Efficient and low-cost anaerobic method and device

A low-cost, high-efficiency technology, applied in chemical instruments and methods, biological sludge treatment, pyrolysis treatment of sludge, etc., can solve the problems of secondary pollution, waste, mud cake easy to block the discharge port, etc., to achieve high efficiency and low Cost structure, reduce operation difficulty, and facilitate the effect of continuous work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

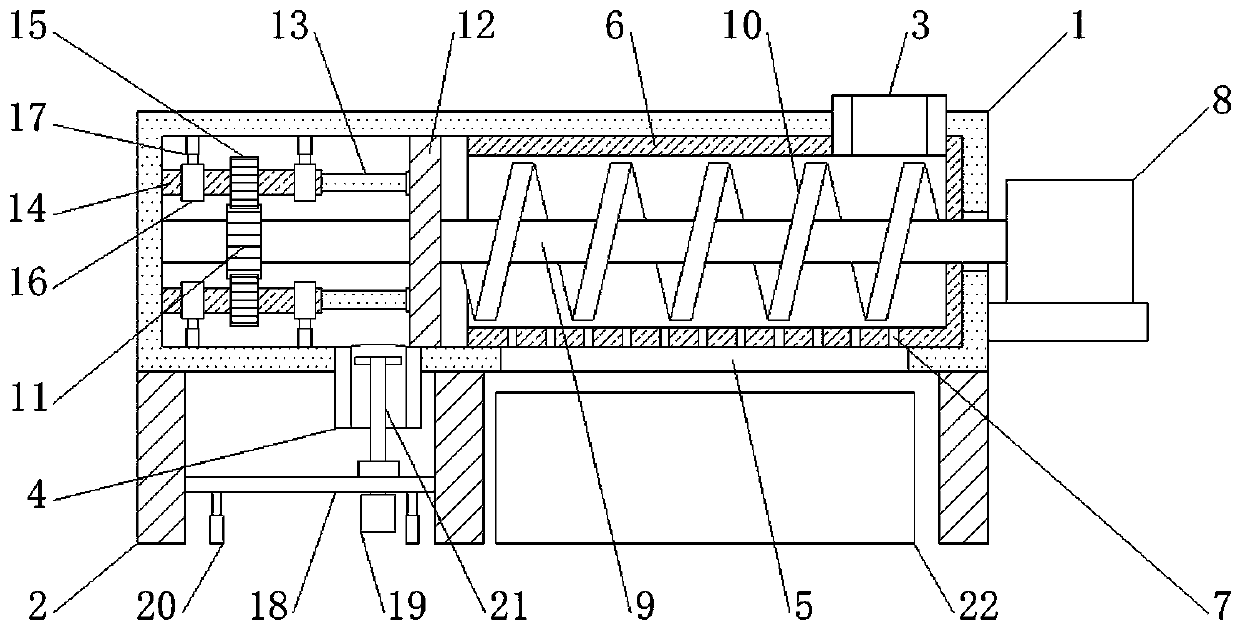

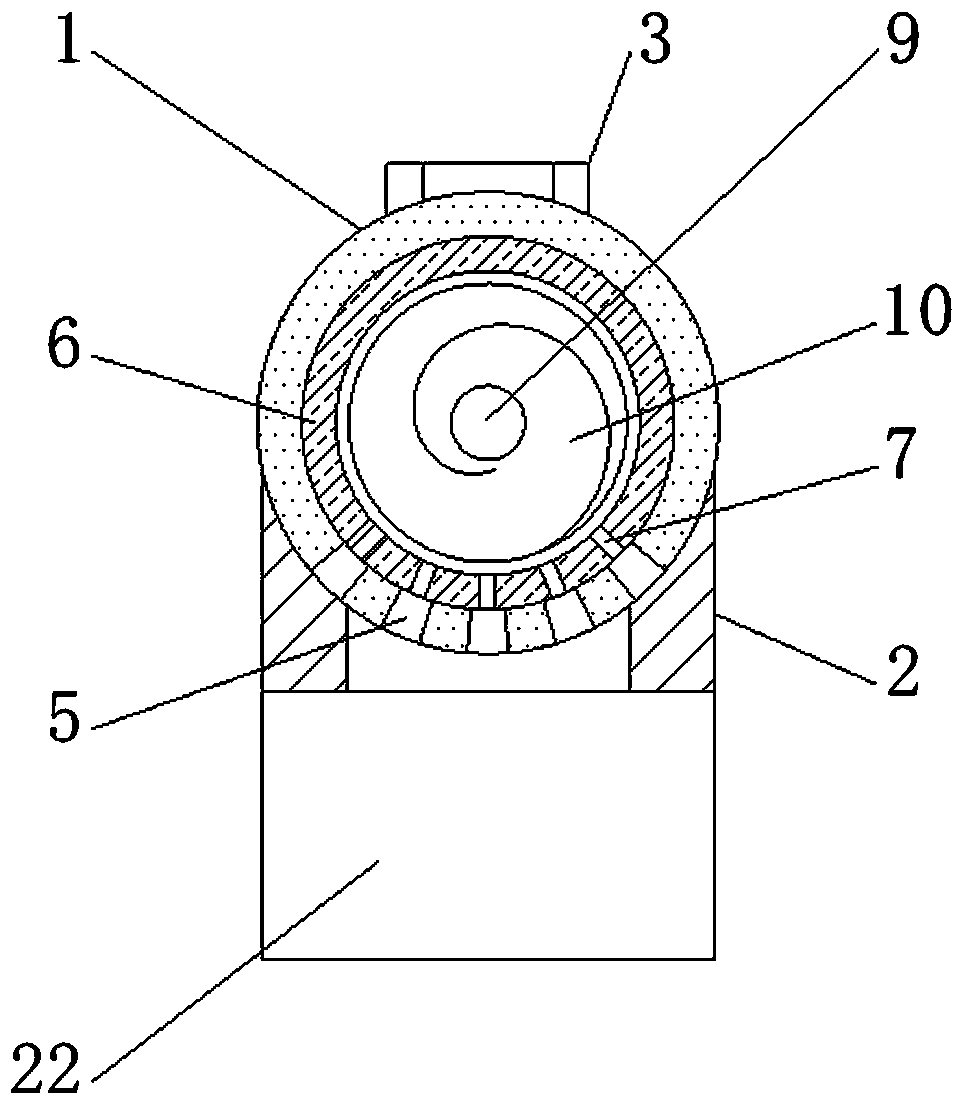

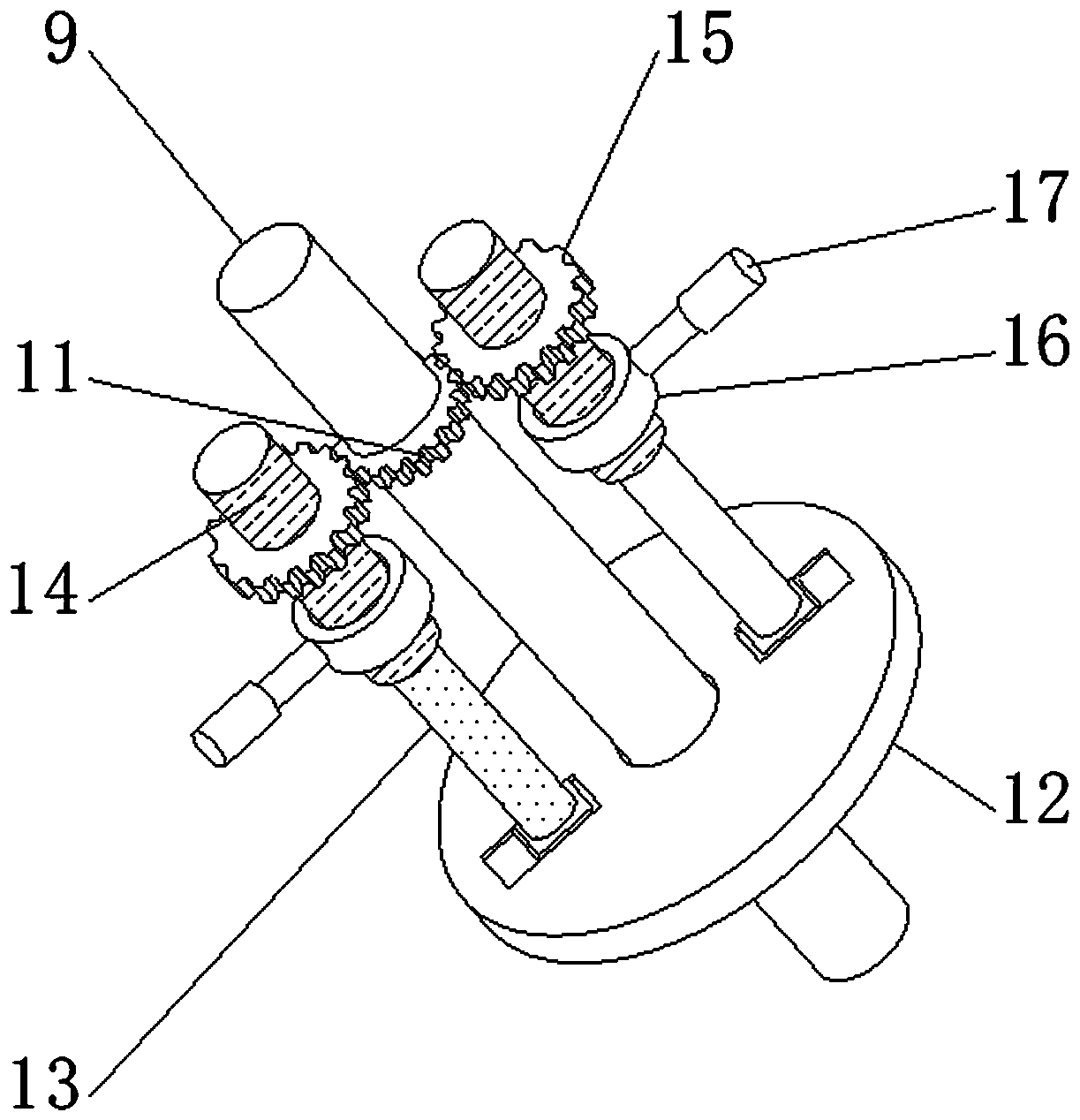

Method used

Image

Examples

Embodiment 1

[0041] Sludge with a water content of 80% is mixed with diluted water until the water content reaches 90%, and then enters the anaerobic unit, and stays in the anaerobic unit for 10 days. The mud concentration tank is concentrated to a water content of 97%, and the concentrated clarified water enters the thermal hydrolysis reactor together with the biogas residue, and the boiler provides continuous and stable high-pressure saturated steam (pressure 1.1-1.2Mpa) to the reactor. Heat the mud, inject saturated steam for 30 minutes, stop injecting saturated steam and keep for 20 