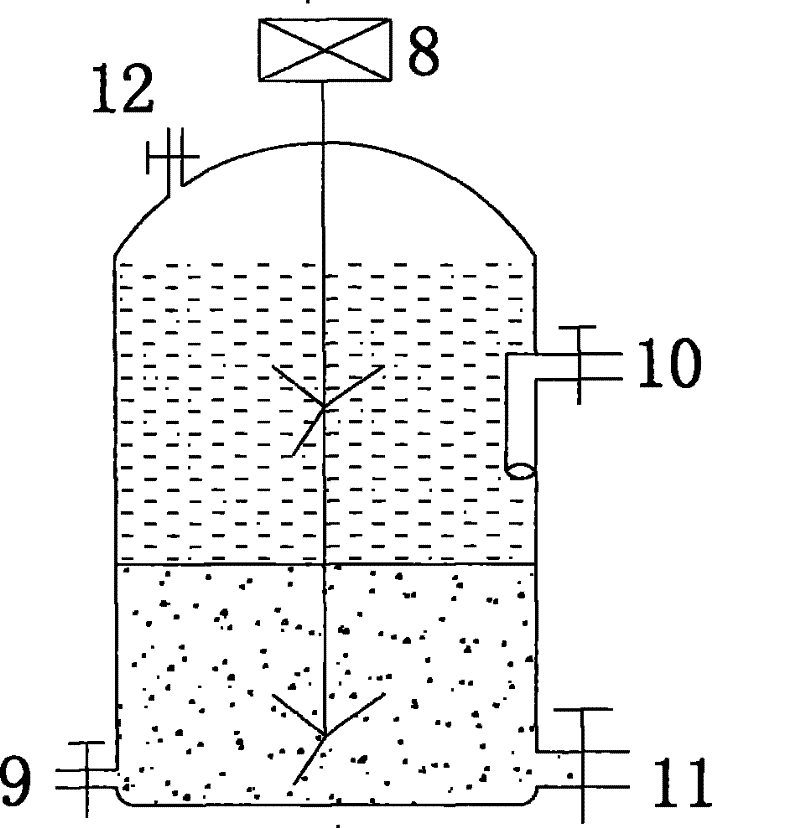

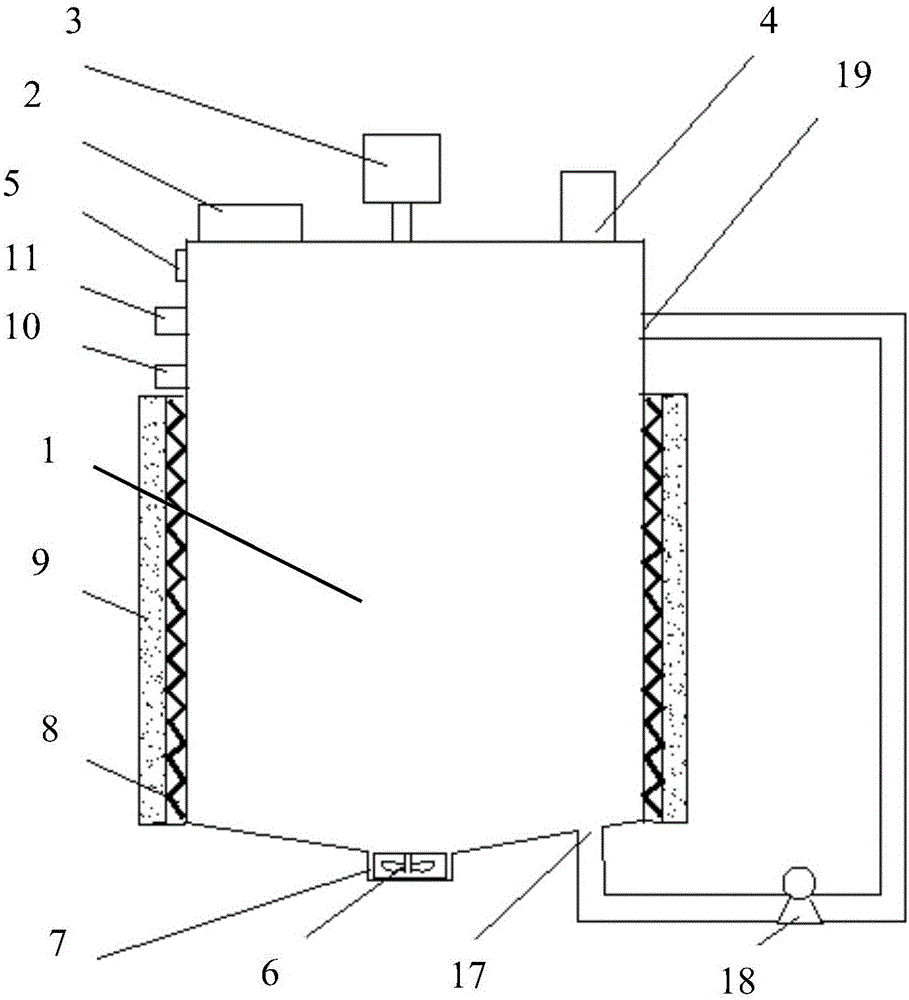

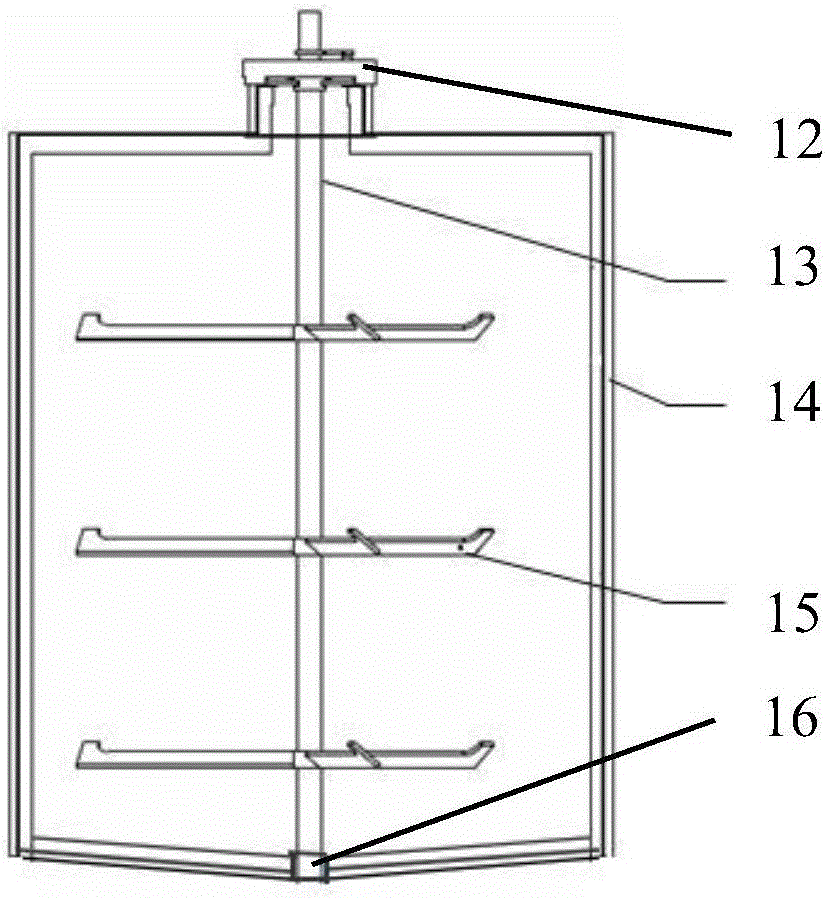

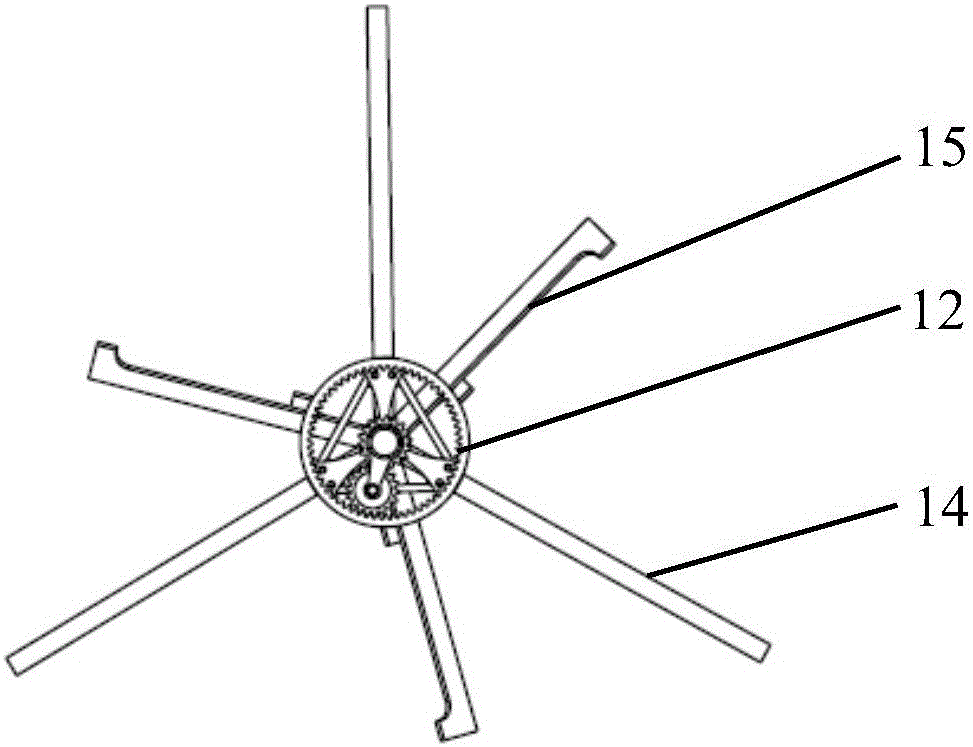

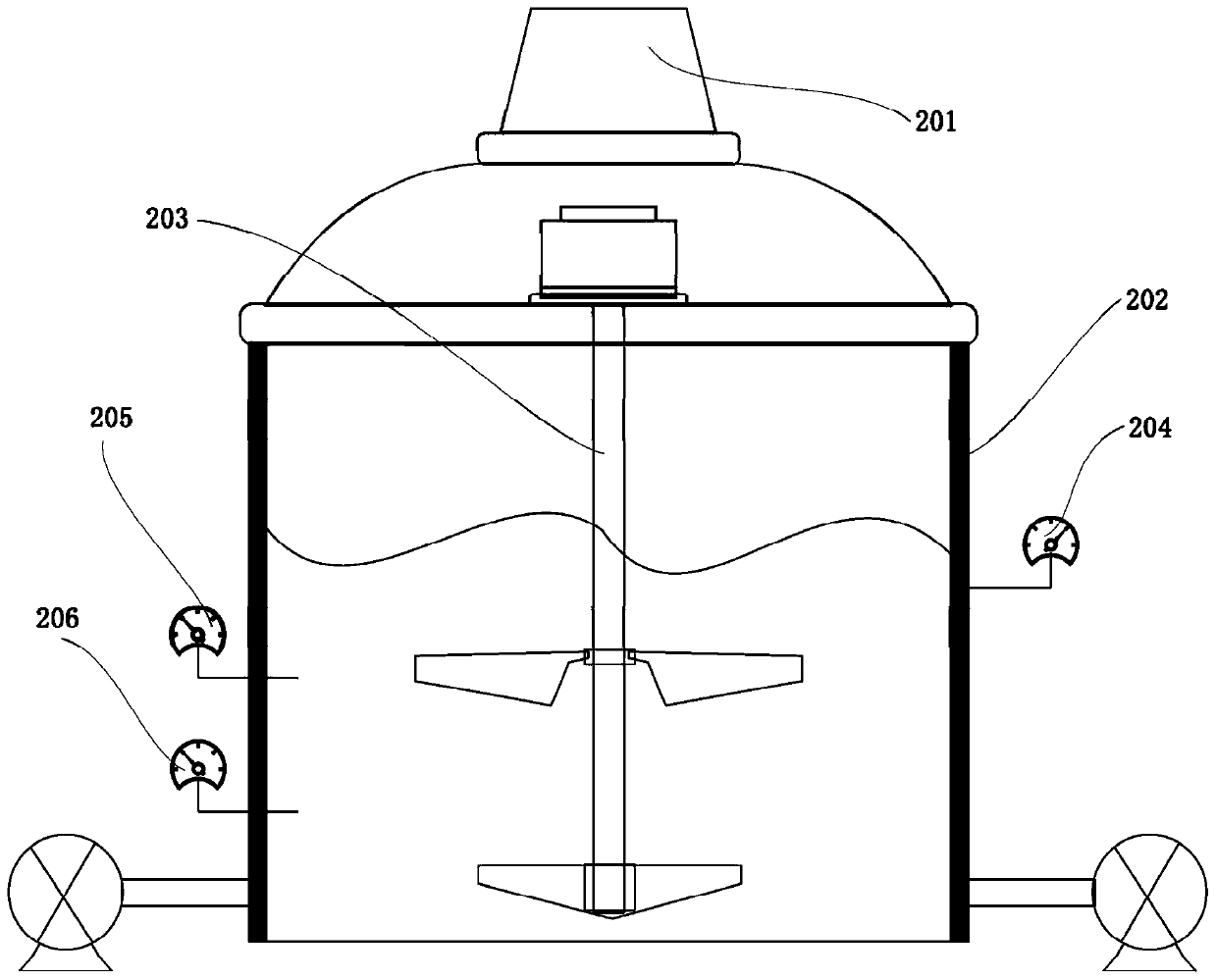

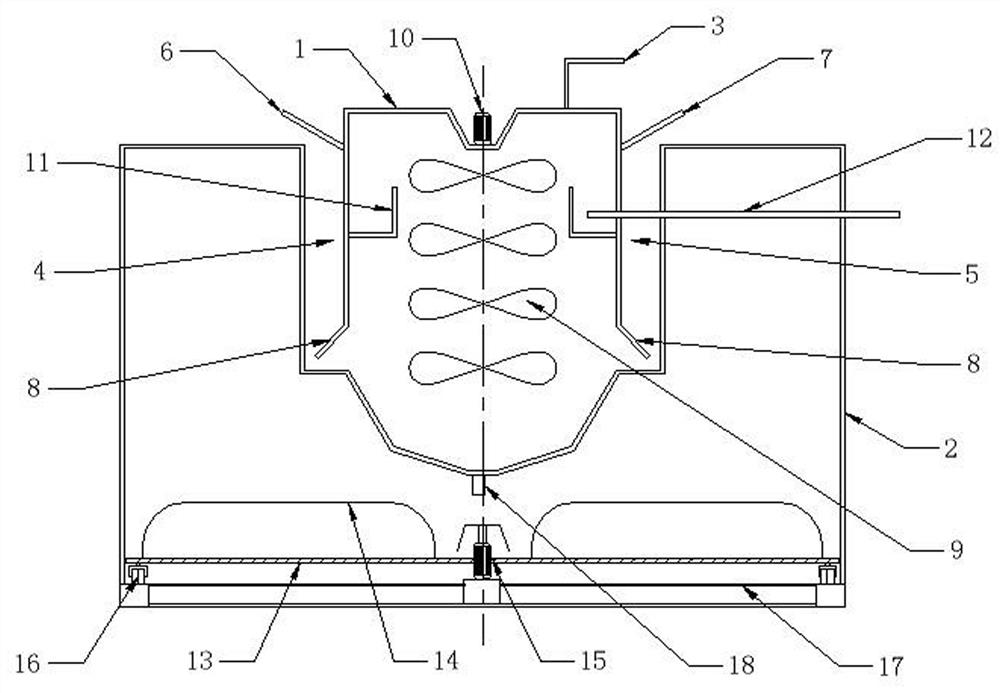

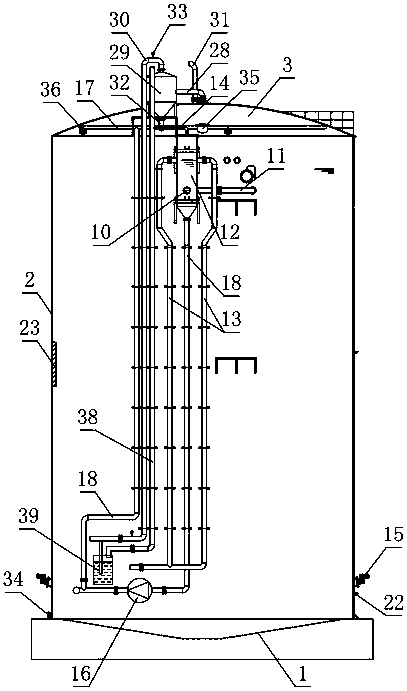

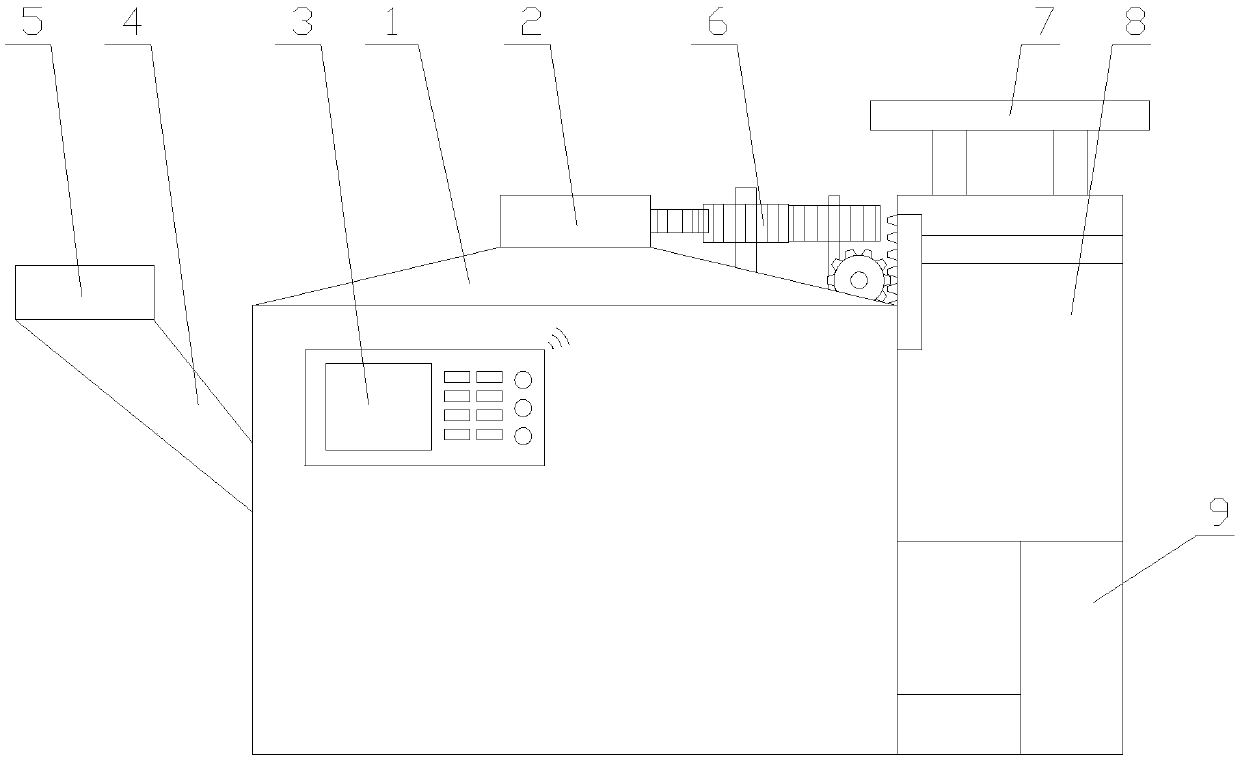

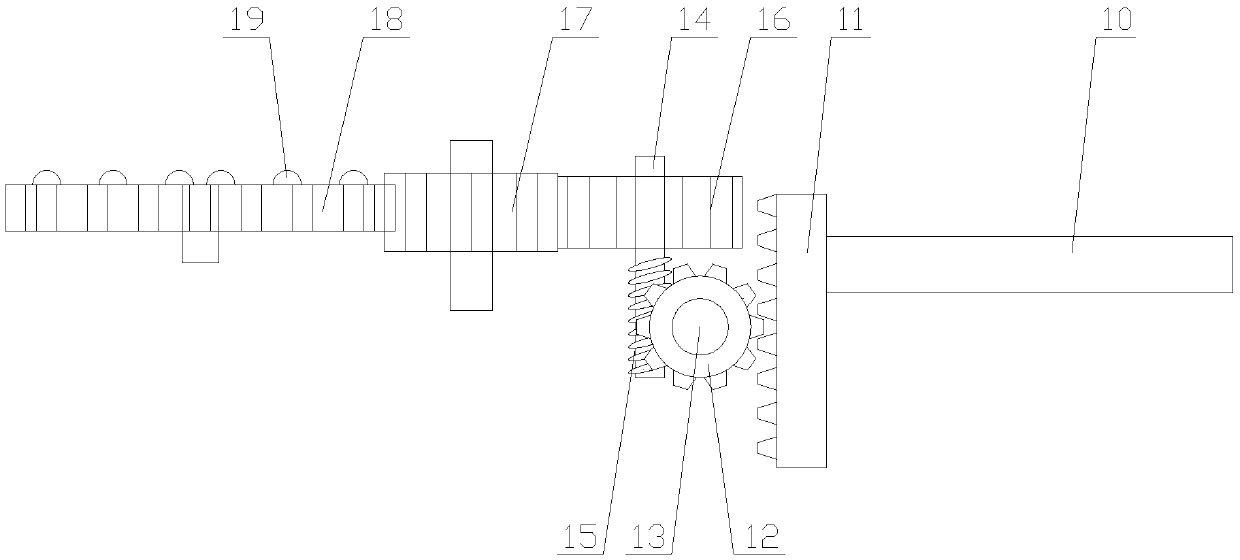

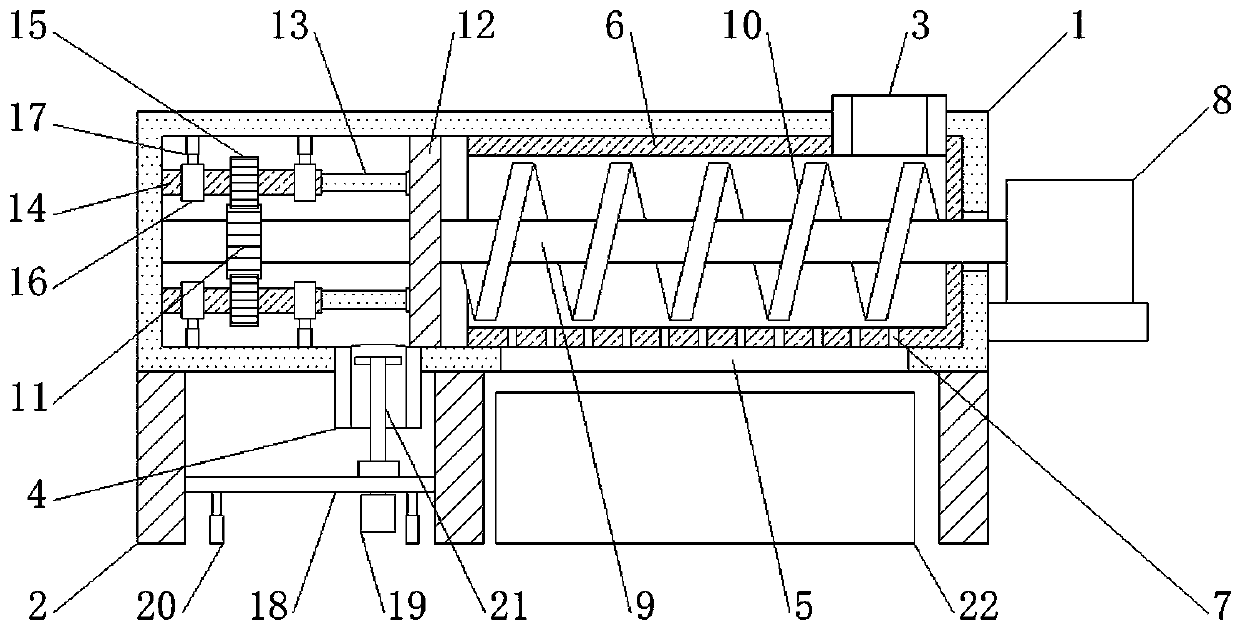

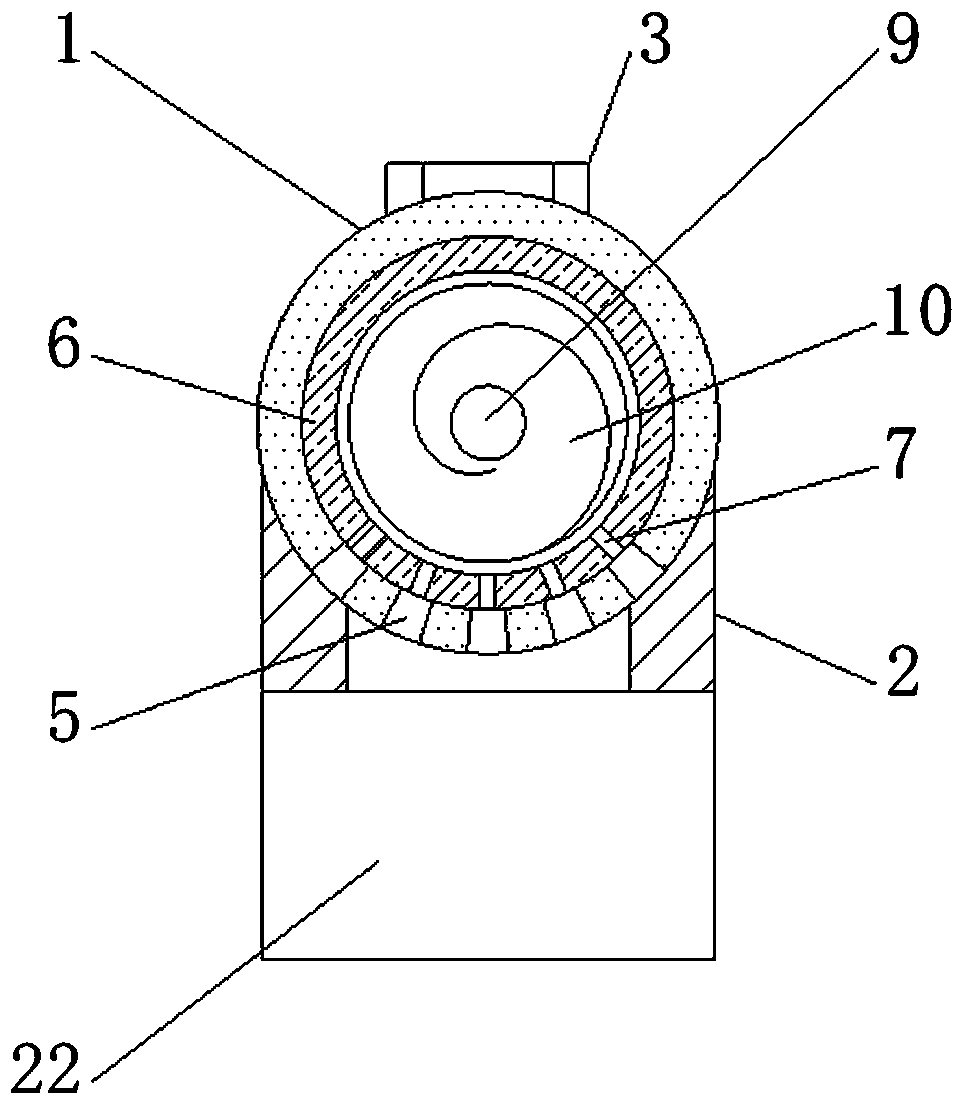

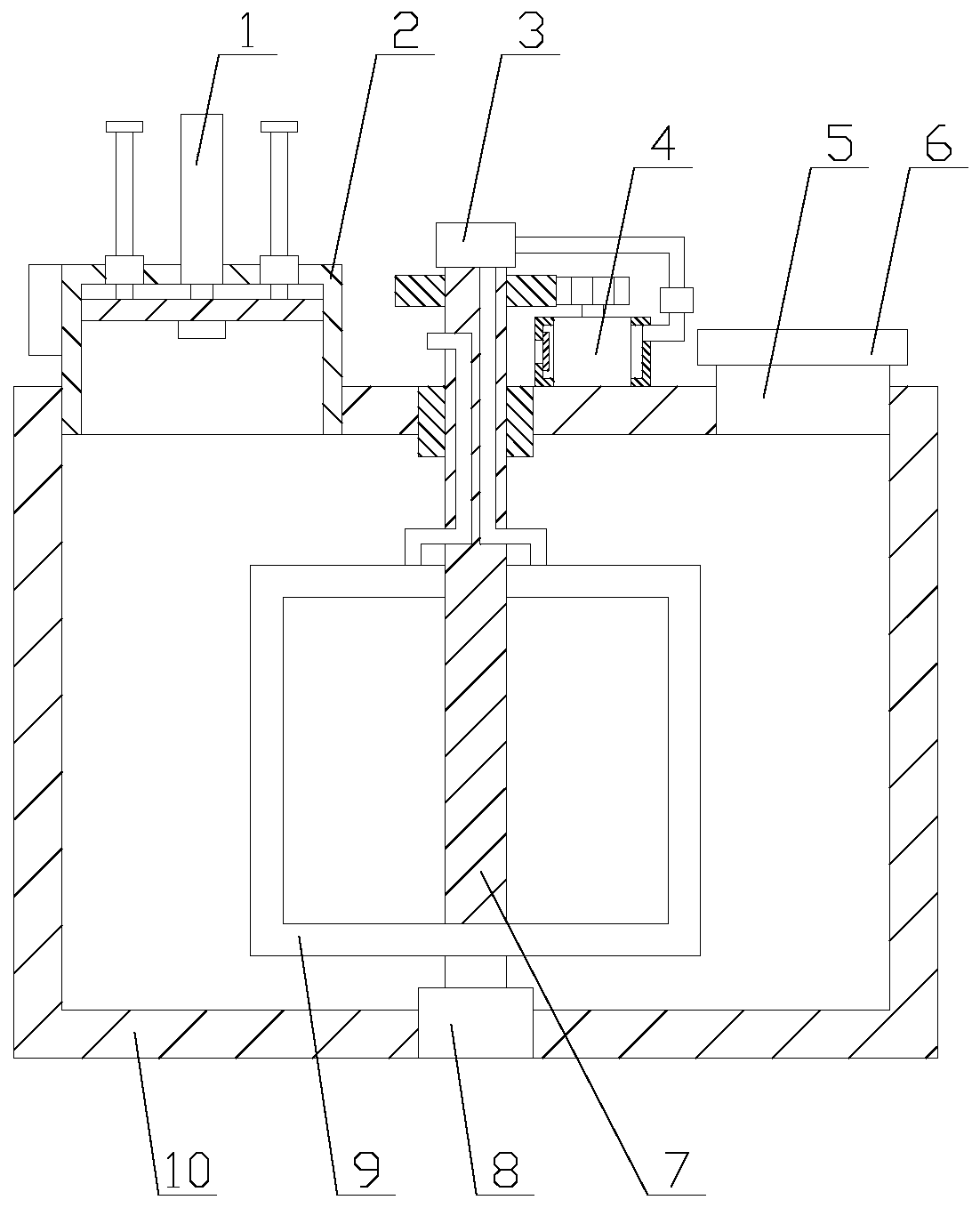

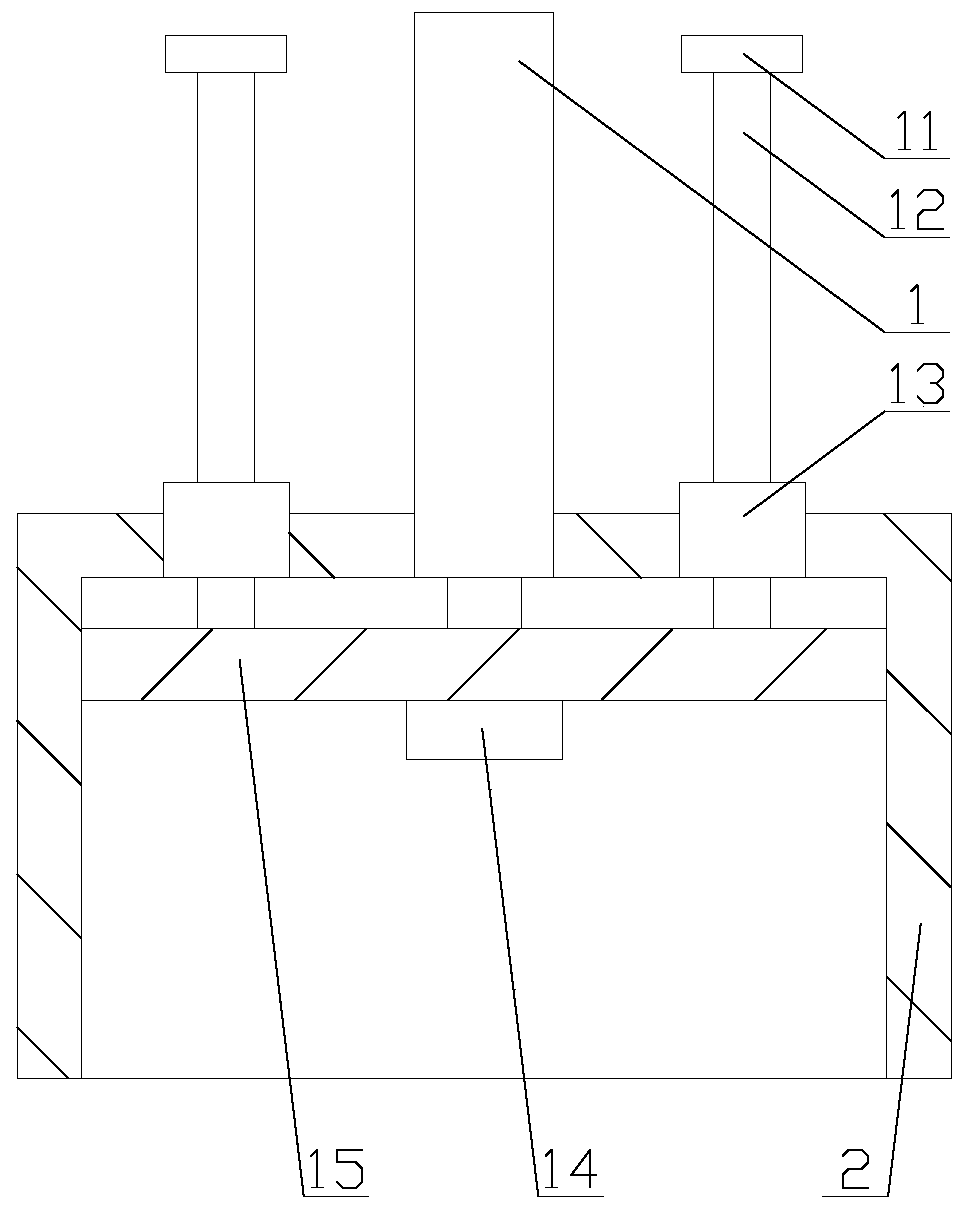

Fermenting mixing tank for resourceful utilization of methane

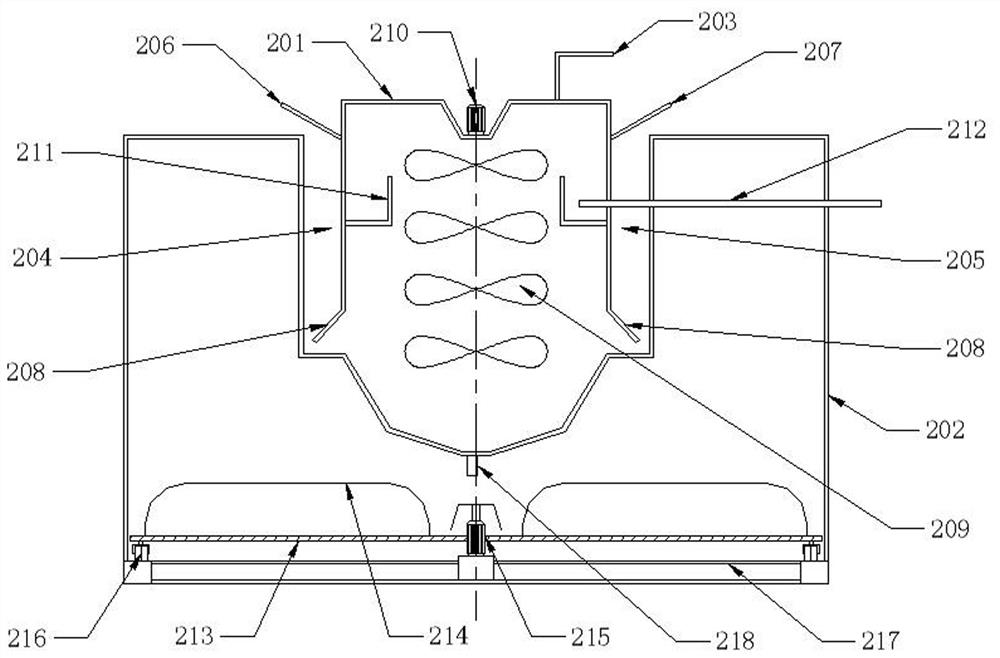

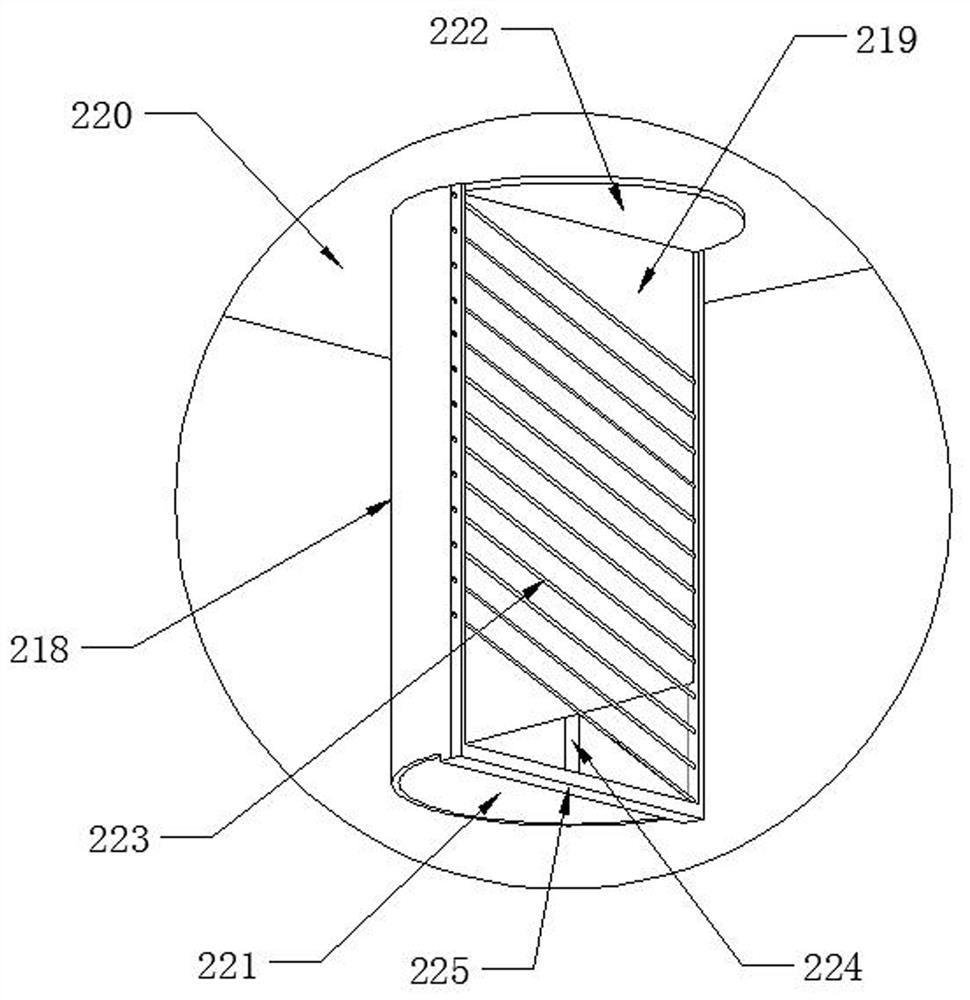

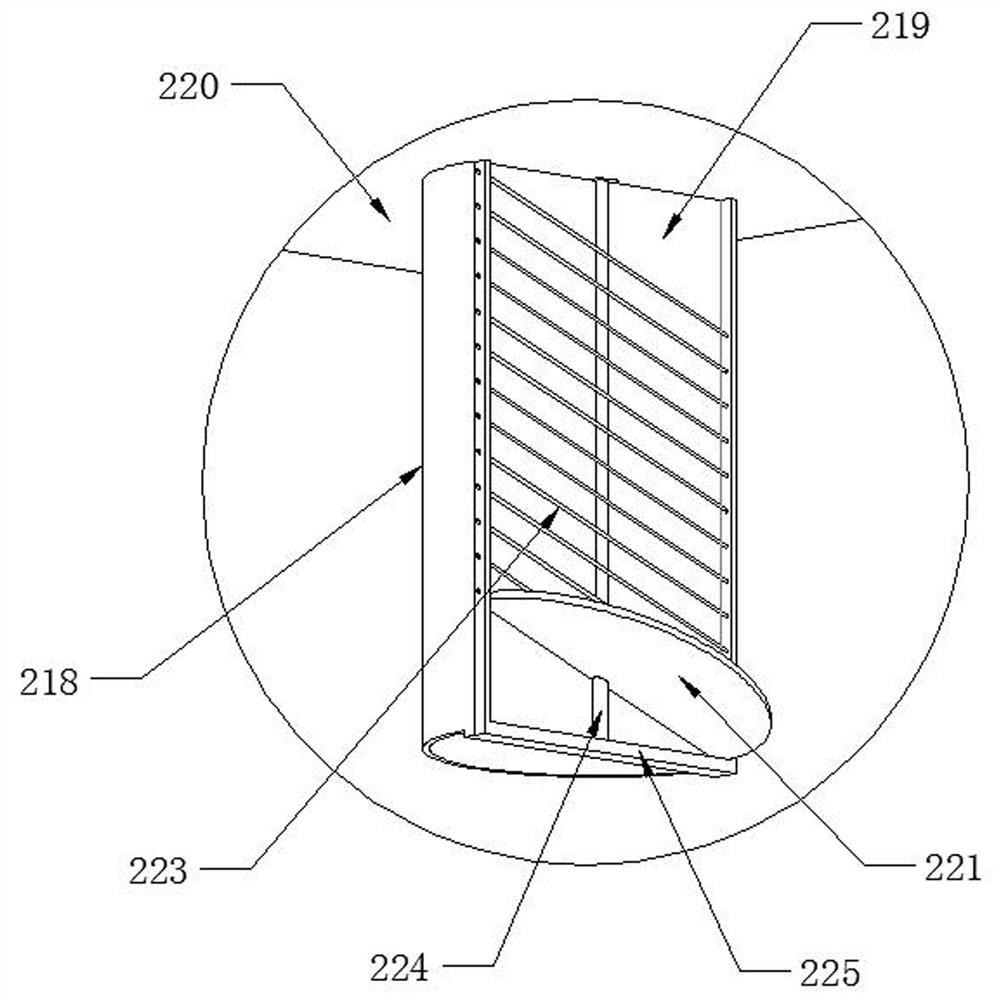

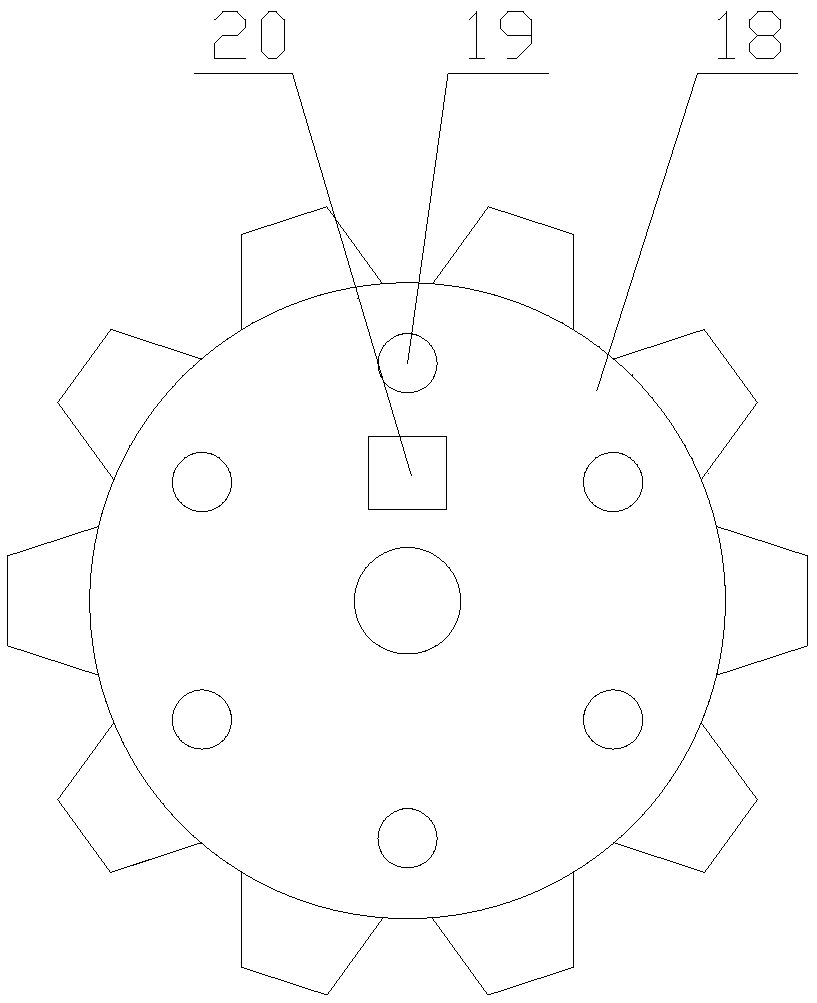

PendingCN105176806AStir wellImprove the efficiency of biogas productionBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlBiochemical engineering

The invention discloses a fermenting mixing tank for resourceful utilization of methane. The tank as a system is high in automation level and has a temperature control function; fermenting material and fermenting liquor at the bottom of the tank are allowed to flow cyclically into the top end of the tank from a reflow outlet through a reflow structure, thereby enabling vertical full mixing of the fermenting material and the fermenting liquor; meanwhile, under stirring action of stirring blades, the fermenting material and the fermenting liquor are fully mixed more efficiently, thus efficiency of methane production by straws is improved; in addition, whole equipment is automatically controlled in connection with a PLC (programmable logic controller).

