A method for high-efficiency phosphorus recovery coupled with anaerobic fermentation to treat livestock and poultry manure

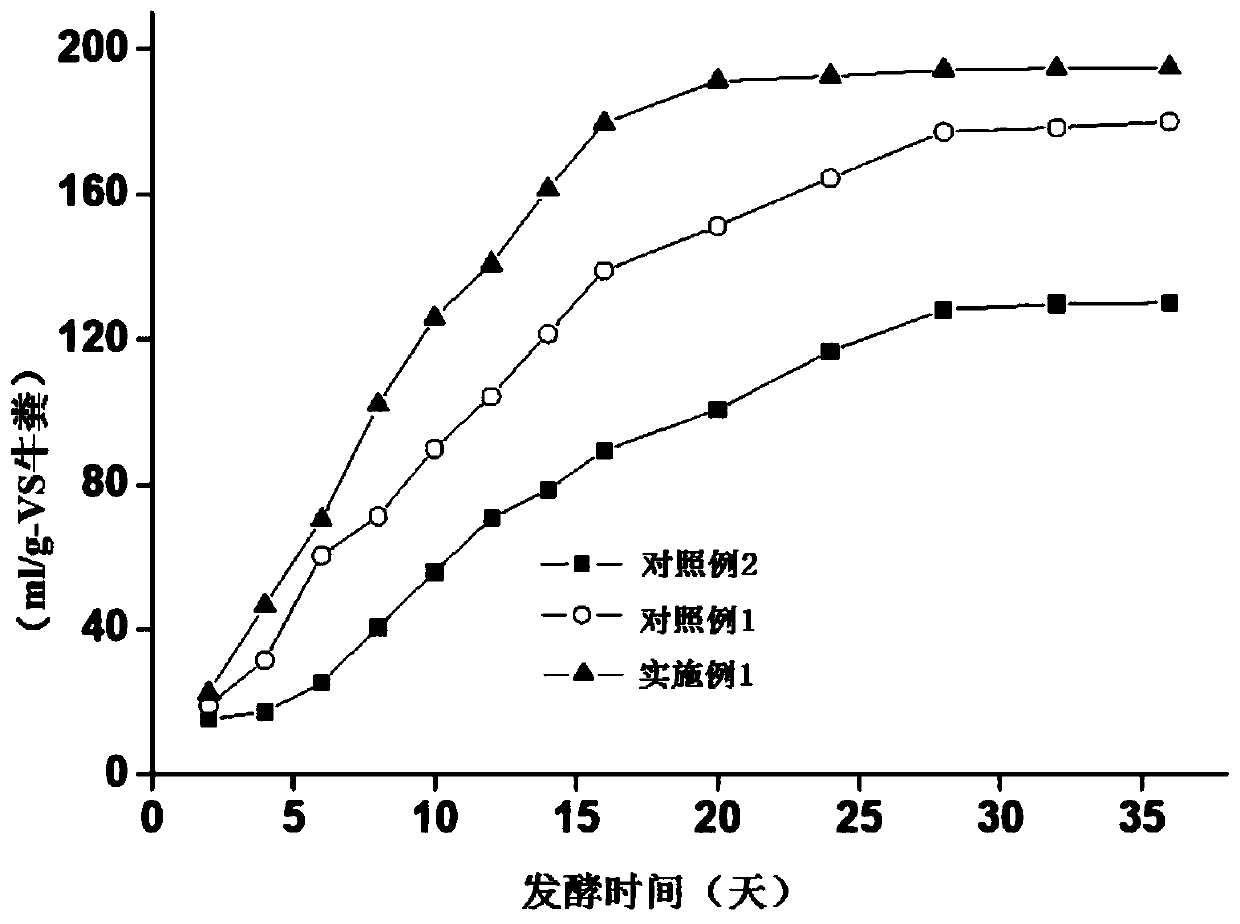

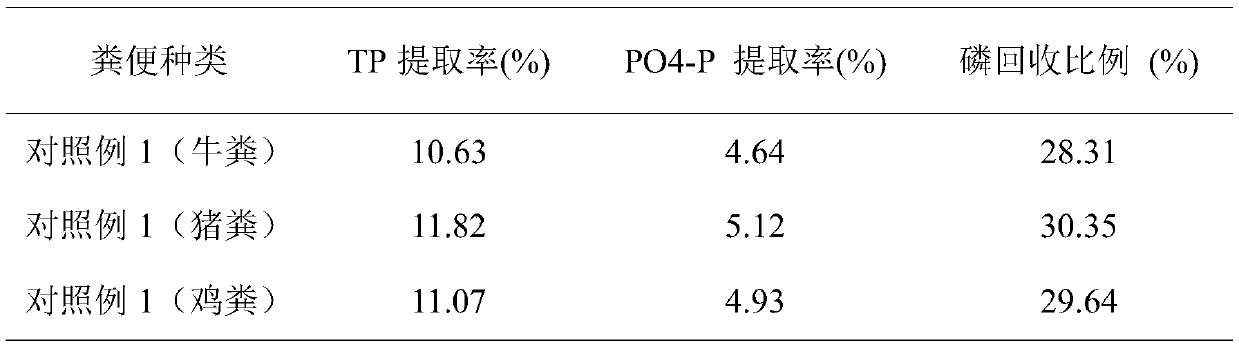

An anaerobic fermentation, livestock and poultry manure technology, applied in the field of breeding waste treatment, can solve the problems of low efficiency, low orthophosphate recovery efficiency, low methane conversion efficiency, etc., achieve high efficiency, promote extraction and recovery, recovery Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

