A high-efficiency straw fermentation method using straw silage to increase biogas production

A fermentation method and straw technology, applied in the field of high-efficiency straw fermentation, to achieve the effects of inhibiting activity, low-cost resource utilization, and enhancing fresh-keeping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

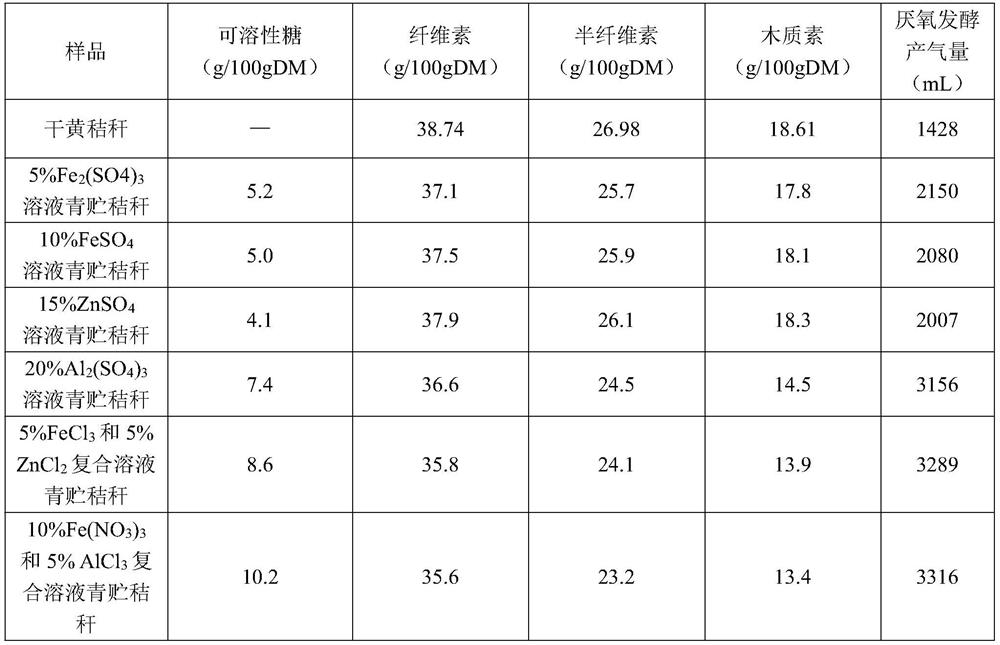

Embodiment 1

[0028] A high-efficiency straw fermentation method using straw silage to increase biogas production, the method comprising the following steps:

[0029] 1). Raw material processing: Harvest the whole plant corn stalks with ears at the wax ripening stage, and crush them to a length of 15mm to form straw scraps with a moisture content of 60%-70%;

[0030] 2). Soaking in silage additives: put straw scraps into 5% Fe 2 (SO4) 3 Solution mixing, Fe 2 (SO4) 3 The mass ratio of the solute to the green straw is 1:20, and the soaking time is 40 minutes in an ultrasonic cleaner; the ultrasonic cleaner is used to apply ultrasound while soaking; the ultrasonic frequency is 25kHz, and the power is 50w.

[0031] 3). Vacuum silage: put the soaked straw fragments and silage additive mixture into a sealed bag, and the sealed bag is evacuated by a vacuum pump to form an anaerobic environment, and stored in a vacuum airtight manner for 30 days to obtain silage straw. The composition of straw ...

Embodiment 2

[0036] A high-efficiency straw fermentation method using straw silage to increase biogas production, the method comprising the following steps:

[0037] 1). Raw material processing: Harvest the whole plant corn stalks with ears at the wax ripening stage, and crush them to 10mm to form straw scraps with a moisture content of 60%-70%;

[0038] 2). Soaking in silage additives: put the straw scraps into FeSO with a mass concentration of 10% 4 Solution mixing, FeSO 4 The mass ratio of the solute to the green straw is 1:100, and it is soaked in an ultrasonic cleaner for 90 minutes; while soaking, the ultrasonic cleaner is used to apply ultrasound; the ultrasonic frequency is 25kHz, and the power is 50w.

[0039] 3). Vacuum silage: Put the soaked straw fragments and silage additive mixture into a sealed container, and the sealed container is evacuated by a vacuum pump to form an anaerobic environment, and stored in a vacuum airtight manner for 60 days to obtain silage straw. The co...

Embodiment 3

[0044] A high-efficiency straw fermentation method using straw silage to increase biogas production, the method comprising the following steps:

[0045] 1). Raw material processing: Harvest the whole plant corn stalks with ears at the wax ripening stage and crush them to 5mm to form straw scraps with a moisture content of 60%-70%;

[0046] 2). Soaking of silage additives: put straw scraps into 15% ZnSO 4 Solution mixing, ZnSO 4 The mass ratio of the solute to the green straw is 1:200, and it is soaked in an ultrasonic cleaner for 120 minutes; ultrasonic cleaner is used to apply ultrasound while soaking; the ultrasonic frequency is 25kHz, and the power is 50w.

[0047] 3). Vacuum silage: Put the soaked straw fragments and the mixture of silage additives into a sealed container, and the sealed container is evacuated by a vacuum pump to form an anaerobic environment, and stored in a vacuum airtight manner for 90 days to obtain silage straw. The composition of straw after silage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com