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

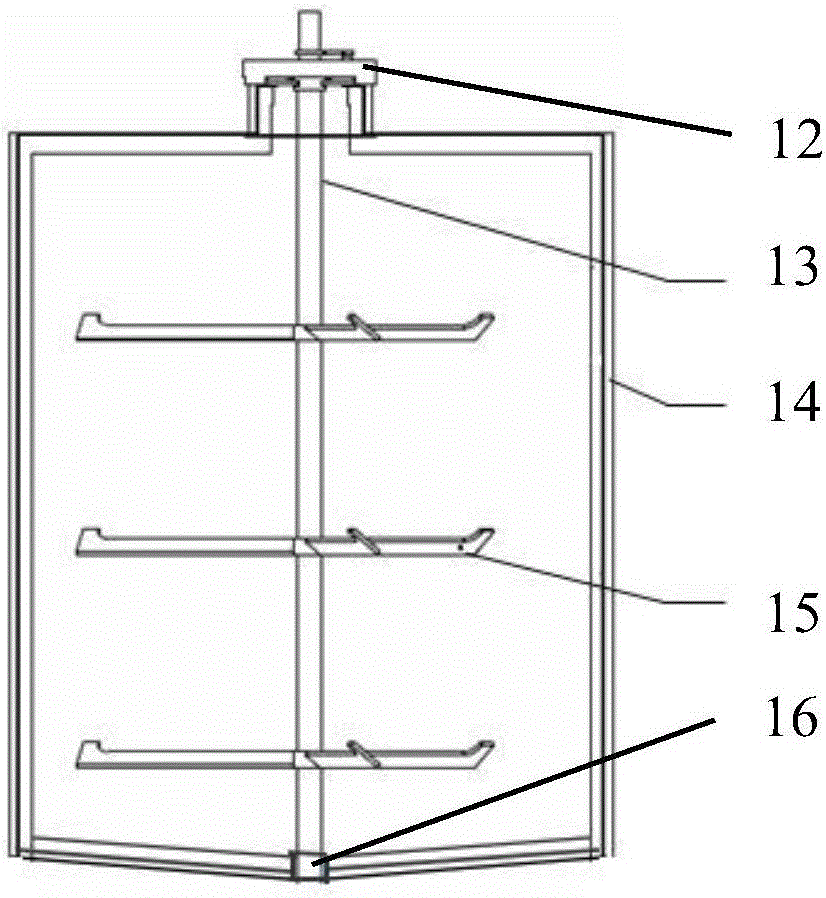

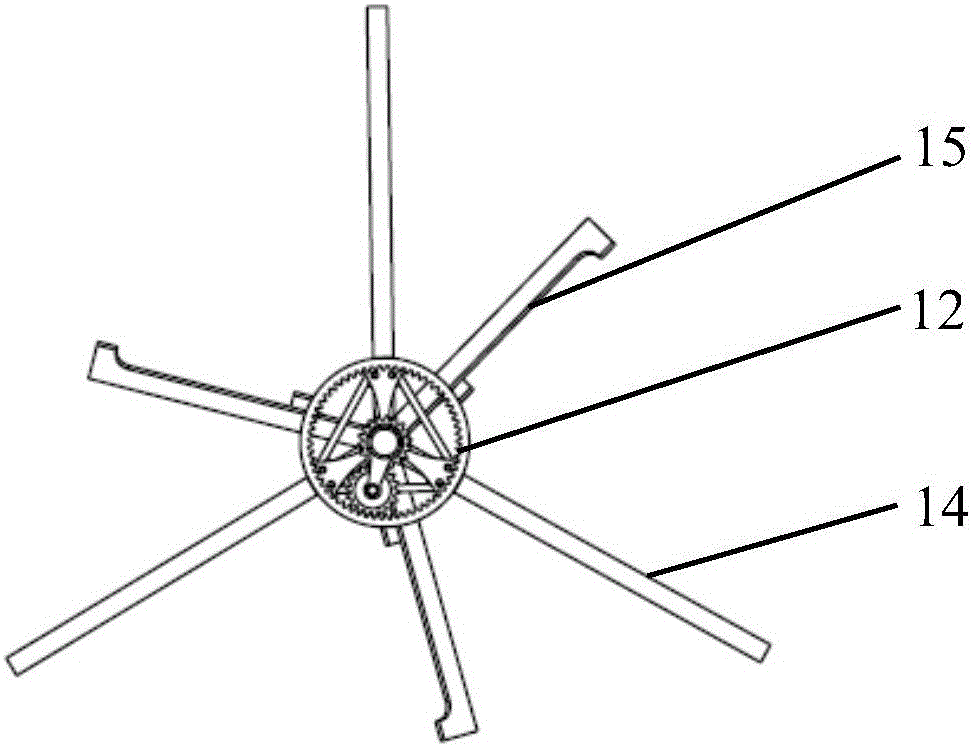

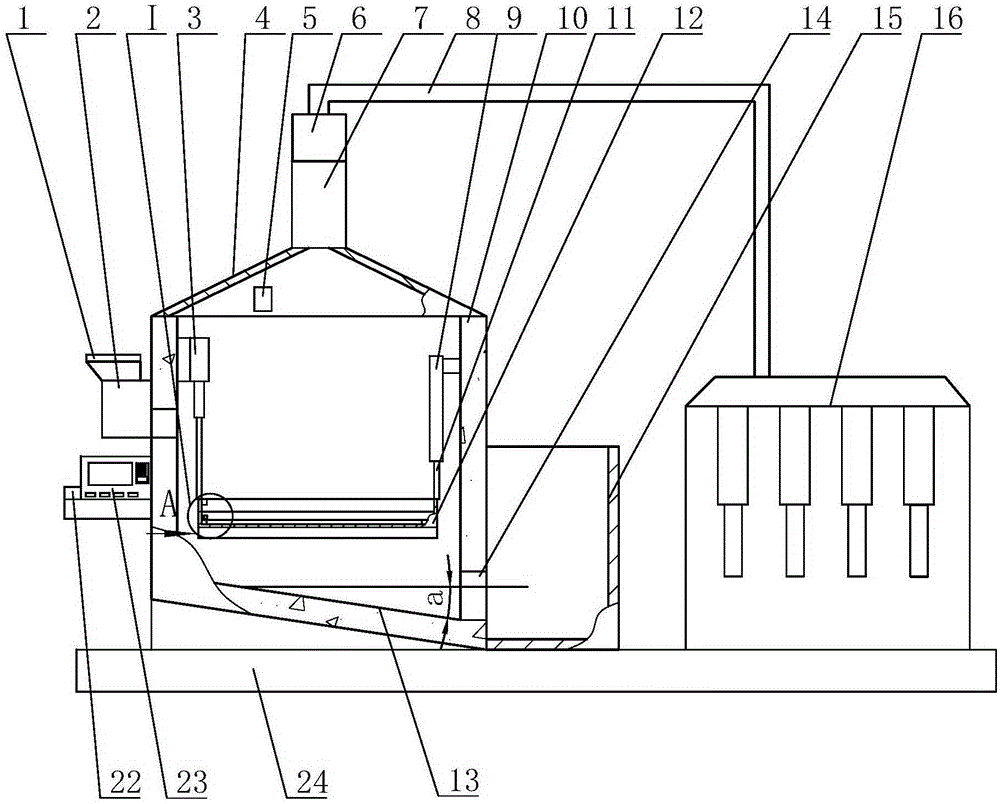

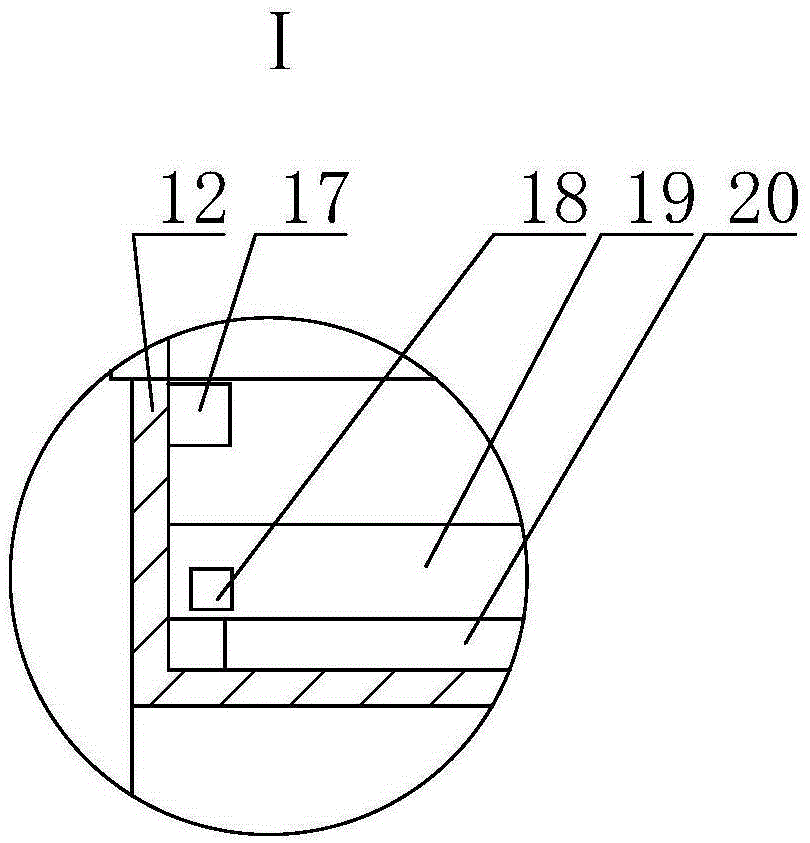

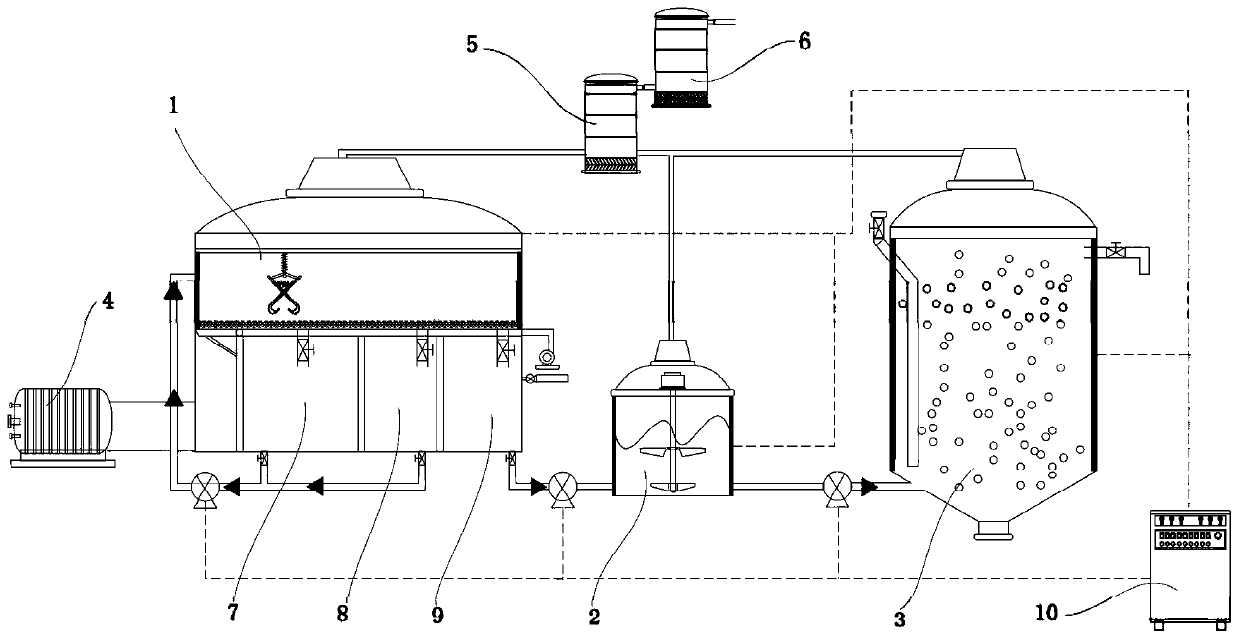

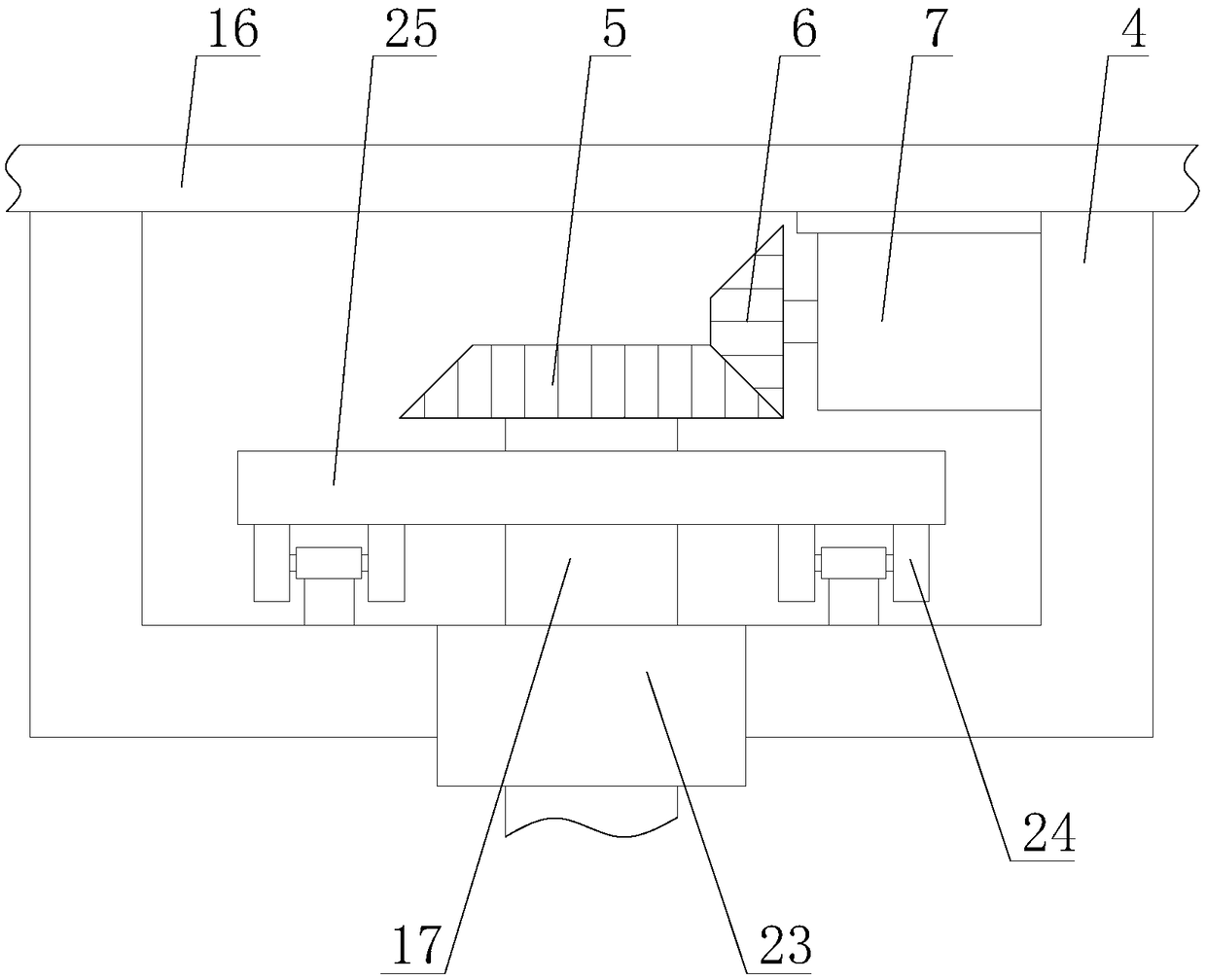

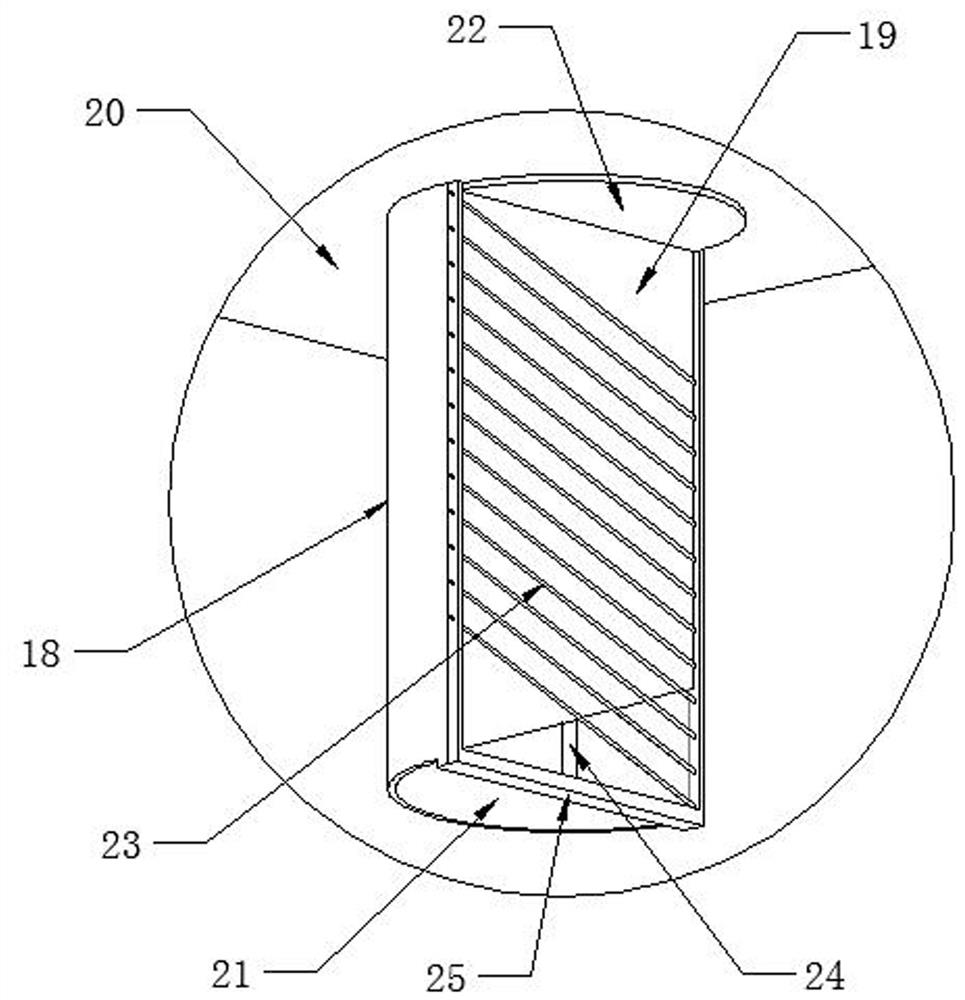

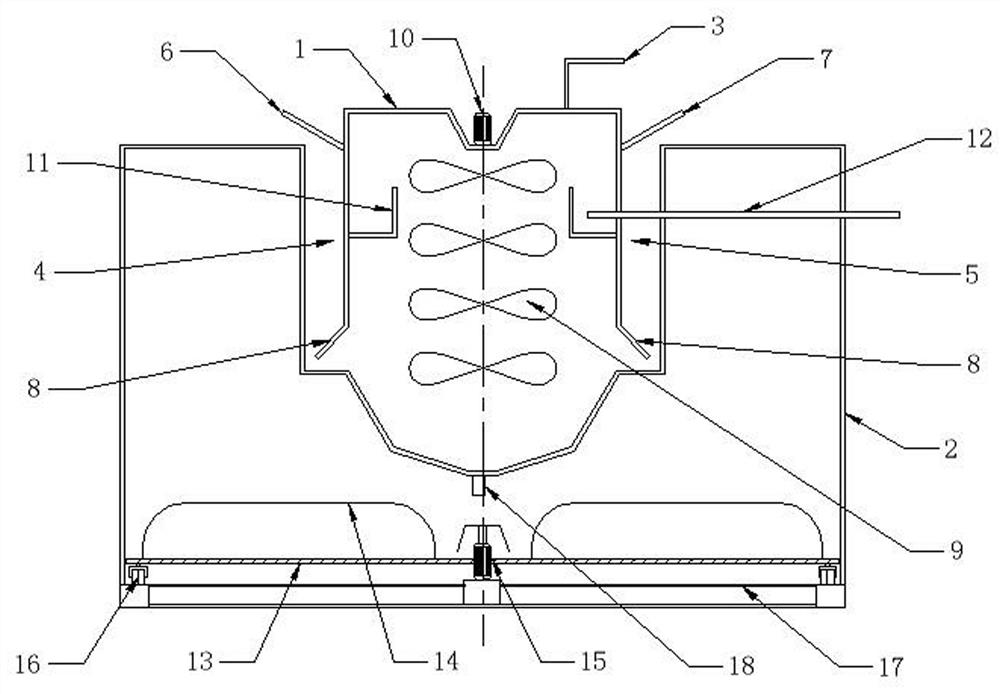

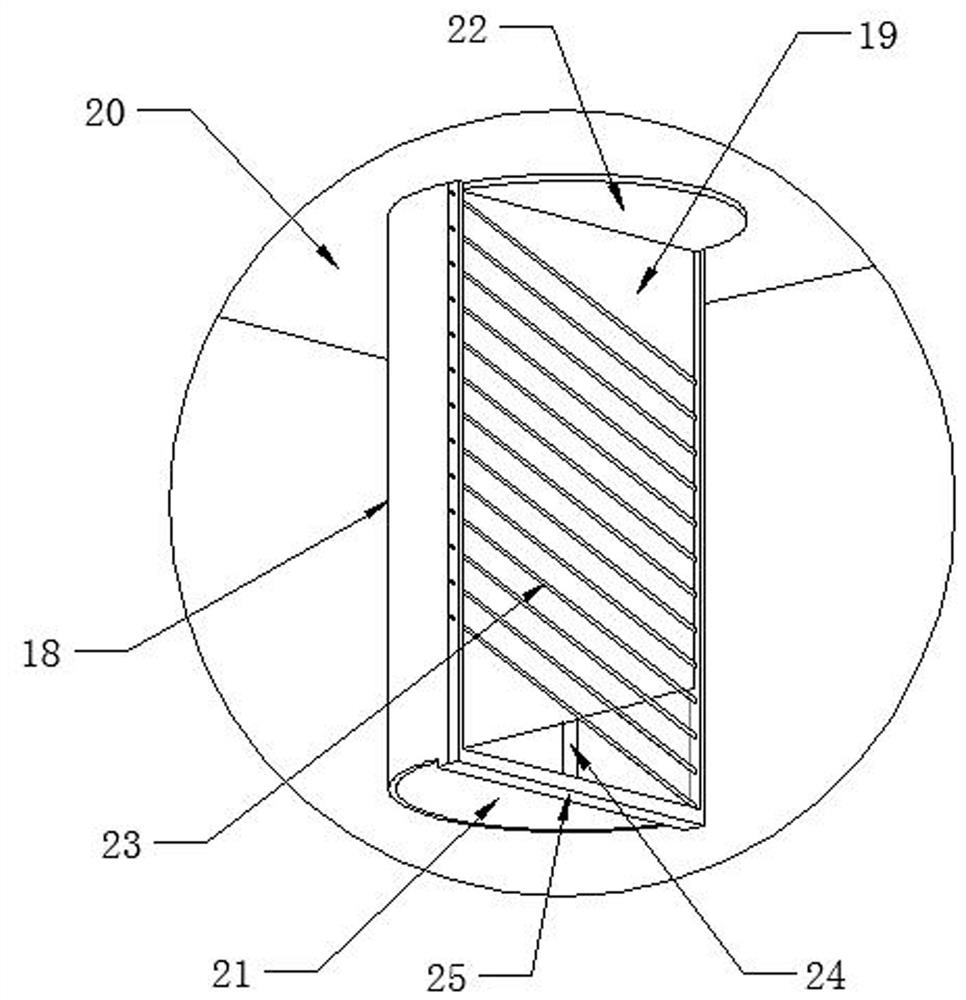

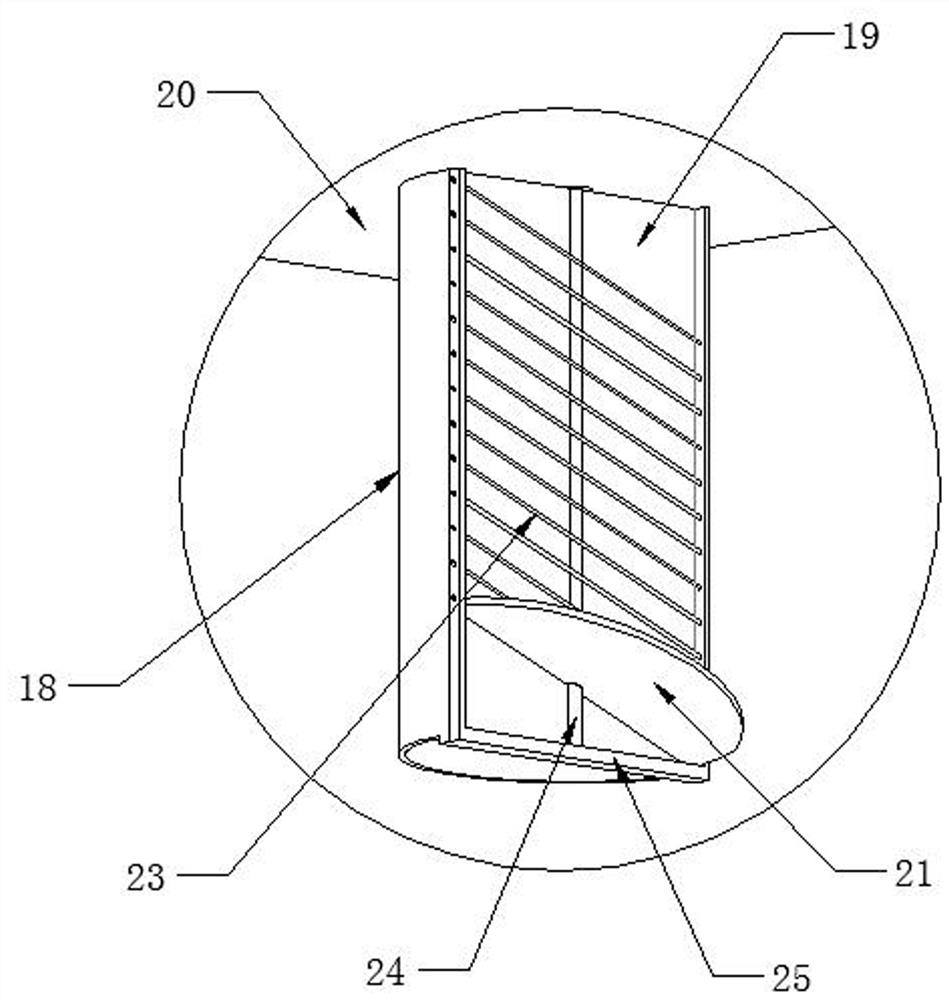

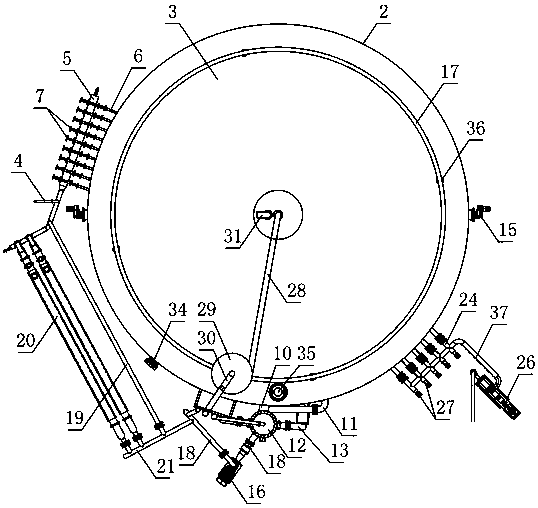

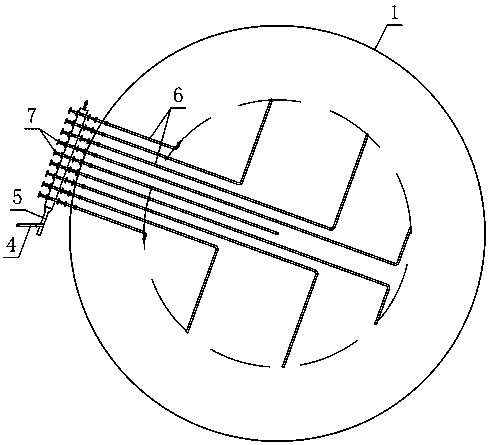

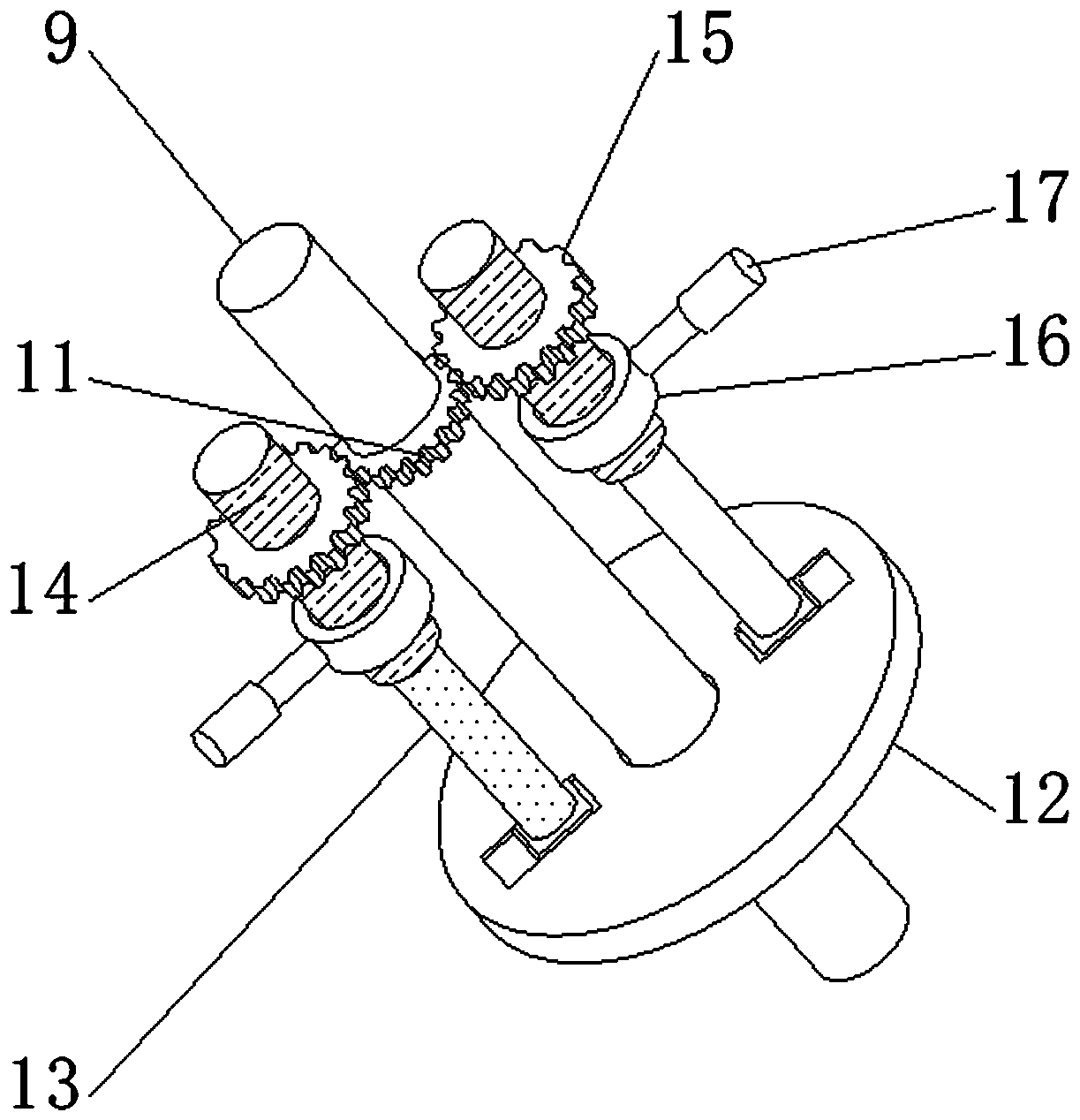

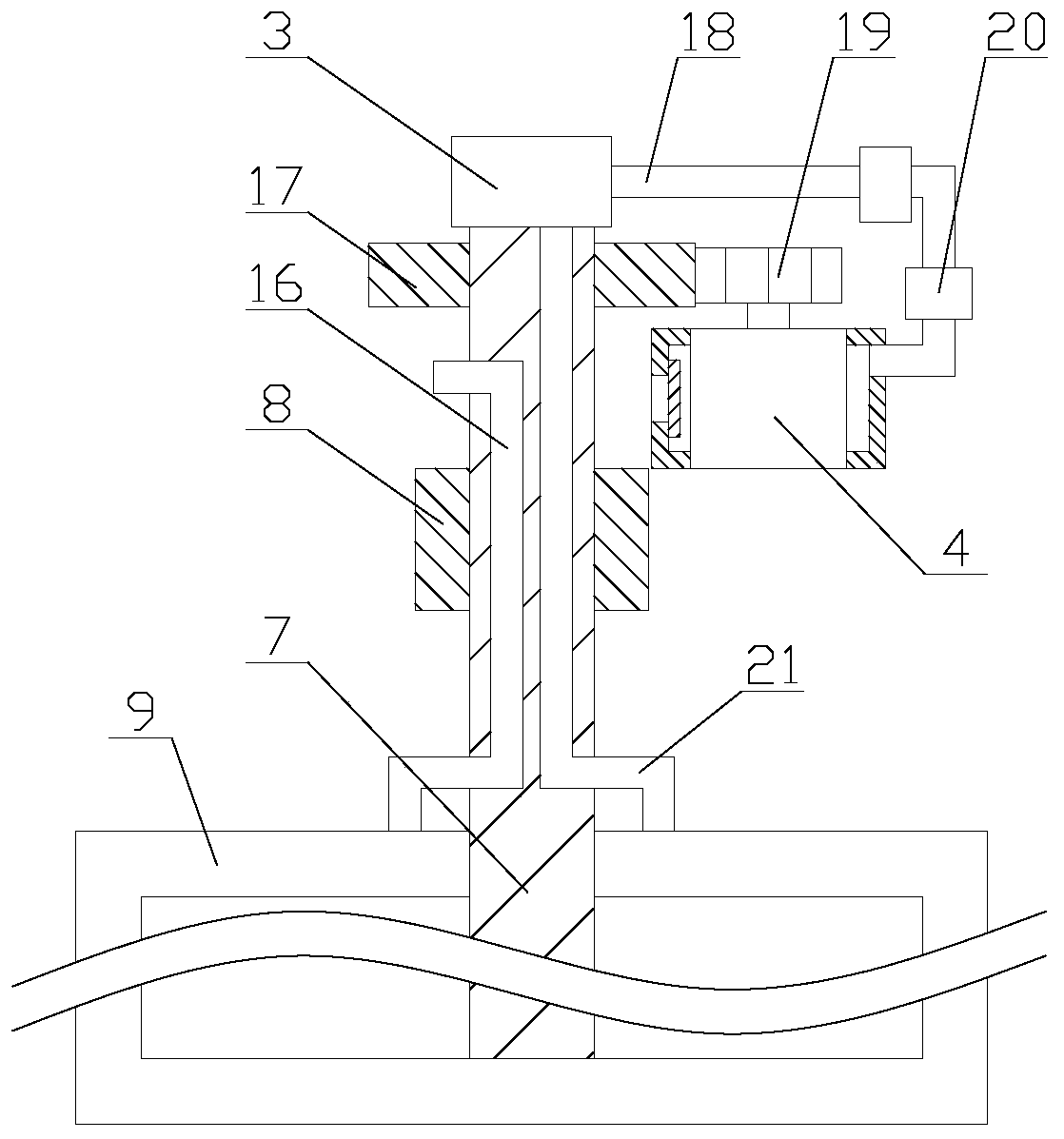

Operating method of CSTR integrated reactor in marsh gas resourceful treatment system

InactiveCN106085836AImprove stirring efficiencyImprove the efficiency of biogas productionBioreactor/fermenter combinationsBio-organic fraction processingPropellerProcess engineering

The invention discloses an operating method of a CSTR integrated reactor in a marsh gas resourceful treatment system. In the CSTR integrated reactor, a reverse-flow system and a reverse stirring device are added, so that the stirring efficiencies for smashed straw and anaerobic fermentation liquid can be effectively improved; in the stirring process, a material can form convection between two stirring blades, so that the problem that the traditional blender only stirs but not mixes the material is solved, and thus the efficiency of producing methane by adopting straw is improved; meanwhile, a screw propeller is arranged at a material outlet, so that a waste material can be rapidly discharged from a tank.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

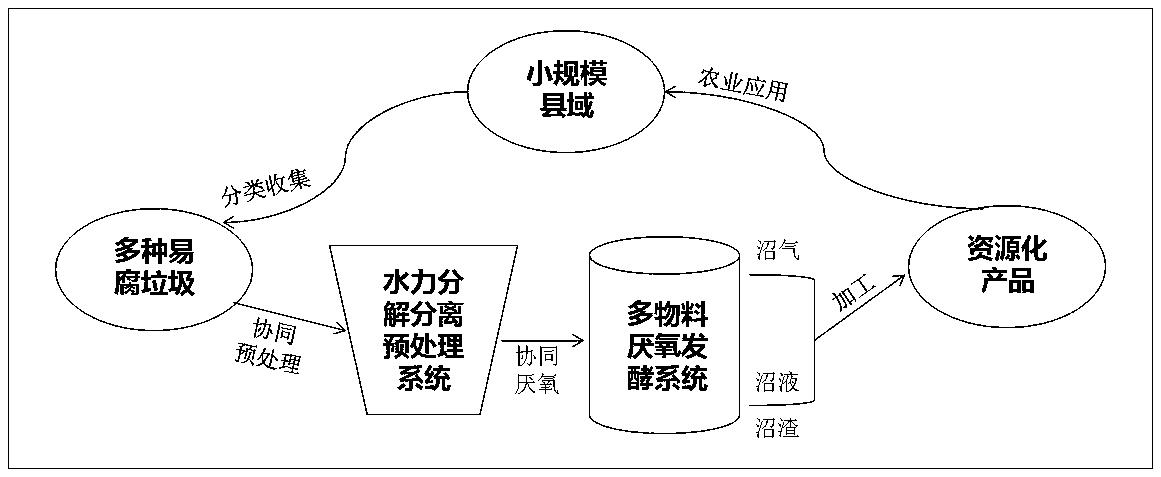

Efficient collaborative reclamation utilization method for various small-scale county-area perishable wastes

InactiveCN110560450AEfficient collaborative resource utilizationImprove homogeneous pulping effectSolid waste disposalFecesDecomposition