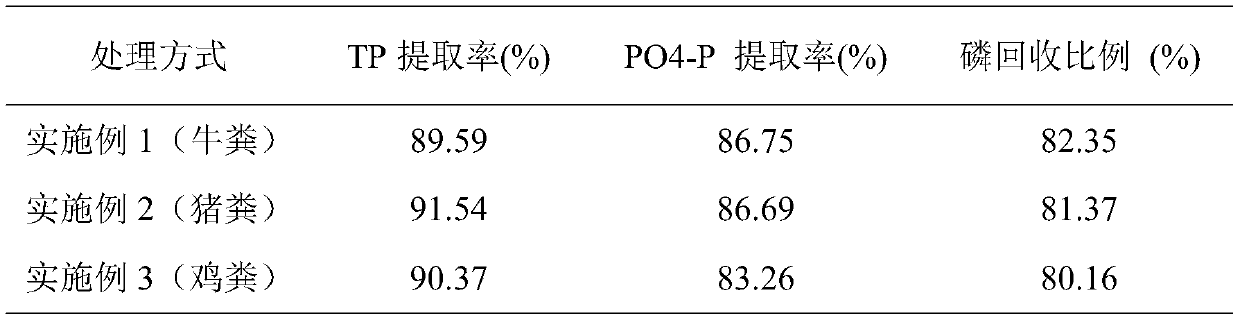

Embodiment 1

[0027] A method for efficiently treating cow dung, comprising the steps of:

[0028] (1) hydrothermal pretreatment: take by weighing 25g dry cow dung, phosphorus content is 0.55% in the dry cow dung, to wherein adding hydrochloric acid and water carry out hydrothermal pretreatment, the total mass concentration of hydrochloric acid in the hydrothermal pretreatment mixed system is 0.1%, the total solid content of dry cow dung is 5%, the mixed system is subjected to hydrothermal pretreatment at 200°C for 0.5h, and then solid-liquid separation is carried out, and solid phase product I and liquid phase product I are collected;

[0029] (2) Phosphorus recovery treatment: add NaOH to the liquid phase product I to adjust the pH to 10, stir at 150rpm for 20 minutes, then let it stand for 30 minutes, and then separate the solid phase product II and the liquid phase product II by centrifugation. , the solid phase product II was collected, and after detection, the solid phase product II w...

Embodiment 2

[0032] A method for efficiently processing pig manure, comprising the following steps:

[0033] (1) hydrothermal pretreatment: take by weighing 50g dry pig manure, phosphorus content is 0.65% in the dry pig manure, to wherein adding nitric acid and water carry out hydrothermal pretreatment, the total mass concentration of nitric acid in the hydrothermal pretreatment mixed system is 1%, the solid content of pig manure is 20%, when the mixture is heated until the temperature reaches 380°C, the hydrothermal pretreatment reaction is stopped, and then the solid-liquid separation is carried out, and the solid phase product I and the liquid phase product I are collected;

[0034] (2) Phosphorus recovery treatment: add Mg(OH) to the liquid phase product Ⅰ 2 and MgO to adjust the pH to 9, stir at 100rpm for 30min, then let it stand for 1min, and then centrifuge to separate solid-phase product II and liquid-phase product II, and collect the solid-phase product II. After testing, the sol...

Embodiment 3

[0037] A method for efficiently treating chicken manure, comprising the following steps:

[0038] (1) hydrothermal pretreatment: take by weighing 100g dry chicken manure, phosphorus content is 0.58% in the dry chicken manure, to wherein adding hydrochloric acid and water carry out hydrothermal pretreatment, the total mass concentration of hydrochloric acid in the hydrothermal pretreatment mixed system is 5%, the solid content of chicken manure is 40%, the mixed system is subjected to hydrothermal pretreatment at 100°C for 6 hours, and then solid-liquid separation is carried out, and solid phase product I and liquid phase product I are collected;

[0039] (2) Phosphorus recovery treatment: add Ca(OH) to the liquid phase product Ⅰ 2 or CaO to adjust the pH to 11, stir at 300rpm for 5 minutes, and then let it stand for 20 minutes, then filter and separate the solid and liquid to obtain the solid-phase product II and liquid-phase product II, and collect the solid-phase product II ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com