A device for wet anaerobic biogas production from kitchen waste

A food waste and biogas technology, applied in biochemical equipment and methods, specific-purpose bioreactors/fermenters, gas production bioreactors, etc., can solve problems such as poor gas overflow, sand accumulation, scum, etc. , to achieve uniform material and temperature distribution, smooth gas overflow, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

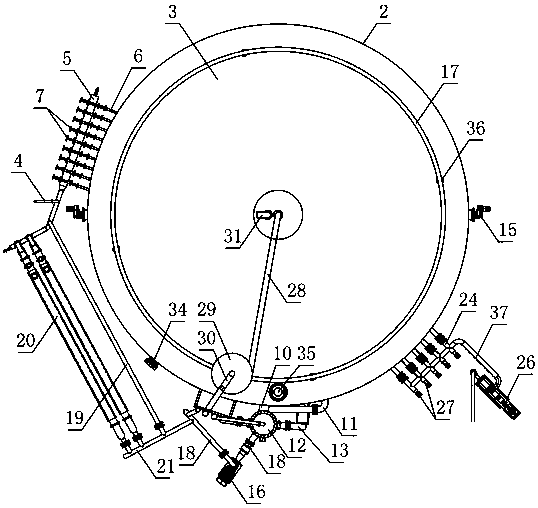

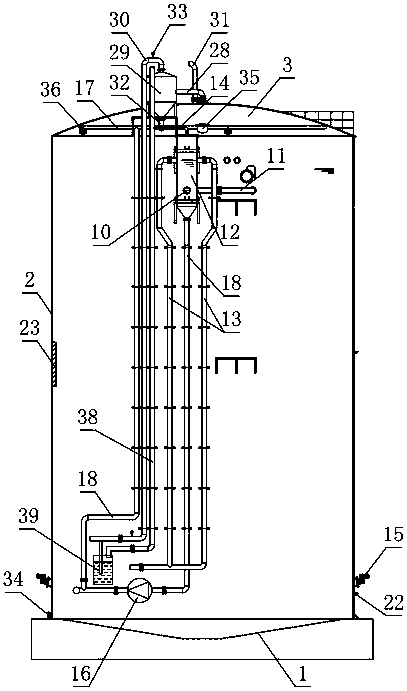

[0024] Such as Figure 1-Figure 5 As shown, a device for wet anaerobic biogas production from kitchen waste, which includes a fermentation tank, a uniform material distribution system, a uniform discharge system, a stirring and slag breaking system, a heat balance system, a sand and slag discharge system, and biogas collection system,

[0025] The fermenter body is composed of a fermenter cone bottom 1 at the bottom, a fermenter side wall 2 in the middle, and a fermenter vault 3 in the upper part, which are sealed and connected.

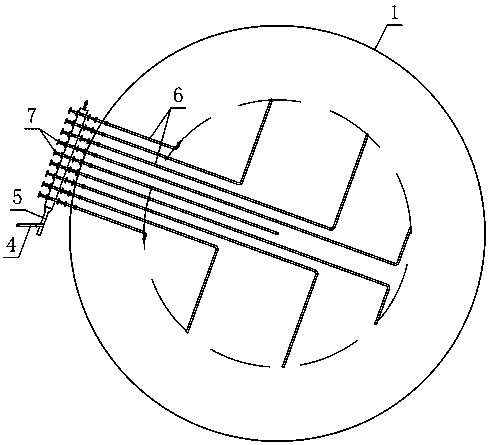

[0026] The uniform distribution system includes feed pipe 4, distributor 5, uniform feed branch pipe 6, uniform feed branch pipe high-pressure flushing valve 7, feed pipe 4 is connected to distributor 5, and distributor 5 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com