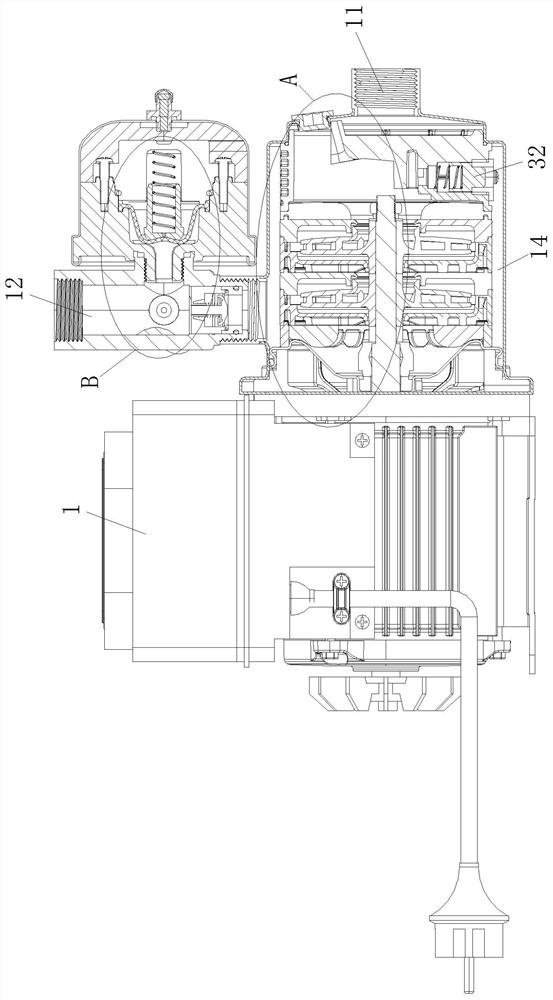

A self-priming centrifugal pump

A self-priming centrifugal pump and pump body technology, applied in the field of centrifugal pumps, can solve the problems of reduced service life, high noise, and large impact on the internal parts of the pump body, so as to accelerate the separation of water and gas, reduce wear, and reduce cavitation. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

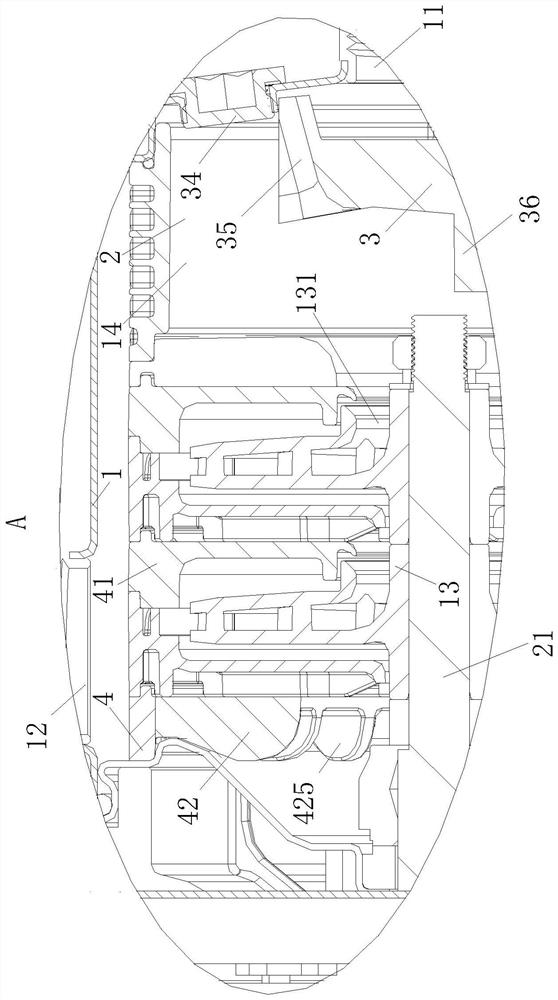

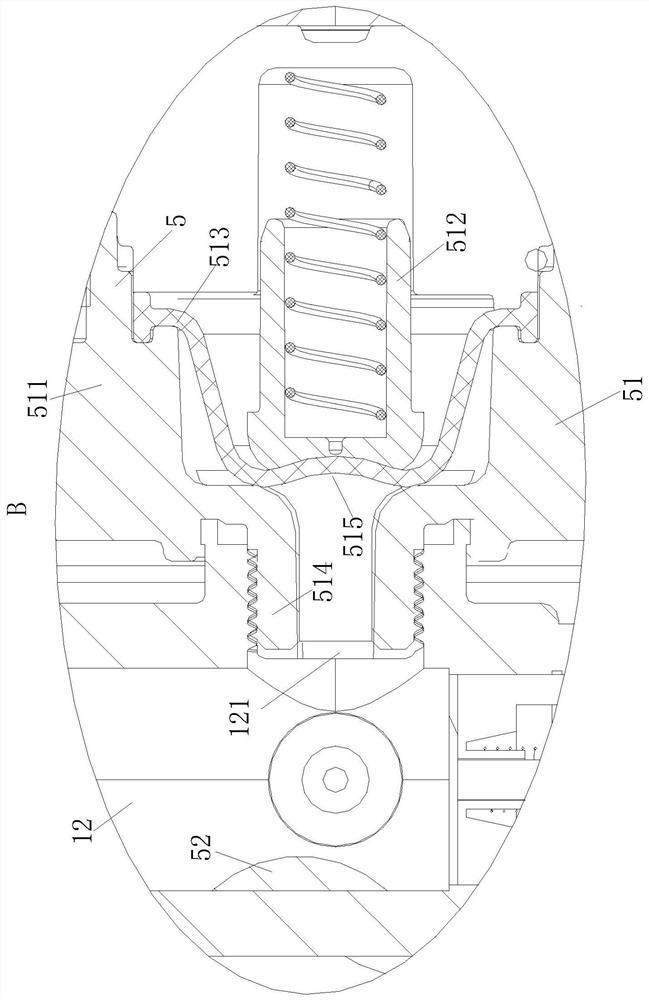

[0034]As a specific embodiment of the present invention, the guide body includes a general guide body 41 and a terminal guide body 42, and the general guide body 41 is installed on the rotating shaft 21 at the gap between the impellers 13; The guide body 42 is installed on the rotating shaft 21, and is located on the side of the impeller 13 away from the water inlet 11, and the end guide body 42 is located below the water outlet 12; the end guide body 42 includes a guide ring 421 and a guide plate 422, the The drainage ring 421 is nested on the side wall of the water inlet channel 2, and the inner surface of the drainage ring 421 is fixedly connected with a drainage plate 422, and the junction of the surface of the drainage plate 422 facing the impeller 13 and the inner surface of the drainage ring 421 is evenly arranged. A plurality of water outlet grooves 423 ; a No. 1 through hole 424 is provided in the middle of the diversion plate 422 , and the rotating shaft 21 passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com