The invention discloses an efficient collaborative reclamation utilization method for various small-scale county-area perishable wastes. The method comprises the following steps of (1) building a county-area organic perishable waste comprehensive reclamation utilization park, and building a pretreatment system and a biotransformation reclamation utilization system; (2) uniformly collecting classified food waste, kitchen waste, fruit and vegetable waste, livestock and poultry feces and the like in an area to form a scale effect, and performing efficient homogenizing, slurrying and impurity removing in the pretreatment system based on hydraulic decomposition separation to generate organic matter mixed slurry with the proper C / N ratio; and (3) guiding the organic matter mixed slurry into ananaerobic digestion system for multi-material collaborative anaerobic fermentation, and converting the organic matter mixed slurry into biogas, biogas residue and biogas slurry for providing biomass fuel gas and high-quality organic fertilizer for the area. According to the method, through efficient collaborative pretreatment and anaerobic fermentation, the biogas yield is improved, the balance and the fertilizer efficiency of effective nutrient components in the biogas residue and biogas slurry are improved, and finally the efficient collaborative reclamation of the various small-scale county-area perishable wastes is realized.

Owner:中国环境保护集团有限公司 +2

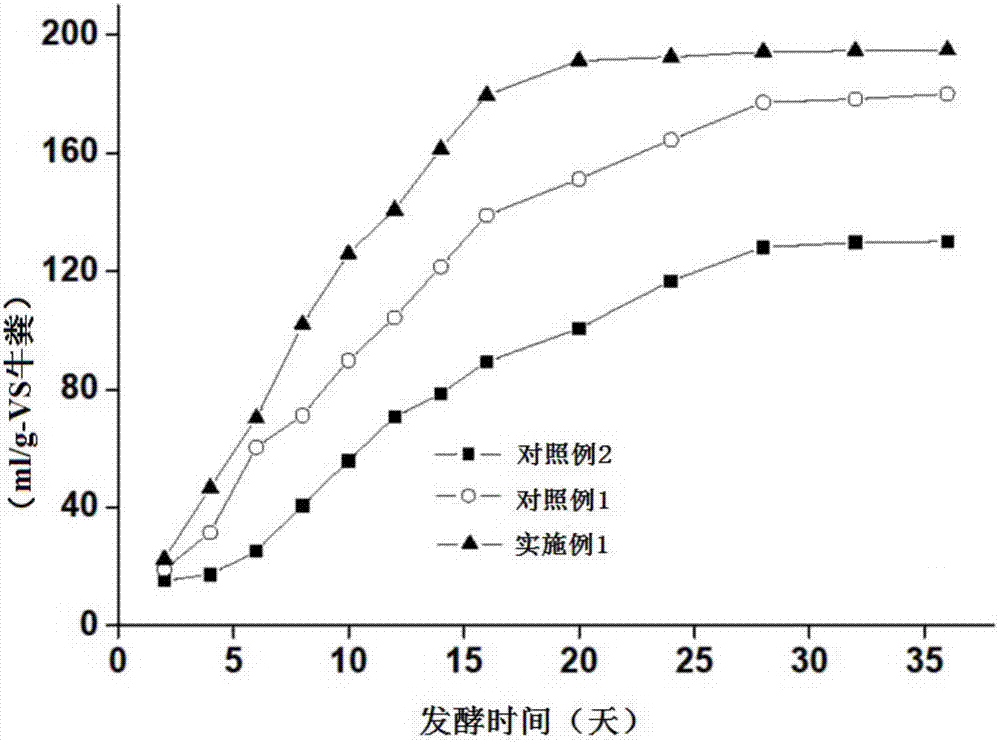

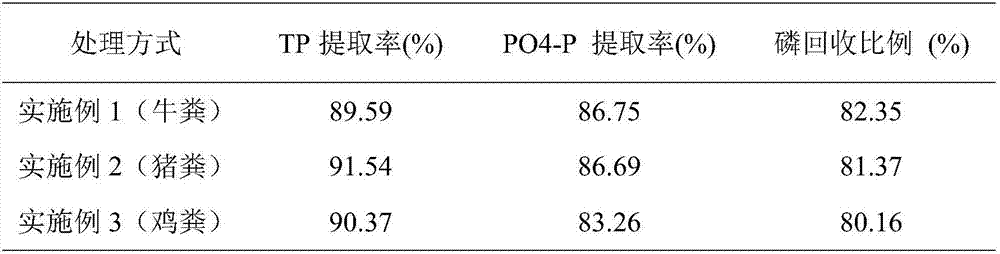

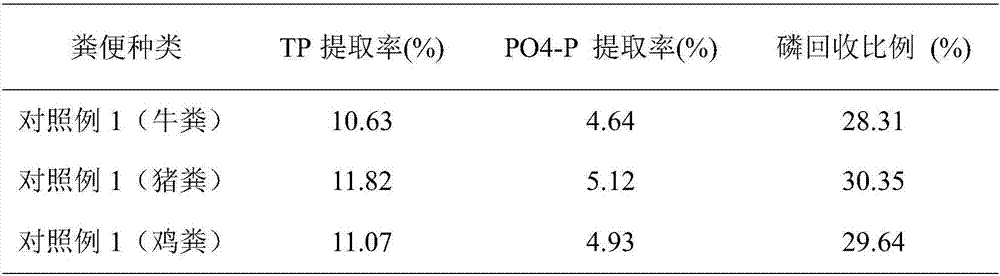

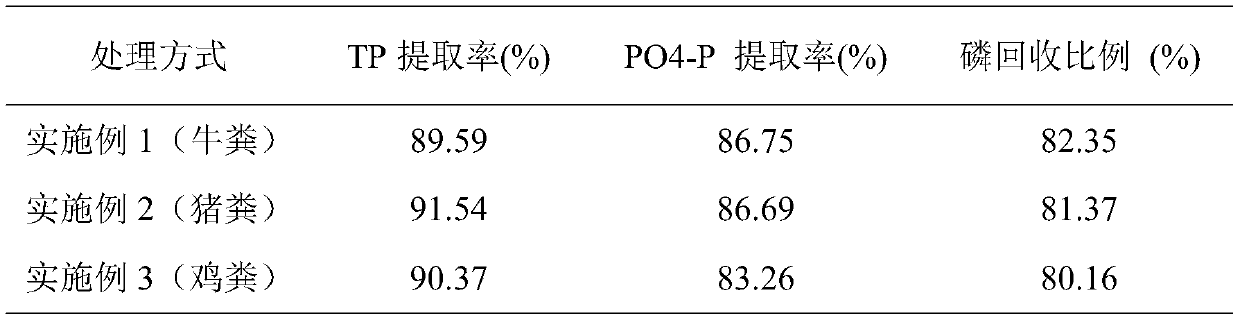

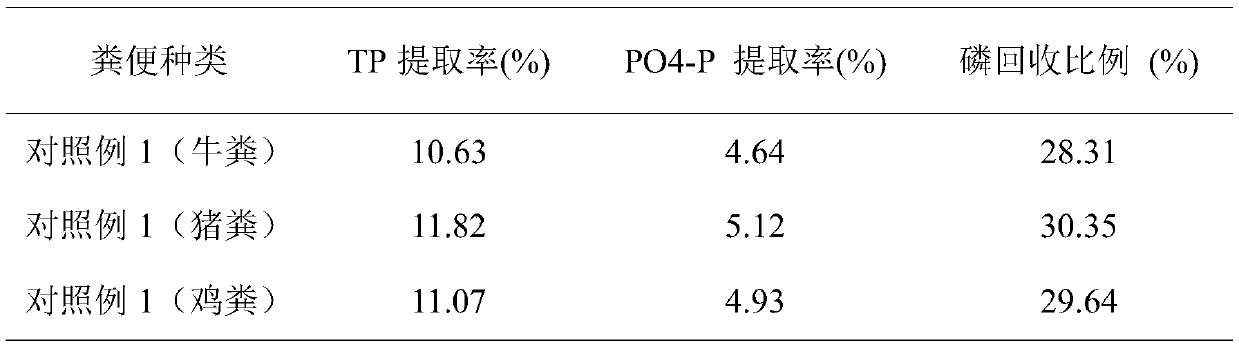

Method for treating livestock and poultry manure through efficient phosphate recovery coupled anaerobic fermentation

ActiveCN107140615AImprove recycling efficiencyImprove efficiencyPhosphatesWaste water treatment from animal husbandryNutrientLivestock

The invention provides a method for treating livestock and poultry manure through efficient phosphate recovery coupled anaerobic fermentation, belonging to the technical field of treatment of cultivation waste. The method comprises the following steps: (1) carrying out hydrothermal pretreatment on the livestock and poultry manure; (2) carrying out phosphate recovery on the pretreated livestock