A granulation system for processing high temperature liquid slag

A liquid slag and granulation technology, which is applied in the field of high-temperature liquid slag processing, to achieve the effects of ensuring uniformity, saving costs, and enhancing the granulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

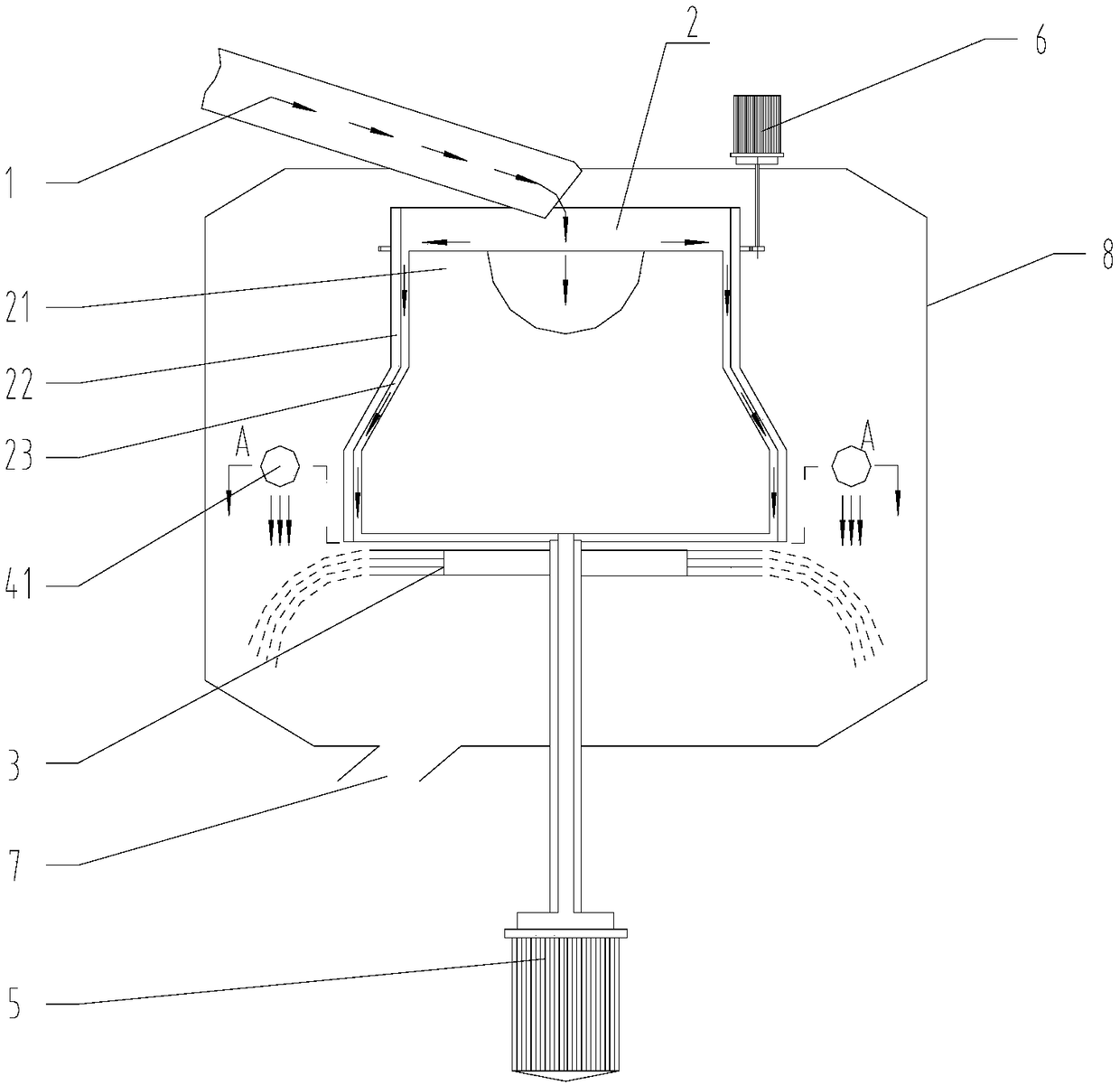

[0043] The present invention provides a granulation system for processing high-temperature liquid slag, which is arranged inside the boiler furnace 8, and the high-temperature liquid slag flow from the slag ditch 1 is introduced above, and the slag flow is discharged from the main combustion chamber . The small slag particles granulated by the present invention are finally discharged through the slag outlet 7 of the boiler, and the high-temperature slag small particles will be further recovered from waste heat, and the H produced in the slag flow granulation process 2 S and SO x Wait for the harmful gas to be discharged in the inside of the boiler furnace 8, and then be discharged after being processed through the flue. The structure of a granulation system for processing high-temperature liquid slag of the present invention is as follows Figure 1-Figure 3 As shown, it includes: a slag curtain forming device 2, a granulation device 3 and a granulation particle flow guiding ...