minutes; then open the pressure relief valve to start exhaust and pressure relief, open the discharge valve at the end of exhaust, and discharge the treated mud obtained by thermal hydrolysis treatment; After the discharged treatment mud is cooled, dehydration treatment is carried out to obtain the press filtrate and dewatered cake with a water content of 45%, and the press filtrate is returned to the previo...

Embodiment 2

[0043] Sludge with a water content of 80% is mixed with diluted water until the water content reaches 90%, and then enters the anaerobic unit, and stays in the anaerobic unit for 10 days. The mud concentration tank is concentrated to a water content of 97%. The concentrated clarified water and biogas residue enter the thermal hydrolysis reactor, and the boiler provides continuous and stable high-pressure saturated steam (pressure 1.2-1.3Mpa) to the reactor. Heating the mud, injecting saturated steam for 20 minutes, stopping injecting saturated steam and maintaining it for 10 minutes; then opening the pressure relief valve to start exhaust and pressure relief, and opening the discharge valve at the end of the exhaust to discharge the treated mud obtained by thermal hydrolysis treatment; The discharged treatment mud is cooled and dehydrated to obtain the press filtrate and dewatered cake with a water content of 40%, and the press filtrate is returned to the front stage as dilutio...

Embodiment 3

[0045]Sludge with a water content of 80% is mixed with diluted water to a water content of 92% and then enters the anaerobic unit and stays in the anaerobic unit for 10 days. The mud concentration tank is concentrated to a water content of 97%. The concentrated clarified water and biogas residue enter the thermal hydrolysis reactor, and the boiler provides continuous and stable high-pressure saturated steam (pressure 1.3-1.4Mpa) to the reactor. The mud is heated, injected with saturated steam for 10 minutes, stopped injecting saturated steam and kept for 5 minutes; then opened the pressure relief valve to start exhaust and pressure relief, and opened the discharge valve at the end of the exhaust to discharge the treated mud obtained by thermal hydrolysis treatment; The discharged treatment mud is cooled and dehydrated to obtain the press filtrate and dewatered cake with a water content of 35%, and the press filtrate is returned to the front stage as dilution water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com