and poultry manure; and (3) carrying out anaerobic fermentation on the pretreated and nutrient salt-recovered livestock and poultry manure. The method provided by the invention is a nutrient salt recovery and anaerobic fermentation coupled process for the livestock and poultry manure based on hydrothermal pretreatment, the extraction and recovery of phosphate in the livestock and poultry manure are well accelerated, the anaerobic fermentation performance of the livestock and poultry manure is improved, and the maximum resource transformation and utilization of the livestock and poultry manure are realized.

Owner:BIOGAS SCI RES INST MIN OF AGRI

Method for preparation of organic fertilizer from organic solid waste

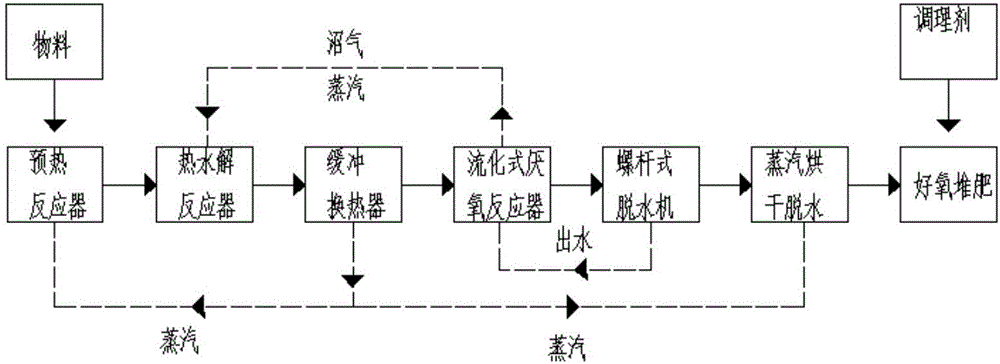

InactiveCN106518183AImprove dehydration performanceImprove efficiencyBio-organic fraction processingClimate change adaptationChemistryDigestion

The invention discloses a method for preparation of an organic fertilizer from organic solid waste. The method includes: preheating an organic solid waste mixture with a solid content of 2.5-20% by a preheating reactor, then using hot steam with a pressure of 0.6MPa and at a temperature of 155-170DEG C to conduct thermal hydrolysis and digestion, making the treated material enter a fluidized anaerobic reactor by a buffer heat exchanger to carry out anaerobic digestion biogas production reaction, applying the produced biogas to a front-end heating link, sending a mixture obtained by anaerobic reaction to a screw type dehydrator and conducting steam drying and dehydration, adding a proper conditioning agent into a filter cake, then sending the mixture to a composting system to carry out aerobic composting treatment, thus finally obtaining the organic fertilizer. Compared with the traditional method of preparing organic fertilizer from organic solid waste, the method provided by the invention has the characteristics of high degree of automation, short biogas production time and high efficiency, achieves cyclic utilization of heat energy, greatly reduces the dosage of the conditioning agent, and has better effect.