Embodiment 2

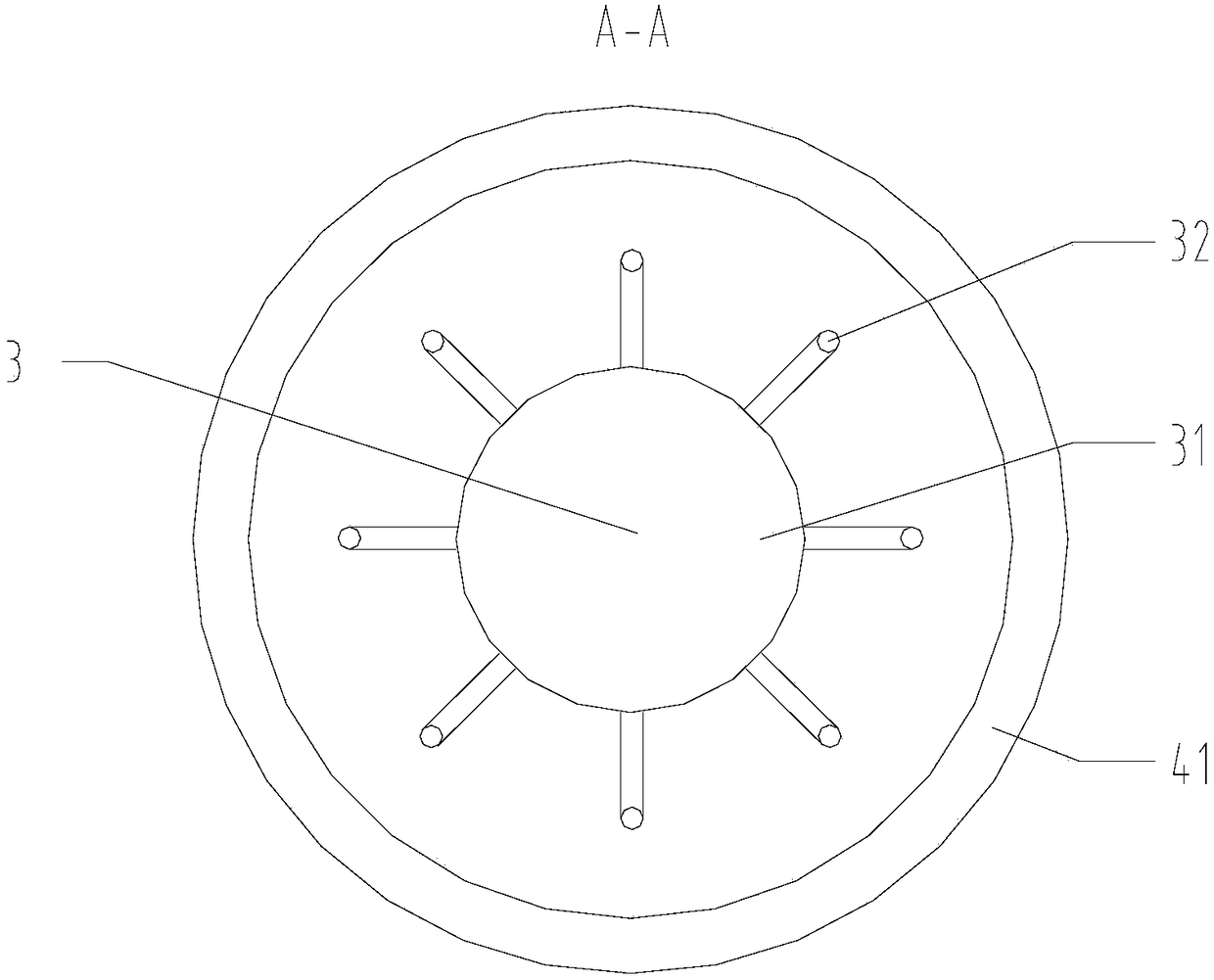

[0053] The difference between the second embodiment of the present invention and the first embodiment is that the granulation device 3 in the above-mentioned embodiment 1 is arranged below the overflow platform 21, while the granulation device 3 in the second embodiment of the present invention is arranged on the sleeve 22 below. The structure of this granulation device 3 of embodiment two is as follows Figure 4 As shown, it includes an annular cavity 31 and nozzles 32 , and the nozzles 32 are arranged in a circular array on the inner circle of the cavity 31 based on the center of the cavity 31 . This structure of the granulation device 3 can make the medium ejected from the nozzle 32 spray towards the center of the granulation device 3, so that the circular slag curtain flowing out of the flow guide channel 23 will be close to the center and go down to the center after being granulated. The slag outlet 7 of the boiler is discharged.

Embodiment 3

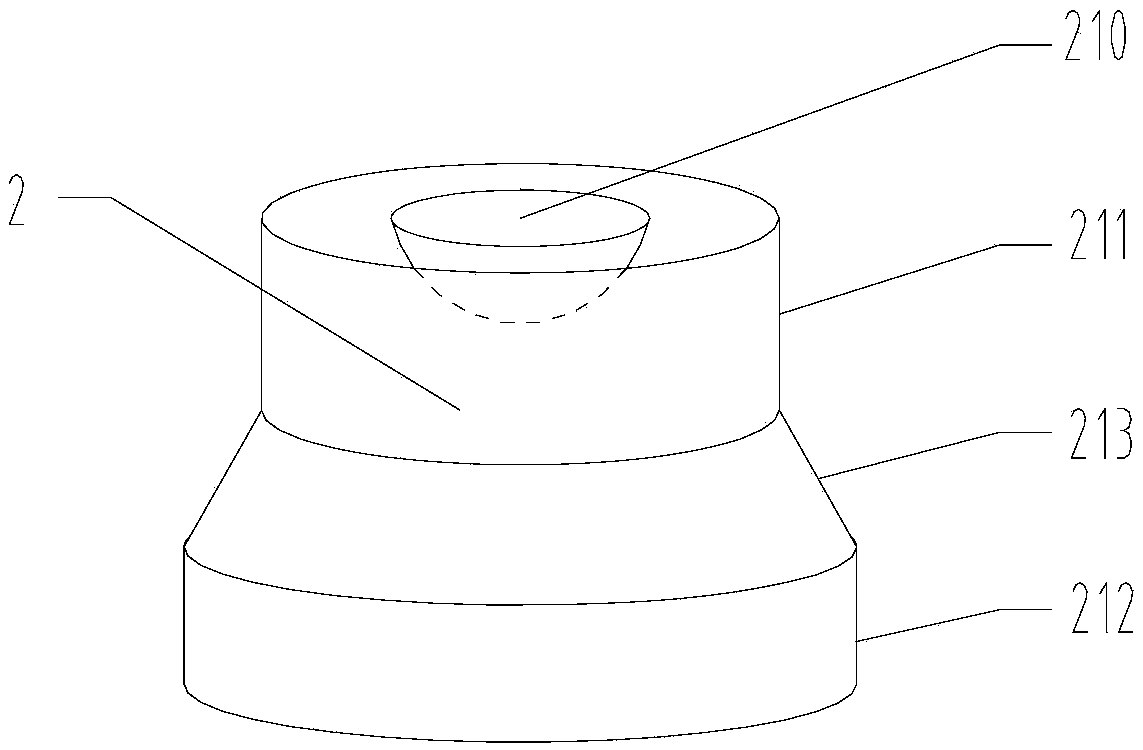

[0055] Embodiment 3 adds a liner on the basis of the above-mentioned embodiment 1 or embodiment 2, and the liner is attached to the overflow on the upper platform of the flow platform 21 , and the middle recess is attached to the inner side of the overflow tank 210 . The liner effectively protects the overflow platform 21. When it needs to be replaced, just lift the liner and replace it. Thereby effectively prolonging the service life of overflow platform 21 Life.

[0056] The above-mentioned embodiment is described by taking the overflow platform 21 including the upper cylinder 211, the lower cylinder 212 and the round platform 213 between them as an example, but the present invention is not limited thereto, and the structure of the overflow platform 21 can also be only It is a circular frustum structure, it can also be a columnar structure, and it can also be a structure of other shapes.

[0057] The sleeve 22 or the overflow platform 21 in the above embodiments may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com