A device and method for reducing kasugamycin content in kasugamycin residue

A technology of kasugamycin and residue, which is applied in the field of reducing the content of kasugamycin residue in kasugamycin, can solve the problems of low combustion calorific value, increased enterprise cost, and high daily incineration cost, so as to improve biogas production efficiency, reduce treatment costs, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

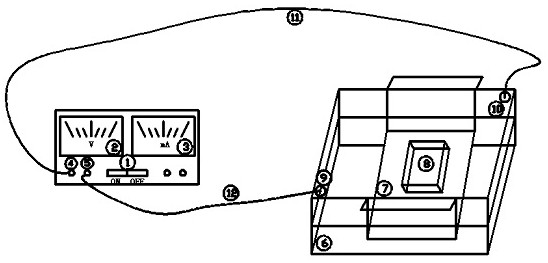

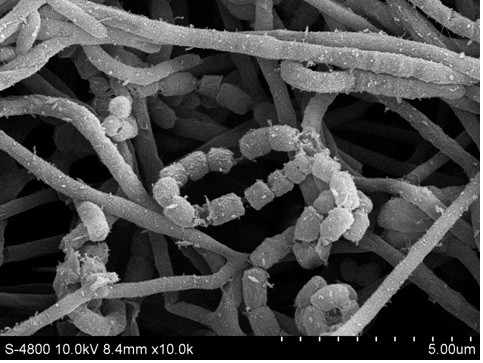

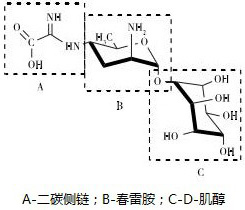

[0060] In order to determine the impact of time and voltage on the kasugamycin content of kasugamycin residue, select 178 hours of fermentation liquid (mycelia scanning electron microscope see figure 2 ) The acidified acidified solution is filtered through a ceramic membrane, the selected voltage is 30, 50, 70, 90, 110, 130, 170 volts of direct current voltage, the electrophoresis liquid in the electrophoresis tank is PBS buffer (pH=7.2), electrophoresis The time is 90min, and the porous supports are agarose gel, polyacrylamide gel and pectin. The specific results are shown in Table 1.1.

[0061] Table 1.1 The effect of different voltages on the removal of Kasugamycin residues

[0062]

[0063] It can be seen from Table 1.1 that as the voltage continues to increase, the removal rate of kasugamycin of each support residue is constantly increasing, between 30-100 volts, the greater the increase, and after 110 volts, the upward trend Not obvious; between 30-50 volts of DC vo...

Embodiment 2

[0065] In order to determine the impact of time on the kasugamycin content of the kasugamycin residue, select the electrophoresis time to be 30, 45, 60, 75, 90, 105 and 120min, DC voltage 110 volts, the electrophoresis liquid of the electrophoresis tank is PBS buffer (pH =7.2), the porous supports are agarose gel, polyacrylamide gel and pectin, the specific results are shown in Table 2.1.

[0066] Table 2.1 Effect of different electrophoresis time on the removal effect of kasugamycin residues

[0067]

[0068] It can be seen from Table 2.1 that between the electrophoresis time of 30-90, as the electrophoresis time prolongs, the removal efficiency of kasugamycin of the residue increases with the prolongation of time, and the removal rate difference between the three supports is compared in pairs Not significant (p>0.05), between 90-120, the removal rate of kasugamycin under each substrate is decreased, because the migration rate of positive and negative ions charged by kasug...

Embodiment 3

[0070] In order to determine whether the kasugamycin content of the kasugamycin residue affects the removal rate of the residue kasugamycin, the kasugamycin residue in the ceramic membrane filtration section is selected, diluted 2 times with the residue quality, stirred evenly, the electrophoresis voltage is 110 volts, and the electrophoresis The time is 90min, and the electrophoresis fluid in the electrophoresis tank is PBS buffer (pH=7.2). The specific results are shown in Table 2.1.

[0071] Table 3.1 Effect of kasugamycin content in kasugamycin residue on the removal rate of kasugamycin in residue

[0072]

[0073] It can be seen from Table 3.1 that when the kasugamycin residue is diluted in a ratio of 0-2 4 Between dilutions, the removal rate of kasugamycin under each support increases with the increase of the dilution factor, this is because kasugamycin hydrochloride is in the certain situation of each support space volume, and kasugamycin hydrochloride and The resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com