Owner:JIANGSU UNIV OF TECH

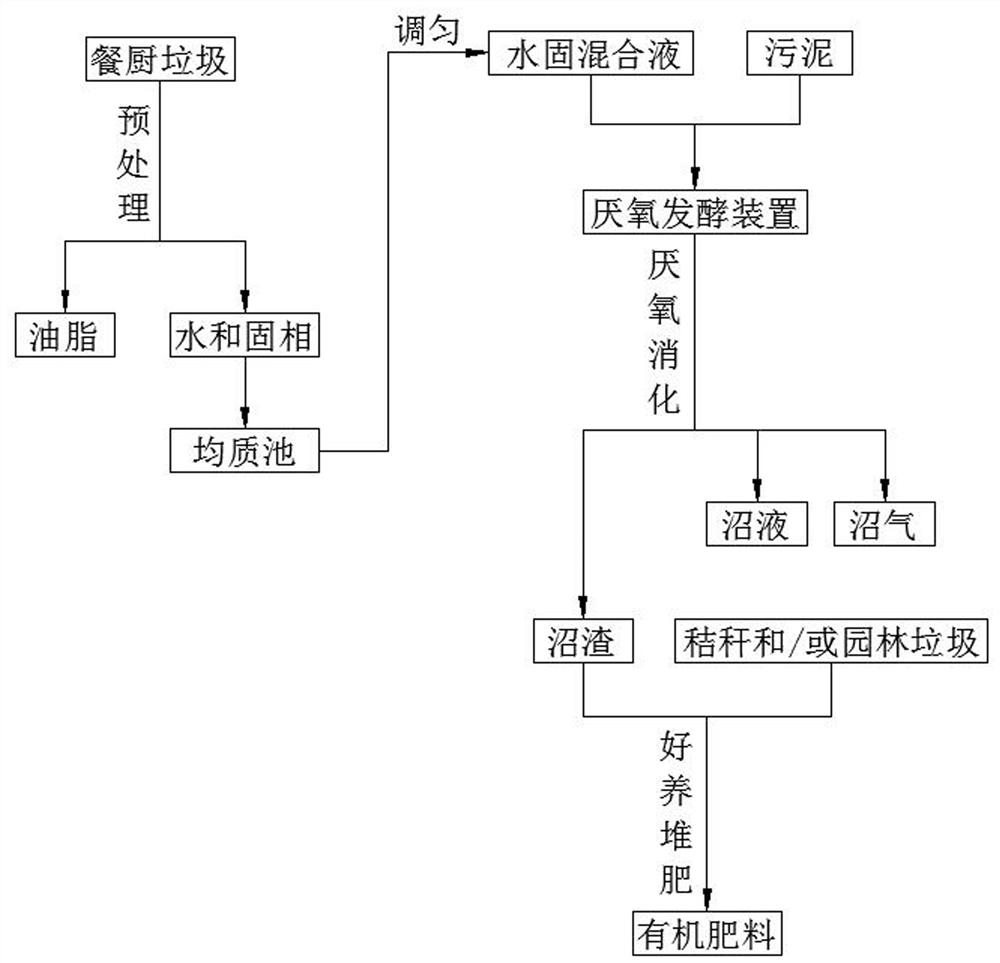

Kitchen waste integrated treatment system based on biotechnology and energy coupling

ActiveCN112592809AAvoid influenceIncreased degradation rateBioreactor/fermenter combinationsBio-organic fraction processingProcess engineeringEnvironmental engineering

The invention provides a kitchen waste integrated treatment system based on biotechnology and energy coupling, and belongs to the technical field of kitchen waste treatment. The problems that resources are wasted to a certain extent, aerobic composting and anaerobic digestion have many defects and the like in an existing garbage treatment method are solved. The kitchen waste integrated treatment system comprises a pretreatment device, an anaerobic fermentation device and an aerobic composting device; the pretreatment device treats kitchen waste into water-solid mixed slurry; the anaerobic fermentation device performs anaerobic digestion on the water-solid mixed slurry and generates biogas, biogas slurry and biogas residues; the aerobic composting device is used for performing aerobic composting on the biogas residues; the anaerobic fermentation device comprises an anaerobic tank; the aerobic composting device comprises an aerobic tank; the top of the aerobic tank is provided with a recess; and the anaerobic tank is arranged in the recess. The kitchen waste integrated treatment system has the advantages that an anaerobic digestion technology and an aerobic composting technology supplement each other; continuous feeding and a two-phase process of a single anaerobic tank are realized by adopting two stages of feeding cabins; and simultaneous treatment of multiple kinds of garbageis realized.

Owner:ZHEJIANG NORMAL UNIVERSITY

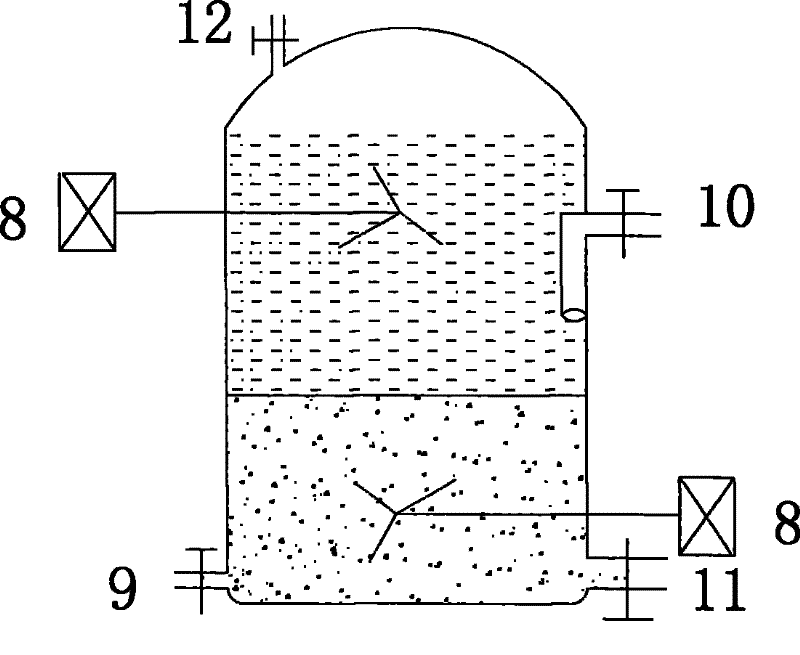

Technology method for high-efficiency anaerobic fermentation production of biogas by lignocellulose-rich materials

InactiveCN108866110ASolve efficiency problemsSolve concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseOxygen

The invention belongs to the technical field of a biogas preparation method, and provides a technology method for high-efficiency anaerobic fermentation production of biogas by lignocellulose-rich materials. The technology method comprises the following steps of material pulping, biological treatment, facultative hydrolyzing and acid production, anaerobic fermenting, solid and liquid separating, refluxing and the like. The technology method solves the problems of low pretreatment efficiency of the lignocellulose-rich materials, overhigh concentration of reflux biogas, and low biogas productionefficiency in the prior art.

Owner:河北京安瑞能环境科技有限公司

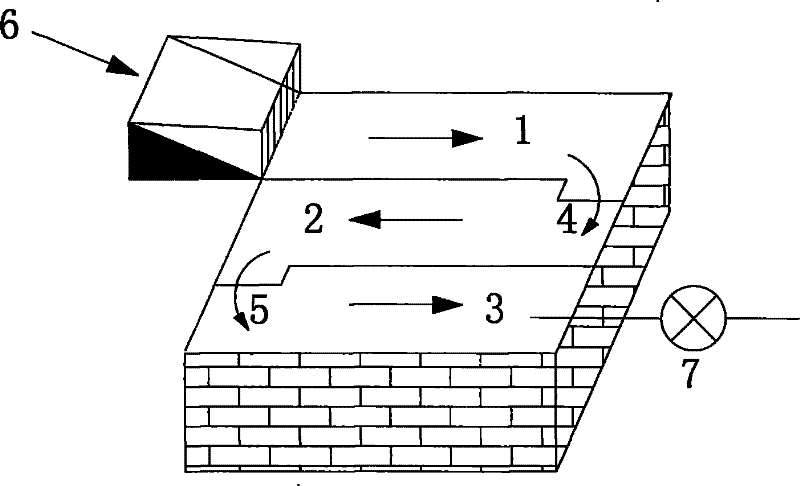

Method for anaerobic fermentation of bloom blue algae

InactiveCN101337758BPrevent encrustationAvoid dischargeWaste based fuelBiological sludge treatmentPhylum CyanobacteriaRetention time

The invention relates to a method for the anaerobic fermentation of bloom-forming cyanobacteria, and belongs to the technical field of the agricultural environmental protection. The method comprises the following steps: pumping the bloom-forming cyanobacteria to a zigzag type acidification pool; and pumping the bloom-forming cyanobacteria after being subjected to acidification treatment to an agitating type anaerobic digestion tank after being improved, so as to generate marsh gas after the anaerobic fermentation. Through combining the promotion or unload or transportation process of the bloom-forming cyanobacteria with deswelling treatment, the investment of a deswelling dedicated device is reduced; the cost is reduced; the effective volume of the subsequent anaerobic digestion tank is improved through the mechanical action of a pump and the extension of the acidification time of the cyanobacteria; and the retention time of the bloom-forming cyanobacteria in the anaerobic digestion tank is shortened; through adding an agitator at the upper part of the digestion tank, the bloom-forming cyanobacteria and sludge at the bottom are fully in contact mixture, thereby increasing the gas production rate of the volume and the organic load, and improving the running efficiency of engineering.

Owner:JIANGSU ACAD OF AGRI SCI

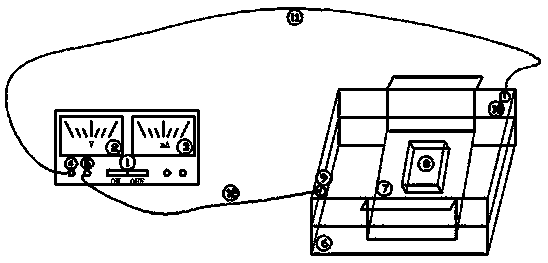

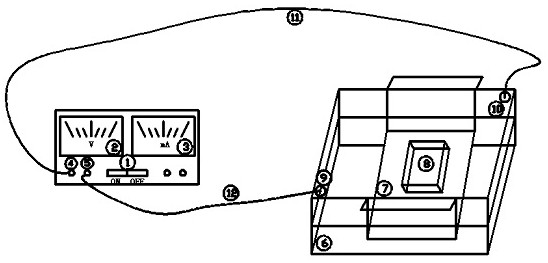

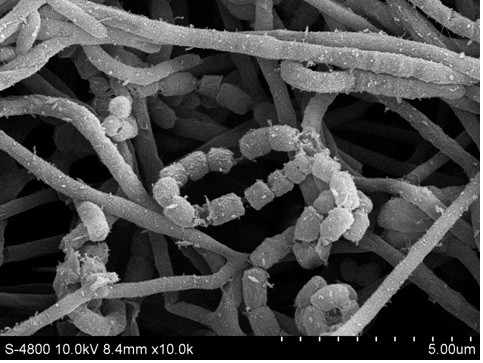

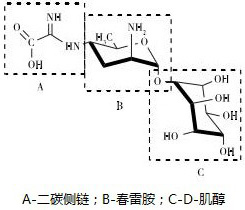

Device and method for decreasing kasugamycin content in kasugamycin residue

ActiveCN109358105AReduce inhibitionImprove the efficiency of biogas productionComponent separationMaterial analysis by electric/magnetic meansElectrophoresisSeparation technology

The invention relates to a device and method for decreasing the kasugamycin content in kasugamycin residue. A direct current electrophoresis and macromolecular glue separation technology is adopted, as for the adopted device, macromolecular glue is placed in a general electrophoresis device, a square hole is dug in the macromolecular glue, the macromolecular glue is arranged at the bottom layer ofthe hole to serve as an underskirt, PBS, a 0.8% sodium chloride solution and a Tris-HCl buffer solution serve as an electrolyte, and the kasugamycin residue is put into the square hole of the macromolecular glue or is directly subjected to electrophoresis. According to the device, kasugamycin in the kasugamycin residue can be well removed, thus the kasugamycin can be subjected to better resourceutilization, in addition, the macromolecular glue is a biodegradable material, the kasugamycin in the residue enters the macromolecular glue through electrophoresis, and the kasugamycin entering the macromolecular glue can be reutilized through the separation technology, wherein the macromolecular glue with the kasugamycin being removed can be recycled.

Owner:陕西绿盾环境工程研究院有限公司

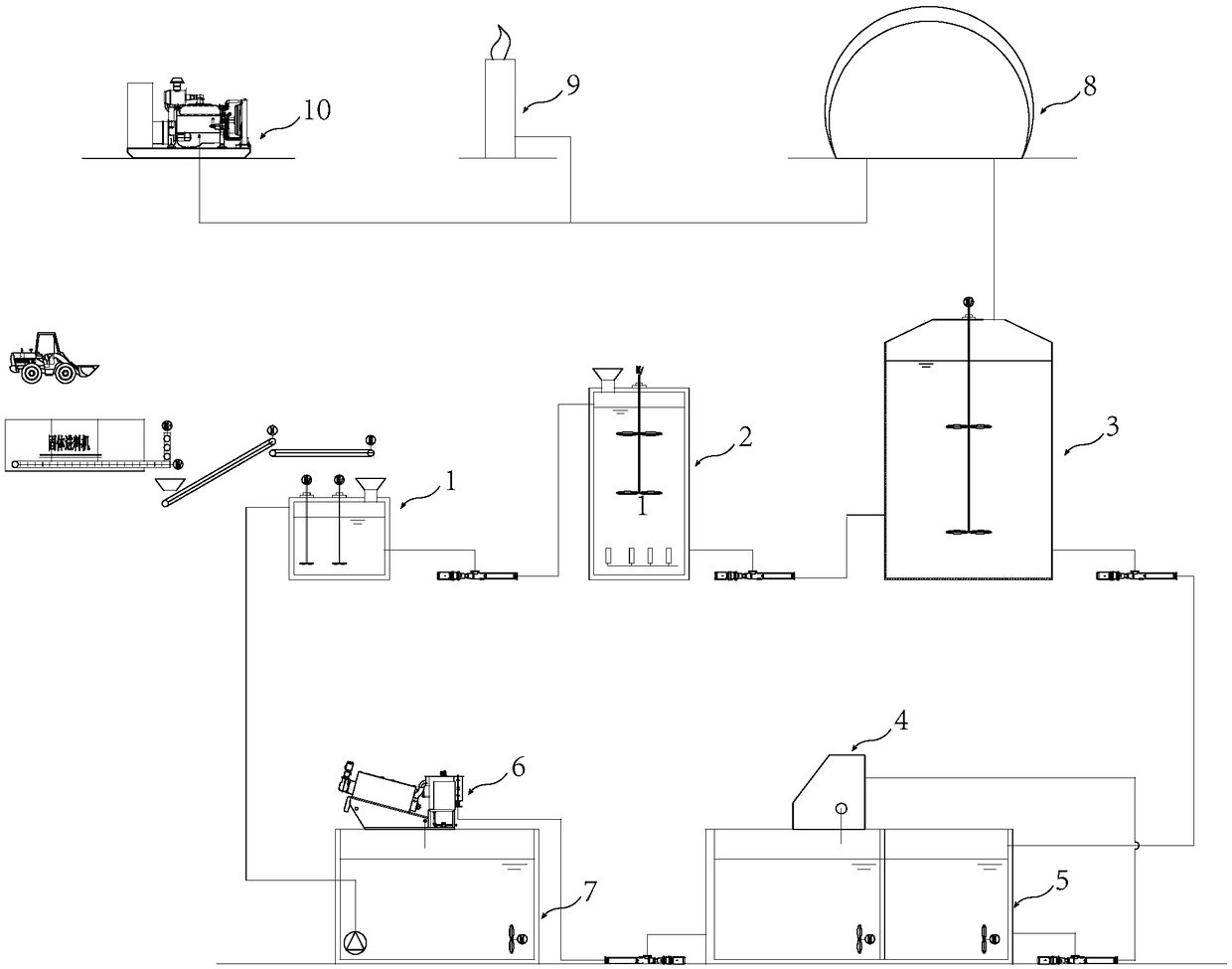

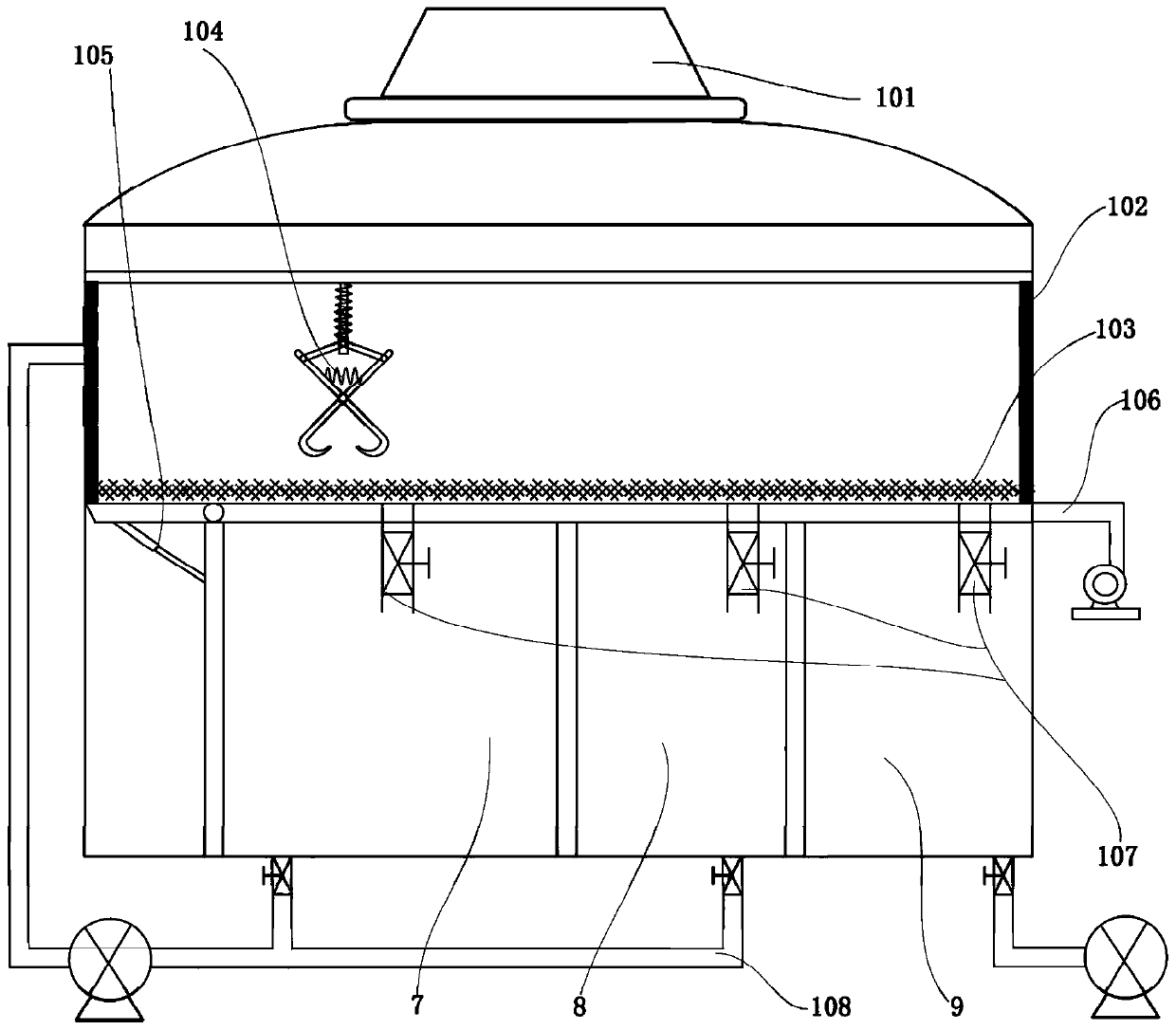

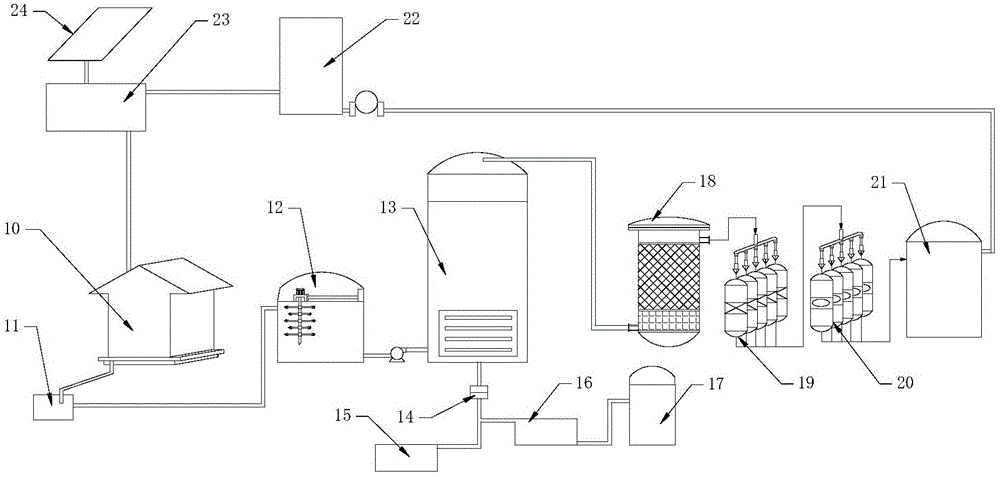

Resourceful marsh gas treatment system based on integrated CSTR reactor

InactiveCN105969657AImprove stirring efficiencyImprove the efficiency of biogas productionBioreactor/fermenter combinationsBio-organic fraction processingRefluxPropeller

The invention discloses a resourceful marsh gas treatment system based on an integrated CSTR reactor. The resourceful marsh gas treatment system comprises a straw storage bin, a rapid degradation tank, a hydrolysis tank, an independent heat exchanger, the integrated CSTR reactor, a biogas purification device, a foliar fertilizer bin, a marsh gas temporary-storage pool, a solid-liquid separator and an organic fertilizer bin. The integrated CSTR reactor comprises a tank body, a motor, a reverse stirring device and a reflux system. The reflux system and the reverse stirring device are added in the integrated CSTR reactor so that the resourceful marsh gas treatment system can effectively improve the mixing efficiency of crushed straws and anaerobic fermentation liquor and facilitate improvement of the marsh gas production efficiency of the straws. In addition, a propeller is added at a discharging port of the resourceful marsh gas treatment system, and waste can be quickly discharged from the tank body.

