A method and device for preparing biogas by three-stage co-fermentation of straw and manure

A co-fermentation, three-stage technology, applied in the intersection of agricultural science and environmental science, can solve the problems of insufficient residence time, slow hydrolysis rate of straw, and low degree of hydrolysis, so as to improve resource recovery rate, improve biogas production efficiency, reduce inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

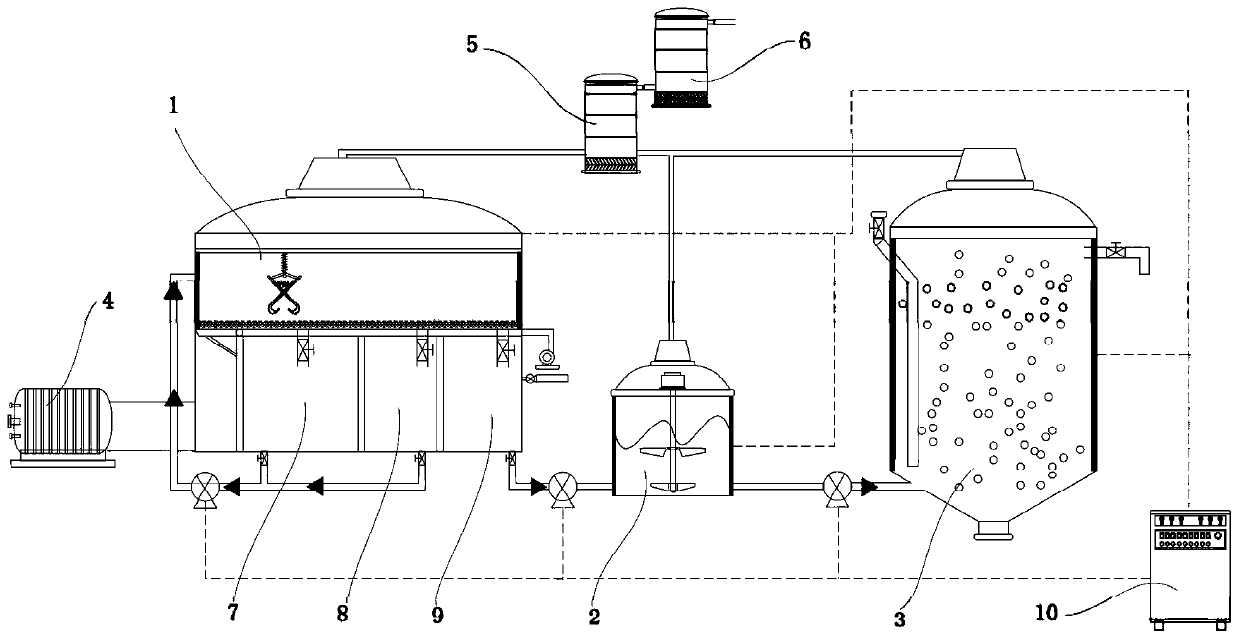

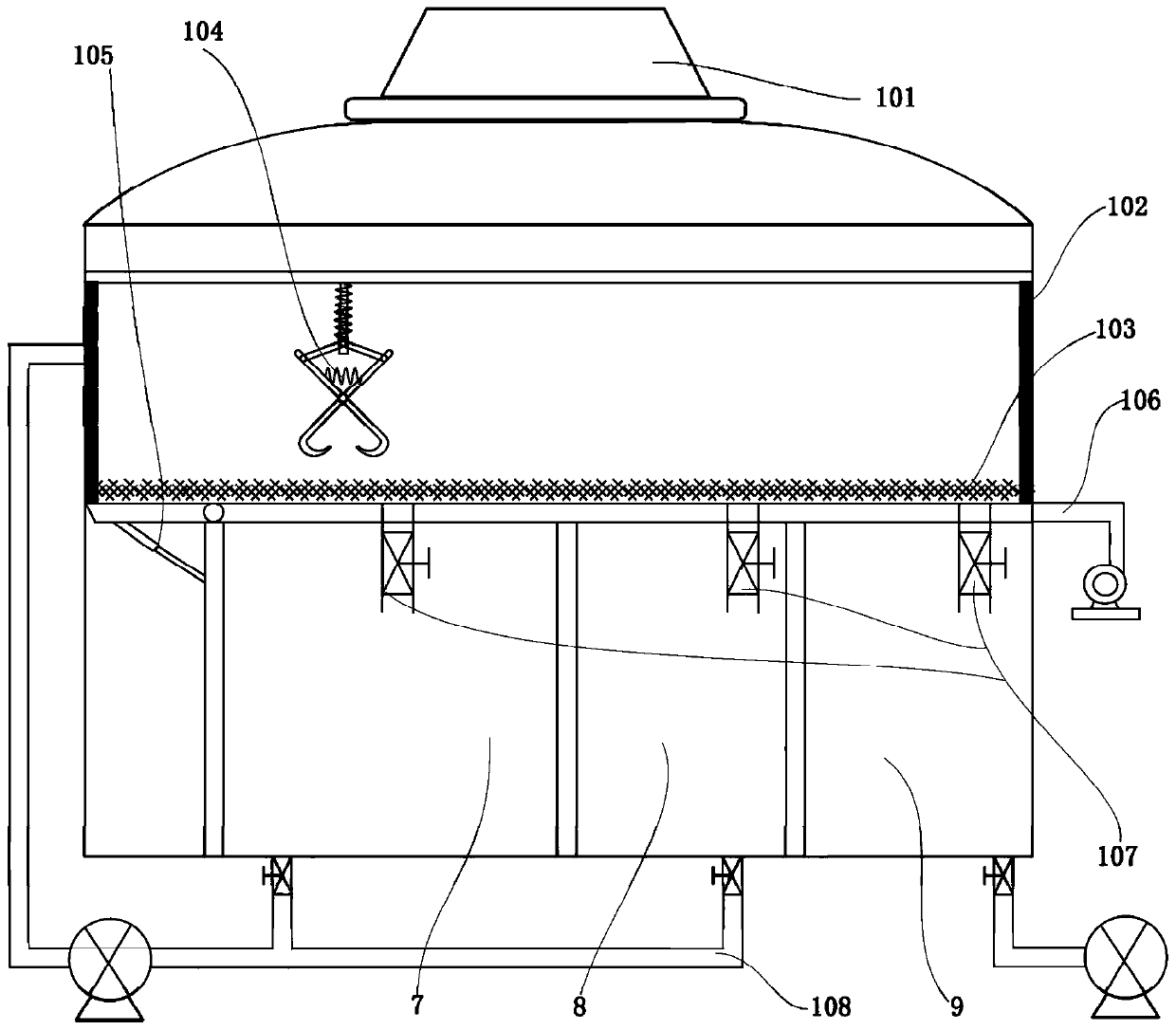

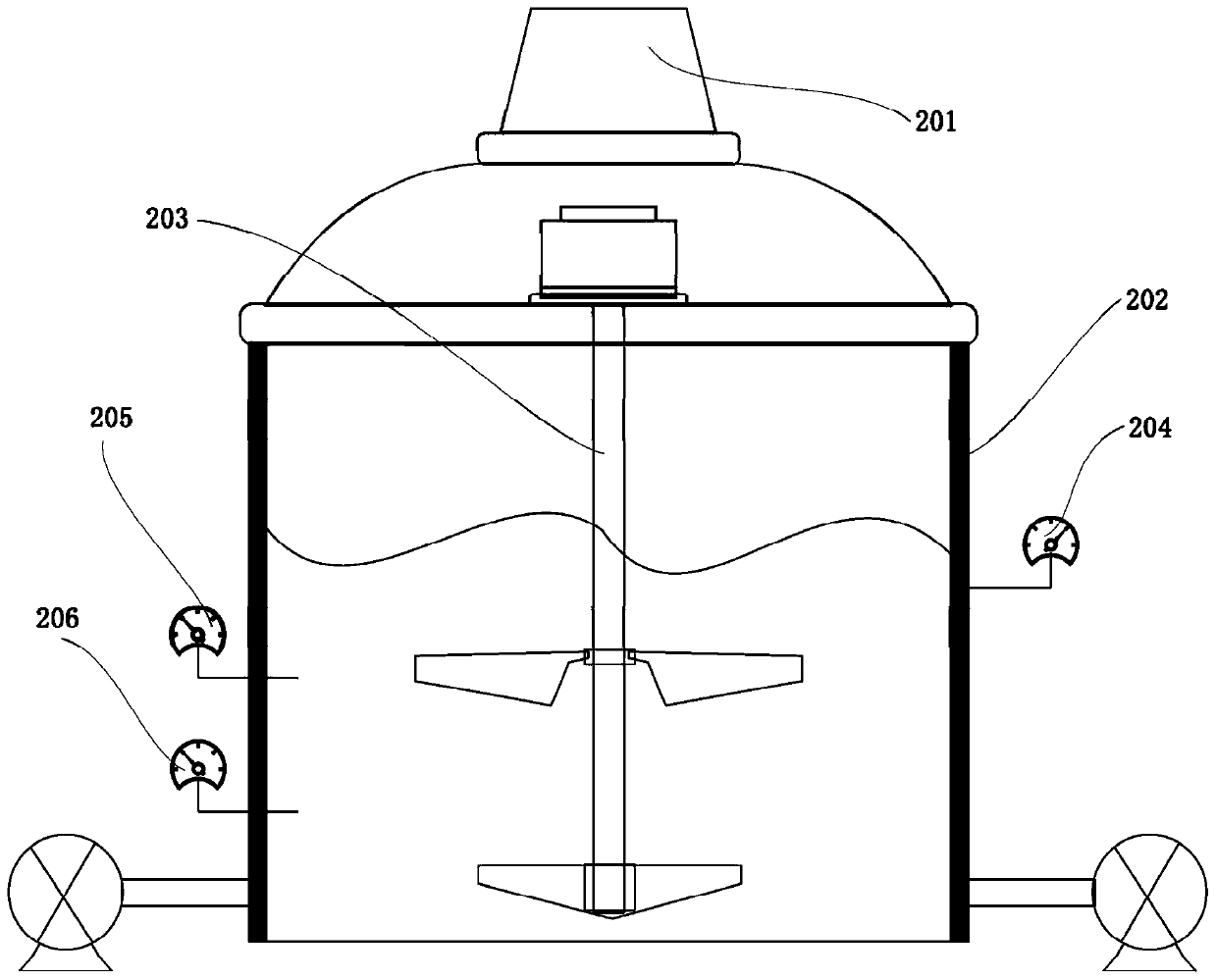

[0038] Such as figure 1 As shown, a device for preparing biogas by three-stage co-fermentation of straw and manure, including an open-close aerobic hydrolysis leaching tank 1, a liquid acidification tank 2, an anaerobic fermentation tank 3, an aerobic composting device 4, an animal