Operating method of CSTR integrated reactor in marsh gas resourceful treatment system

一种处理系统、运行方法的技术,应用在CSTR一体化反应器的运行领域,能够解决废料黏在装置内壁、不易排出、搅拌效率影响秸秆发酵效率沼气产气率等问题,达到提高效率、提高搅拌效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

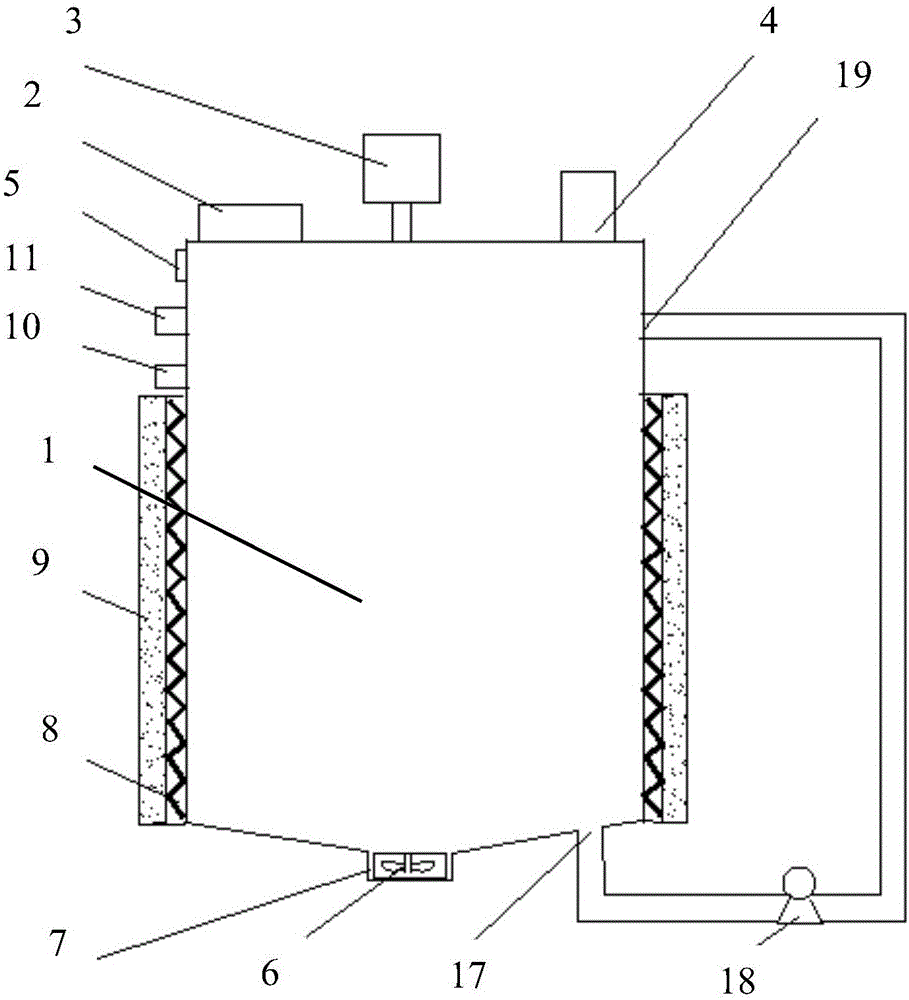

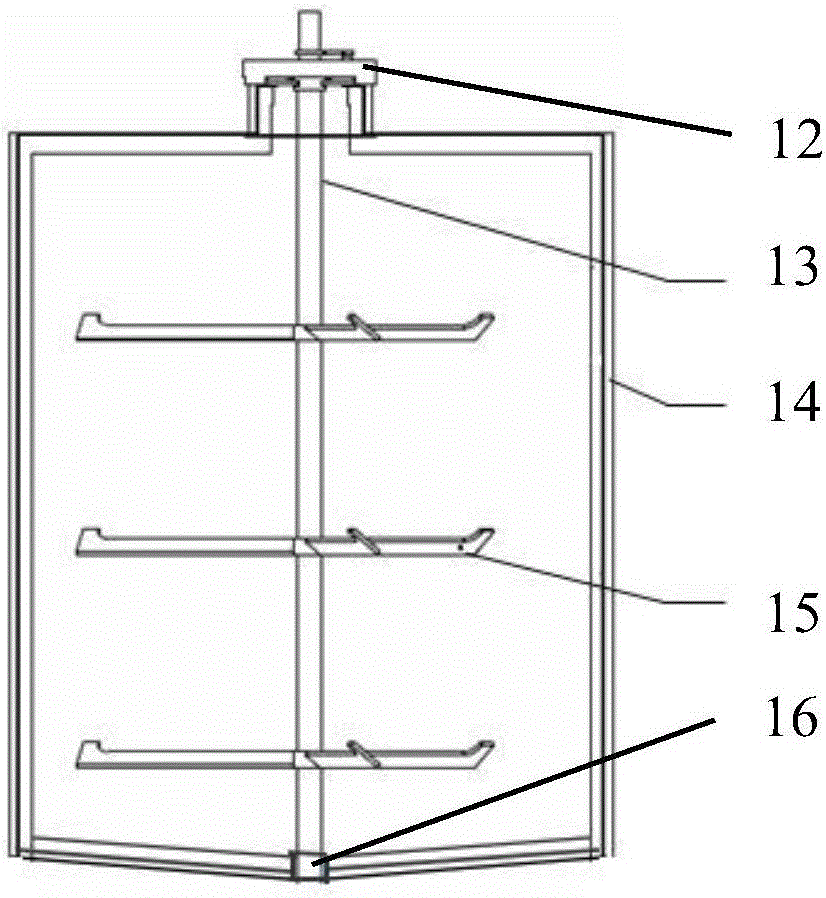

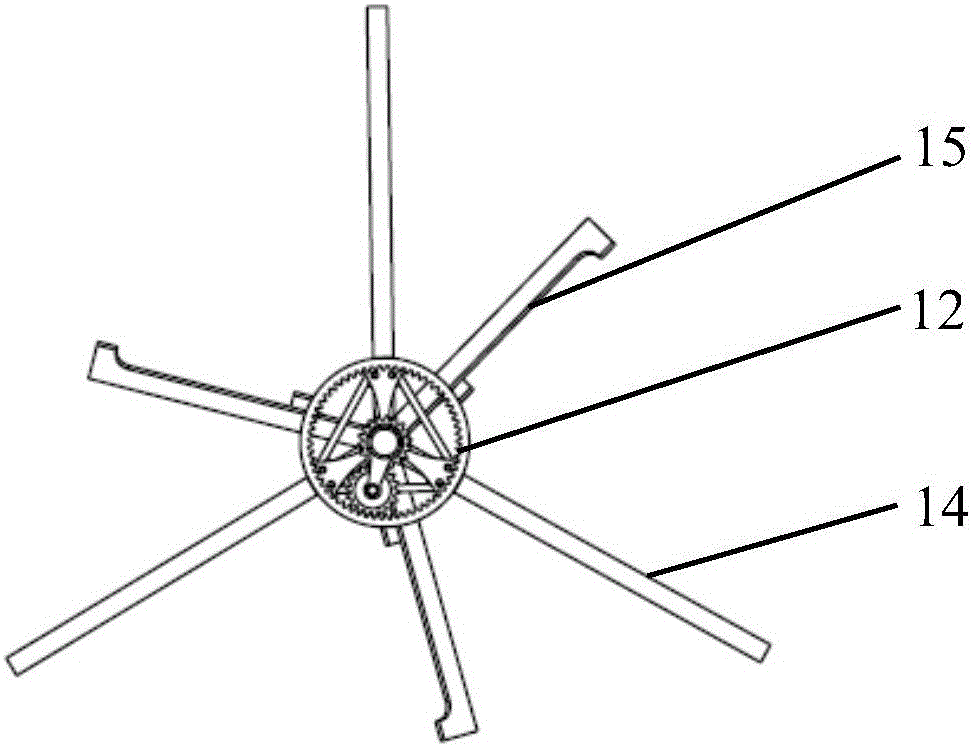

[0018] as attached Figure 6 As shown, a biogas resource treatment system based on a CSTR fermentation device involved in the present invention includes a straw storage bin a, a rapid degradation tank b, a hydrolysis tank c, an independent heat exchanger d, a CSTR integrated reactor e, a biogas Purification device f, foliar fertilizer bin g, biogas slurry temporary storage tank h, solid-liquid separator i, organic fertilizer bin j; the straw storage bin is connected to the rapid degradation tank; the rapid degradation tank is connected to the hydrolysis tank through pipelines; the hydrolysis tank is connected through pipelines It is connected with an independent heat exchanger; the independent heat exchanger is connected with the CSTR integrated reactor and the solid-liquid separator through pipelines; the CSTR integrated reactor is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com