Owner:TIANZI ENVIRONMENT PROTECTION INVESTMENT HLDG LIMITED

Treatment method for efficient anaerobic production of acid and gas from kitchen waste

InactiveCN109650690AAvoid high levels of organic matterSpeed up the biogas production processBiological sludge treatmentBiogasOrganic acid

The invention relates to the technical field of resource-based treatment of organic solid waste, in particular to a treatment method for efficient anaerobic production of acid and gas from kitchen waste, which comprises the following steps of: 1) pretreating the kitchen waste; 2) producing acid by anaerobic fermentation; 3) carrying out solid-liquid separation and reflux of organic acids; and 4) producing biogas efficiently through an organic acid separation solution. By the adoption of the treatment method for high efficient anaerobic production of acid and gas from the kitchen waste, fast and efficient anaerobic fermentation of the kitchen waste to produce acid and biogas is achieved; generation of a large amount of the organic acids due to an excessive organic content of the kitchen waste in an anaerobic digestion process is effectively avoided, thereby preventing inhibition of a subsequent anaerobic process due to low pH of a reaction system; a secondary regulation of the pH of thereaction system is not necessary; the process of the production of biogas is greatly accelerated; high efficiency of the production of biogas is achieved; and fast speed and high degree of automationare achieved.

Owner:常州市环境卫生管理处

Biomass power generating equipment

InactiveCN105176800AQuick layeringEasy dischargeBioreactor/fermenter combinationsGas production bioreactorsEngineeringProcess engineering

The invention discloses biomass power generating equipment capable of producing biogas in a layered manner. The biomass power generating equipment comprises a base, wherein a methane tank and a gas-powered generator are mounted on the upper portion of the base, a guide cover is mounted on the upper portion of the methane tank, an oxygen content sensor is mounted on one side inside the guide cover, a gas pump is mounted on the upper portion of the guide cover, the gas outlet of the gas pump is connected with a gas pipe, one end of the gas pipe is connected with the gas pump, and the other end of the gas pipe is connected with the gas-powered generator. The biomass power generating equipment has the advantages that biomass can be layered fast through a simple process and structural design during methane producing, methane inside the biomass can be discharged fast, the methane producing efficiency of the biomass power generating equipment is increased by 10-15% as compared with existing biomass power generating equipment, and the power generating efficiency of the biomass power generating equipment is increased greatly.

Owner:SHANDONG HUANNENG DESIGN INST

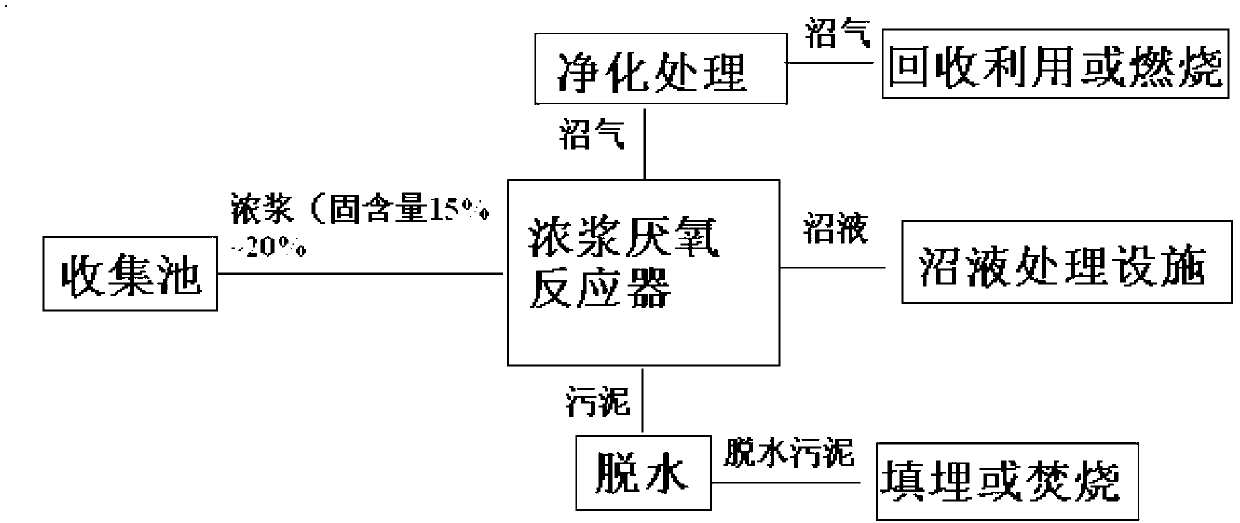

Anaerobic treatment method of kitchen garbage

InactiveCN103103214ASimple processEasy to controlWaste based fuelFermentationTotal solid contentLitter

The invention discloses an anaerobic treatment method of kitchen garbage. The anaerobic treatment method comprises the following steps of: mixing the to-be-treated kitchen garbage to dense slurry; and then anaerobically treating the dense slurry to obtain biogas liquid, biogas and sludge, thereby realizing the treatment on the kitchen garbage, wherein the total solid content in the dense slurry is 15%-20%. The anaerobic treatment method is simple in process, easy to control and low in treatment expense. A semi-solid dense slurry anaerobic technology (the total solid content is kept at 15-20%) is adopted, devices needed in conveying and digestion steps are simple and are easy to debug, the technology is stable, the biogas production efficiency is high and the standing time is short. The project scale adaptability is wide and unit equipment modularization is achieved.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

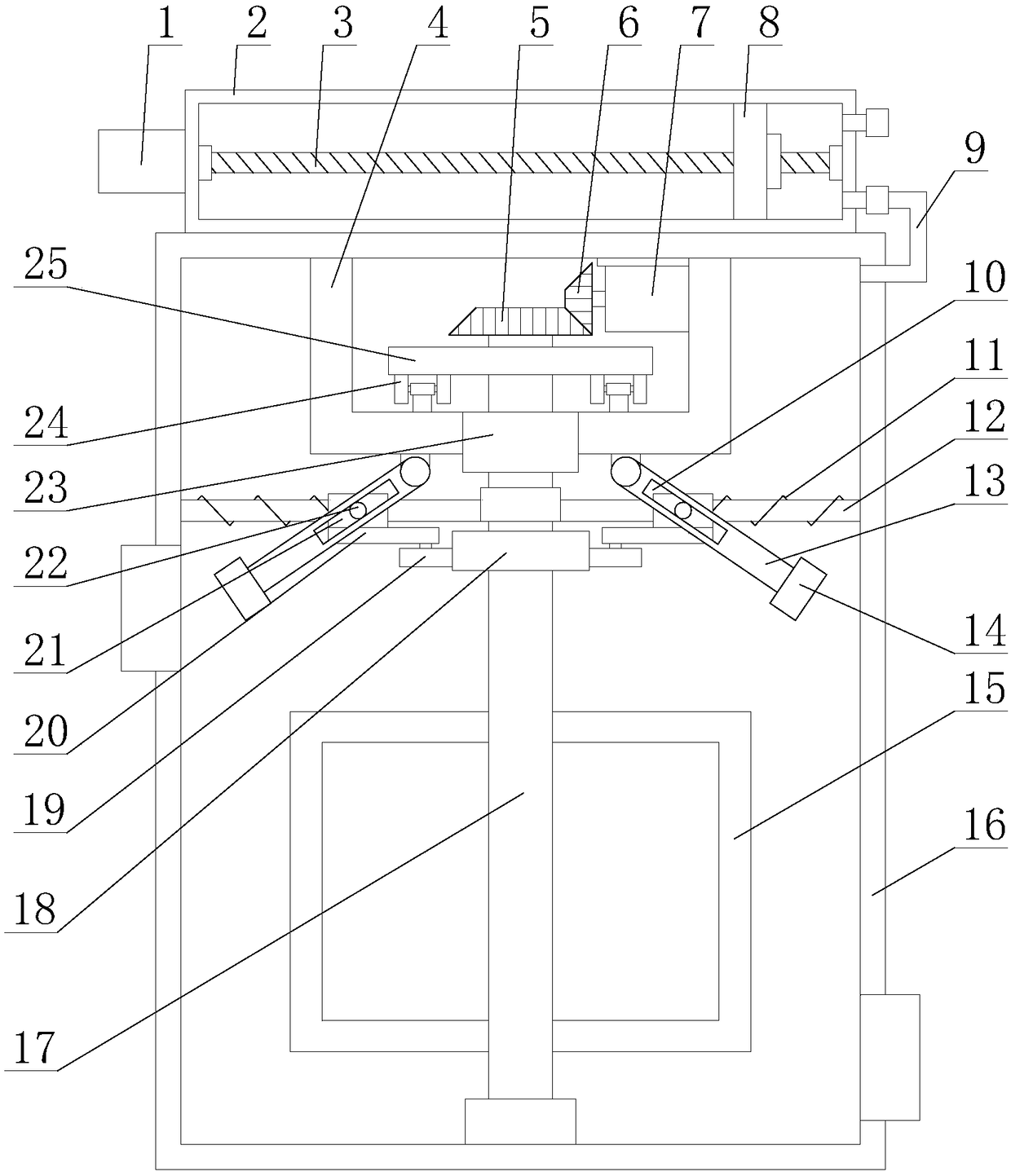

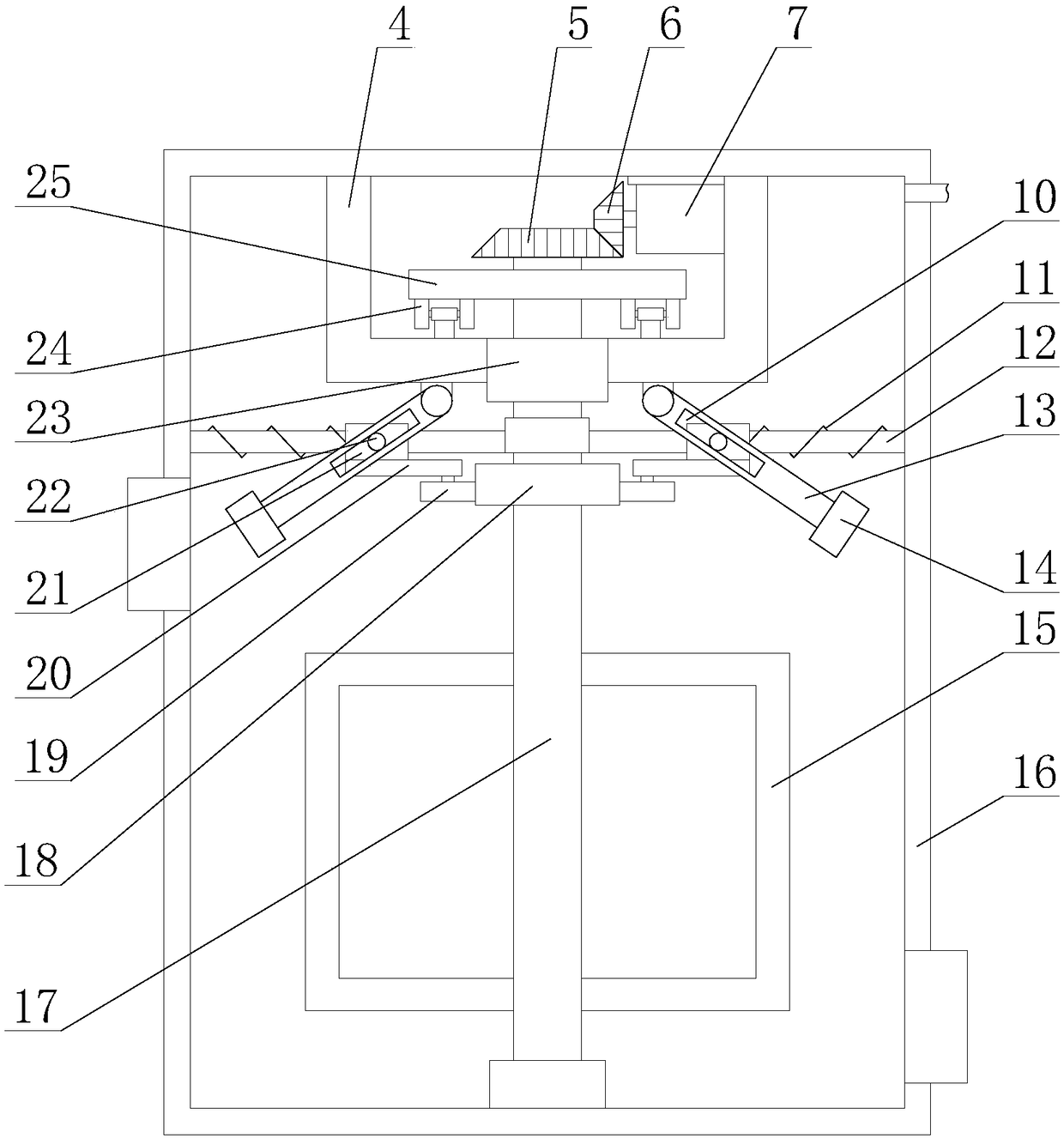

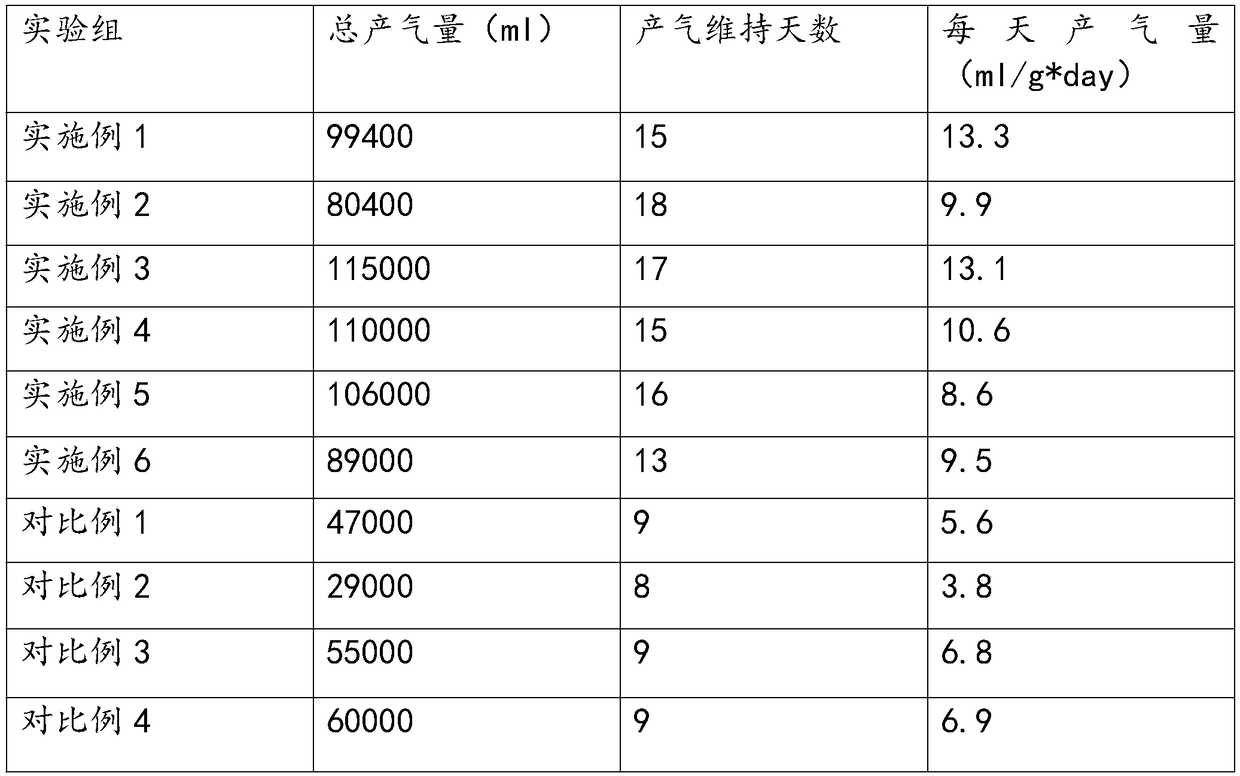

A method and device for preparing biogas by three-stage co-fermentation of straw and manure

ActiveCN110079448BSolve the problem of incomplete hydrolysisImprove the efficiency of biogas productionBioreactor/fermenter combinationsBio-organic fraction processingEnvironmental engineeringFermentation

The invention discloses a device for preparing biogas by three-stage co-fermentation of straw and manure, which comprises an open and closed aerobic hydrolysis leaching tank, a liquid acidification tank, an anaerobic fermentation tank, an aerobic composting device, and livestock and poultry manure Collection pond, lime water pond, high solute liquid collection pond, hydrogen sulfide gas absorber, ammonia gas absorber and system automatic control cabinet; the invention also discloses a method for preparing biogas by three-stage co-fermentation of straw and manure, including Three consecutive co-fermentation processes of aerobic hydrolysis of straw manure, rapid acidification of high solute liquid and high buffer anaerobic fermentation. The invention provides a three-stage biogas fermentation method and supporting equipment for co-producing fertilizer and gas with refractory straw combined with high-nitrogen perishable livestock and poultry manure, by improving the hydrolysis conversion efficiency of straw and reducing the inhibition of anaerobic fermentation process To improve the efficiency of anaerobic fermentation, realize efficient recycling of resources, and reduce the pollution load of biogas slurry.

Owner:NANCHANG UNIV

Efficient type biogas digester

InactiveCN109112059AImprove efficiencyImprove stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringWaste management

The invention relates to an efficient type biogas digester. The efficient type biogas digester comprises a main body, and further comprises a stirring mechanism and a storage mechanism, wherein the stirring mechanism comprises a supporting frame, a rotary shaft, a first drive assembly, a supporting sleeve, a supporting assembly, a shell crushing assembly and two or more stirring paddles; the shellcrushing assembly comprises a guide rod, a cam, two swing rods, two slide slots, two movable sleeves, two springs, two slide blocks, two knocking blocks, two transmission rods and two guide wheels; the storage mechanism comprises a second drive assembly, a storage tank, a piston and a gas conveying tube. In the efficient type biogas digester disclosed by the invention, the stirring mechanism candrive the knocking blocks to move up and down in a reciprocating mode while driving the stirring paddles to rotate, so that hard shells on the surface of organic garbage are crushed by the knocking blocks, and therefore, efficiency of generating biogas by the biogas digester is improved; and the storage mechanism can pump biogas inside the main body into the storage tank, so that pressure inside the biogas digester is reduced, and therefore, safety of the biogas digester is improved.