Poultry manure collection pool 7, lime water pool 8, high solute liquid collection pool 9, hydrogen sulfide gas absorber 5, ammonia gas absorber 6 and system automatic control cabinet 10, livestock and poultry manure sewage collection pool 7, lime water pool 8, high The solute liquid collection tank 9 is arranged side by side under the open-close aerobic hydrolysis leaching tank 1, and the connection between the open-close aerobic hydrolysis leaching tank 1, the livestock and poultry manure collection tank 7, and the lime water pool 8 is through a down-drain pipeline 107 and The pumping pipeline 108 is used for material circulation, and the open-close aerobic hydrolysis leaching tank 1 and the high-...

Embodiment 2

[0048] This embodiment also uses a three-stage co-fermentation device for straw and manure to produce biogas in Example 1, and combines straw with pig manure for three-stage co-fermentation to produce biogas.

[0049] After the straw that is taken is chopped, spread in the opening and closing type aerobic hydrolysis leaching tank 1, thickness 45cm, the lime water (calcium hydroxide concentration is 20%) in the lime pool 8 is extracted to the opening and closing type aerobic hydrolysis In the leaching tank 1, submerge and soak the softened straw for 16 hours and then drain it back to the lime pool 8 through the filter screen of the supporting plate 103; pump the pig urine foam manure in the livestock and poultry manure collection tank 7 into the open-close aerobic hydrolysis leaching tank 1 for soaking After 12 hours, the clear liquid was discharged back to the livestock and poultry manure collection pool 7 through the filter screen; then inoculate the fertile topsoil of the pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com