Owner:SHENZHEN LVYUAN HUIZHI TECH CO LTD

A kind of anaerobic digestion treatment method of kitchen waste

ActiveCN112845531BIncrease profitEnergy self-sufficiencyBio-organic fraction processingWaste processingOil and greaseProcess engineering

The invention provides an anaerobic digestion treatment method for kitchen waste, which belongs to the technical field of kitchen waste treatment. It solves the problems that resources are wasted to a certain extent in the existing garbage disposal methods, which are not environmentally friendly, and there are still many disadvantages in aerobic composting and anaerobic digestion. The present invention comprises the following steps: ①, pretreat the kitchen waste, and separate oil and water-solid mixed liquid; ②, send the water-solid mixed liquid into a homogeneous pool and mix thoroughly; ③, send the thoroughly mixed water-solid mixed liquid into Anaerobic digestion is carried out in the anaerobic fermentation device, and anaerobic digestion produces biogas, biogas residue and biogas slurry; ④, the generated biogas residue is added to the aerobic composting device for thermal composting, and at the same time, the aerobic composting device is continuously filled with straw and / or nutrients such as garden waste. The invention has the advantages that the anaerobic digestion technology and the aerobic composting technology complement each other; the continuous feeding and the two-phase process of a single anaerobic tank are realized by adopting two-stage feeding cabins; and multiple kinds of garbage are processed simultaneously.

Owner:ZHEJIANG NORMAL UNIVERSITY

Kitchen waste treatment all-in-one machine

ActiveCN112845533AIncrease profitEnergy self-sufficiencyBio-organic fraction processingTransportation and packagingProcess engineeringEnvironmental engineering

The invention provides a kitchen waste treatment all-in-one machine which belongs to the technical field of kitchen waste treatment, and solves the problems that an existing garbage treatment method wastes resources to certain extent, is not green and environmentally friendly, and has many defects in anaerobic composting and aerobic digestion. The kitchen waste treatment all-in-one machine comprises an anaerobic fermentation device and an aerobic composting device, wherein the anaerobic fermentation device comprises an aerobic tank, a biogas collecting hole is formed in the top of the aerobic tank; the aerobic composting device comprises an aerobic tank, a pit is formed in the top of the aerobic tank; the aerobic tank is arranged in the pit; an addition sandwich layer is formed between the inner wall of the pit and the anaerobic tank; the lower part of the addition sandwich layer communicates with an anaerobic digestion tank through a delay supply mechanism; the bottom of the anaerobic digestion cavity communicates with anaerobic composting cavity, and a communication portion is equipped with a biogas sag discharge mechanism. The kitchen waste treatment all-in-one machine has the advantages of integrating an aerobic digestion technology with an anaerobic composting technology, realizes continuous feeding and two-phase process of a single anaerobic tank through two-stage feeding, and can treat multiple kinds of garbage at the same time.

Owner:ZHEJIANG NORMAL UNIVERSITY

A device for wet anaerobic biogas production from kitchen waste

ActiveCN106085837BOverflow smoothlyLess prone to scumBioreactor/fermenter combinationsBiological substance pretreatmentsHeat balanceAerobic digestion

The invention discloses a wet-type anaerobic marsh gas preparation device for kitchen waste and belongs to the field of anaerobic digestion tanks. The wet-type anaerobic marsh gas preparation device comprises a fermentation tank body, a material evenly-distributing system, a uniform discharging system, a stirring and residue breaking system, a heat balance system, a sand and residue draining system and a marsh gas collecting system. By means of cooperation of the systems, an anaerobic digestion tank resists impact loads; dross, crusting and blockage are not prone to occurrence, gas overflows smoothly, and no sand is accumulated on the bottom of the fermentation tank body; materials and temperature in the fermentation tank body are distributed evenly; the marsh gas generation efficiency is high, and overhauling and maintaining are convenient.

Owner:上海浦东环保发展有限公司

A method for preparing biogas from irradiated pretreatment crop straw

ActiveCN109182391BEasy to operateNo pollution in the processWaste based fuelFermentationMethane yieldPulp and paper industry

Owner:HUNAN AGRICULTURAL UNIV

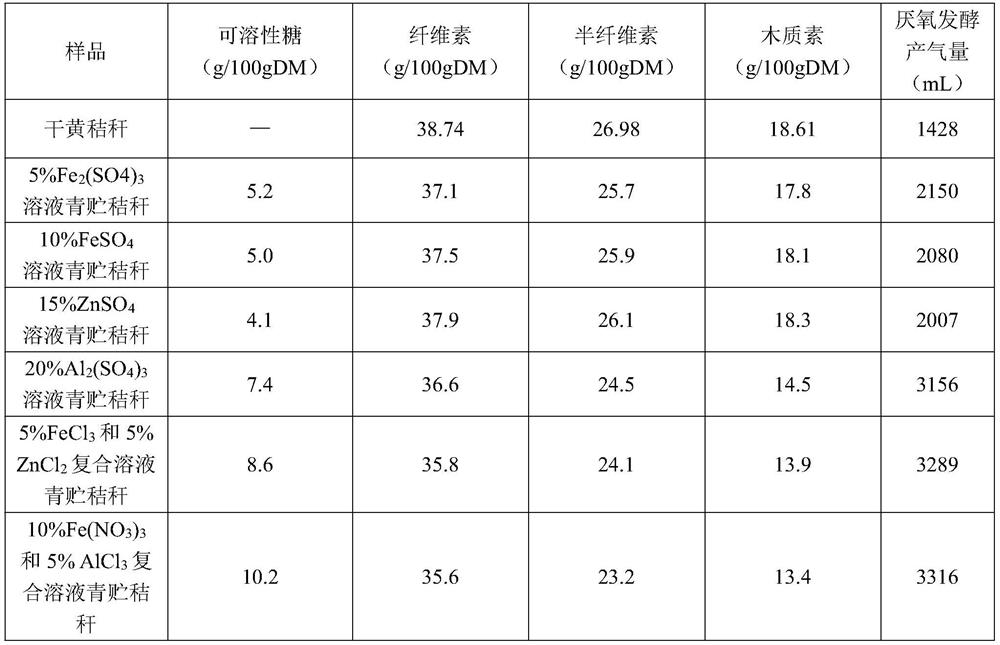

A high-efficiency straw fermentation method using straw silage to increase biogas production

ActiveCN107574187BImprove the efficiency of biogas productionEfficient resource utilizationWaste based fuelAnimal fodder preservationBiotechnologyBiogas production

The invention relates to a high-efficiency straw fermentation method using straw silage to increase biogas production, which comprises the following steps: 1). Raw material processing: crushing freshly harvested green straw to form straw scraps; 2). Soaking the silage additive: soaking the straw Put the crushed material into the silage additive solution and soak for 30-120 minutes. The silage additive adopts a metal salt solution with a mass percentage concentration of 0.5%-20%. 3). Vacuum silage: put the soaked straw fragments and silage additive mixture into a sealed container, and the sealed container is evacuated by a vacuum pump to form an anaerobic environment, and stored in a vacuum airtight manner for 30-120 days to obtain silage straw; 4 ). Biogas production by anaerobic fermentation: the obtained silage straw is subjected to anaerobic fermentation, and the mass ratio of the anaerobic fermentation inoculum to the dry matter of the silage straw is 1:1‑50. The invention can effectively increase the amount of biogas produced by the straw, so as to finally realize resourceful utilization of the straw with high efficiency and low cost.

Owner:TIANJIN CHENGJIAN UNIV

A device and method for reducing kasugamycin content in kasugamycin residue

ActiveCN109358105BReduce inhibitionImprove the efficiency of biogas productionComponent separationMaterial analysis by electric/magnetic meansElectrophoresesElectrolytic agent

The invention relates to a device and method for decreasing the kasugamycin content in kasugamycin residue. A direct current electrophoresis and macromolecular glue separation technology is adopted, as for the adopted device, macromolecular glue is placed in a general electrophoresis device, a square hole is dug in the macromolecular glue, the macromolecular glue is arranged at the bottom layer ofthe hole to serve as an underskirt, PBS, a 0.8% sodium chloride solution and a Tris-HCl buffer solution serve as an electrolyte, and the kasugamycin residue is put into the square hole of the macromolecular glue or is directly subjected to electrophoresis. According to the device, kasugamycin in the kasugamycin residue can be well removed, thus the kasugamycin can be subjected to better resourceutilization, in addition, the macromolecular glue is a biodegradable material, the kasugamycin in the residue enters the macromolecular glue through electrophoresis, and the kasugamycin entering the macromolecular glue can be reutilized through the separation technology, wherein the macromolecular glue with the kasugamycin being removed can be recycled.

Owner:陕西绿盾环境工程研究院有限公司

A biogas digester for urban waste recycling based on bim technology

ActiveCN106801010BImprove practicalityRealize automatic biogas collectionBioreactor/fermenter combinationsBiological substance pretreatmentsDrive shaftBiogas production

The invention relates to a biogas digester for recycling urban garbage based on a BIM (building information modeling) technology. The biogas digester comprises a biogas producing mechanism and a BIM operation and maintenance controller, wherein the biogas producing mechanism comprises a main body, a heating mechanism and a central control mechanism; an opening and closing mechanism is arranged at the top of the main body; the opening and closing mechanism comprises a driving assembly, a transmission assembly and an opening and closing assembly; the transmission assembly comprises a first gear, a first transmission shaft, a second transmission shaft, a second gear and a third gear; the heating mechanism comprises a heating assembly and a stirring assembly. In the biogas digester for recycling the urban garbage based on the BIM technology, according to the rise and fall of the medium water level in a water pressure compartment, the driving assembly controls the opening and closing assembly through the transmission assembly to achieve opening and closing of a second through hole in a top cap, so that automatic biogas collection of the biogas digester is achieved and the practicality of the biogas digester is improved; furthermore, through coordination of the heating assembly and the stirring assembly, the main body is uniformly heated, the biogas production efficiency is improved, and the practicality of the biogas digester is improved.

Owner:浙江爱源环境工程有限公司

Marsh gas production system

InactiveCN106281995ASimple structureEasy to useBioreactor/fermenter combinationsBio-organic fraction processingFertilizerScrap

The invention provides a marsh gas production system which comprises a nursing piggery and a waste storage box, wherein the nursing piggery is connected with the waste storage box through a dirt collection pipe; the waste storage box is connected with a stirrer; the stirrer is connected with a fermentation tank through a liquid extraction pump; the bottom of the fermentation tank is connected with a solid-liquid separator; the solid-liquid separator is connected with a solid fertilizer tank and a liquid collection tank; the liquid collection tank is connected with a liquid fertilizer tank; a steam-water separator is arranged at the top of the fermentation tank; a marsh gas outlet is formed in a position, located in the steam-water separator, on the fermentation tank, and is connected with a desulfuration and dehydration tank; the desulfuration and dehydration tank is connected with a dehydration bottle group and a desulfuration bottle group in sequence; the desulfuration bottle group is connected with a gas storage tank; the gas storage tank is connected with a marsh gas boiler; the marsh gas boiler is connected with a hot water storage tank. The marsh gas production system provided by the invention is simple in structure, convenient to use, reasonable in design, high in marsh gas production efficiency and high in waste utilization efficiency, and has the advantages of energy conservation, environment friendliness and use reliability.

Owner:中粮家佳康农牧(天津)有限公司

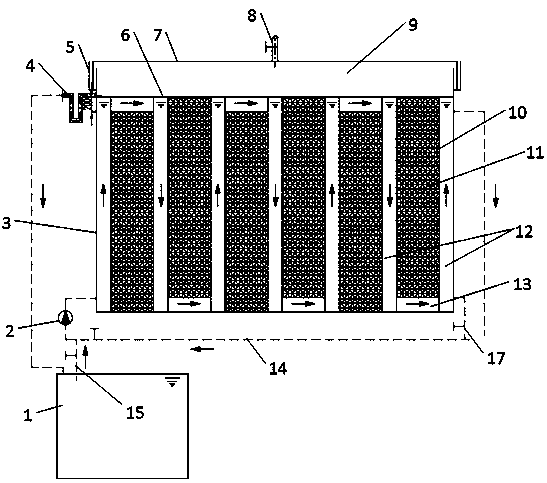

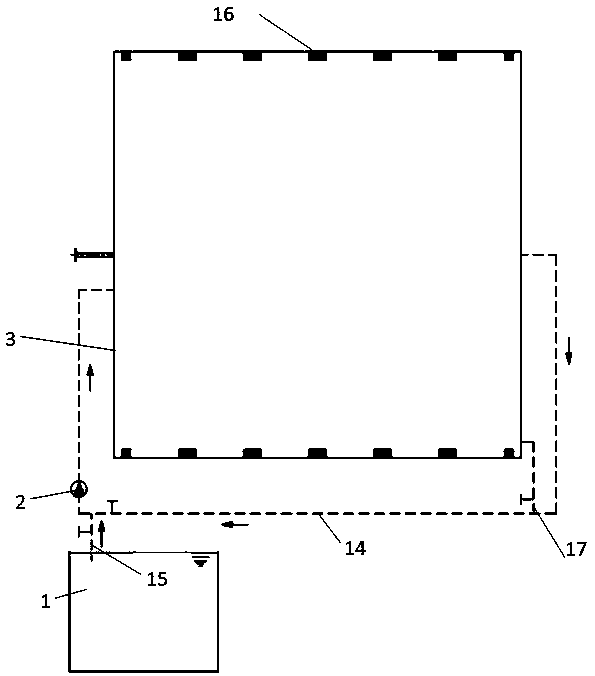

Honeycomb straw fermentation system and fermentation method thereof

ActiveCN106916732BFully contactedIncrease concentrationGas production bioreactorsWaste based fuelBiotechnologyFermentation broth

The invention discloses a beehive type straw fermentation system and a fermentation method. The fermentation system comprises a fermentation device, wherein a plurality of filling units for directly filling straw are arranged in the fermentation device; the top surfaces of the filling units are positioned on the highest water line in the fermentation device; the bottom surfaces of the filling units are positioned at the lowest water line at the bottom of the fermentation device; each filling unit comprises a straw filling region and a fermentation liquid overflowing region positioned at the end part of the straw filling region; the two adjacent filling units are positively and reversely arranged in the fermentation device; the fermentation liquid overflowing regions in positive and opposite arrangement form a liquid baffling fermentation passage in the fermentation device; the liquid inlet end of the liquid baffling fermentation passage is connected with a liquid inlet pipeline, and the liquid outlet is connected with a circulation pipeline. The beehive type straw fermentation system and the fermentation method has the advantages that the full contact of anaerobes and straw can be effectively ensured; the fermentation concentration and the gas production efficiency of a fermentation reactor are improved; the pretreatment on the straw is not needed; the raw material pretreatment operation flow process of straw engineering is reduced.

Owner:四川中沼生物能源检测有限责任公司

Efficient and low-cost anaerobic method and device

PendingCN109879566ASelf-balancing supplyImprove the efficiency of biogas productionSludge treatment by pyrolysisBiological sludge treatmentSludgeWastewater

The invention discloses an efficient and low-cost anaerobic method and device. The efficient and low-cost anaerobic method comprises the steps of size mixing, anaerobic process, pyrohydrolysis and dehydration, wherein sludge is subjected to size mixing firstly and then enters an anaerobic unit, biogas generated by the anaerobic unit provides energy for a boiler, the boiler provides heat for the pyrohydrolysis unit after the anaerobic unit, the sludge subjected to the pyrohydrolysis is dehydrated by special equipment to obtain mud cakes meeting the standard, and generated waste water is returned to a size mixing unit for reuse, and the special equipment is a dehydration device for an efficient and low-cost anaerobic process. According to the efficient and low-cost anaerobic method and device, the production efficiency is greatly improved, the production cost is remarkably reduced, and the efficient and low-cost anaerobic method and the device are environmentally friendly, efficient andlow in energy consumption.

Owner:SHENZHEN ECO SOLUTION TECH CORP

A method for producing biogas with molasses as substrate

ActiveCN103789351BPromote fermentation efficiencyImprove fermentation effectWaste based fuelFermentationCelluloseFermentable sugar

The invention discloses a method for producing biogas by taking molasses as a substrate. The method can be used for turning waste into wealth, the fermentation scale can be adjusted according to practical needs, the biogas generation efficiency is high, acidification does not occur easily in the fermentation process, and the problem of solid and semisolid raw materials is avoided in the collection and transportation of raw materials; compared with the technology taking the wastewater of molasses fermentation ethanol as a substrate, the molasses substrate adopted by the method disclosed by the invention contains a large amount of fermentable sugar as well as a large amount of fermentable components, the organic components in the molasses are efficiently utilized and directly applied to biogas fermentation, and thus the biogas fermentation efficiency and effect are better; moreover, the adopted technology and equipment are simpler, and a hydrolysis process of lignocellulose raw material is avoided; by adopting the method disclosed by the invention, the biogas fermentation technology is popularized in the regions with abundant molasses sources, and the development of renewable energy of the country and even the world is greatly accelerated.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

A method for high-efficiency phosphorus recovery coupled with anaerobic fermentation to treat livestock and poultry manure

ActiveCN107140615BImprove recycling efficiencyImprove the efficiency of biogas productionPhosphatesWaste water treatment from animal husbandryFecesLivestock manure

The invention provides a method for treating livestock and poultry feces with high-efficiency nutrient salt recovery coupled with anaerobic fermentation, and belongs to the technical field of breeding waste treatment. The method comprises the following steps: (1) performing hydrothermal pretreatment on livestock and poultry manure; (2) performing phosphorus recovery treatment on the pretreated livestock and poultry manure; Anaerobic fermentation of poultry manure. The treatment method provided by the present invention is based on hydrothermal pretreatment of livestock and poultry manure nutrient salt recovery and anaerobic fermentation coupled process, this process well promotes the extraction and recovery of phosphorus in livestock and poultry manure, and the treatment of livestock and poultry manure The improvement of anaerobic fermentation performance has realized the maximum resource conversion and utilization of livestock and poultry manure.

Owner:BIOGAS SCI RES INST MIN OF AGRI

Method for generating biogas by fermenting pig excrement of pig farm and plants

InactiveCN108866111AAnaerobic fermentation time is shortHigh methane contentWaste based fuelFermentationPig farmsActivated sludge

The invention discloses a method for generating biogas by fermenting pig excrement of a pig farm and plants. The method comprises the following steps: reasonably matching plant straws with a catalyst,and carrying out pre-treatment; then mixing the pre-treated plant straws and fresh pig excrement; adding water and uniformly stirring; adjusting the moisture content and adjusting the C / N ratio to obtain a mixed solution; then adding activated sludge into the mixed solution as an inoculant; after regulating the pH (Potential of Hydrogen) value, putting into an anaerobic reactor; carrying out anaerobic fermentation at middle temperature. According to the method disclosed by the invention, the problems that the pig excrement of the pig farm has a great amount and is difficult to treat, and thestraws are not allowed to be combusted are combined, the pig excrement and the straws are matched with the catalyst to obtain an optimal fermentation process, and the fermentation time is shortened, so that the pig excrement is rapidly treatment and accumulation is avoided.

Owner:凤台县正祥农业科技发展有限公司

Efficient biogas digester with pressure regulating function

InactiveCN110564606AWith pressure regulating functionImplement storageBioreactor/fermenter combinationsBiological substance pretreatmentsCombustionDrive shaft

The invention relates to an efficient biogas digester with a pressure regulating function. The efficient biogas digester comprises a main body, a feeding port and a cover plate, the efficient biogas digester also comprises a stirring mechanism and a pressure regulating mechanism, wherein the pressure regulating mechanism comprises a pressure regulating tank, an air cylinder, a lifting plate, a pressure sensor and two support assemblies; the stirring mechanism comprises a drive shaft, a first pipeline, a second pipeline, a third pipeline, a rotary joint, a stirring pipe, a drive assembly, a heat storage assembly, an air pump and two mounting bearings; each support assembly comprises a support rod, a limiting block and a support casing; the drive assembly comprises a motor, a first gear anda second gear; and the heat storage assembly comprises a heat storage box and a filter net. In the efficient biogas digester with the pressure regulating function, the probability of crusting of organic fertilizer is reduced by the stirring mechanism, the biogas production efficiency of the biogas digester is improved, the pressure in the biogas digester can be regulated by the pressure regulatingmechanism, so that the pressure in the biogas digester is kept stable, and the combustion efficiency and stability of cookers are improved.

Owner:蒙泽喜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com